Patents

Literature

51results about How to "Reduced design strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Speed-changing device

ActiveUS20060217225A1Improve efficiencyLarge capacityHybrid vehiclesToothed gearingsLow speedHigh energy

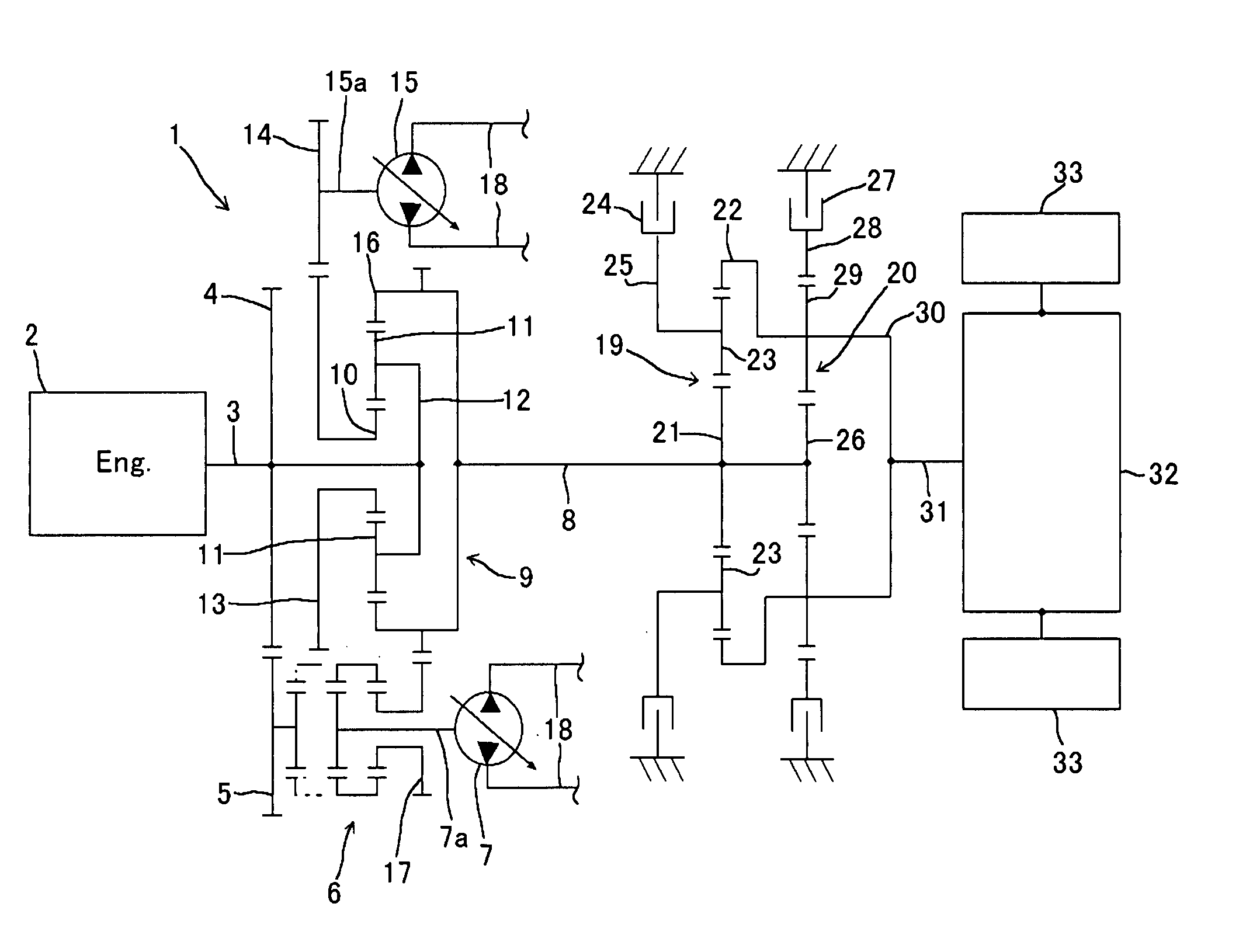

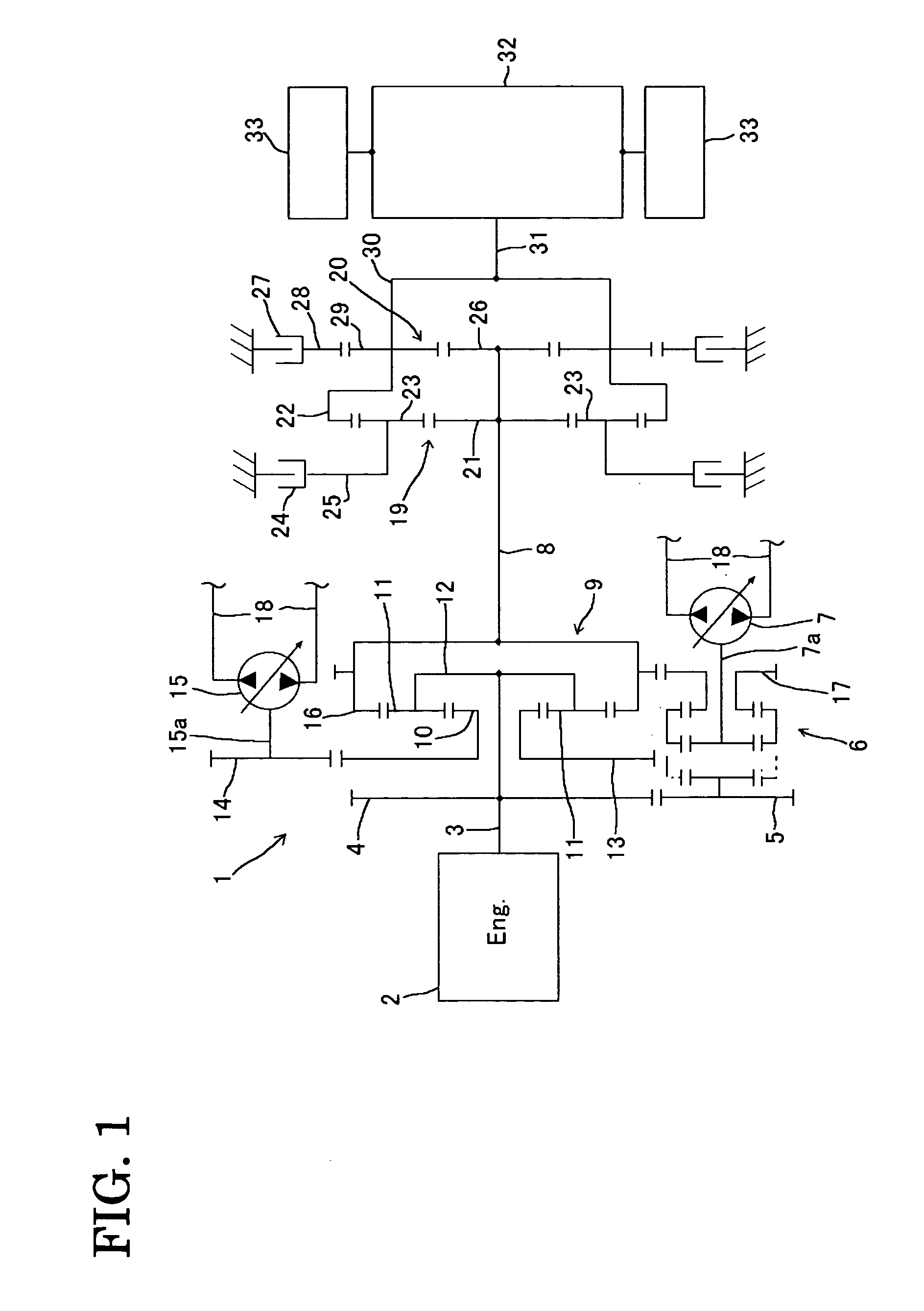

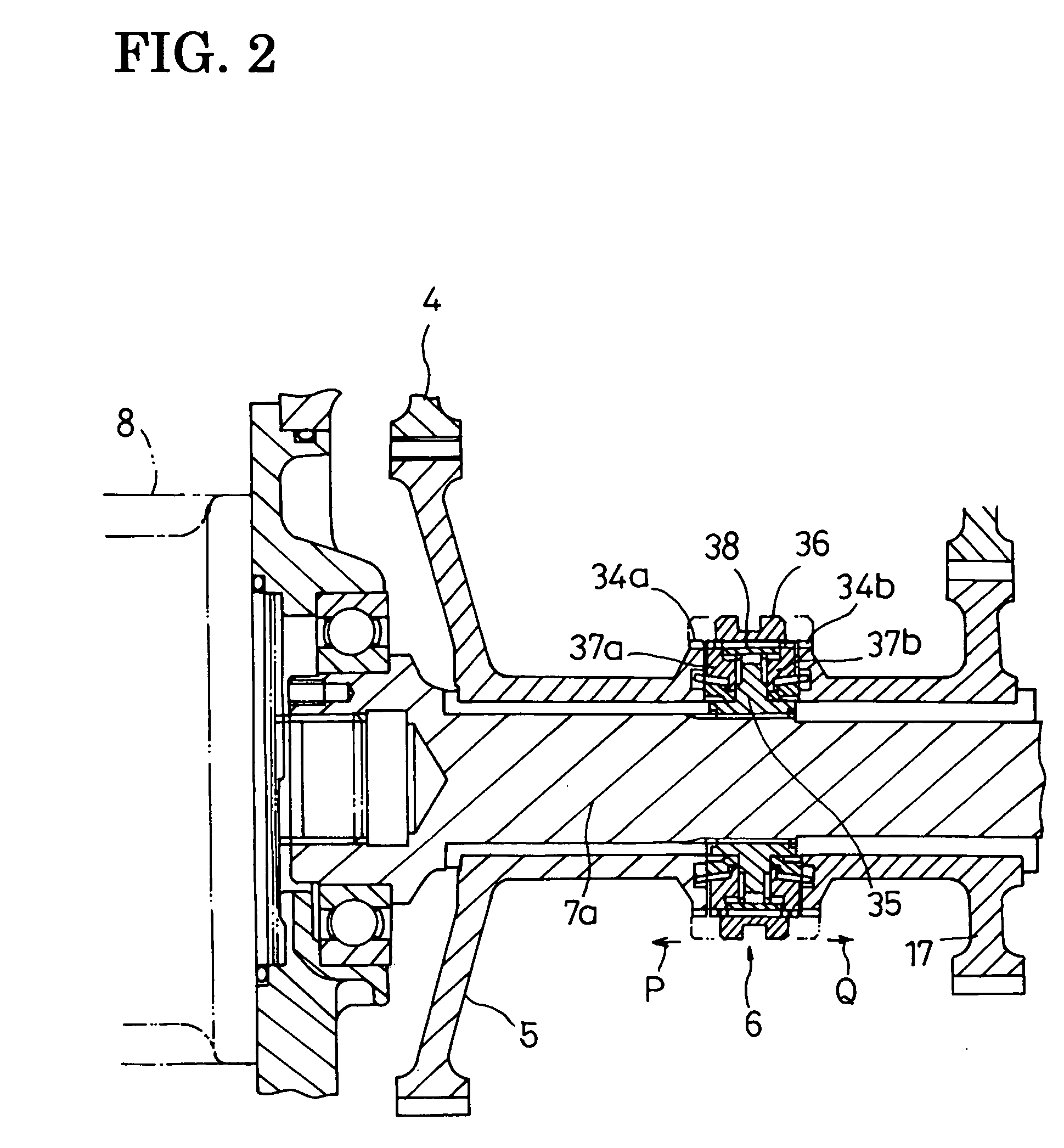

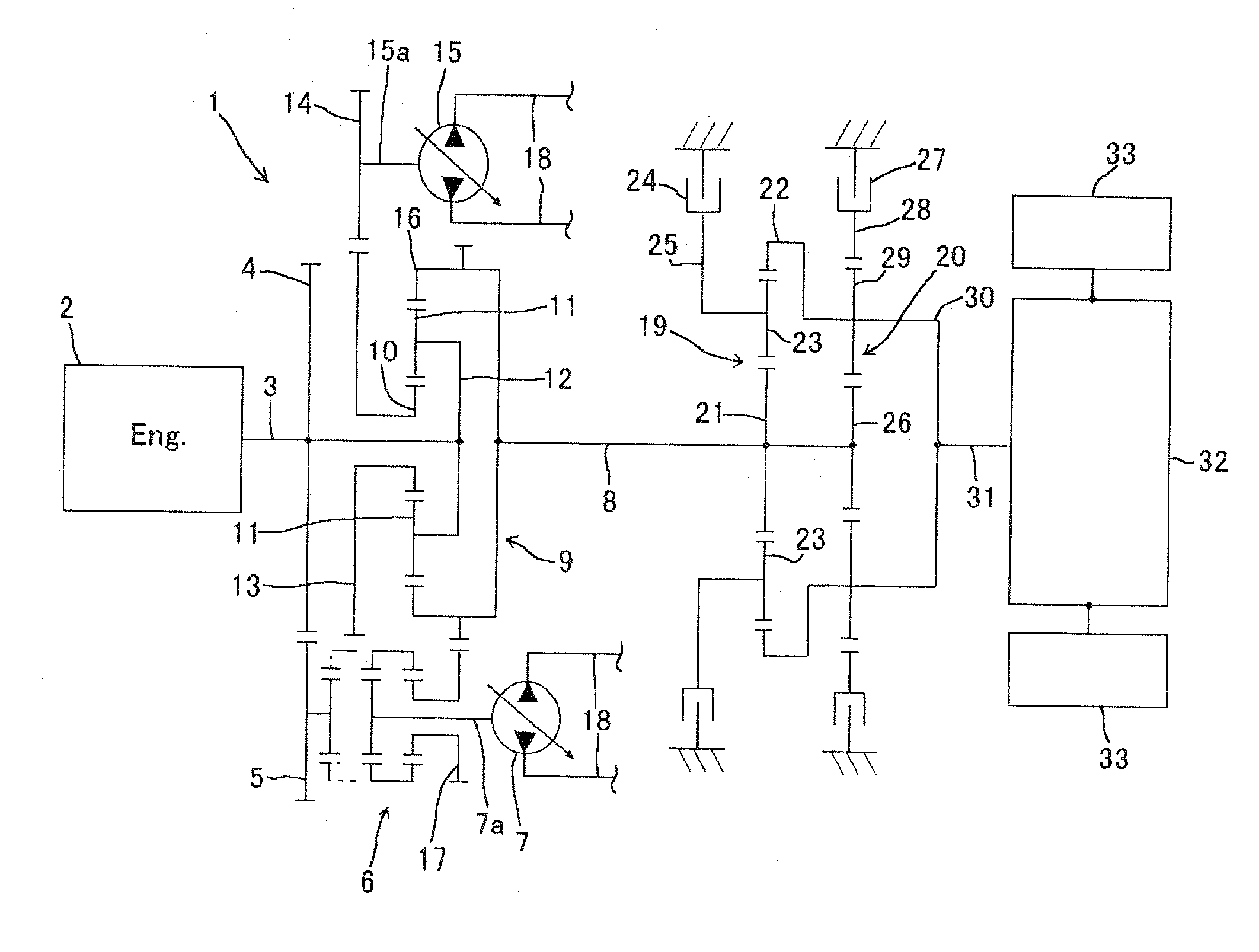

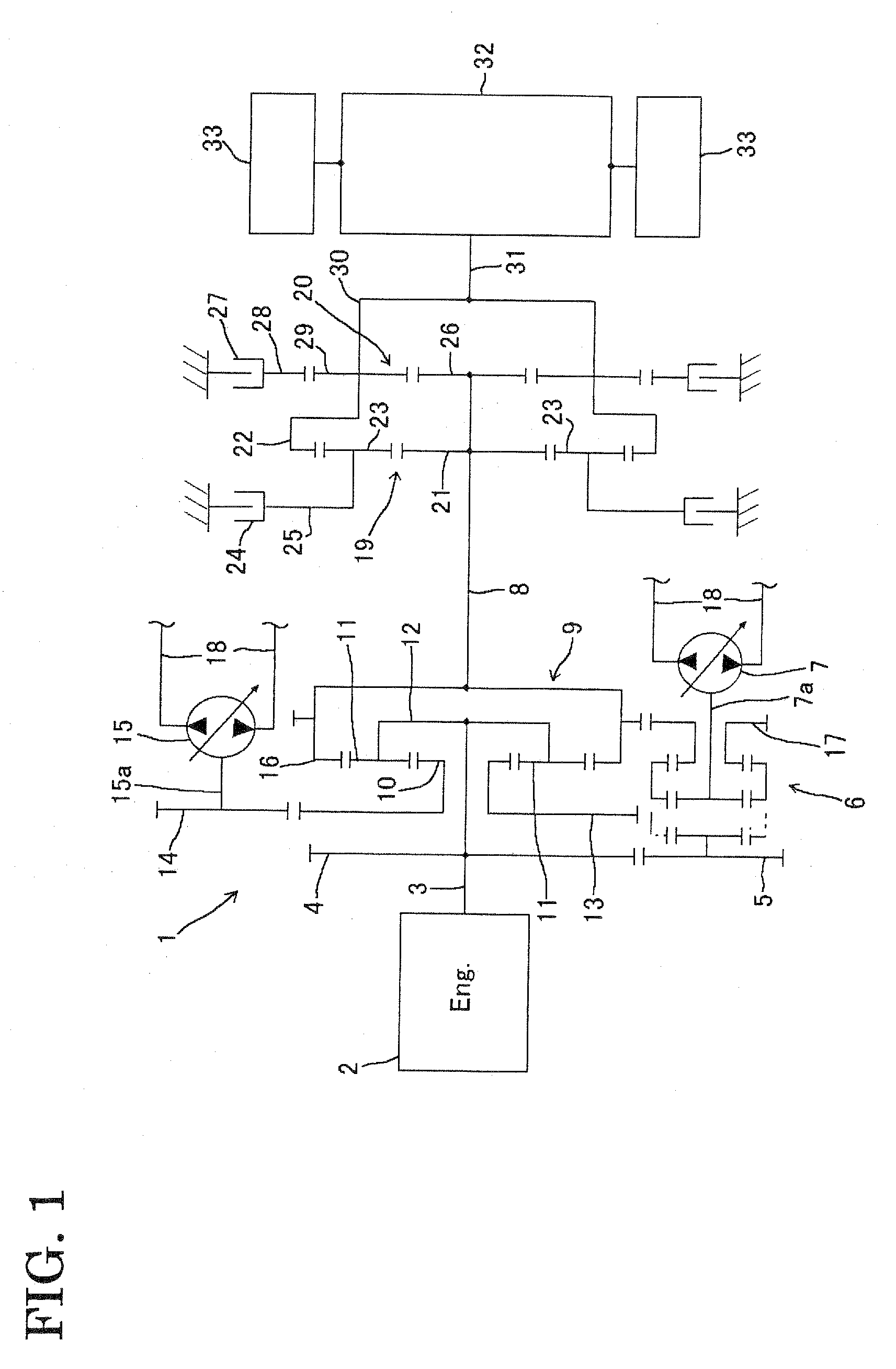

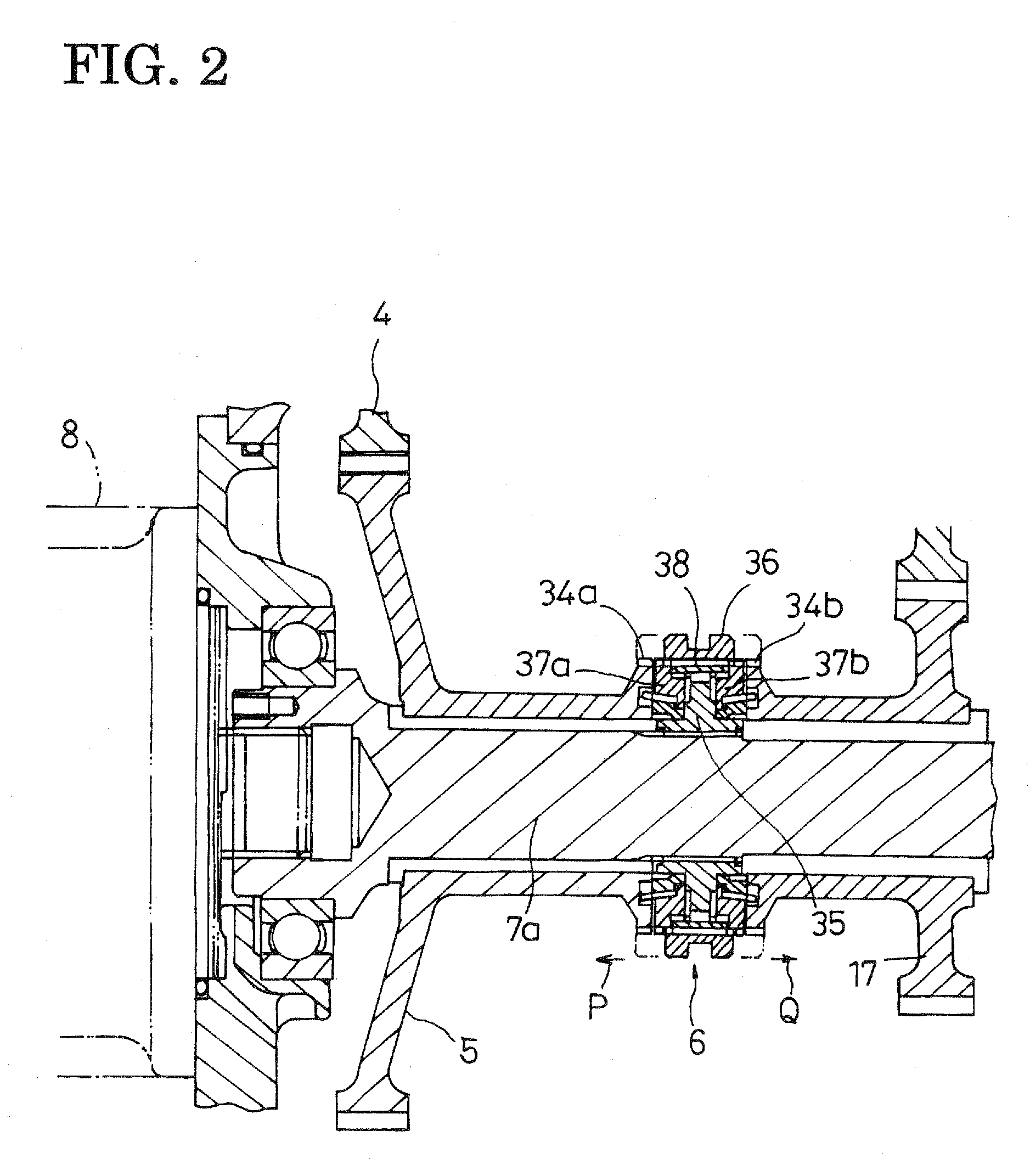

A transmission is provided which has a very compact system configuration and is capable of exerting high energy efficiency over all speed regions from a low speed region to a high speed region, while providing improved operability free from a torque shortage. To this end, the transmission has an input shaft 3, an intermediate output shaft 8, a planetary gear mechanism 9, a first pump-motor 7, and a second pump-motor 15 connected to the first pump-motor 7, the input shaft 3 being coupled to a first element (planetary carrier 12) of the planetary gear mechanism 9, the second pump-motor 15 being coupled to a second element (sun gear 19) of the planetary gear mechanism 9, the intermediate output shaft 8 being coupled to a third element (ring gear 16) of the planetary gear mechanism 9, and the transmission further comprising a switching mechanism (synchromesh mechanism 6) for selectively coupling the first pump-motor 7 to either the input shaft 3 or the intermediate output shaft 8.

Owner:KOMATSU LTD

Speed-changing device

ActiveUS20080108467A1Shorten speedIncrease in loss of horse powerHybrid vehiclesGas pressure propulsion mountingLow speedHigh energy

A transmission is provided which has a very compact system configuration and is capable of exerting high energy efficiency over all speed regions from a low speed region to a high speed region, while providing improved operability free from a torque shortage. To this end, the transmission has an input shaft, an intermediate output