Stable production method for hot rolling of thin-gauge ultrahigh-strength quenching-partitioning steel

A stable production, ultra-high strength technology, applied in the direction of metal rolling, metal rolling, workpiece heating devices, etc., can solve the problems of unproposed stable production, increased difficulty in the production of thin-gauge products, and great difficulty in the hot rolling process, reaching The effect of improving production stability, improving plate shape quality, and reducing process temperature drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

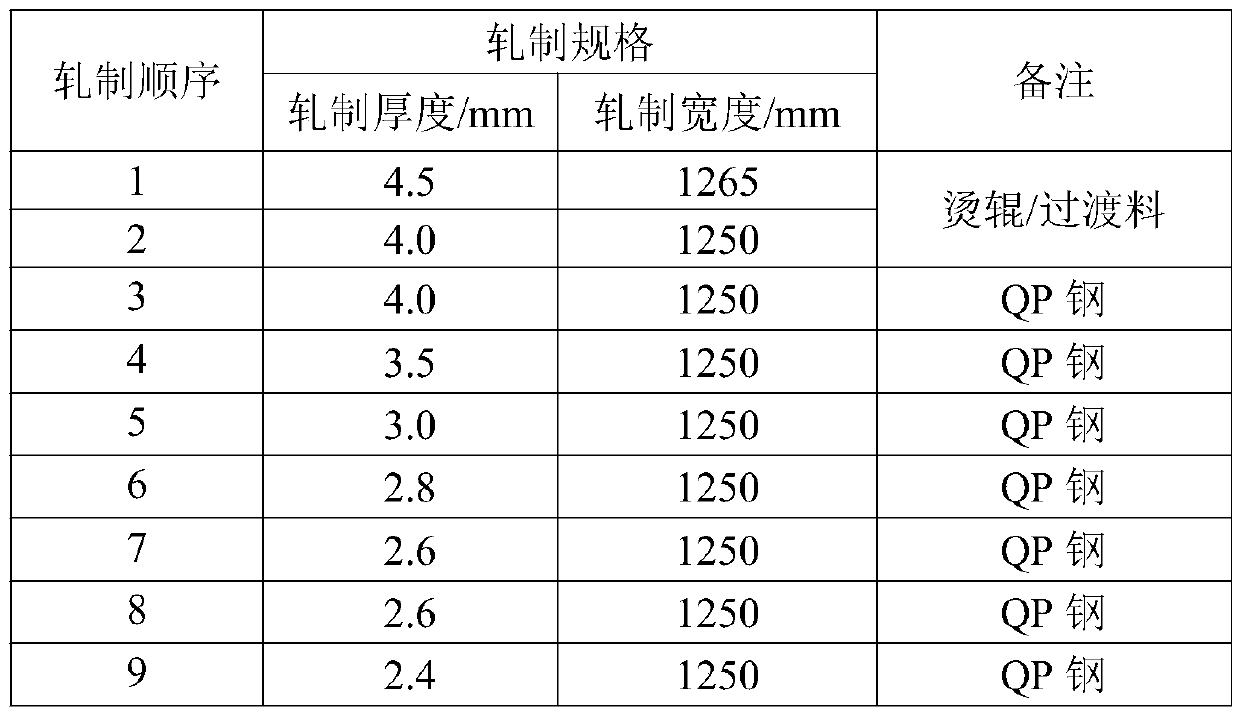

Image

Examples

Embodiment Construction

[0028] The technical solutions in the embodiments of the present invention are clearly and completely described in further detail below. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

[0029] Explanation of technical terms of the present invention:

[0030] Roll period: the length of the strip rolled by the rolls on the rolling mill, generally expressed in kilometers;

[0031] Rough rolling mill: refers to the rough rolling mill in the hot-rolled strip production line, through repeated rolling of 1-5 passes, the thicker slab or cast slab is rolled into a relatively thin intermediate billet, that is, the present invention provides Arrived R1 rolling mill and R2 rolling mill for five passes;

[0032] Finishing rolling mill: refer to the finishing rolling mill in the hot-rolled strip production line, 7 stand continu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com