Device for removing scale of trioxane heat exchanger

A kind of paraformaldehyde and heat exchanger technology, applied in the direction of cleaning heat transfer devices, lighting and heating equipment, washing, etc., can solve the problems of waste of cleaning materials, high pressure of sewage treatment, etc., to reduce pressure, reduce comprehensive energy consumption, The effect of reducing material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

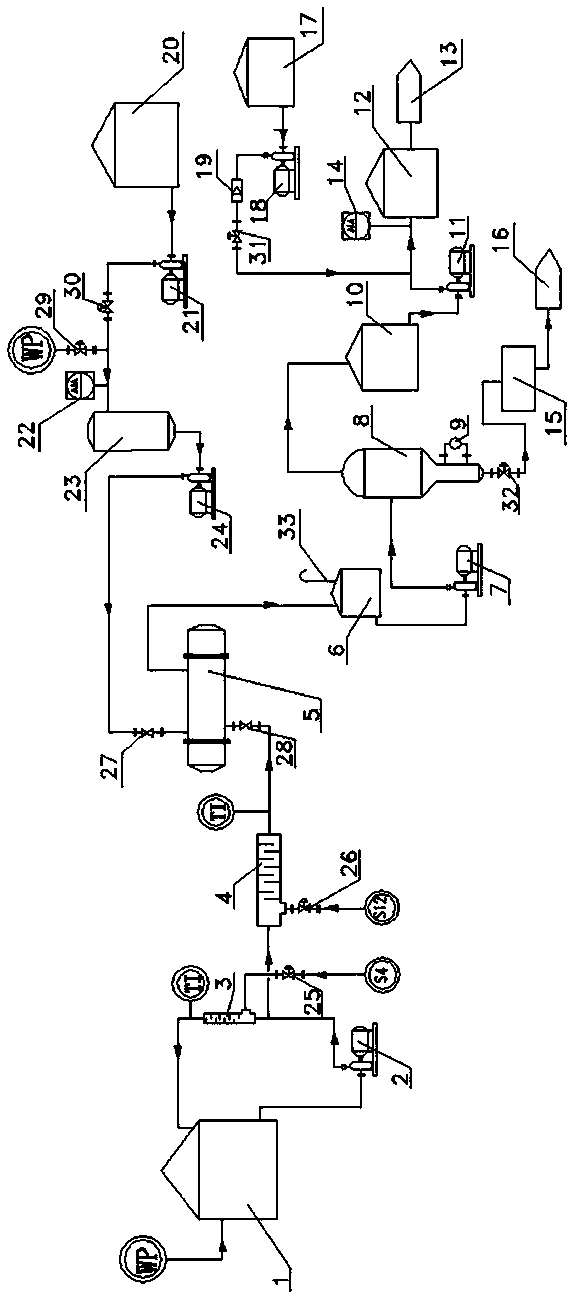

[0020] as attached figure 1 As shown, a device for removing fouling of a paraformaldehyde heat exchanger includes a steam heating system, an alkali distribution system and a waste liquid recovery system. The steam heating system includes a desalted water tank 1, a first heat pump 2, a mixing heater 4, Static mixer 3 and heat exchanger E6 5;

[0021] The alkali distribution system includes a first alkali addition tank 20, a first alkali addition pump 21, a desalinated water pipe, a second alkali addition tank 23 and a second alkali addition pump 24;

[0022] The waste liquid recovery system includes a recovery tank 6, a recovery pump 7, a decanter 8, a filter press 15, a solid treatment system 16, a buffer tank 10, a buffer pump 11, a sulfuric acid delivery pump 18, a neutralization tank 12 and a sewage treatment system 13 ;

[0023] The outlet of the desalted water tank 1 is connected with the inlet of the first heat pump 2, the outlet of the first heat pump 2 is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com