shaft, a planetary gear mechanism, a first pump-motor, and a second pump-motor connected to the first pump-motor, the input shaft being coupled to a first element of the planetary gear mechanism, the second pump-motor being coupled to a second element of the planetary gear mechanism, the intermediate output shaft being coupled to a third element of the planetary gear mechanism, and the transmission further comprising a switching mechanism for selectively coupling the first pump-motor to either the input shaft or the intermediate output shaft.

Owner:KOMATSU LTD

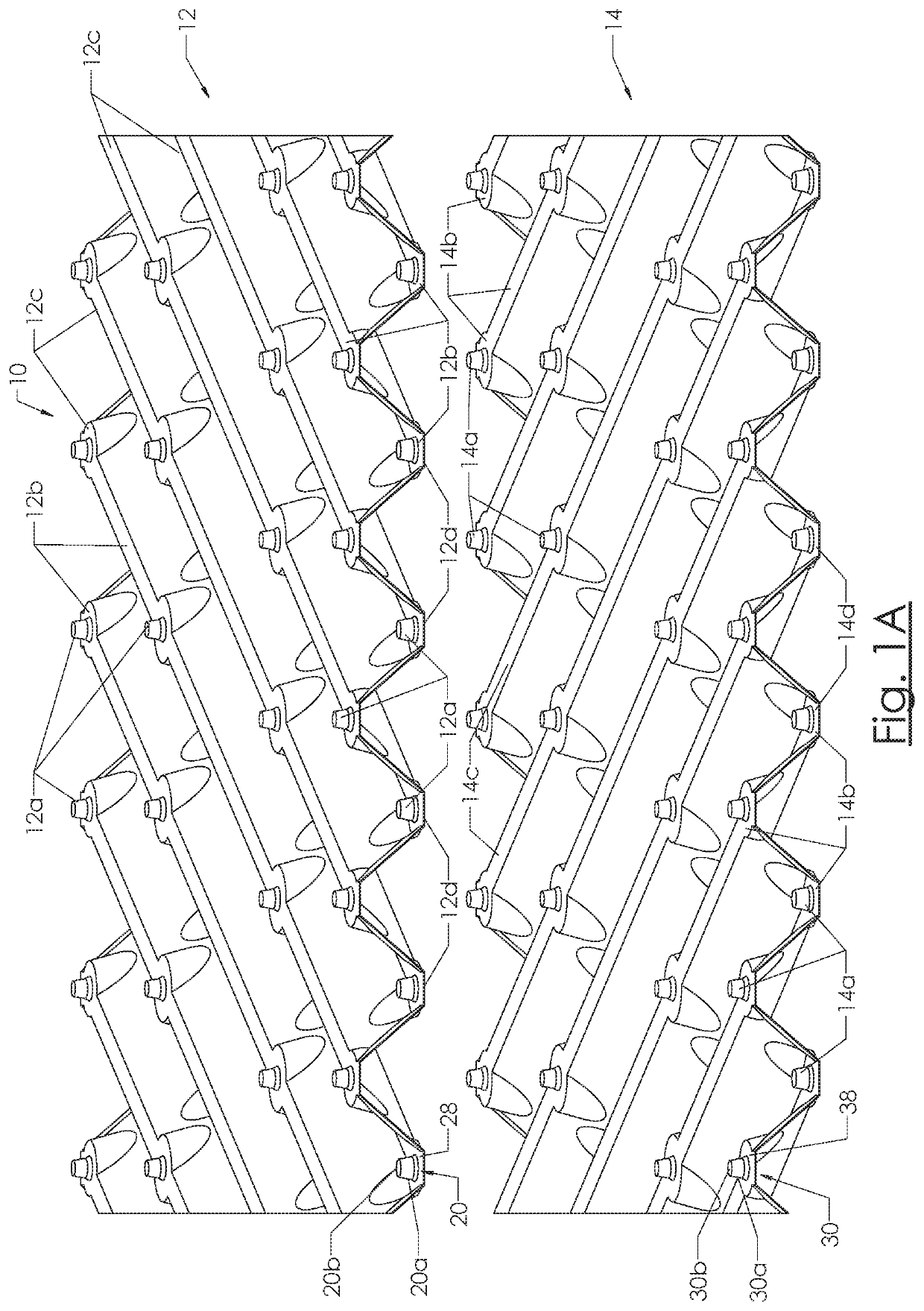

Circularly polarized antenna array having spinning characteristic in space structure

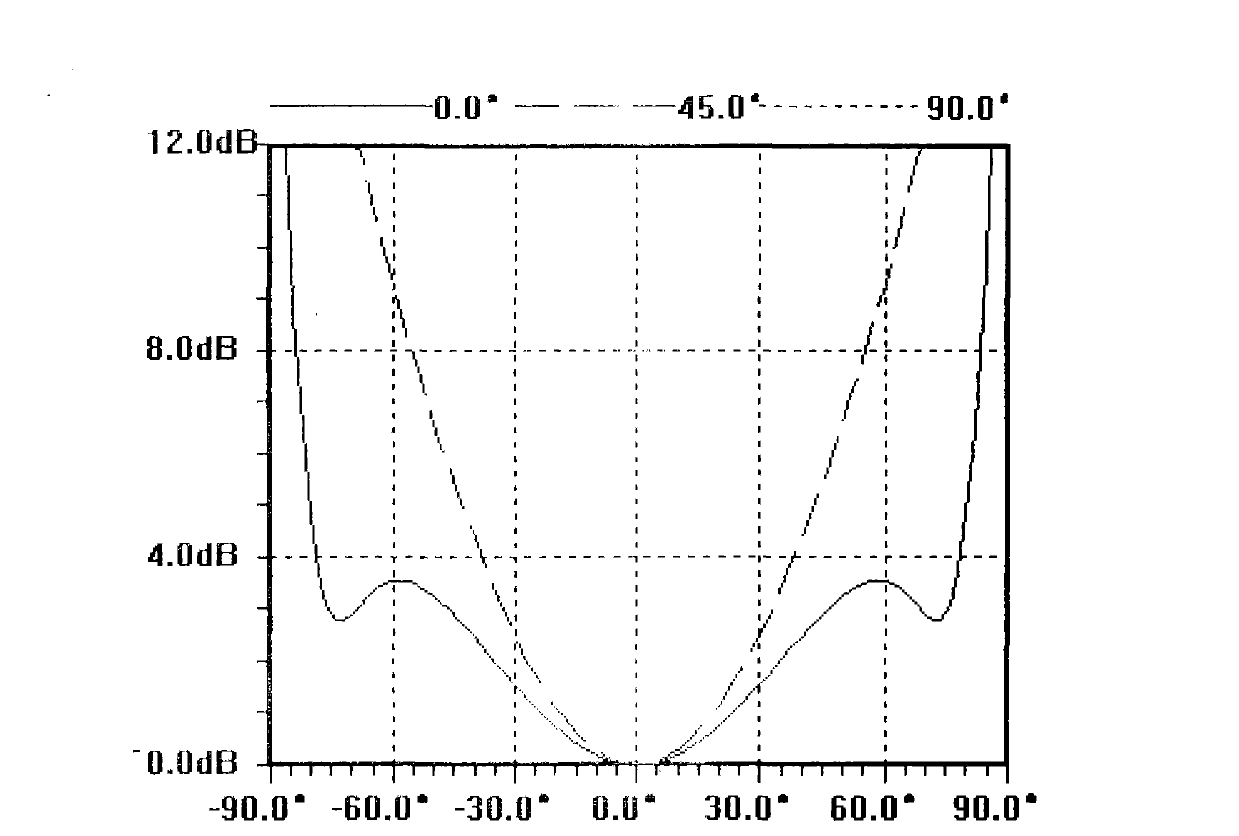

InactiveCN103219595AReduce volumeReduce weightRadiating elements structural formsPolarised antenna unit combinationsPhysicsDipole antenna

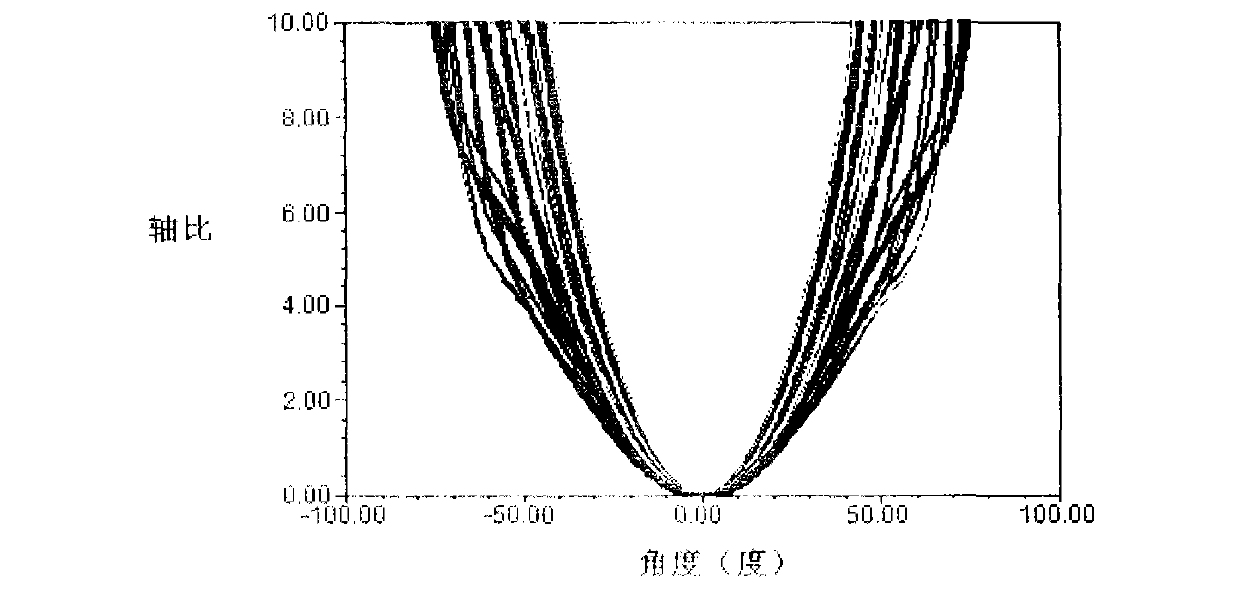

The invention provides a circularly polarized antenna array having a spinning characteristic in a space structure. The circularly polarized antenna array is provided with an antenna array face divided into a plurality of sub arrays. The antenna array face adopts a circularly polarized antenna sub array structure having the spinning characteristic and is divided into the plurality of rectangular sub arrays (10). Each of rectangular sub arrays (10) is provided with four spinning units which is equivalent to one spinning sub array in the space structure and adopts four pendulous cross dipole antenna units as a group, rectangular array arrangement is formed in a space, and four pendulous cross dipole antennas of each sub array are respectively arranged on top points of four corners of each rectangular array and are clockwise arranged in 0-degree, 90-dgree, 180-degree and 270-degree spinning mode. By adopting the circularly polarized antenna array, the circularly polarized radiation performance can be achieved well, and design size of each unit is not required to be changed.

