Efficient double-line suction plastic production method and device

A production method and high-efficiency technology, applied in the field of high-efficiency double-line blister production methods and equipment, can solve the problems of poor quality and transparency of product blisters, single product types, and low production efficiency, so as to simplify equipment structure and improve utilization efficiency , The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

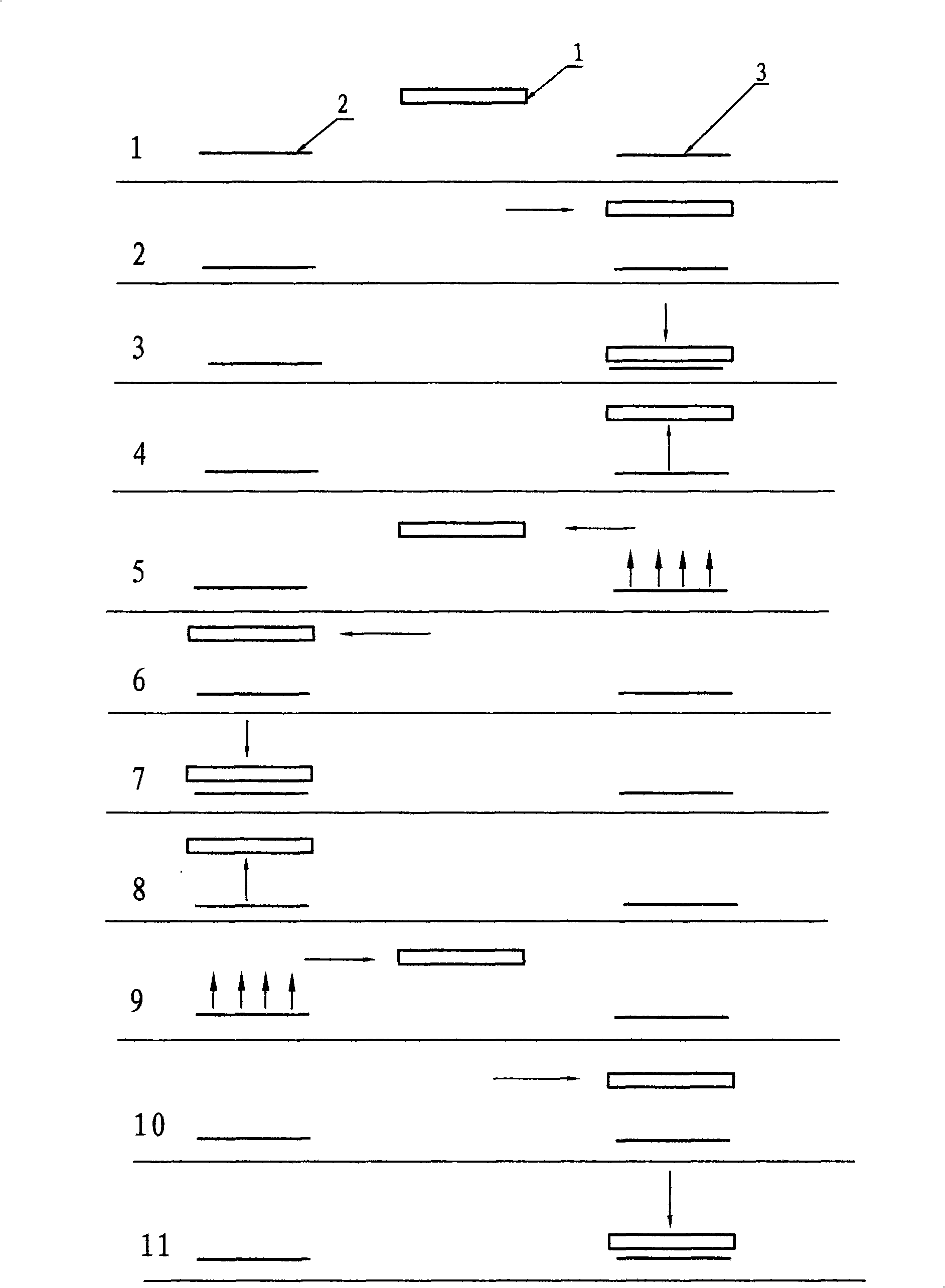

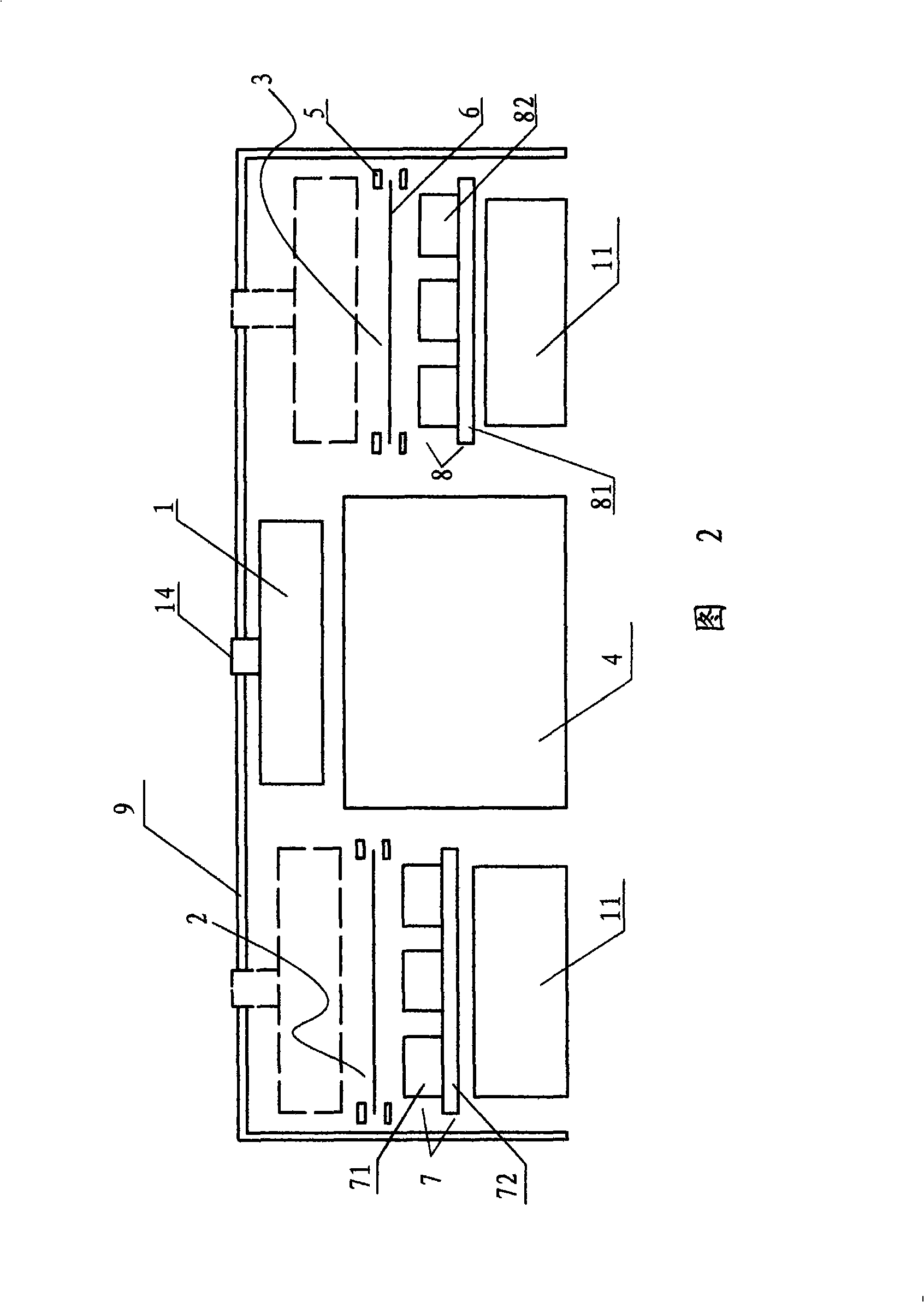

