Main-auxiliary type multi-heat-source series-connection grid-connected heating device

A heating device and multi-heat source technology, applied in the directions of household heating, heating system, space heating and ventilation, etc., can solve the problems of disconnection from the Internet, waste of heat source resources and human resources, no peak regulation, and backup functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

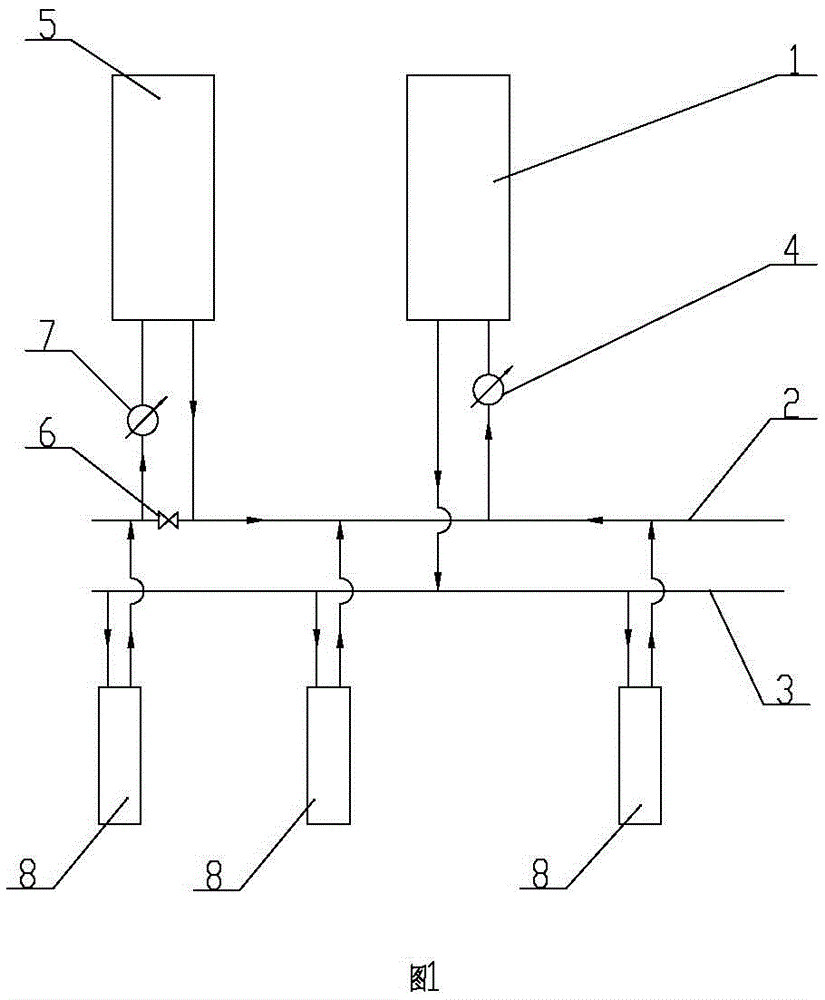

Embodiment 1

[0021] Embodiment one: as attached figure 1As shown, in this embodiment, the main and auxiliary multi-heat source series grid-connected heating device includes a main heat source 1 and an auxiliary heat source 5, a check valve 6 is provided on the primary return line 2, and the water inlet of the auxiliary heat source 5 The water outlet of the auxiliary heat source 5 is communicated with the primary return line 2 on the right side of the one-way valve 6 through the pipeline; the water inlet of the main heat source 1 is connected with the single It is connected to the primary return water line 2 on the right side of the valve 6; the water outlet of the main heat source 1 is connected to the primary water supply line 3 through a pipe; An auxiliary circulation pump 7 is provided on the pipeline; a main circulation pump 4 is provided on the pipeline between the water inlet of the main heat source 1 and the primary return water pipeline 2 on the right side of the one-way valve 6 . ...