Owner:LINGBAYI ELECTRONICS GRP

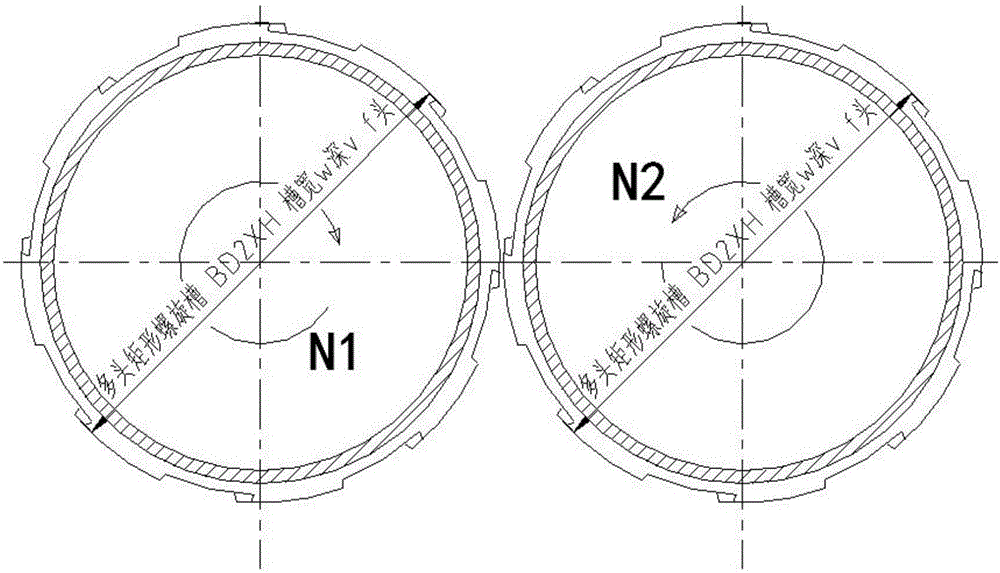

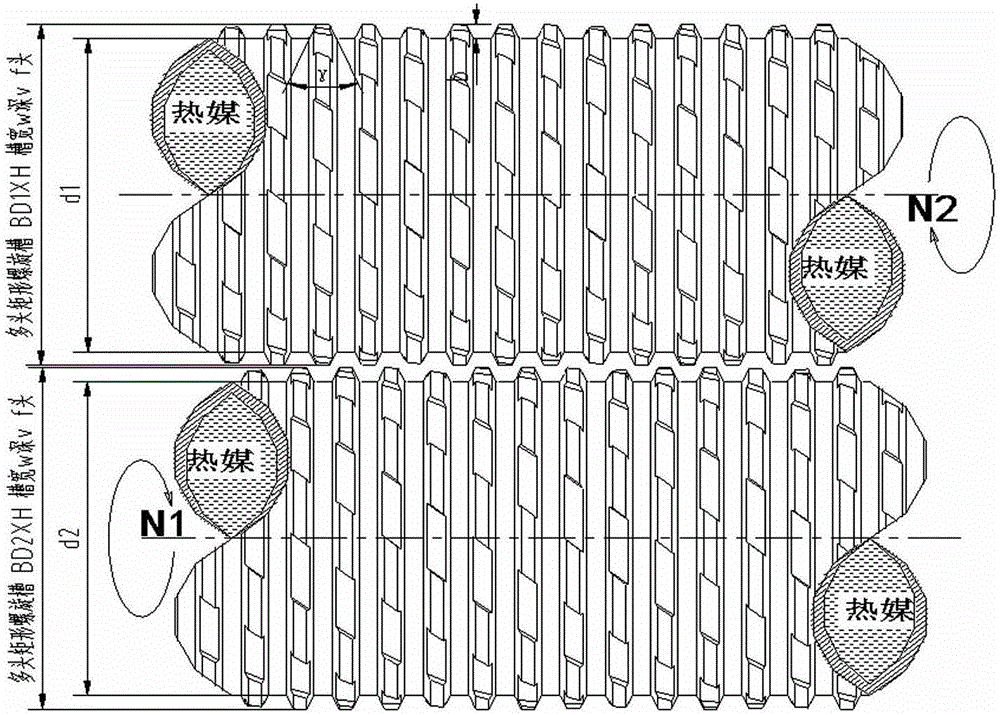

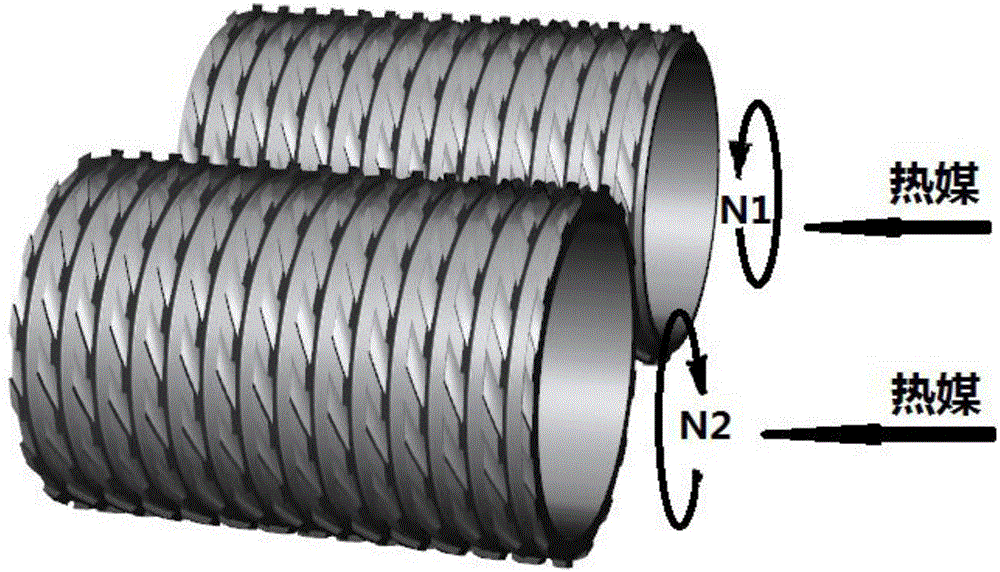

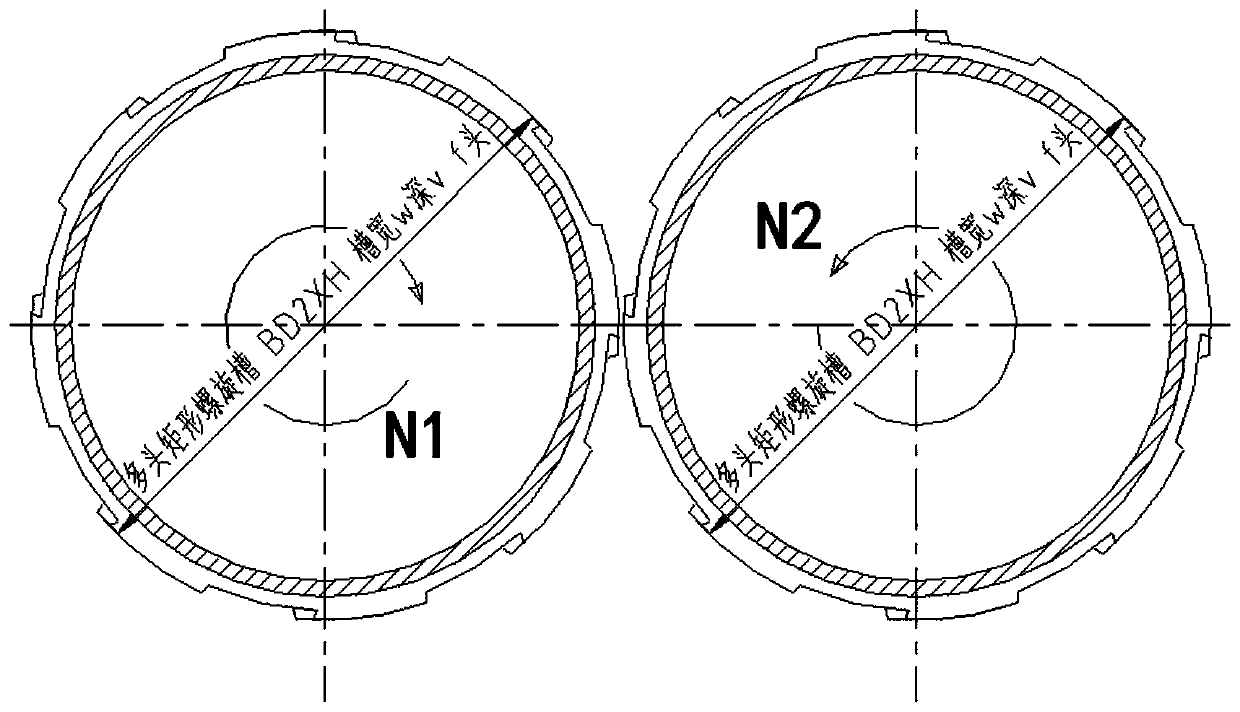

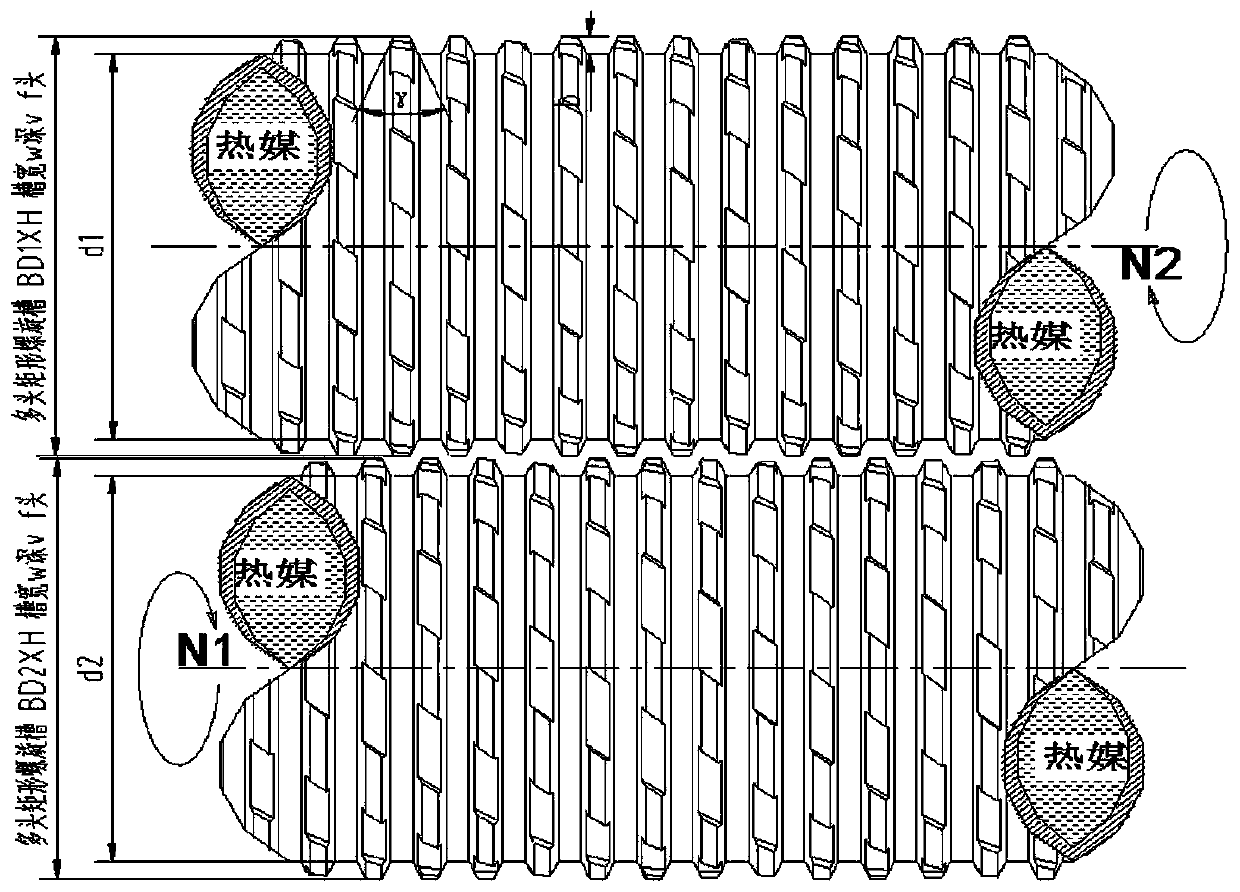

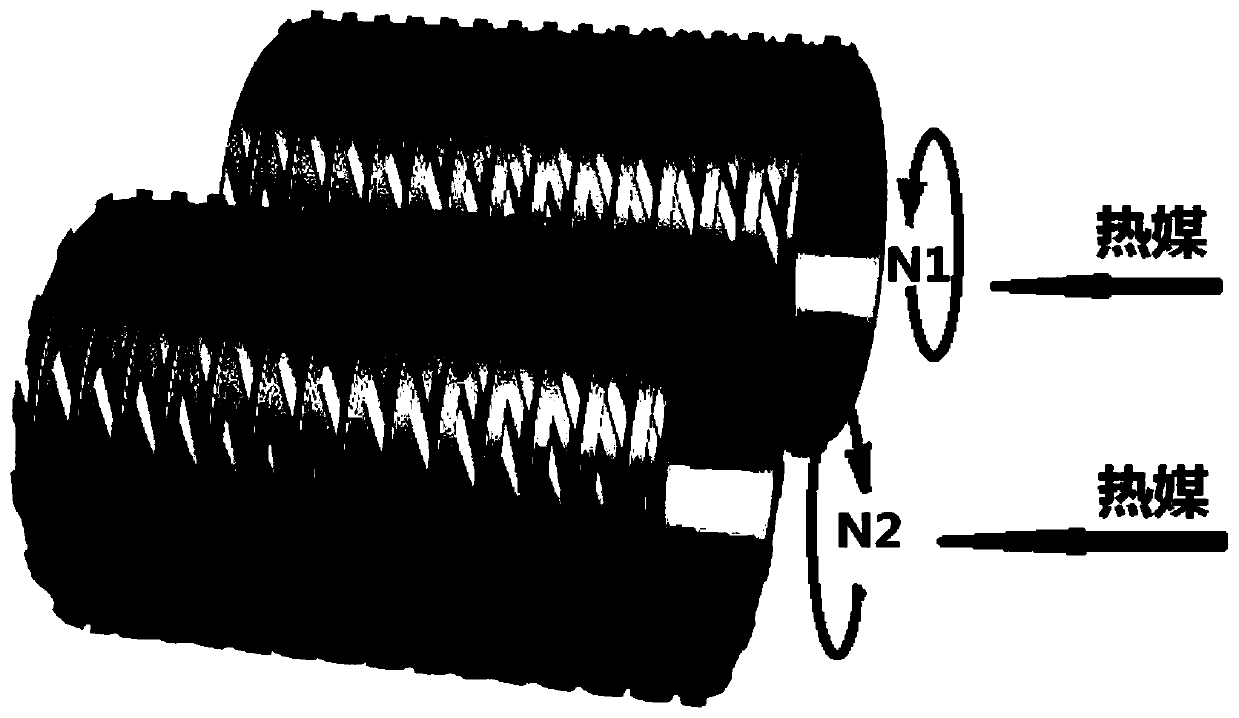

Combined-type granulator

ActiveCN106422974AAchieve maximum surfaceAchieve superficialityGranulation by pressingForeign matterSoft materials

The invention belongs to a wet material granulation principle and an equipment combination process, and particularly relates to a combined-type granulator. The combined-type granulator comprises a plurality of layers of combined box bodies, a temporary storage feed bin and a plurality of layers and groups of roller mills. Each group of roller mills is equipped with a rotary joint, a cleaning blade, an elastic stripping frame, a material baffle and a guide plate; a waste gas emptying interface is also arranged on each of the box bodies, and an air inlet at a lowest layer of the granulator is arranged on a bracket. The linear velocity of a tooth surface and the flow rate of volume of a rotary drum of each of the roller mills at a second layer are higher than those of a rotary drum of each of the roller mills at a first layer, and the linear velocity of a tooth surface and the flow rate of volume of a rotary drum with a reticular tooth socket or a single radial tooth socket of each of the roller mills at an adjacent lower layer are designed according to the volume properties of materials in the area. According to the granulator disclosed by the invention, hard foreign matters can be stripped, and simple granulation of soft materials in a cream state, a paste state, a slurry state and the like can be realized; meanwhile, caky and blocky materials can be pulled into monomer granules, soft and hard materials can simultaneously enter into the granulator, and granules at an outlet have a plurality of pores and are in an irregular shape.

