Double-line redrying-based processing method and processing device

A technology of processing technology and processing device, which is applied in the field of double-line redrying processing technology and processing device, can solve the problems of reduced availability of tobacco leaves, crushing of tobacco leaves, etc., and achieve the reduction of water-stained tobacco and steamed tobacco, and the quality of leaf moistening The effect of increasing and reducing the comprehensive load of leaf threshing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

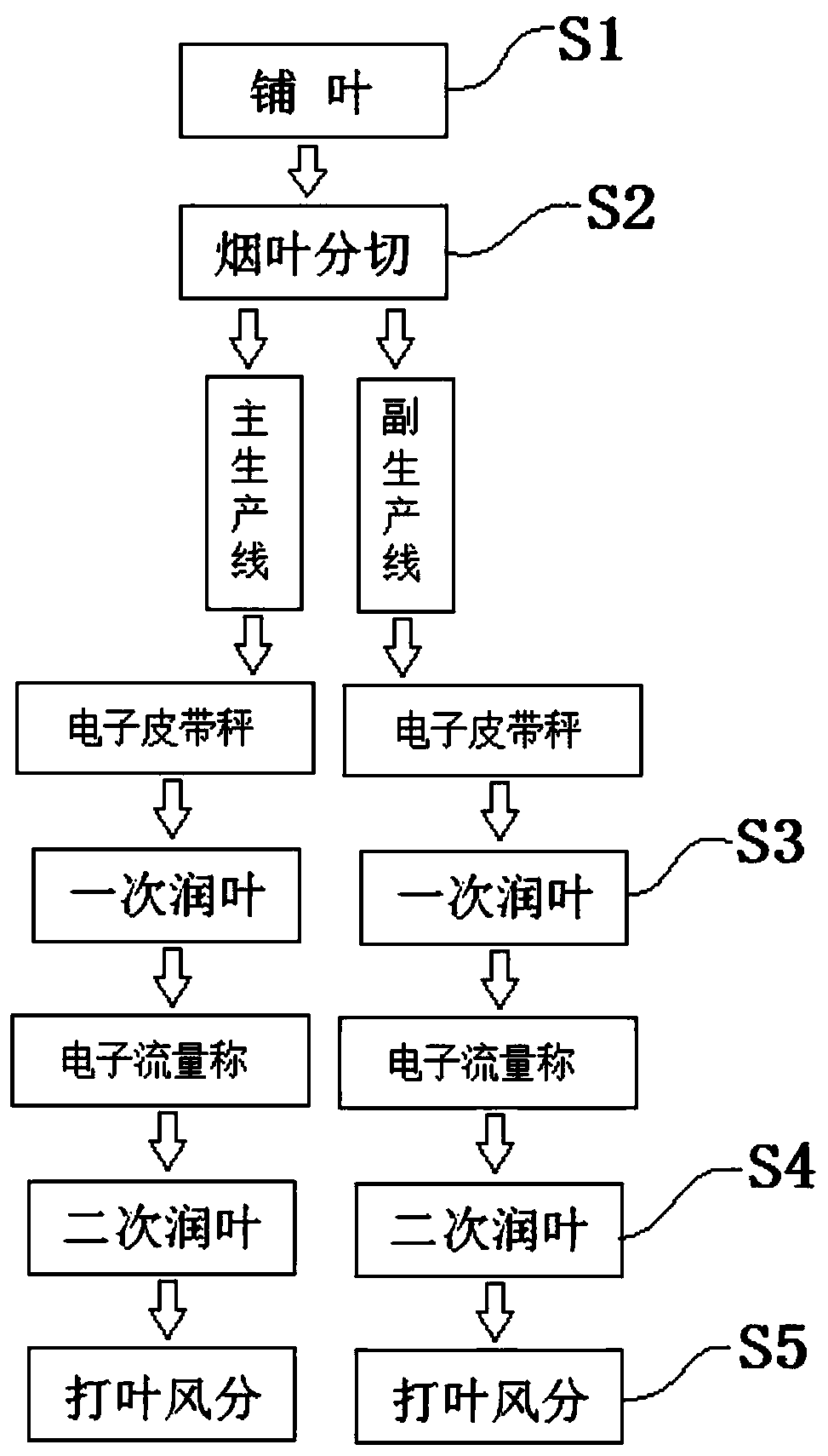

[0042] A processing method based on double-line redrying process, including the following steps,

[0043] S1: Laying the leaves, laying the tobacco leaves in a regular manner, uniform thickness, moderate speed during leaf laying, and strict control of leaf laying quality;

