Offshore oil production platform, and bearing capacity transfer method and transfer device of drilling platform

A technology for drilling platforms and transfer devices, which is applied in the direction of drilling equipment, drill pipes, drill pipes, etc., and can solve the problems of insufficient bearing capacity and insufficient depth of pile legs into the mud, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

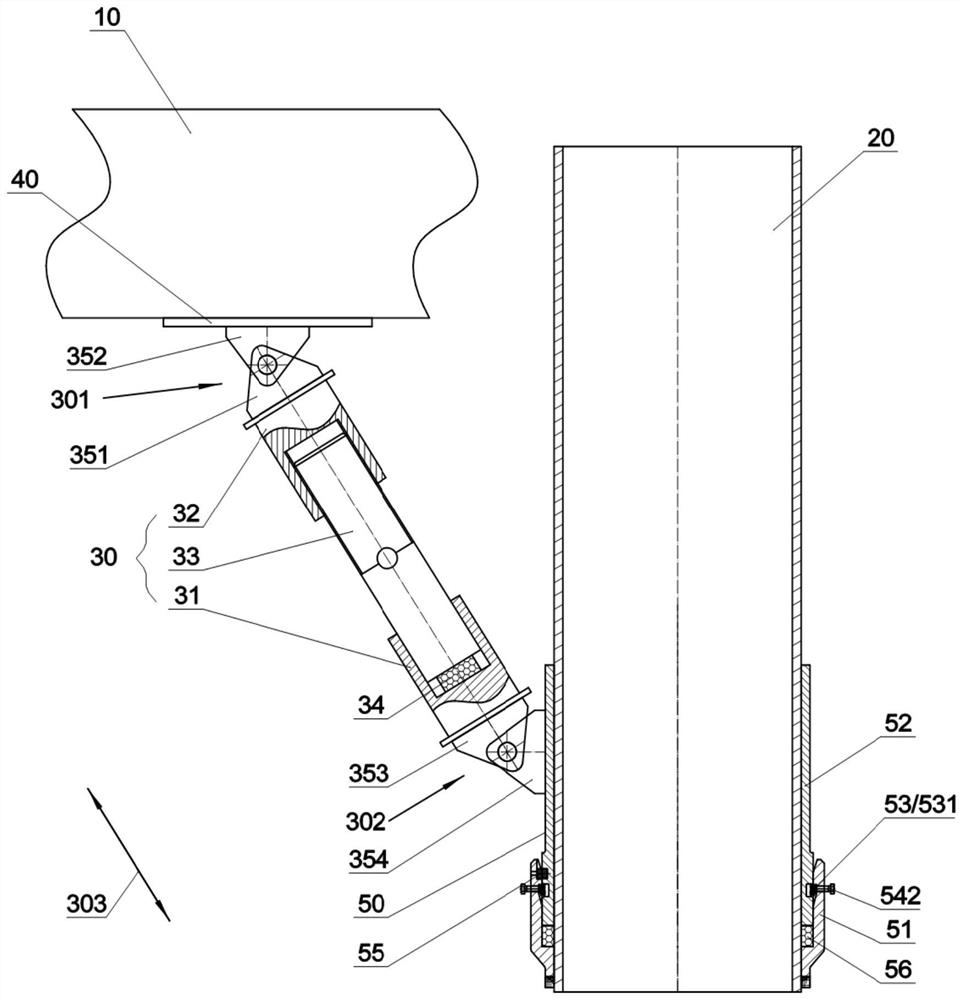

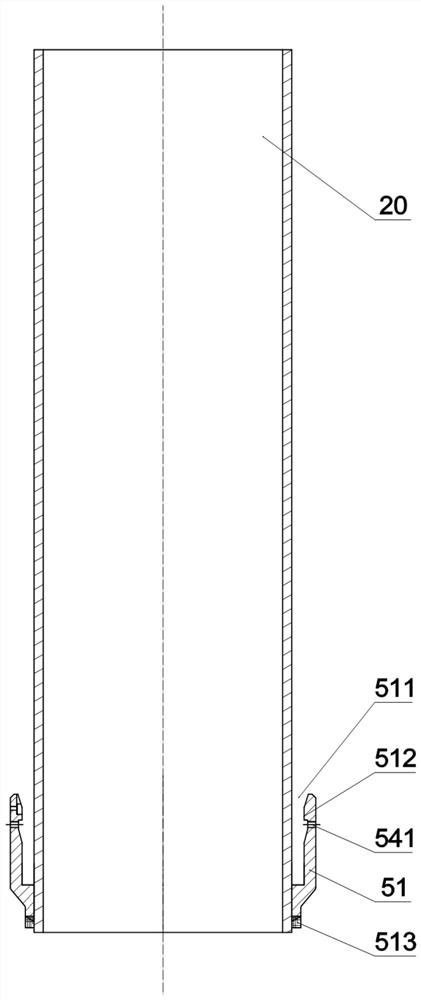

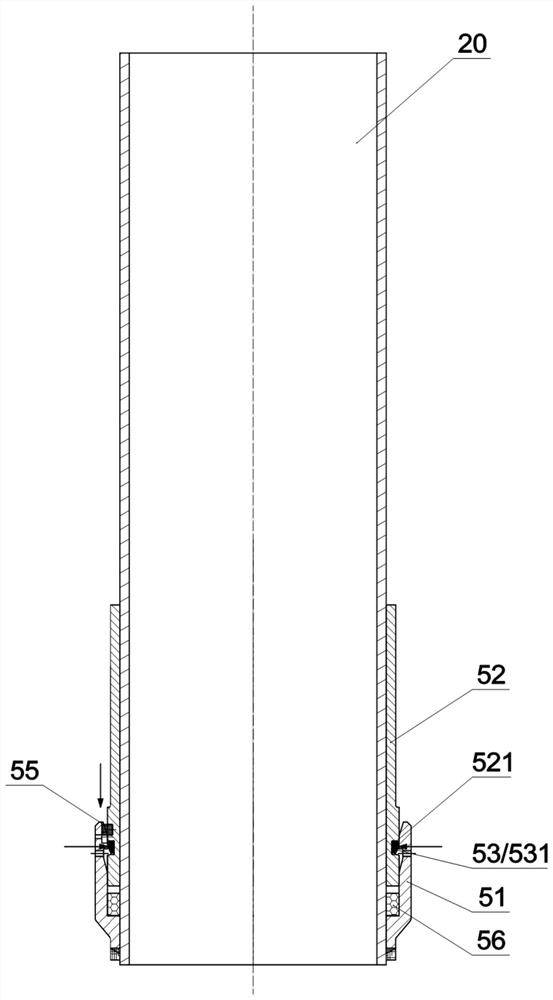

[0048] The present invention provides a water conduit and a drilling platform 10 carrying capacity transfer device, such as figure 1 As shown, the load transfer device includes: a connecting rod body 30, a drilling platform connecting plate 40 and a water riser connecting structure 50, the connecting rod body 30 can transmit vertical loads; the drilling platform connecting plate 40 is connected to the first end 301 of the connecting rod body , the drilling platform connecting plate 40 can be fixedly connected to the drilling platform 10 ;

[0049] By adopting the bearing capacity transfer device, the water riser 20 is connected with the drilling platform 10, so that the water riser 20 can be used as a force-bearing structure, and the load of the drilling platform 10 can be transferred to the drilling platform 10 by utilizing the abundant bearing capacity of the water riser 20. The water conduit 20 is used to increase the ultimate bearing capacity of the drilling platform 10 an...

Embodiment 2

