Method for upgrading and converting wood tar into diesel oil

A technology of wood tar and diesel oil, applied in the petroleum industry, processing hydrocarbon oil, hydrocarbon oil treatment products, etc., can solve the problems of low quality diesel products, insufficient fuel power, strong corrosion, etc., to improve industry competitiveness, increase heat value, the effect of low hydrogen consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

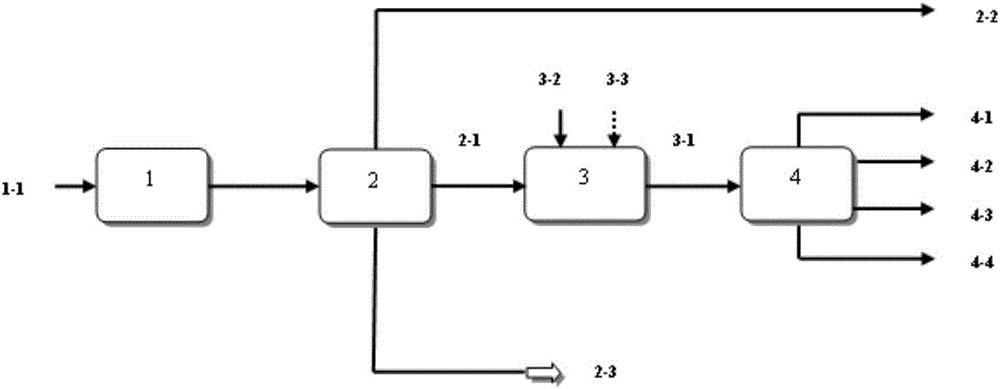

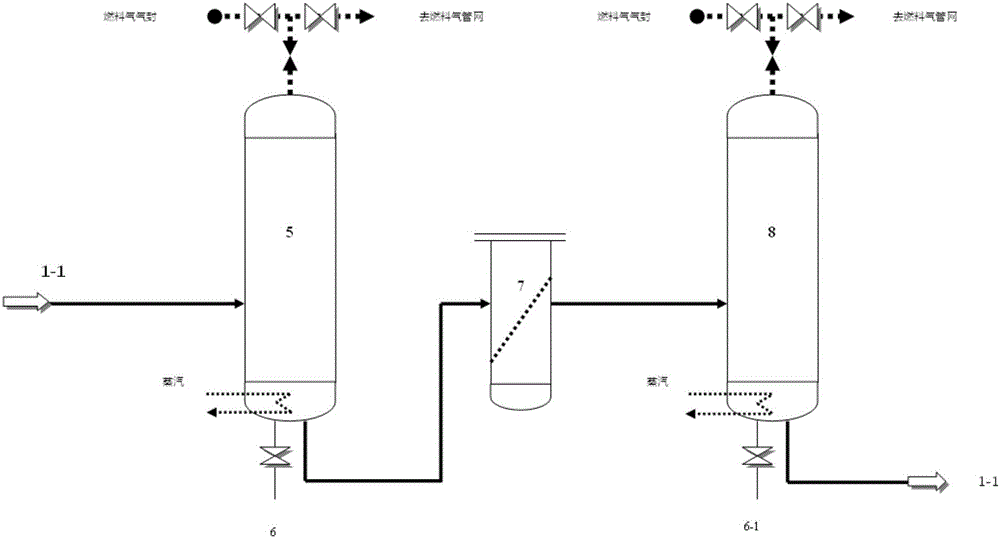

[0050] Specific embodiment one: this embodiment provides a kind of method that wood tar upgrades and converts diesel oil, such as figure 1 As shown, the whole cut wood tar 1-1 enters the raw material pretreatment unit 1 for raw material pretreatment; the pretreated whole cut wood tar enters the raw material pre-fractionation unit 2 to separate light wood tar 2-1, LPG2-2, heavy wood tar The light wood tar 2-3; the light wood tar 2-1 enters the hydrorefining reaction unit 3, and the light shale oil 3-2, hydrogen 3-3 and catalyst undergo catalytic hydrogenation reaction in the hydrogenation reactor to form The low-fraction oil 3-1 enters the product fractionation unit 4 for product fractionation; in the product fractionation unit 4, the hydrogenated oil is separated through the product fractionation tower and the diesel stripper to separate the main product hydrogenated diesel oil 4-3 and the by-product fuel gas 4 -1, light oil 4-2 and hydrogenated tail oil 4-4. The specific imp...

specific Embodiment approach 2

[0077] Specific implementation mode two: combination Figure 1-5 This embodiment will be described.

[0078] Such as figure 1As shown, the whole cut wood tar 1-1 enters the raw material pretreatment unit 1 for raw material pretreatment; the pretreated whole cut wood tar enters the raw material pre-fractionation unit 2 to separate light wood tar 2-1, LPG2-2, heavy wood tar The light wood tar 2-3; the light wood tar 2-1 enters the hydrorefining reaction unit 3, and the light shale oil 3-2, hydrogen 3-3 and catalyst undergo catalytic hydrogenation reaction in the hydrogenation reactor to form The low-fraction oil 3-1 enters the product fractionation unit 4 for product fractionation; in the product fractionation unit 4, the hydrogenated oil is separated through the product fractionation tower and the diesel stripper to separate the main product hydrogenated diesel oil 4-3 and the by-product fuel gas 4 -1, light oil 4-2 and hydrogenated tail oil 4-4.

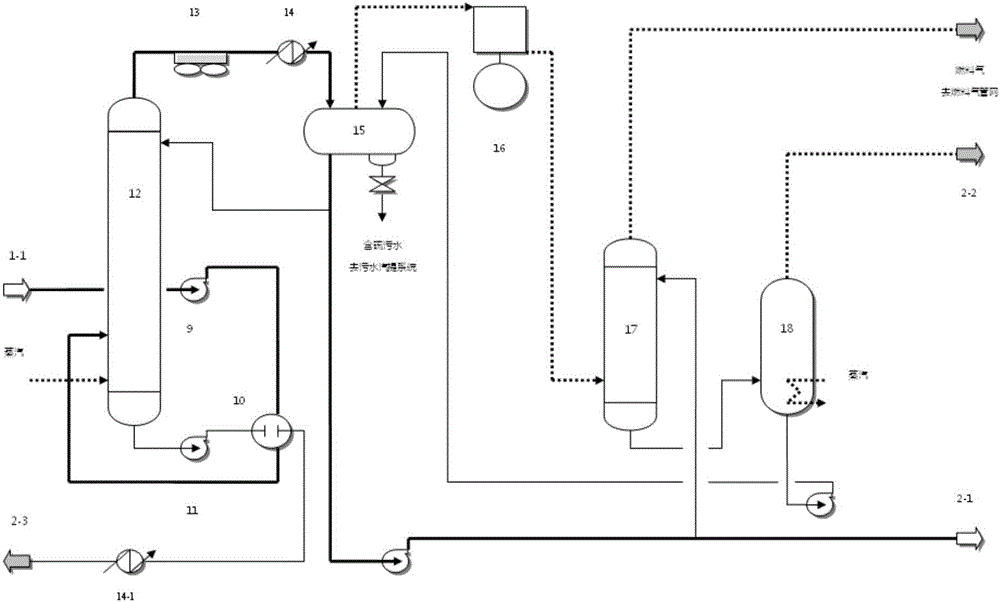

[0079] Such as figure 2 ...

specific Embodiment approach 3

[0112] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the light wood tar is a distillate oil of ≤345°C; the heavy wood tar is a distillate oil of >345°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com