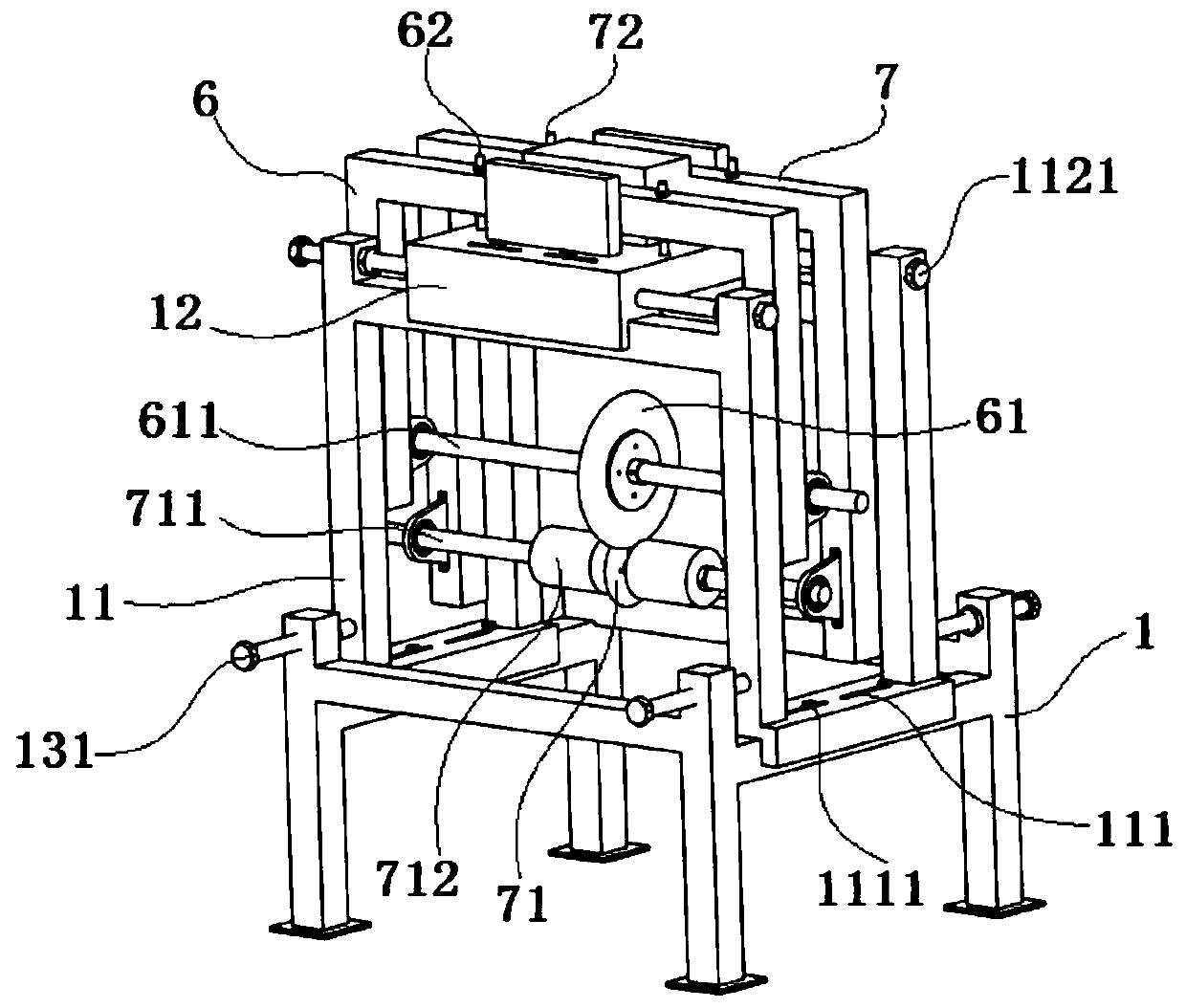

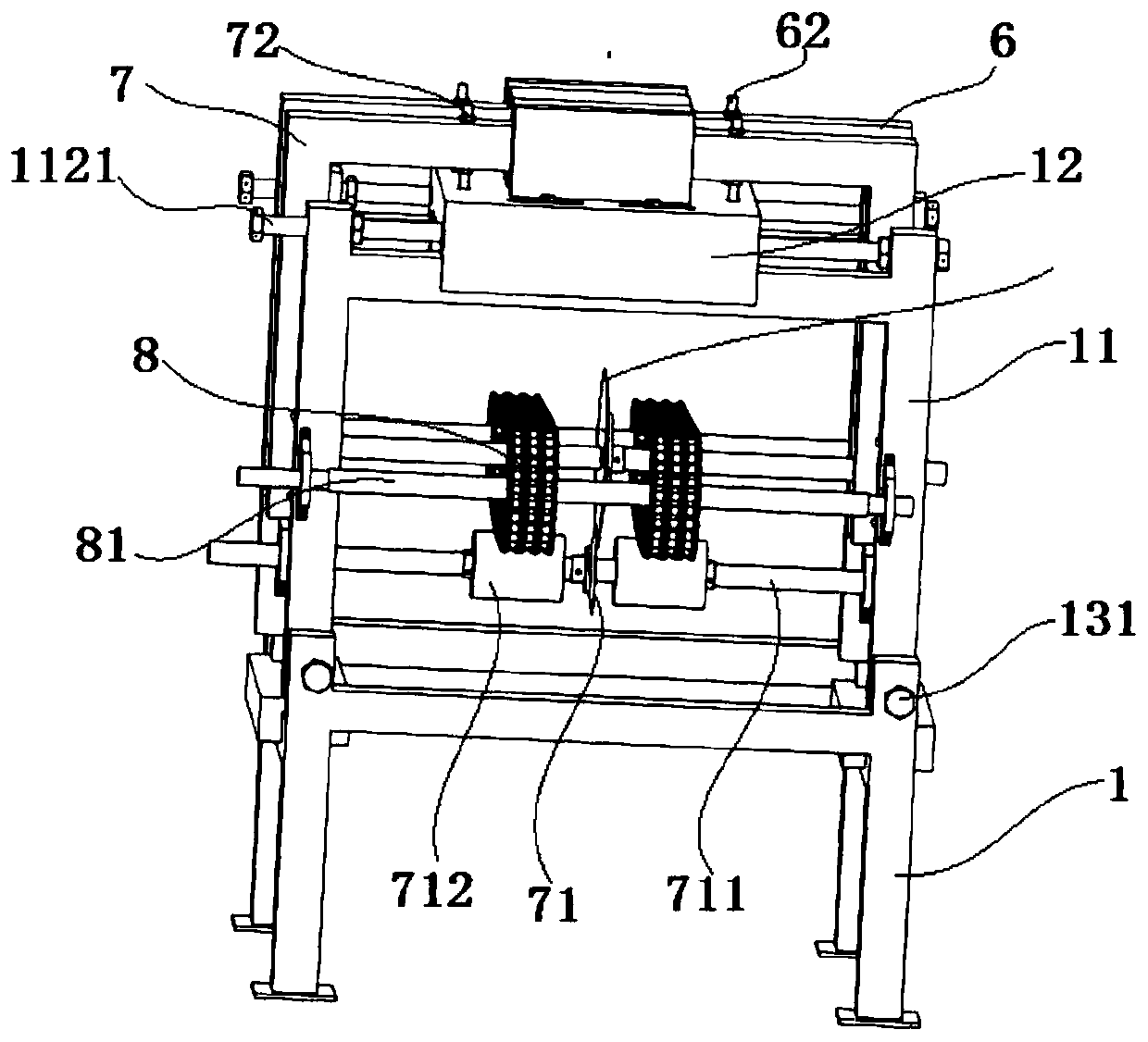

[0044] S2: To cut tobacco, first adjust the position of the cutting knife. Both the upper cutting knife 61 and the lower cutting knife 71 can be adjusted in the vertical, horizontal and vertical directions. The vertical adjustment is adjusted by adjusting the position of the vertical support 11, and the horizontal adjustment is adjusted by adjusting The position of the horizontal support 12 is adjusted, and the vertical direction is adjusted by adjusting the positions of the upper cutter support 6 and the lower cutter support 7 to cut the tobacco leaves from the middle into the upper part with the tip and the lower part with the leaf base. Then the upper part of tobacco leaves and the lower part of tobacco leave...

Embodiment 2

[0053] As attached Figure 1-8 As shown, a double-line re-baking processing device includes a cutting machine 1, a leaf spreading belt 2, a primary leaf dampening device 3, a secondary leaf dampening device 4, and a leaf threshing device 5. The cutting machine 1 is provided with The vertical support 11 and the horizontal support 12 placed horizontally on the vertical support. The horizontal support 12 is provided with an upper cutting knife support 6 and a lower cutting knife support 7 placed in parallel. The upper cutting knife support 6 and the lower cutting knife support 7 are respectively provided There are an upper cutter 61 and a lower cutter 71. The entire cutting machine 1 is set at the end of the leaf spreading belt 2. Below the cutting machine 1 is a left belt conveyor 21 and a right belt conveyor 22 with opposite directions, and a left belt conveyor for separating materials. The ends of the 21 and the right belt conveyor 22 are respectively connected to the main line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com