Embodiment 2

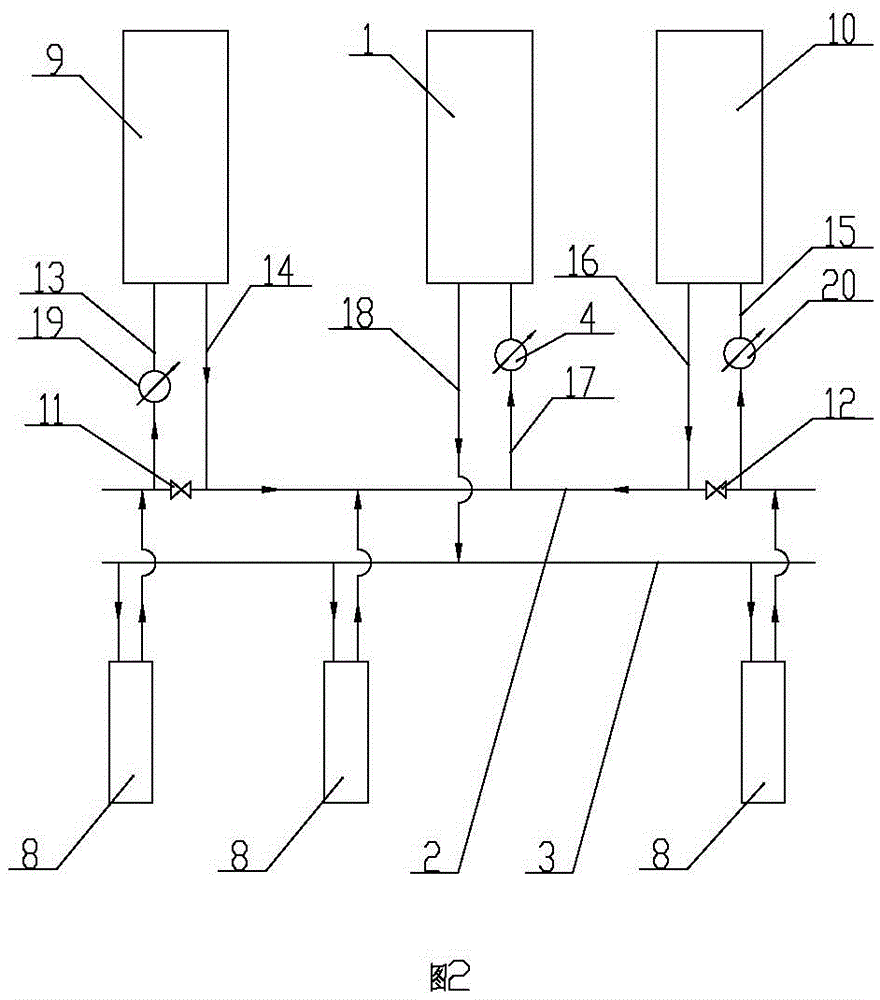

[0026] Embodiment two: as attached figure 2 As shown, this embodiment is basically the same as Embodiment 1, the difference is that the main and auxiliary multi-heat source series grid-connected heating device includes the main heat source 1, the first auxiliary heat source 9 and the second auxiliary heat source 10, and the primary return water The pipeline 2 is provided with a first one-way valve 11 and a second one-way valve 12 in sequence from left to right. The water pipeline 2 communicates, and the water outlet of the first auxiliary heat source 9 communicates with the primary return water pipeline 2 on the right side of the first one-way valve 11 through the second pipeline 14; the water inlet of the second auxiliary heat source 10 communicates with the water inlet through the third pipeline 15. The primary return line 2 located on the right side of the second check valve 12 communicates, and the water outlet of the second auxiliary heat source 10 communicates with the ...

Embodiment 3

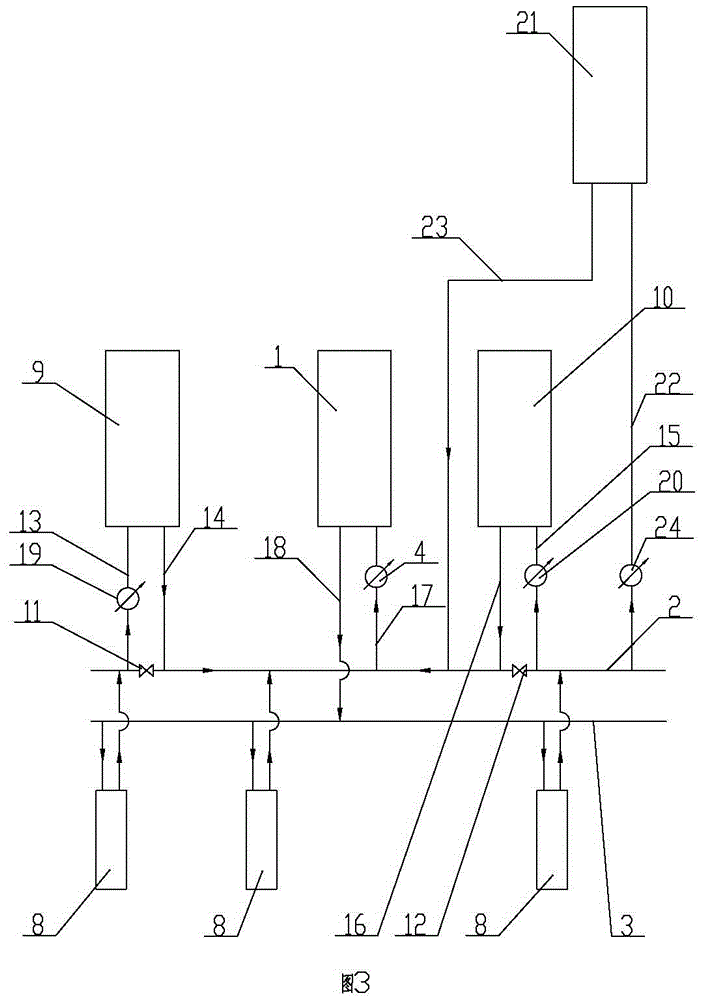

[0027] Embodiment three: as attached image 3 As shown, this embodiment is basically the same as Embodiment 2, the difference is that the main and auxiliary multi-heat source series grid-connected heating device includes a main heat source 1, a first auxiliary heat source 9, a second auxiliary heat source 10 and a third auxiliary heat source The heat source 21 and the primary return water line 2 are provided with a first one-way valve 11 and a second one-way valve 12 in sequence from left to right, and the water inlet of the first auxiliary heat source 9 is connected to the The primary return line 2 on the left side of 11 is connected, and the water outlet of the first auxiliary heat source 9 is connected with the primary return line 2 on the right side of the first one-way valve 11 through the second pipe 14; the water inlet of the second auxiliary heat source 10 The third pipe 15 communicates with the primary return line 2 on the right side of the second one-way valve 12 , a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com