Owner:张元才

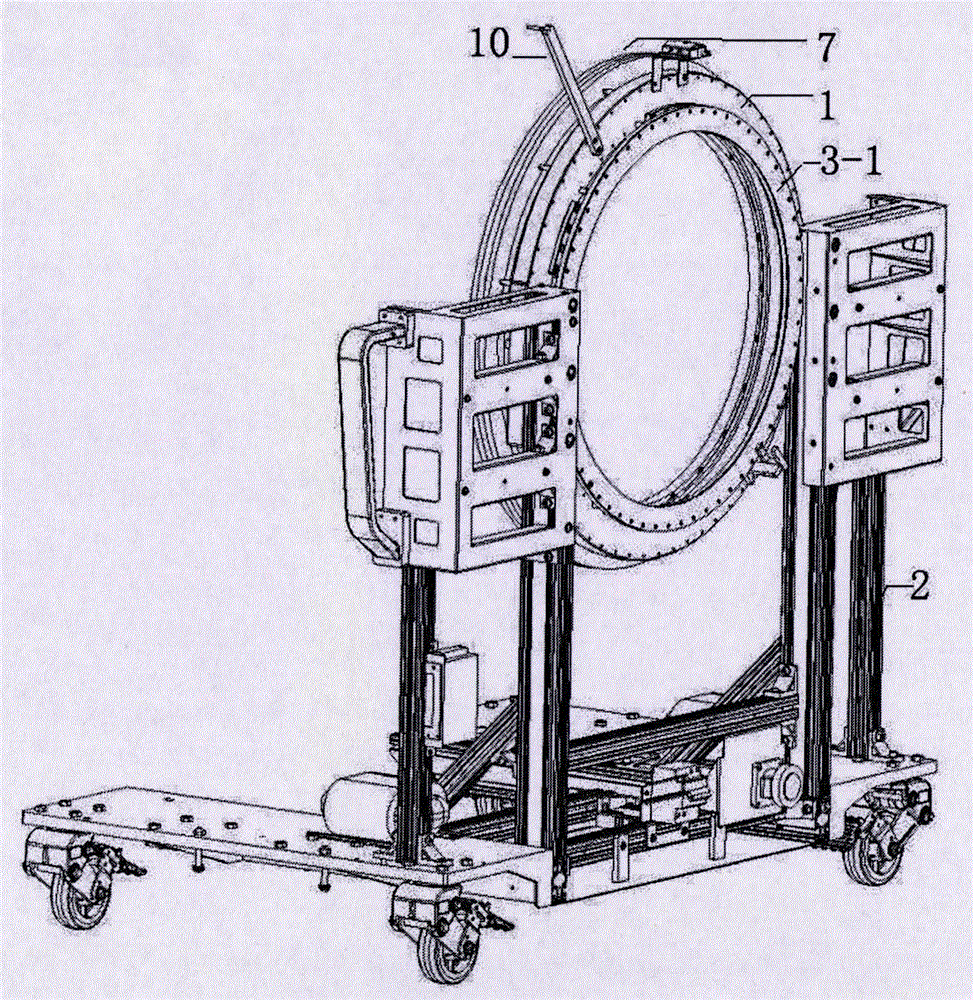

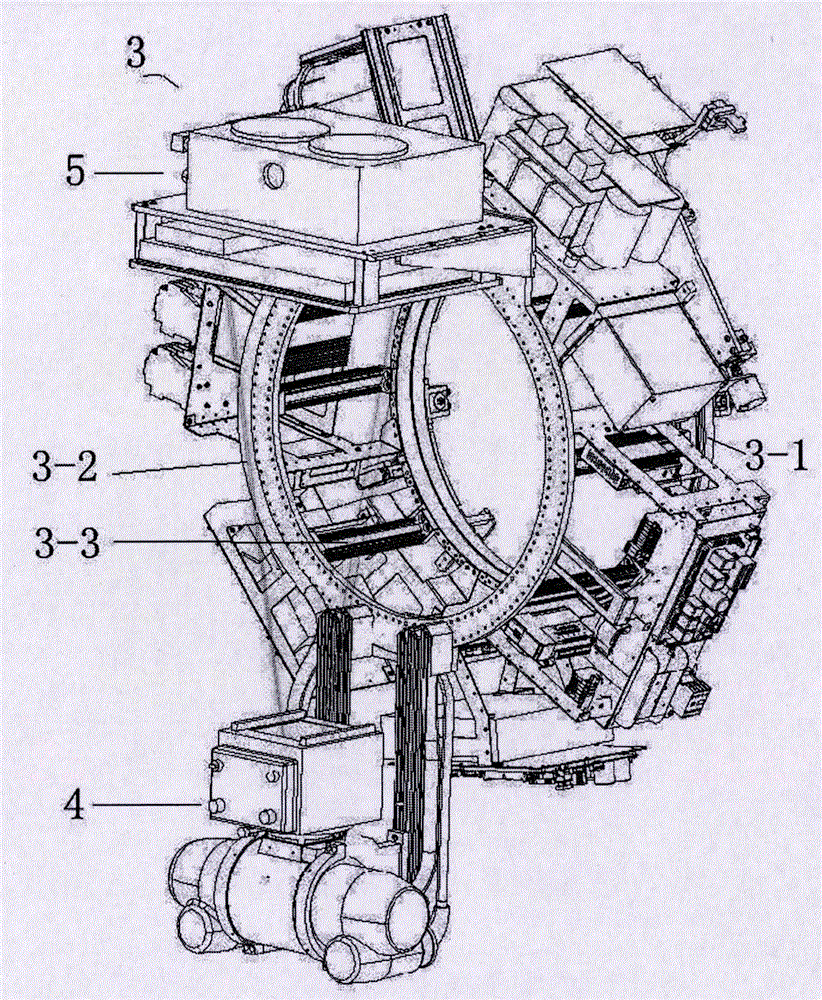

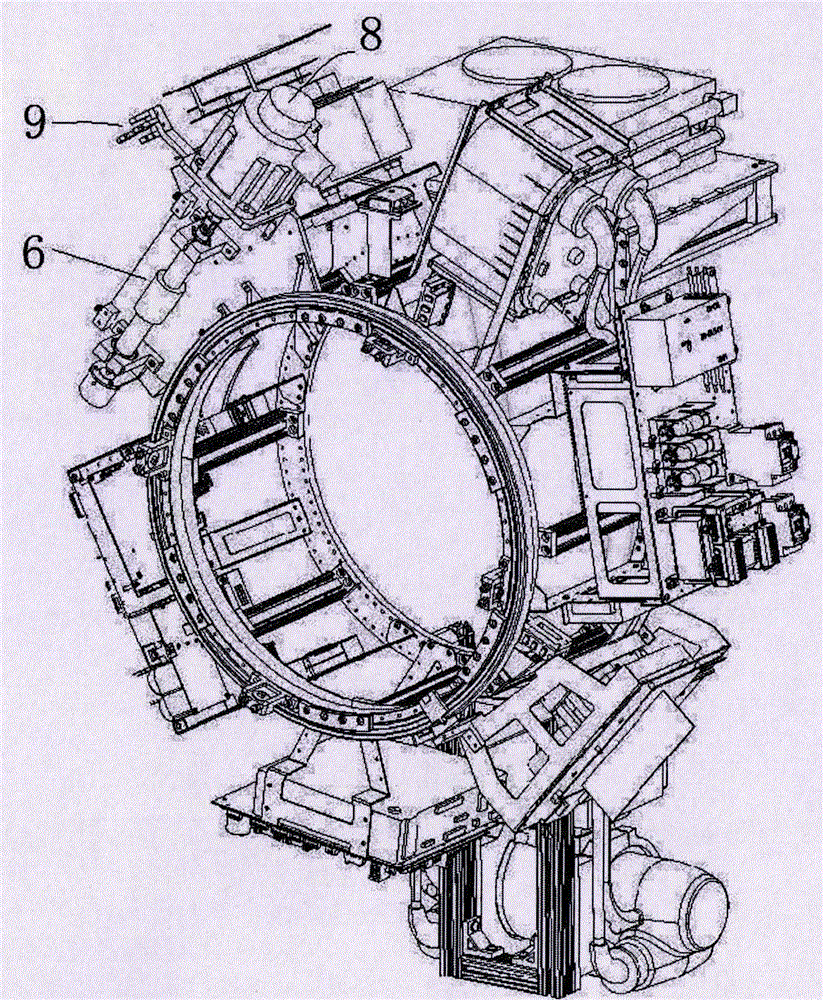

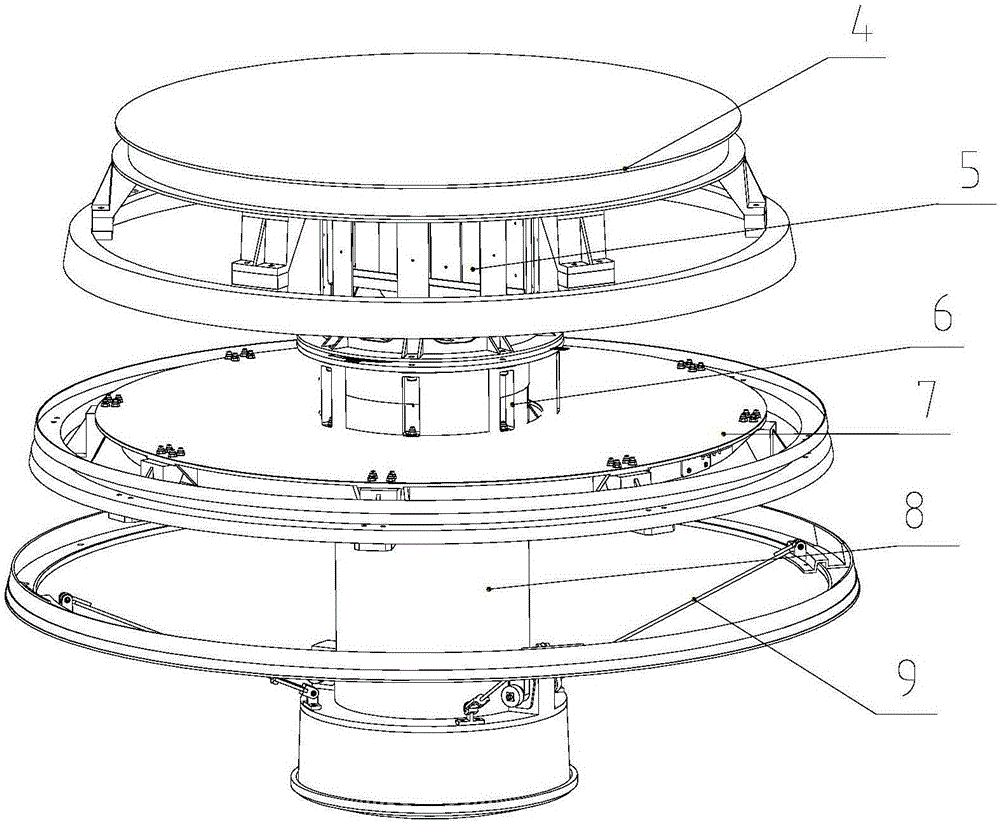

Cage type CT scanner

ActiveCN106667518AReduce design sizeReduce the weight and volume of the whole machineComputerised tomographsTomographyEngineeringRadian

The invention discloses a cage type CT scanner, which reduces and eliminates vibration of the CT scanner itself mainly by reducing the volume and weight of the CT scanner, the rotational radian of a rotating part and the vibration amplitude of the whole machine at the same time in order not to balance correction to eliminate the drive eccentric force and other measures. The cage type CT scanner eliminates a mechanical transmission chain belt cover to reduce the number of components in a motor structure, which not only reduces the cost, also meets the work requirements of the ground, and thus the CT scanner using site becomes wider.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH CHINESE ACADEMY OF SCI

