A kind of thickener and its application

A thickening agent and organic solvent technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of inability to directly reuse the flowback liquid, expensive treatment costs, low pH value, etc., to meet the requirements of continuous mixing. The effect of matching construction requirements, shortening the operation cycle and avoiding processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment provides a thickener, which is composed of the following substances in weight percentage: 50% surfactant, 15% organic solvent, and 35% water.

[0030] According to the difference in salt resistance of surfactants and the synergistic promotion effect between molecules, the present invention selects different types of surfactants for compounding, and they play roles under different salinity degrees, and with the increase of salt concentration, Promote the growth of rod-like and worm-like micelles, and the micelles gradually increase, making the viscosity of the system increase rapidly.

[0031] Preparation process: at normal temperature, dissolve the formulated amount of organic solvent in the formulated amount of water and stir evenly, then add the formulated amount of surfactant while stirring, and stir well to get ready.

[0032] In this example, the surfactant is a mixture of erucamidopropyl dimethylamine, cocamidopropyl betaine, erucamidopropyl hydrox...

Embodiment 2

[0035] This embodiment provides a thickener, which is composed of the following substances in weight percentage: 55% surfactant, 18% organic solvent, and 27% water.

[0036] See Example 1 for the preparation process.

[0037] In this embodiment, the surfactant is a mixture of oleamide propyl dimethyl tertiary amine, lauryl amidopropyl amine oxide and erucamide propyl hydroxysultaine, expressed in weight percent of the thickener , 40% of oleamidopropyl dimethyl tertiary amine, 5% of lauryl amidopropyl amine oxide, and 10% of erucamide propyl hydroxysulfobetaine.

Embodiment 3

[0040] This embodiment provides a thickener, which is composed of the following substances in weight percentage: 60% surfactant, 20% organic solvent, and 20% water.

[0041] See Example 1 for the preparation process.

[0042] In this embodiment, the surfactant is a mixture of fatty alcohol monoacetic acid amide, octadecyltrimethylammonium chloride, and oleic acid amidopropyl betaine. In terms of the weight percentage of the thickener, the fatty alcohol mono Acetamide is 30%, octadecyltrimethylammonium chloride addition is 15%, and oleamidopropyl betaine addition is 15%.

[0043] The organic solvent is methanol.

PUM

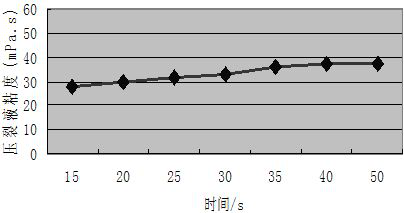

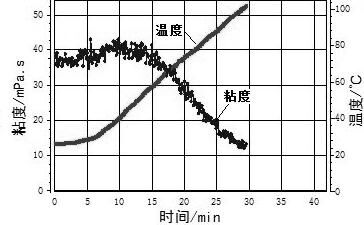

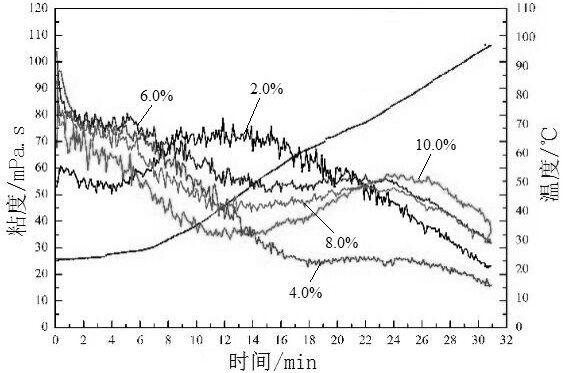

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com