Plugging material as well as preparation method and application thereof

A plugging material and structural unit technology, applied in the field of plugging materials and its preparation, can solve problems such as well wall instability, damage to oil and gas layers, and stuck pipe, so as to improve the plugging pressure bearing capacity, enhance the interface effect, increase The effect of structural rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

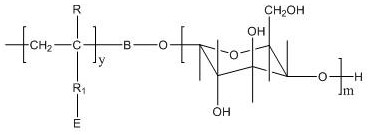

Image

Examples

Embodiment 1

[0055] Weigh 20g of vinyltriethoxysilane and 30g of kaolin, add them into 300ml of ethanol, stir and disperse thoroughly, raise the temperature at 60°C for 3h to obtain material A, then centrifuge, and dry the solid at 90°C for 12h for later use. Take 30g of cornstarch and make it into a 20wt% water suspension, and react at 90°C for 2h to obtain gelatinized starch. Take 25g of methacryloyloxyethyl-N, N-dimethylpropanesulfonate to prepare a 45wt% aqueous solution. Add the material A, gelatinized starch and monomer solution into 220 g of water in which 3 g of sodium dodecylbenzene sulfonate is dissolved, and fully stir to emulsify and disperse. After raising the temperature to 65°C, 1.5 g of ammonium persulfate was added and reacted for 3 hours. After the reaction, wash twice with deionized water, dry at 110° C. for 8 hours, and pulverize to finally obtain the plugging material.

Embodiment 2

[0057] Weigh 7.5g of vinyltrichlorosilane and 30g of kaolin, add them into 300ml of ethanol, stir and disperse fully, raise the temperature at 90°C for 1h to obtain material A, then centrifuge, and dry the solid at 90°C for 12h for later use. Take 30g of cornstarch and make it into 20% water suspension, react at 95°C for 1h to get gelatinized starch. Get 25g of N,N-dimethylallylaminopropanesulfonate and prepare 60% aqueous solution. Add material A, gelatinized starch and monomer solution into 200 g of water in which 10 g of sodium dodecylbenzene sulfonate is dissolved, and fully stir to emulsify and disperse. After raising the temperature to 90°C, 1.3 g of ammonium persulfate was added and reacted for 2 hours. After the reaction, wash twice with deionized water, dry at 120° C. for 10 h, and pulverize to finally obtain the plugging material.

Embodiment 3

[0059] Weigh 30g of vinyltrimethoxysilane and 30g of montmorillonite, add them into 300ml of methanol, fully stir and disperse, raise the temperature at 80°C for 2h to obtain material A, then centrifuge, and dry the solid at 120°C for 8h for later use. Take 30g of potato starch and make it into a 15% water suspension, and react at 90°C for 2h to obtain gelatinized starch. Get 25g of methacryloyloxyethyltrimethylammonium chloride and prepare 40% aqueous solution. Add material A, gelatinized starch and monomer solution into 230 g of water in which 0.23 g of sodium lauryl sulfate is dissolved, and fully stir to emulsify and disperse. After heating up to 60°C, 1.6g of sodium persulfate was added and reacted for 4h. After the reaction, wash twice with deionized water, dry at 100° C. for 8 hours, and pulverize to finally obtain the plugging material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com