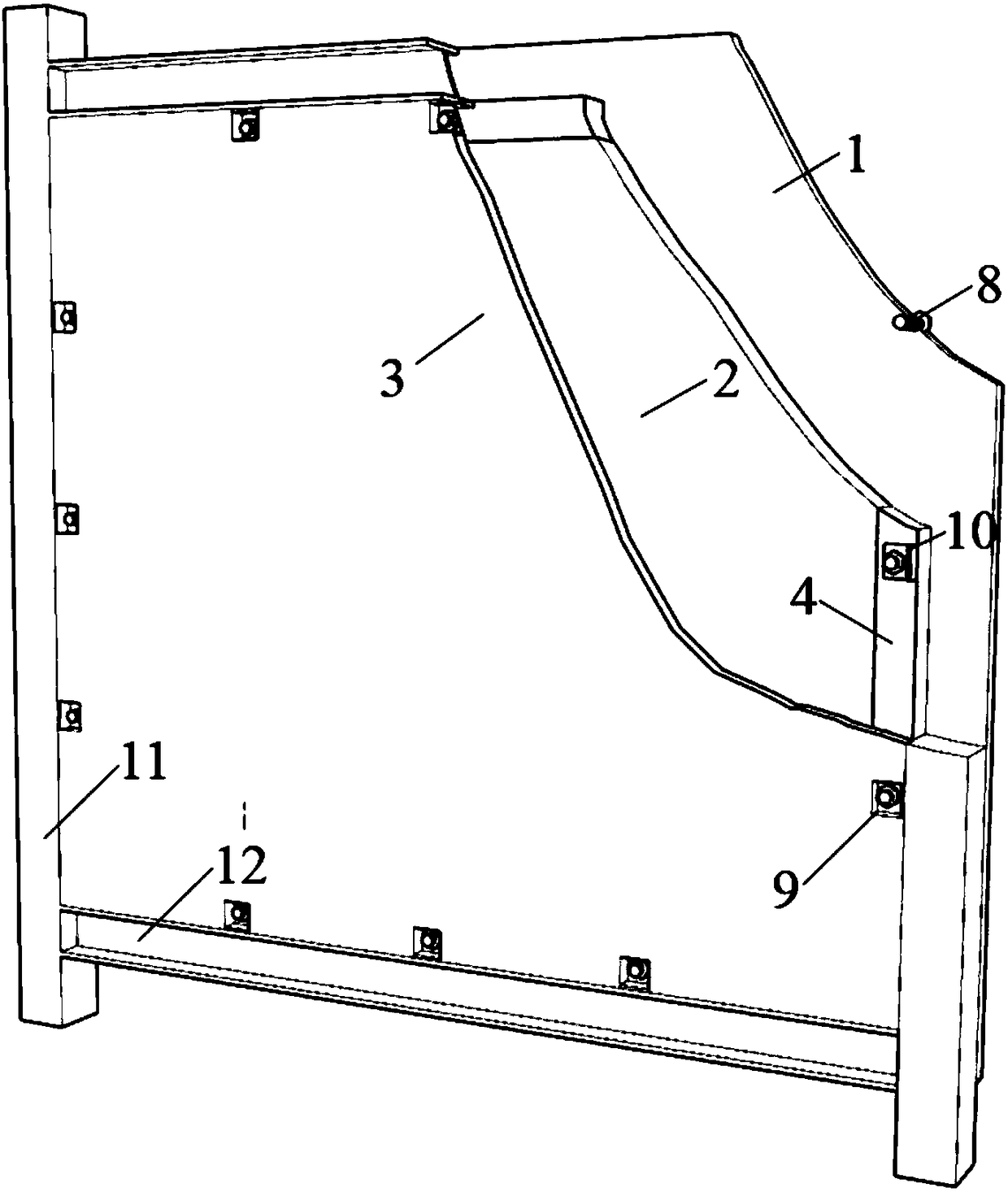

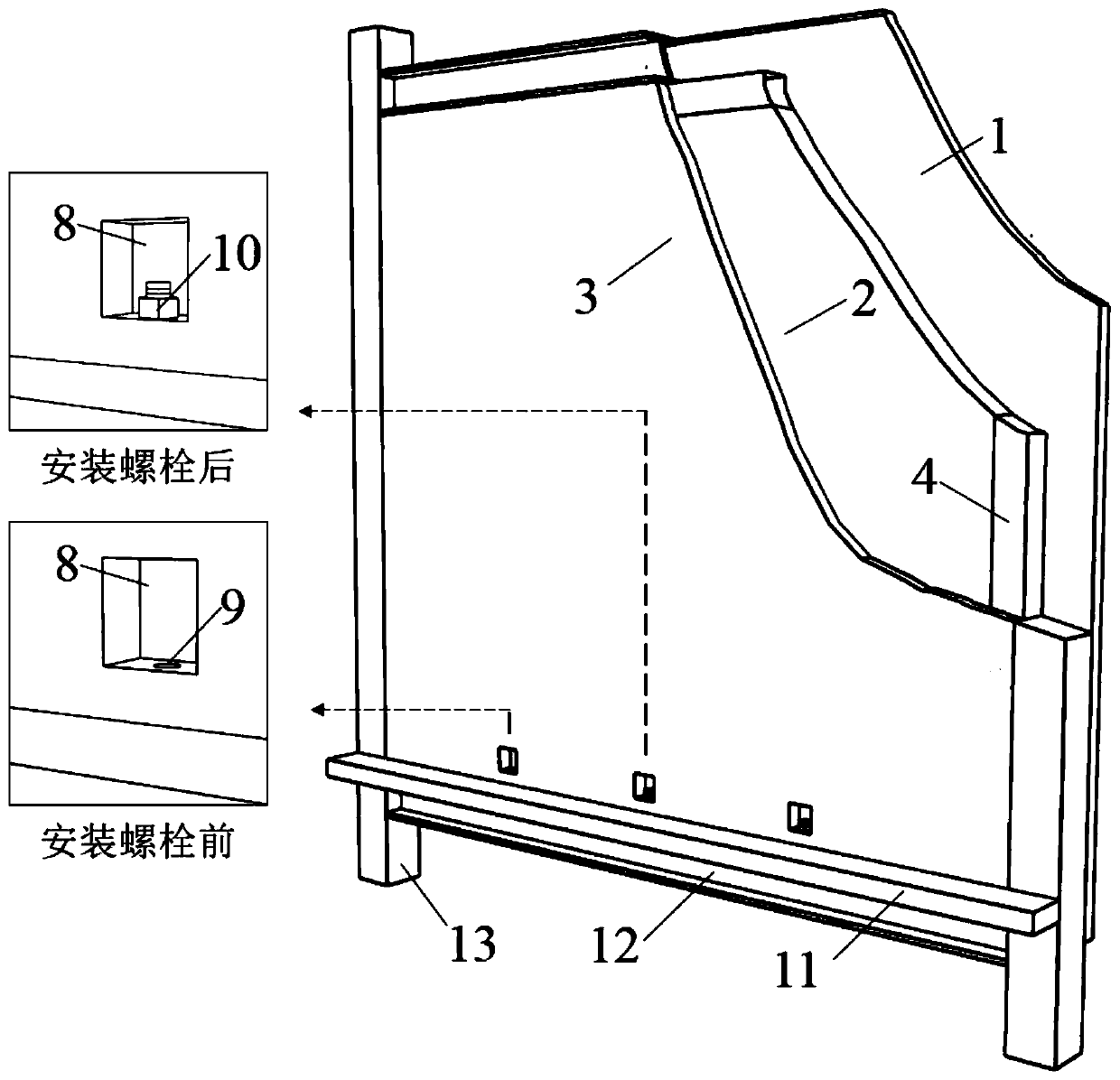

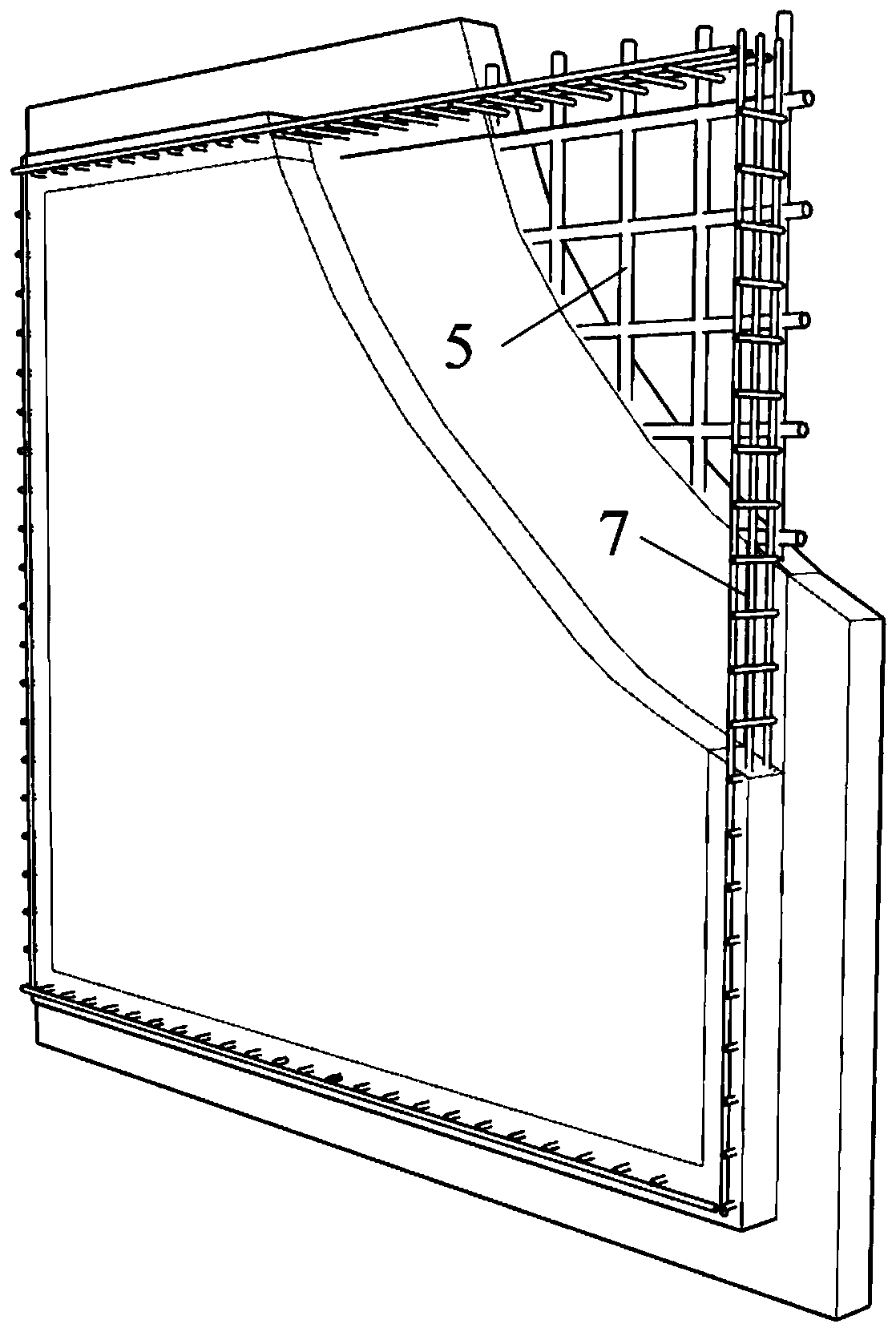

Connecting joint of fabricated concrete composite wall with built-in thermal insulation layer and light steel frame

PendingCN108277887AImprove seismic performanceHigh design strengthWallsHeat proofingThermal insulationSteel frame

The invention belongs to the technical field of connecting and manufacturing of wall joints in building structure engineering and particularly relates to a connecting joint of a fabricated concrete composite wall with a built-in thermal insulation layer and a light steel frame. The composite wall is mounted in a semi-embedded mode, and the built-in thermal insulation layer and inner sheet concreteare embedded into the light steel frame. Beam columns of the light steel frame are externally wrapped with outer sheet concrete. Compared with a traditional fabricated wall, the wall can serve as a structural force-bearing component, transmits loads with the frame beam columns, and participates in house structural force bearing, the house bearing capacity and anti-seismic capacity are improved, wallboards are wrapped with the frame beam columns, and thus steel corrosion is effectively reduced. The joint of the composite wall and the frame achieves bolted connection by means of the methods that bolts are pre-buried into the composite wall and connecting angle steel is welded to the frame structure beam columns, the structure form of the joint is simple, connecting is reliable, constructionis easy, the joint is applied to practical engineering, the building period can be effectively shortened, and the joint is suitable for being applied and popularized in low-rise and high-rise light steel frame structures.

Owner:BEIJING UNIV OF TECH

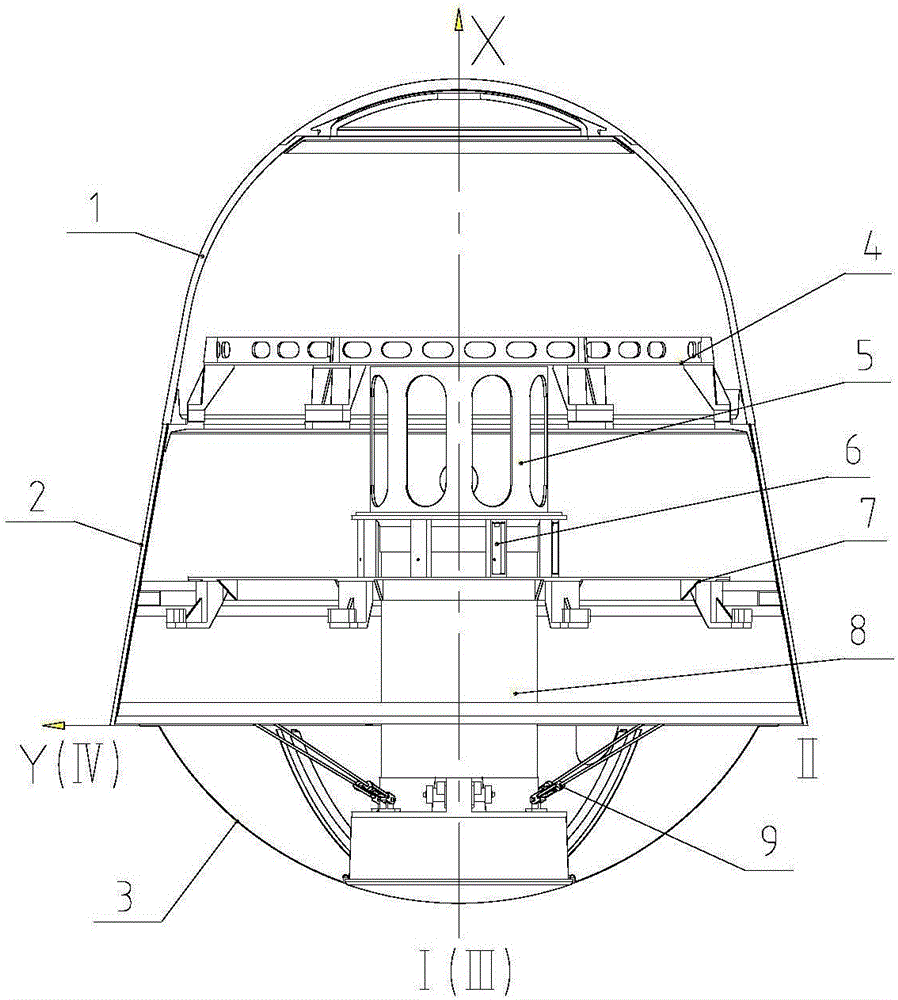

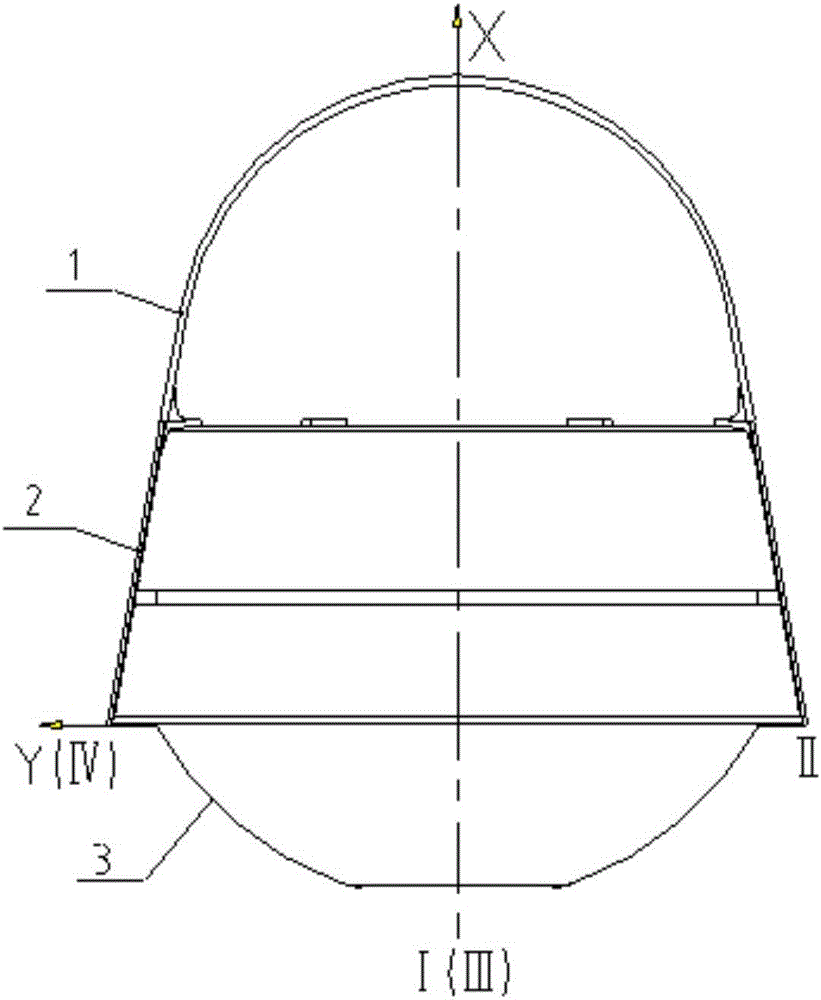

Main load-bearing structure suitable for ballistic reentry recovery capsule

ActiveCN106428634AReduce stress concentrationHigh base frequencyCosmonautic vehiclesCosmonautic partsFundamental frequencyEngineering

The invention discloses a main load-bearing structure suitable for a ballistic reentry recovery capsule, and belongs to the technical field of load bearing of a recovery capsule. The main load-bearing structure suitable comprises a head shell, a stabilizing flare, a flare bottom, an instrument panel, a transition bracket, a support base, a platform, a parachute bay device and a pull rod, wherein two ends of the stabilizing flare are respectively butted with the head shell and the flare bottom; the instrument panel is fixed to an upper end frame of the stabilizing flare; the transition bracket is coaxially mounted on the bottom surface of the instrument panel; the platform is connected with the middle bulkhead of the stabilizing flare; the support base is fixed to the upper surface of the platform; the support base is connected with the transition bracket; after a mounting end of the parachute bay device penetrates through the platform, the mounting end is connected with the support base and the transition bracket, and a parachute deployment end is connected with the stabilizing flare through the pull rod after penetrating through the stabilizing flare; a circular gap of the flare bottom is sealed by the spherical surface of the parachute deployment end of the parachute bay device; the structure can bear up under complicated reentry load conditions, meet the requirements of equipment mounting, increase the transversal fundamental frequency of the capsule body, and achieve lightweight design on the premise of satisfying rigidity and strength.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

