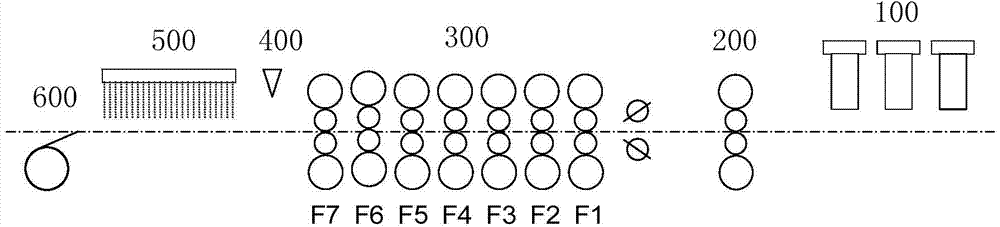

Method for controlling straightness of hot-rolling strip steel by changing spraying width of cooling water

A hot-rolled strip, width control technology, applied in contour control, workpiece cooling device, metal rolling, etc., can solve problems such as large investment and complex engineering, improve plate quality, save renovation costs, and omit heaters or the effect of the baffle device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

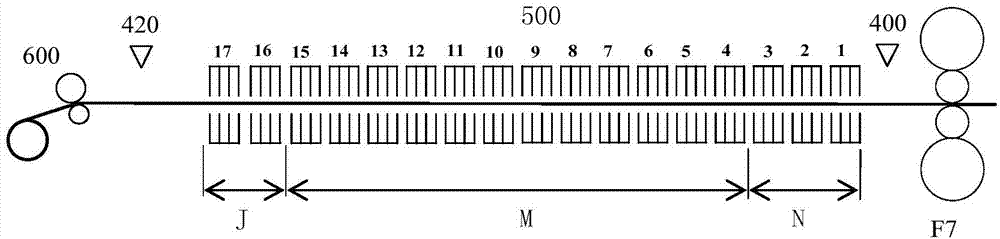

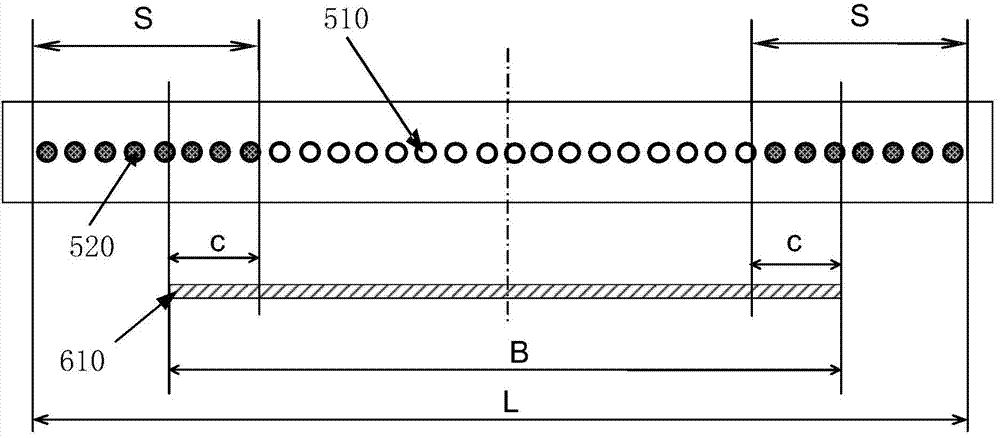

[0049] Applying this method to a hot rolling production, the product specification width range is 750-1650mm, the total laminar flow cooling width is 1780mm, and the product specification range of 1150-1340mm that needs to be improved by edge shielding is 1150-1340mm. In order to improve the transverse temperature uniformity and flatness of the steel strip in the hot rolling process, cooling edge shielding is implemented. take L 1 =1050mm,L 2 =1150mm,L 3 =1250mm, L 4 =1450mm. From formulas 1 and 2, the unilateral shielding width S of different cooling sections can be calculated i Respectively: S 1 =365mm, S 2 =265mm, S 3 =165mm, S 4 =65mm.

[0050] For a hot-rolled stainless steel product BN1D with flatness defects after cooling, with a specification of 2.3*1250 and a total of 23 rolls, the cold-rolled edge masking control is implemented according to the above method.

[0051] Table 1 shows the flatness of products before and after adopting the method of controlling ...

Embodiment 2

[0055] The method of the present invention is applied to a certain hot rolling production. The product specification width range is 750-1650mm, the total laminar flow cooling width is 1780mm, and the product specification range of 950-1250mm needs to be improved by edge shielding to improve flatness defects. In order to improve the transverse temperature uniformity and flatness of the steel strip in the hot rolling process, cooling edge shielding is implemented. take L 1 =850mm, L 2 =950mm, L 3 =1050mm, L 4 =1150mm. According to formulas 1 and 2, the unilateral shielding width S of different cooling sections can be calculated i Respectively: S 1 =365mm, S 2 =265mm, S 3 =165mm, S 4 =65mm.

[0056] For a hot-rolled stainless steel product BN1D with flatness defects after cooling, with a specification of 2.3*1250 and a total of 17 coils, the cold-rolled edge masking control is implemented according to the above method. Table 2 shows the average flatness of the product b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com