Upright steel roof waterproof structure and construction method thereof

A waterproof structure and construction method technology, which is applied to roofs, roof coverings, and roofs using flat/curved panels, etc., can solve problems such as water accumulation in the waterproof layer, difficulty in ensuring waterproof and thermal insulation effects, and excessive water absorption of the thermal insulation layer. , to achieve the effect of reducing short-side lap joints, improving waterproof and thermal insulation effects, and reducing maintenance costs in the later period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to describe the technical solution of the above invention in more detail, specific examples are listed below to prove the technical effect; it should be emphasized that these examples are used to illustrate the present invention and are not limited to limiting the scope of the present invention.

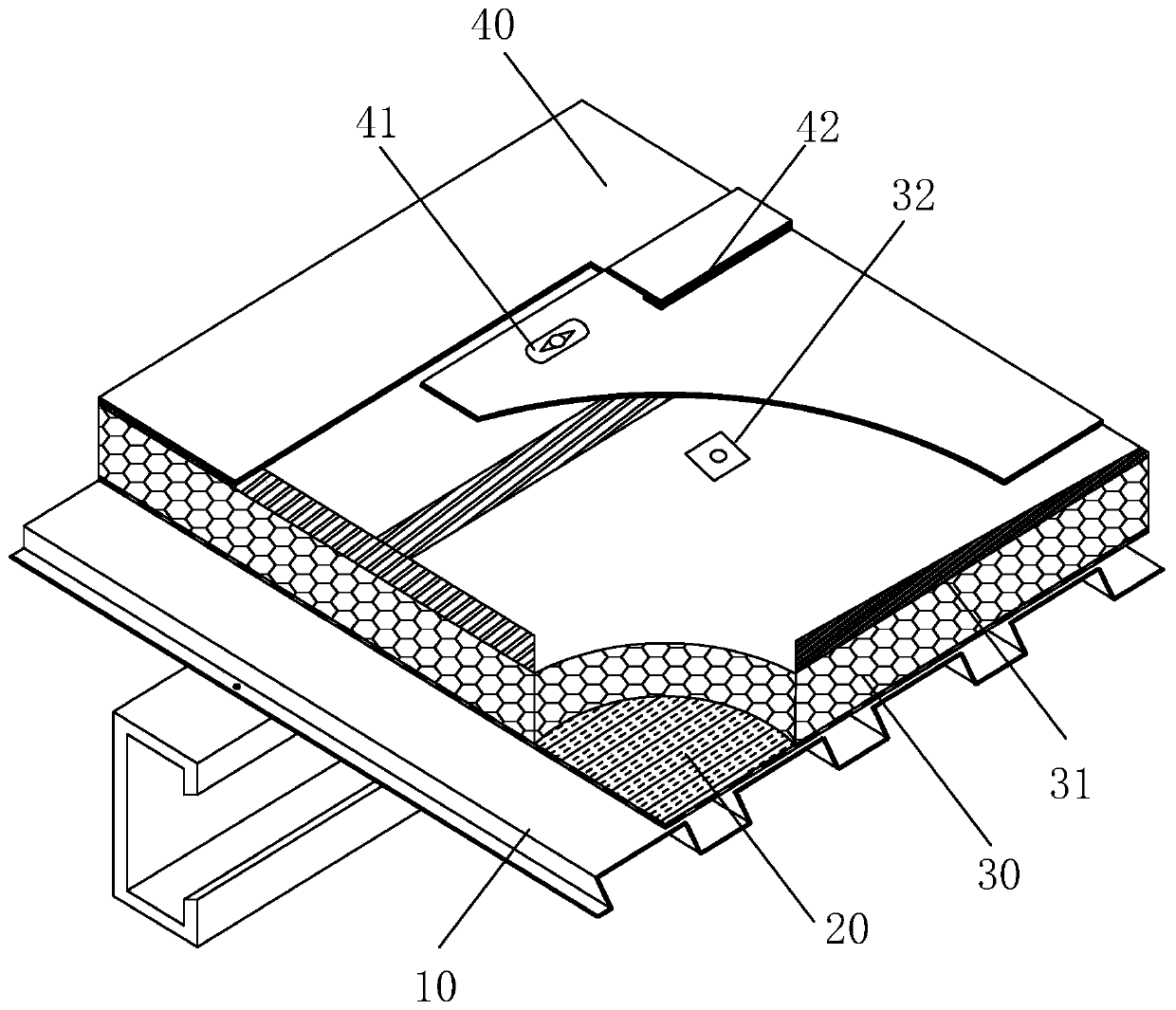

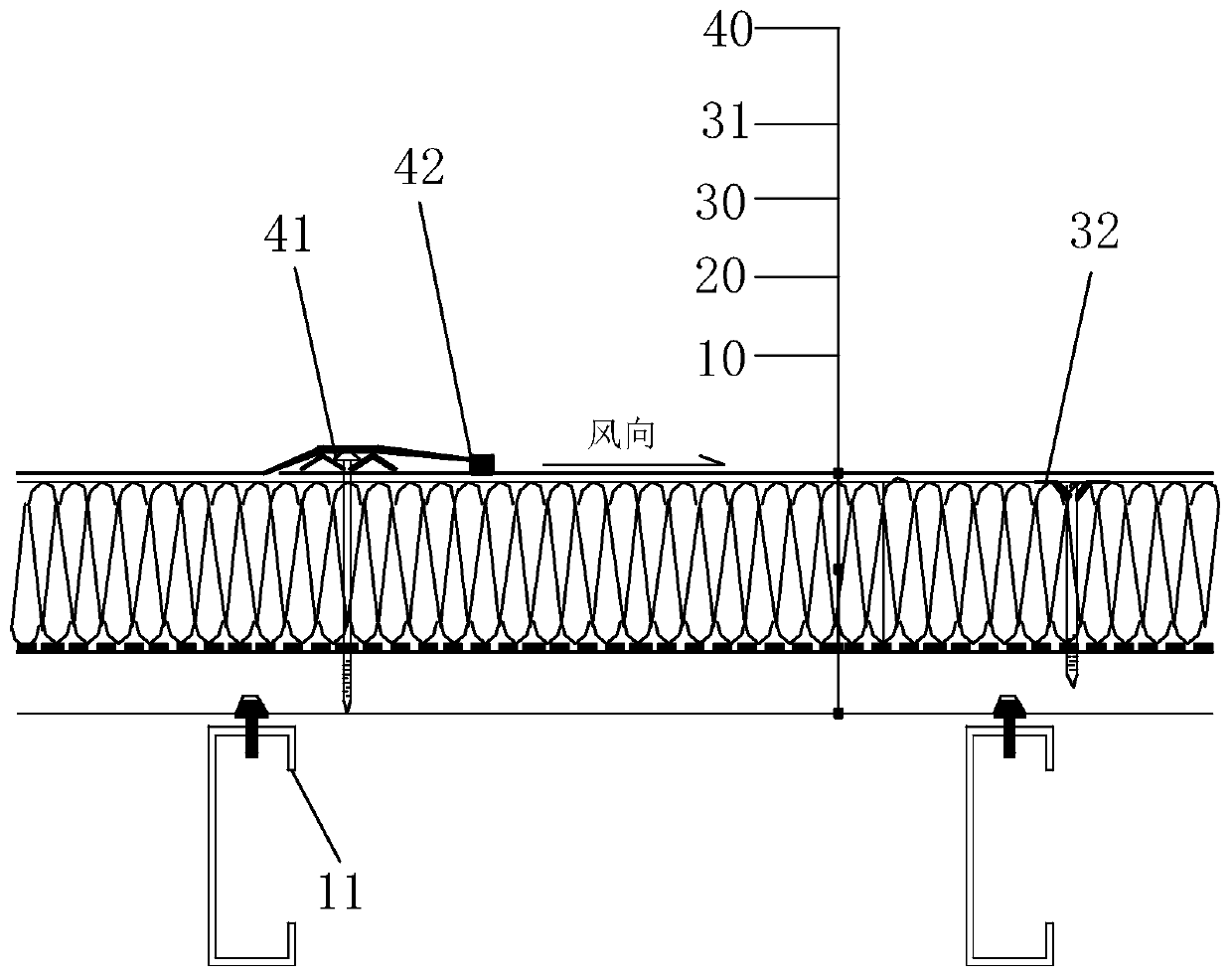

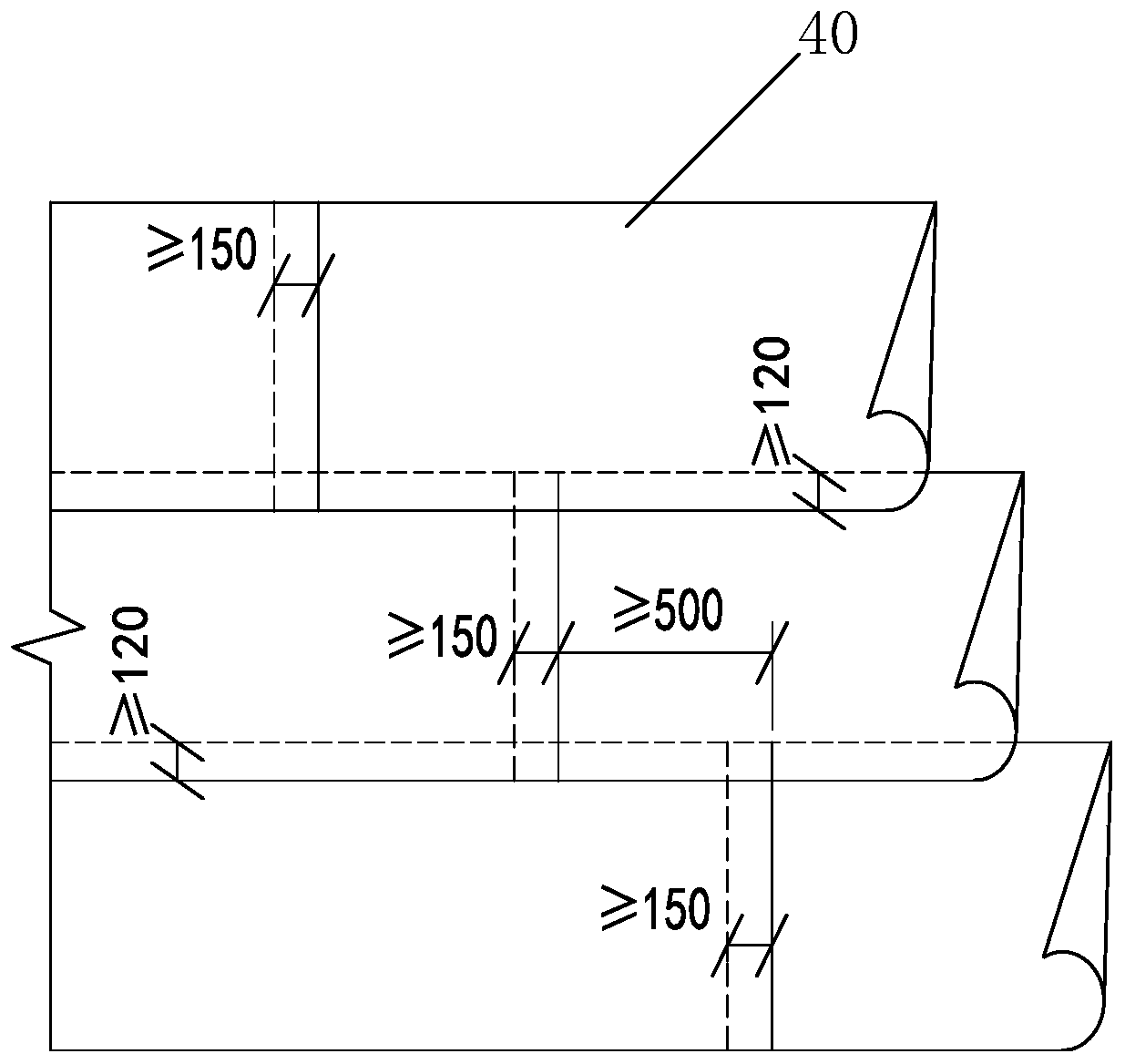

[0030] The upright steel roof waterproof structure provided by the present invention, such as figure 1 with figure 2 As shown, it includes a profiled steel plate 10 fixedly connected to the roof purlin 11; a vapor barrier 20 (for example, a PE moisture-proof membrane), a thermal insulation layer 30, and a waterproof layer 40 are sequentially laid on the profiled steel plate 10; The heat preservation and heat insulation layer 30 is fixed to the profiled steel plate 10 by using first screws and gaskets 32, and the seams of the heat preservation and heat insulation layer 30 are edge-sealed with a 100mm wide polymer waterproof tape 31; The layer 40 is made of a PVC waterproo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com