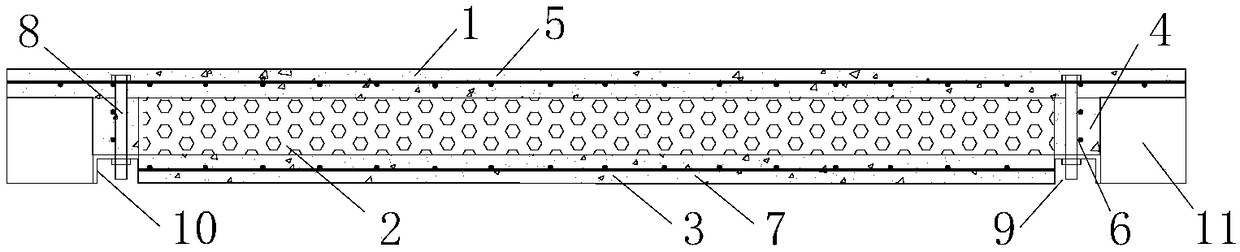

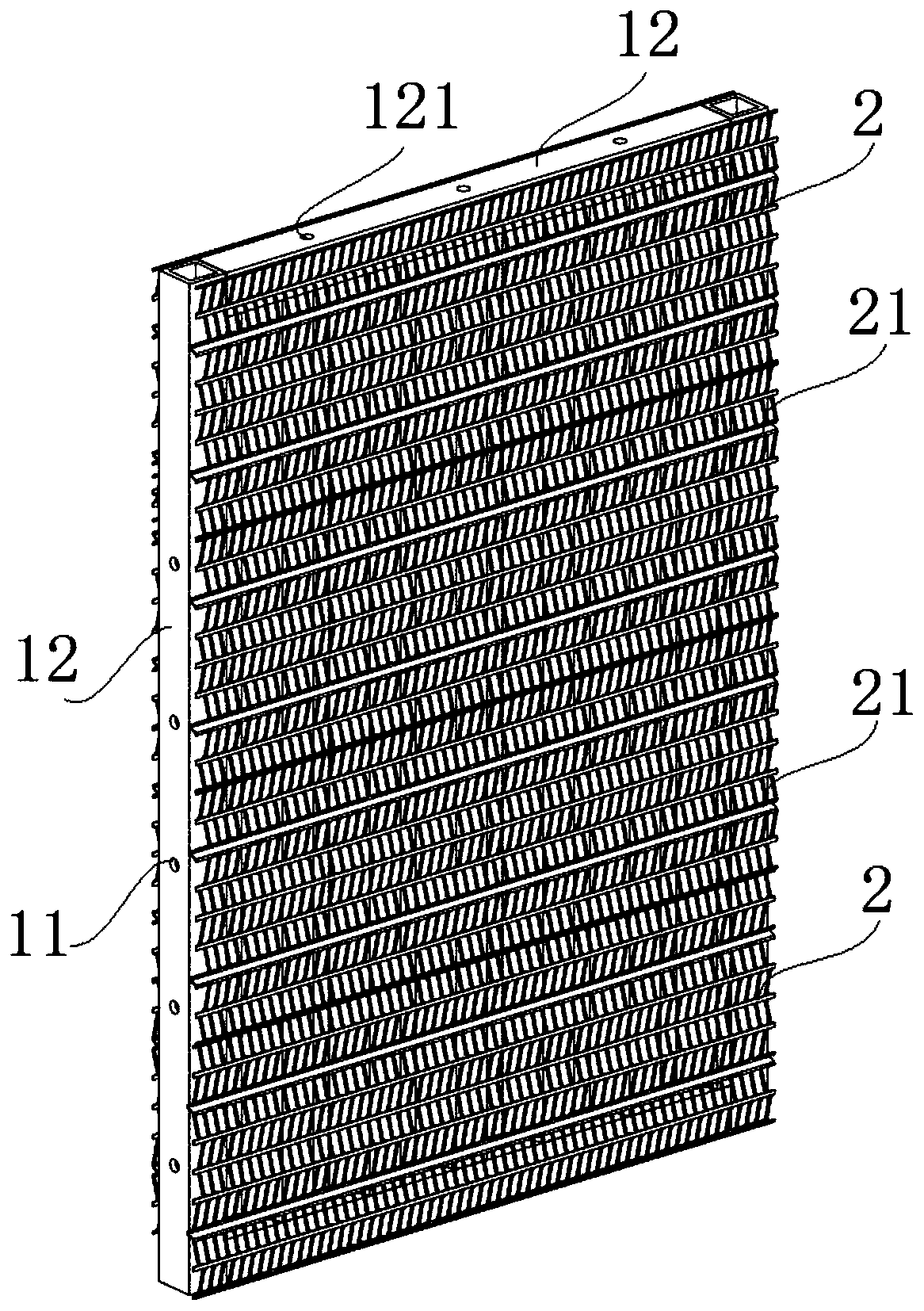

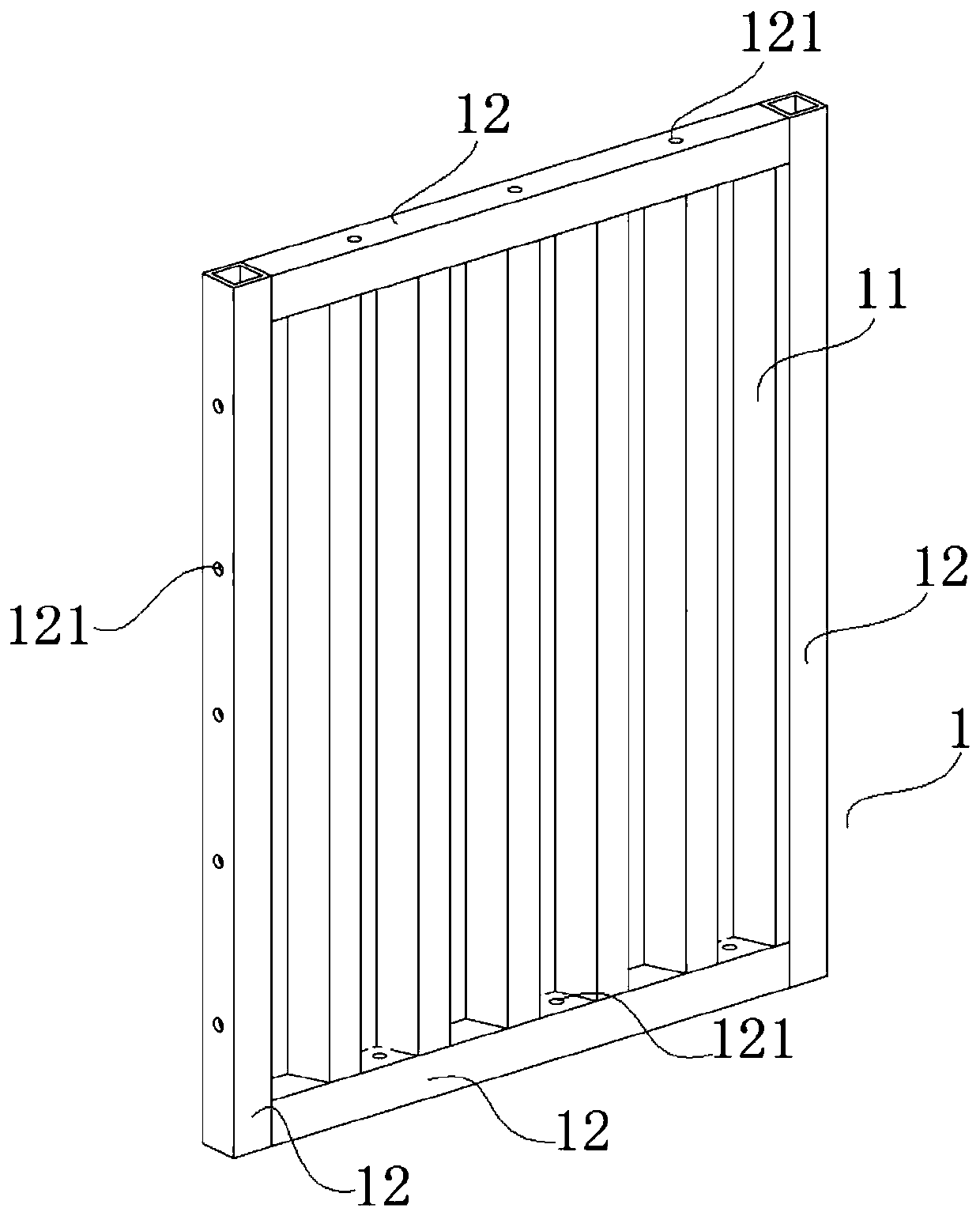

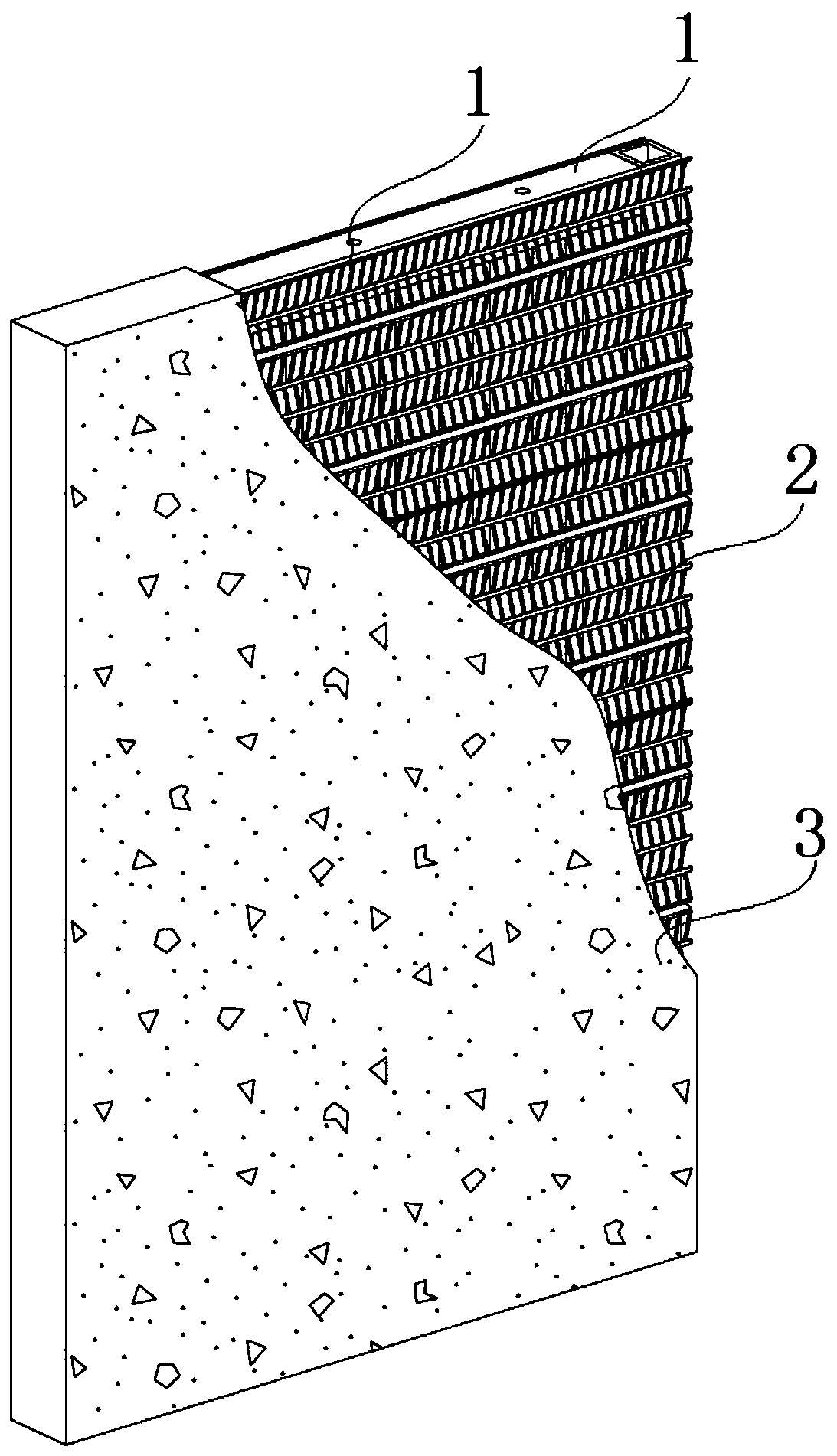

Fireproof composite wall for building protection

PendingCN110607853AReduce thicknessSmall thickness, can increase the use of small spaceWallsHeat proofingEarthquake resistancePre stress

The invention discloses a fireproof composite wall for building protection. The simple wall comprises a bearing wall (1); multiple prestress dispersion layers (2) are transversely bonded on the two sides of the bearing wall (1) end to end; sandwich layer fillers (3) are cast in two space formed by the prestress dispersion layers (2) and the bearing wall (1); the sandwich layer fillers (3), the prestress dispersion layers (2) and the bearing wall (1) are integrally injected to form a simple wall main body. The simple wall is simple in structure and novel in design, improves the earthquake resistance of the overall wall structure, reduces the design strength and cost of wall components, meanwhile, greatly improves the shear resistance and the integrity, and has such advantages as excellent integrity, excellent earthquake resistance, higher bonding and anti-shearing capacity and excellent finished wall molding effect.

Owner:金国洪

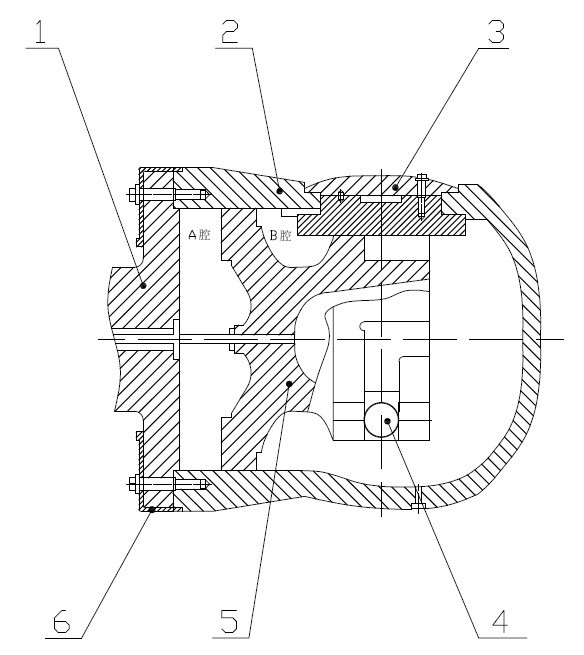

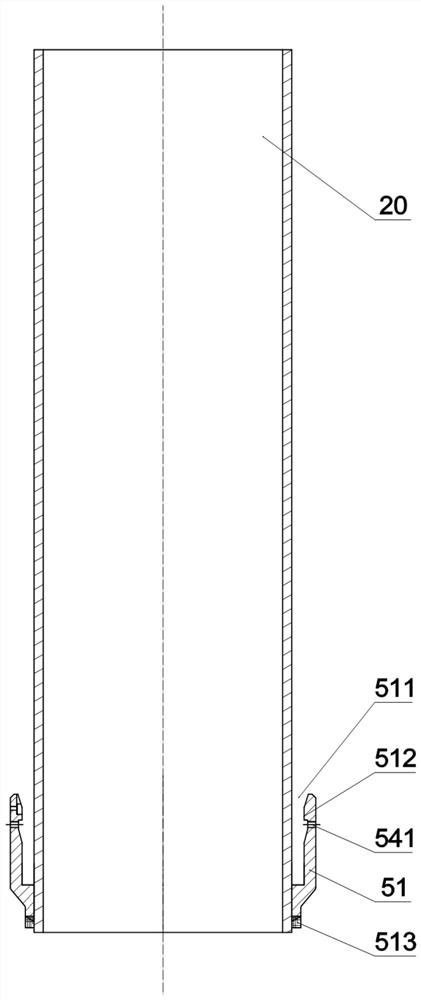

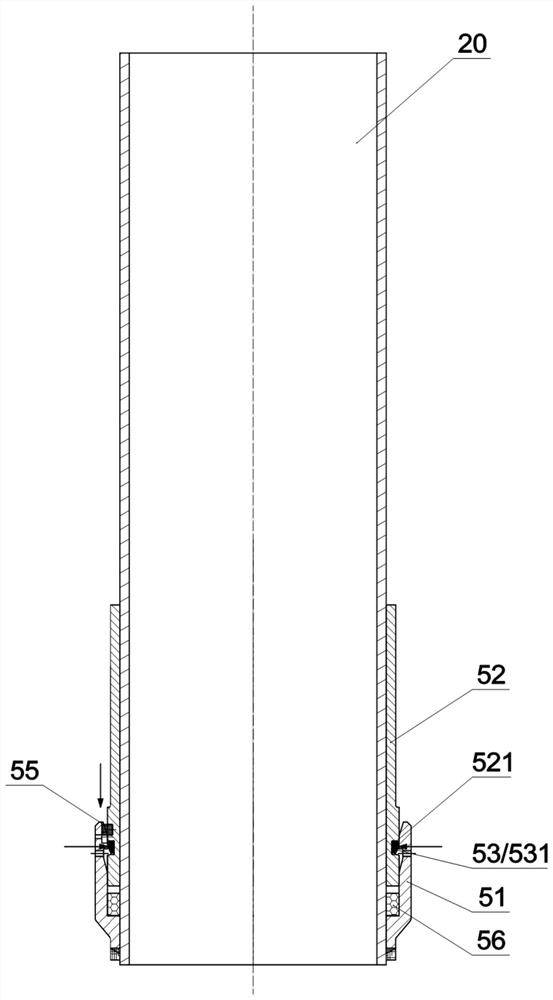

Ship propeller hub with front oil cylinder

The invention discloses a ship propeller hub with a front oil cylinder. The ship propeller hub mainly comprises a hub body, a guide frame, a slide block, a paddle holder, a piston, an oil cylinder supporting baffle and a paddle shaft provided with a single oil tube, wherein the piston is positioned at the front end in the hub body; the hub body is connected with the paddle shaft by bolts; the hub body and a front-end oil cylinder are integrated into a whole; the piston is installed at the end part of the guide frame in the hub by bolts; the front end of the piston, the inner wall of the hub body and the end part of the paddle shaft form a front chamber; the rear end of the piston, the inner wall of the hub body and the oil cylinder supporting baffle form a rear chamber; the rear end of the oil cylinder supporting baffle and the hub body form a lubricating oil chamber; the disk root of the paddle holder is provided with a crank pin; the slide block is sheathed on the crank pin and is arranged in a chute in the middle of the guide frame; the slide block is movably connected with the crank pin and the chute; and the oil tube is communicated with the rear chamber and moves together with the guide frame when working. The ship propeller hub has the characteristics of compact structure, good reliability, good stability of system operation and the like.