[0071] The present invention provides an offshore oil production platform, which comprises: a drilling platform 10, a water-resisting conduit 20, and the above-mentioned device for transferring the carrying capacity between the water-resisting conduit 20 and the drilling platform 10; The drilling platform connection plate 40 in the transfer device is affixed to the drilling platform 10 , and the riser conduit 20 and the riser conduit connection structure 50 in the load transfer device of the drilling platform 10 are affixed to the riser conduit 20 .

[0072] In this offshore oil production platform, the bearing capacity transfer device connects the water riser 20 and the drilling platform 10, so that the water riser 20 can be used as a force-bearing structure, and the load of the drilling platform 10 can be reduced by utilizing the abundant bearing capacity of the water riser 20. Transfer to the riser 20 to increase the ultimate bearing capacity of the drilling platform 10 and ...

Embodiment 3

[0074] The present invention provides a method for transferring the bearing capacity of the drilling platform 10. The method for transferring the bearing capacity includes: adopting the above-mentioned device for transferring the bearing capacity of the water riser 20 and the drilling platform 10; transferring the bearing capacity of the water riser 20 and the drilling platform 10 The drilling platform connection plate 40 in the device is affixed to the drilling platform 10 ;

[0075] The load-bearing capacity transfer method is adopted, and the load-bearing capacity transfer device connects the riser conduit 20 with the drilling platform 10, so that the riser conduit 20 can be used as a force-bearing structure, and the load-bearing capacity of the riser conduit 20 can be used to transfer the load of the drilling platform 10. The load is transferred to the riser 20 to increase the ultimate bearing capacity of the drilling platform 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com