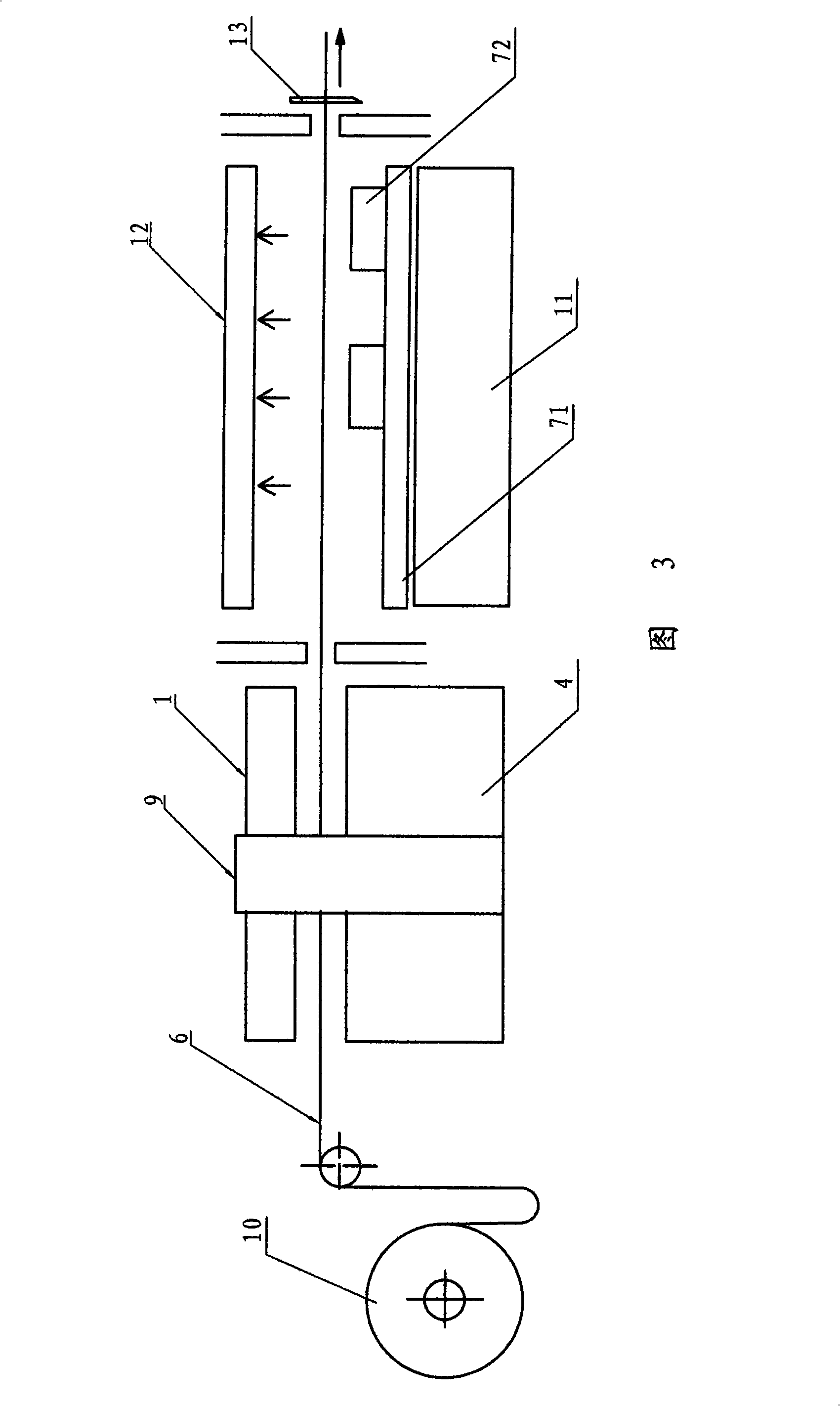

[0044] see figure 1 And Fig. 3, a kind of efficient two-line blister production method, it comprises the following steps:

[0045] 1a) Set up a movable blister heating furnace 1, on the left side and right side directly below the blister heating furnace 1, set a set of vacuum forming processing lines in the longitudinal direction, that is, the left processing line 2 and the right processing line 3, The processing lines 2, 3 each include a thermoforming station 7, 8;

[0046] Directly below the blister heating furnace 1, a matching stove 4 is arranged;

[0047] 1b) Move the blister heating furnace 1 to the initial position, that is, the upper middle position of the two processing lines 2 and 3, power on and heat to the set temperature and keep the temperature constant, so that it enters the standby state;

[0048] At this moment, the right side processing line 3 is charged and fed, and in the present embodiment, the material 6 to be processed is a PETG film; it is positioned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com