Owner:HANGZHOU ADVANCE GEARBOX GRP

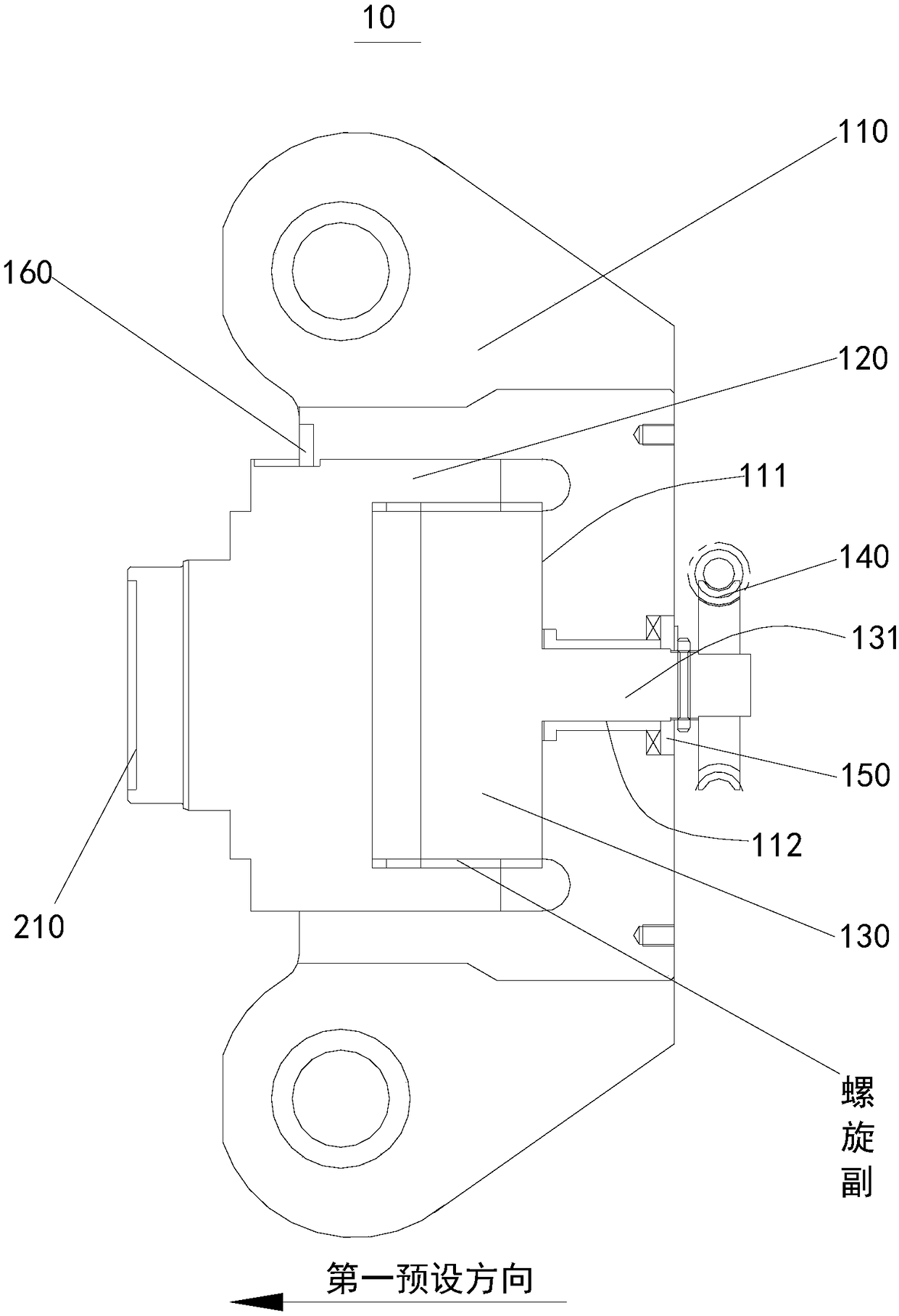

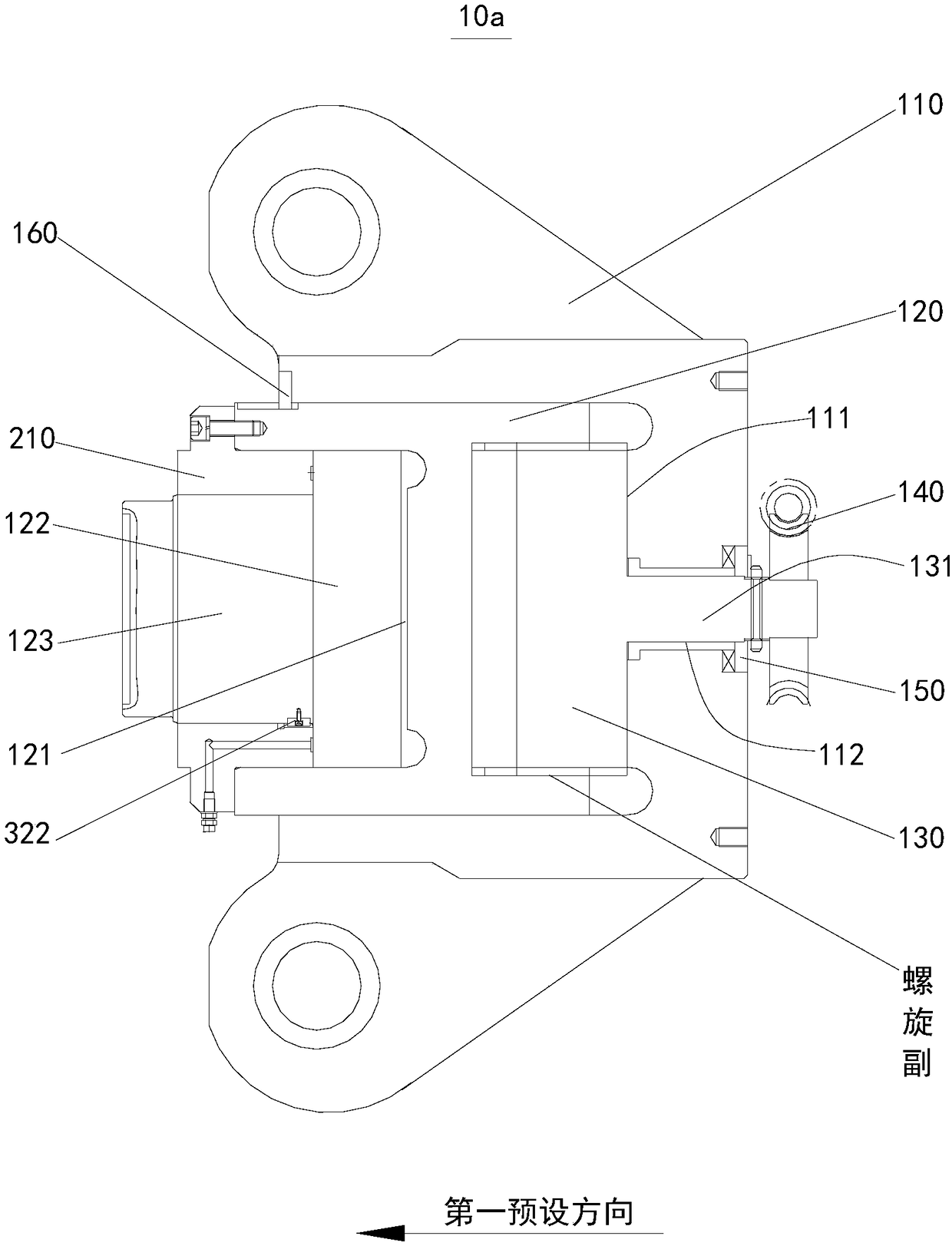

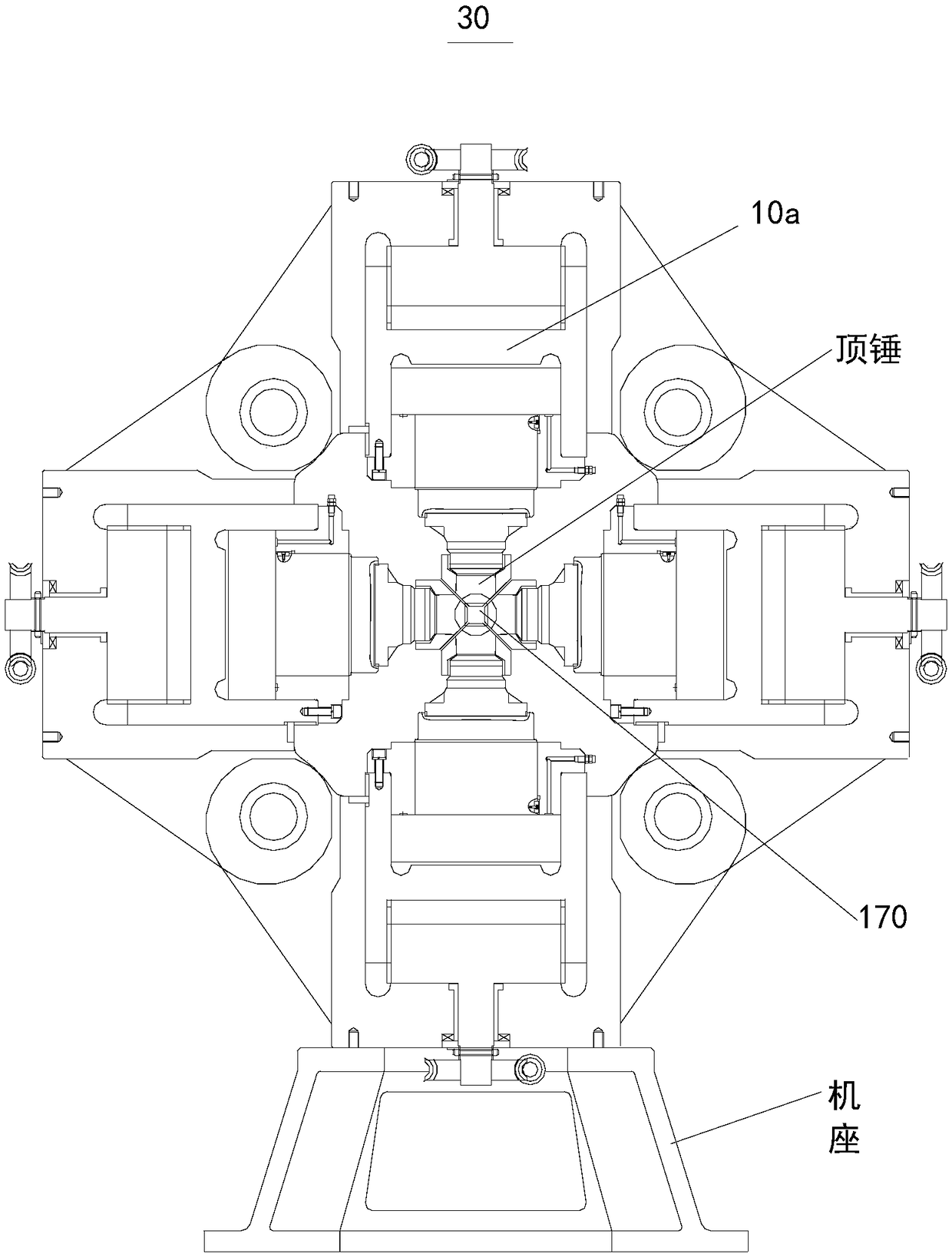

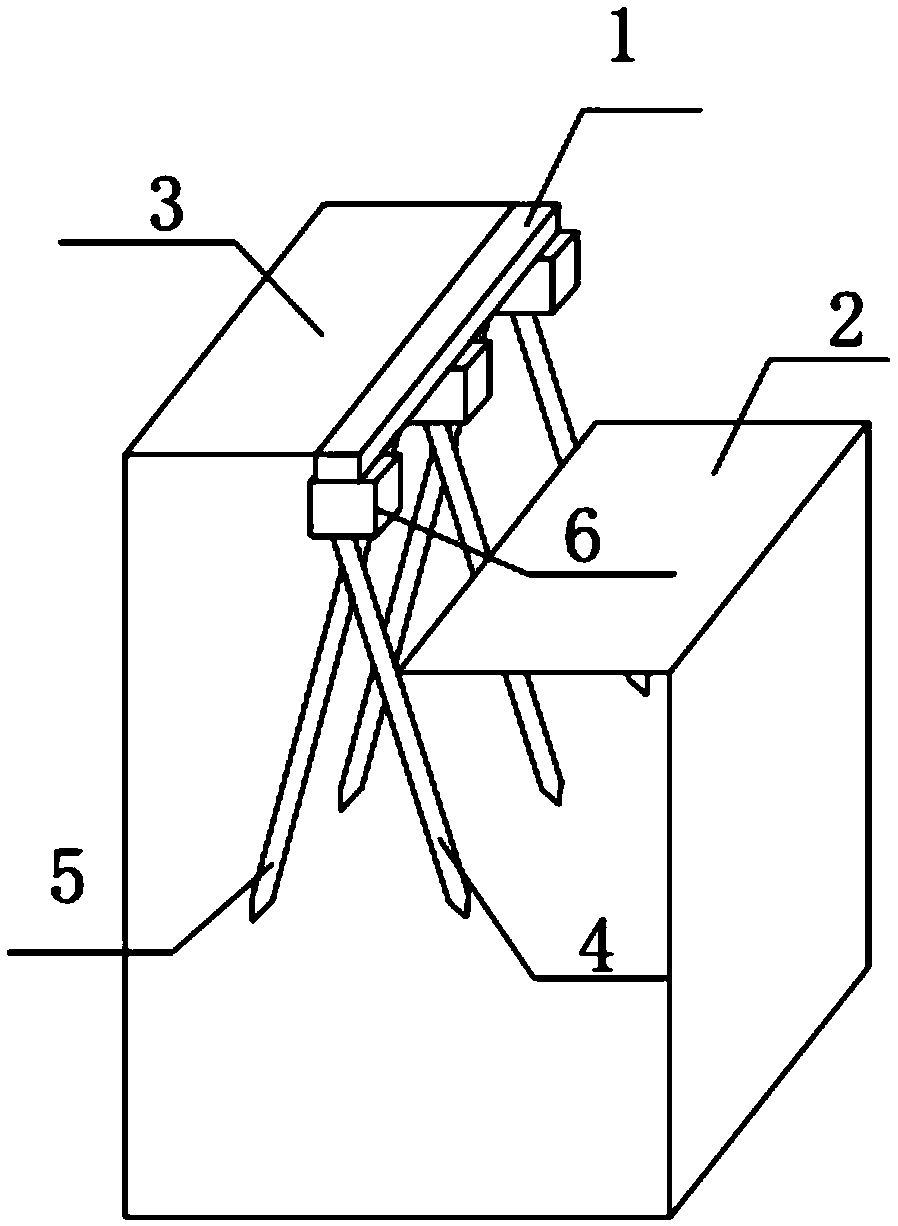

Hinge beam assembly and novel synthesis press

PendingCN108525610AHigh precisionImprove reliabilityUltra-high pressure processesReciprocating motionBearing capacity

The invention relates to the technical field of ultra-hard materials, in particular to a hinge beam assembly and a novel synthesis press. The hinge beam assembly comprises a body, a thrust column, a small-stroke ultrahigh-pressure oil cylinder, a threaded part and a driving device. The thrust column is slidably arranged on the body along a first preset direction, the small-stroke ultrahigh-pressure oil cylinder is arranged at the front end of the thrust column, transmission and bearing connection between the body and the thrust column is formed by the threaded part, and the driving device andthe threaded part are in transmission connection. The thrust column is driven to reciprocate along a first preset direction, the small-stroke ultrahigh-pressure oil cylinder generates ultrahigh-pressure thrust, and the thrust column transmits bearing force to the body. The novel synthesis press is formed on the basis of the hinge beam assembly.

Owner:河南天钻晶体材料有限公司

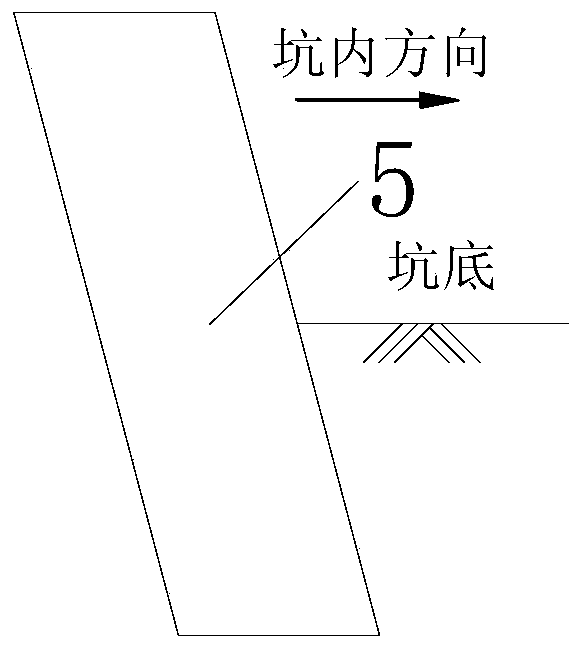

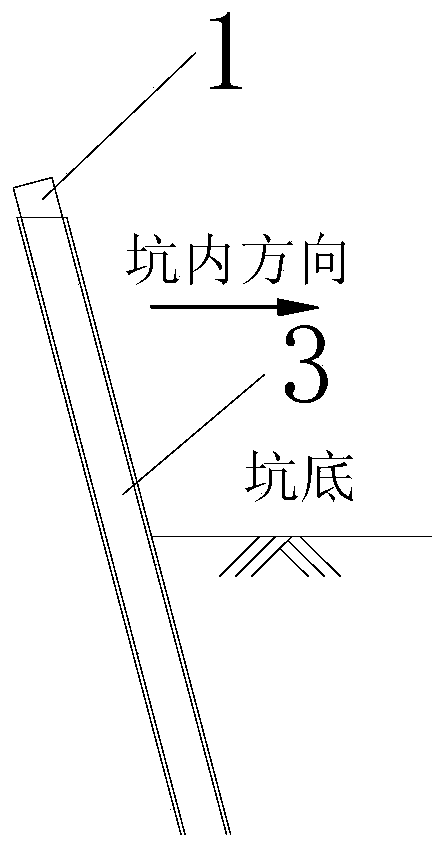

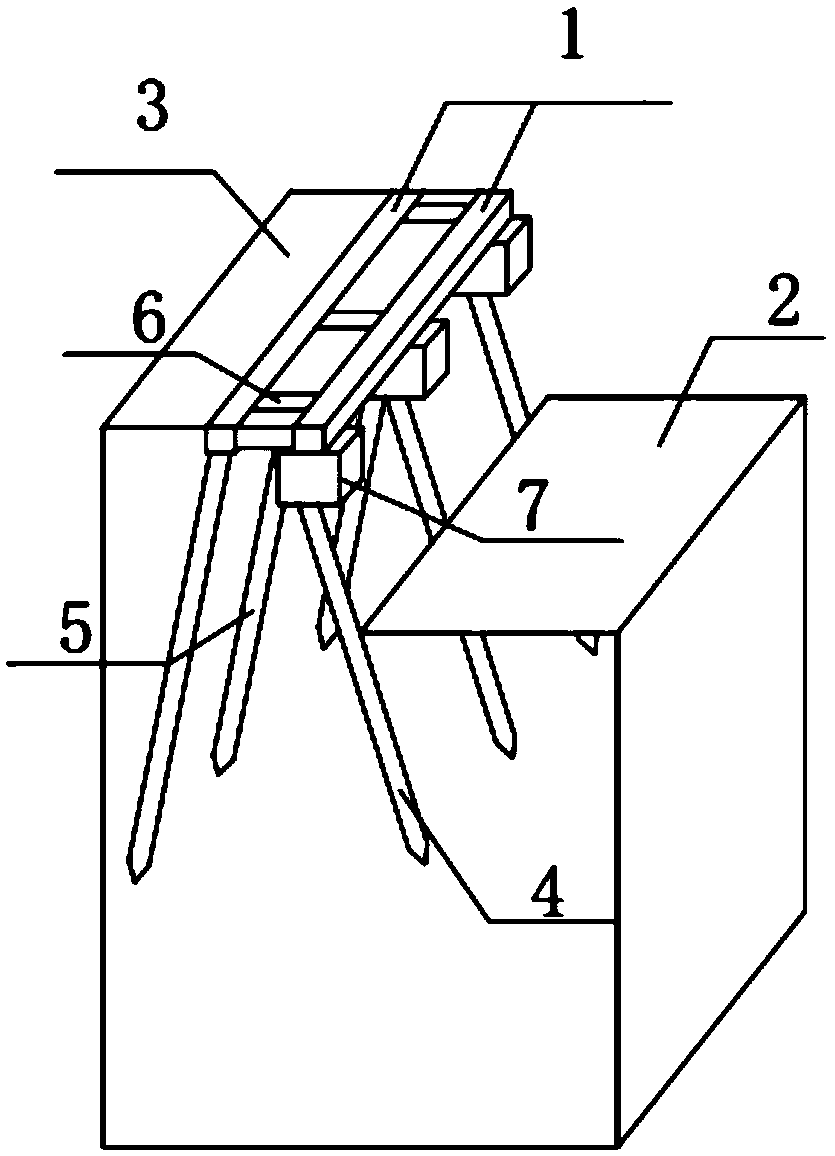

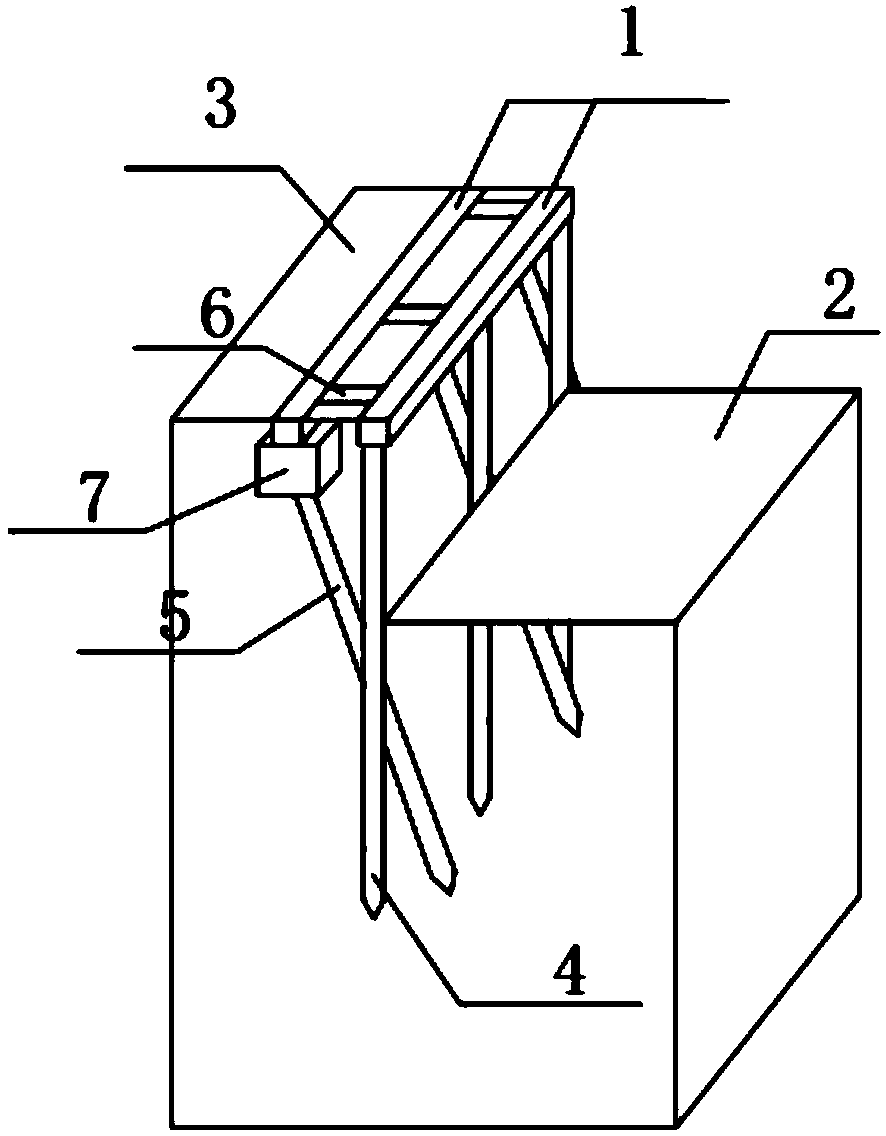

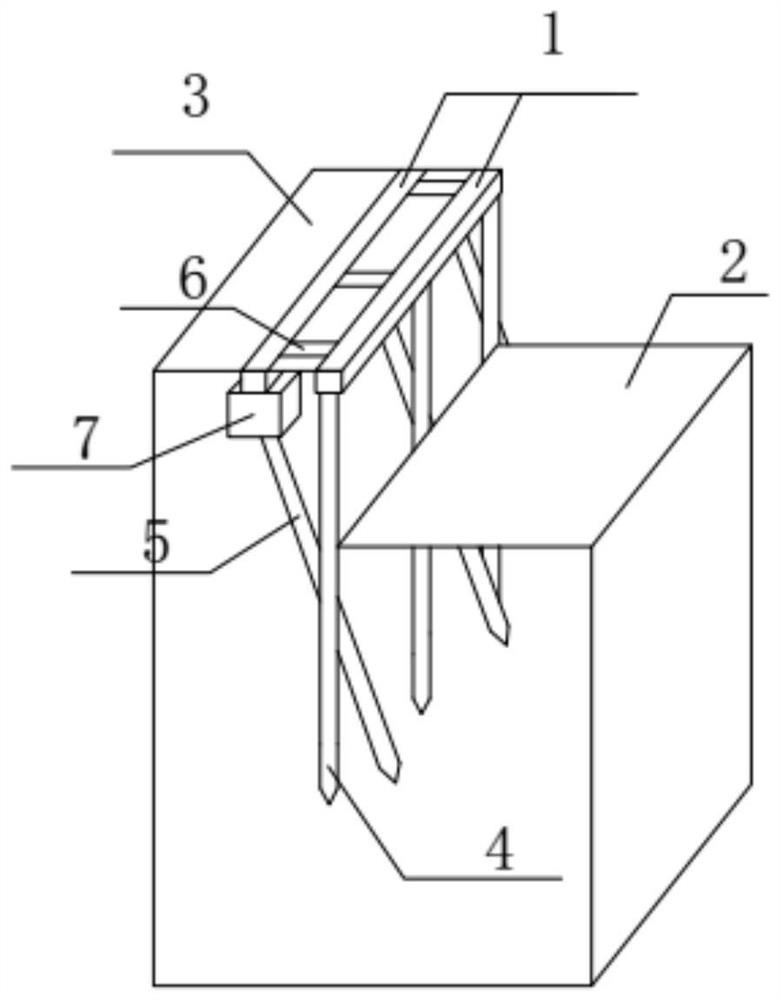

Supporting system and supporting method of slant cement soil mixing pile foundation pit

PendingCN110468850AReduce displacementReduce bending momentExcavationsBulkheads/pilesSupporting systemSoil mixing

The invention discloses a supporting system of a slant cement soil mixing pile foundation pit. The supporting system comprises a slant gravity wall, a cement soil supporting wall where structural steel or precast piles are slantly inserted, double rows of slant pile supports, double rows of pile supports and a gravity and slant supporting combined gravity wall, wherein one row of pile support is straight, and the other row of pile support is slant. In the slant gravity wall, vertical cement soil mixing piles are changed into cement soil mixing piles with certain angles. In the supporting wallwhere structural steel (or precast piles) is (or are) slantly inserted, the structural steel (or precast piles) is (or are) added into the slant cement soil mixing piles. In the double rows of slant pile supports or the double rows of pile supports, two rows of piles are connected through a crown beam. In the gravity and slant supporting combined gravity wall, the slant cement soil mixing piles are driven into one side of the slant gravity wall or the traditional vertical gravity wall to serve as supporting of the gravity wall. According to the supporting system, pile top displacement is reduced to a large degree, the pile body bending moment is reduced, the supporting engineering cost is reduced, the excavation depth is increased, and meanwhile the possibility that overturn damage happensto the foundation pit is reduced.

Owner:TIANJIN UNIV

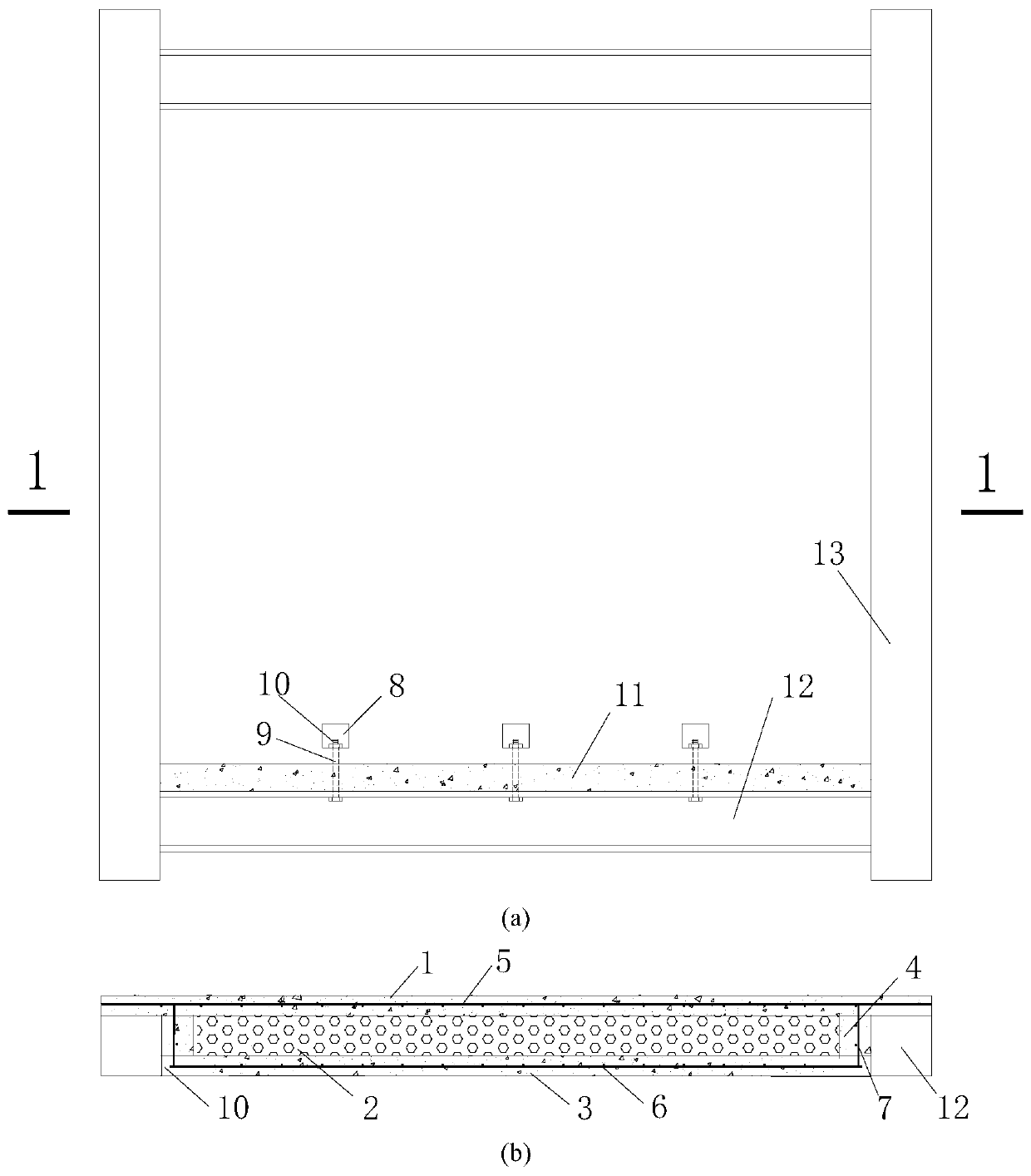

Overhead contact system mast foundation of railway steel and concrete composite beam and steel and concrete composite bridge

PendingCN108222051AImprove running qualityStable supportBridge structural detailsFoundation engineeringReinforced concreteEngineering

The invention discloses an overhead contact system mast foundation of a railway steel and concrete composite beam. The overhead contact system mast foundation comprises a bridge flange; the bridge flange is connected with main beams; the bridge flange comprises a reinforced concrete layer and supporting components; a mast is arranged above each supporting component; each supporting component is connected with the bottom part of the reinforced concrete layer; and the masts are connected with the bridge flange through a pre-embedded steel slab. The masts can be supported stably by adopting the structure of the overhead contact system mast foundation, thereby being conducive to guaranteeing perpendicularity and stability of the masts, and avoiding mast collapse and settlement; reinforcing steel bars in concrete of the bridge floor flange do not need to be added, so that design strength and construction difficulty are effectively lowered, forming quality is increased, construction cost isprevented from being increased greatly, installation positions of the masts are convenient to arrange, operating quality of an overhead contact system is increased, and the safety of railway electrictransmission lines is enhanced.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

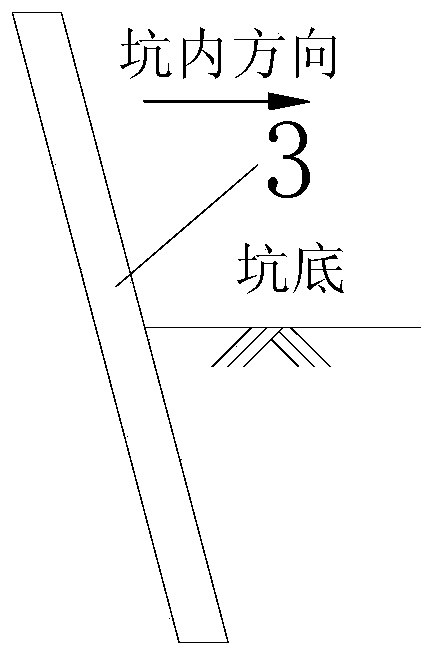

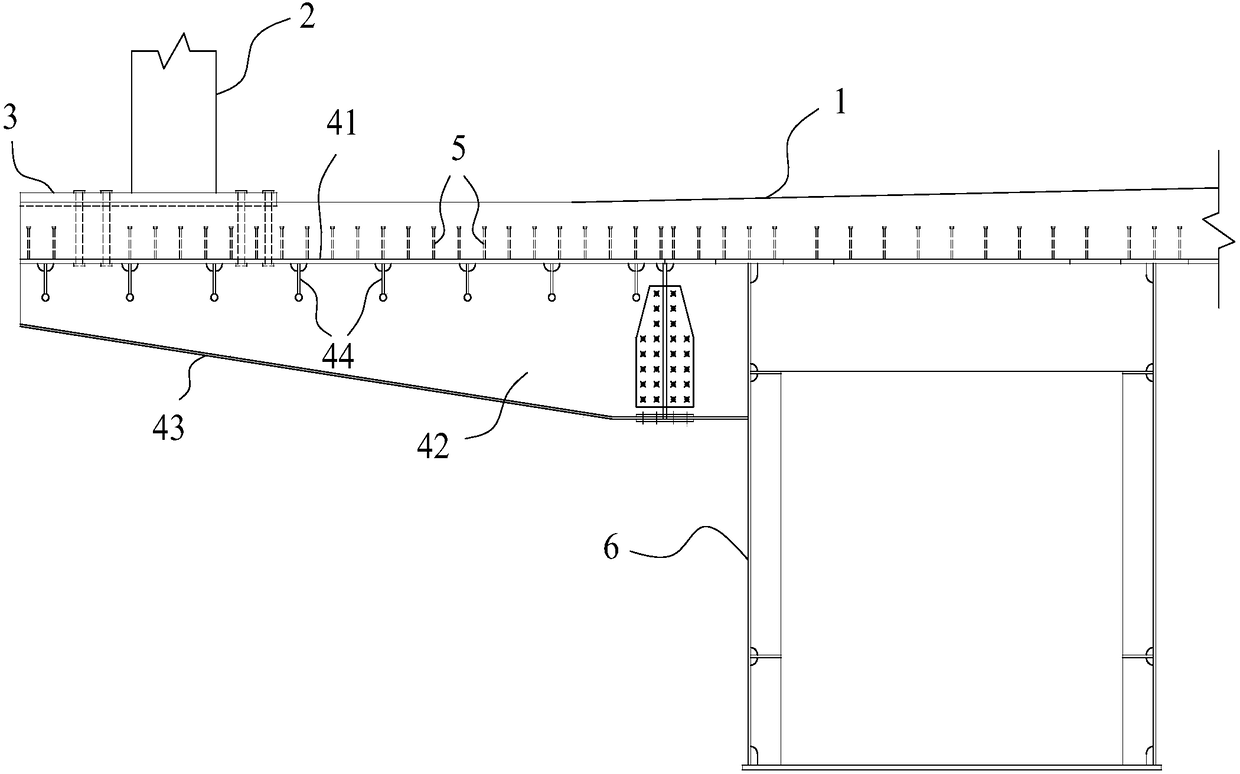

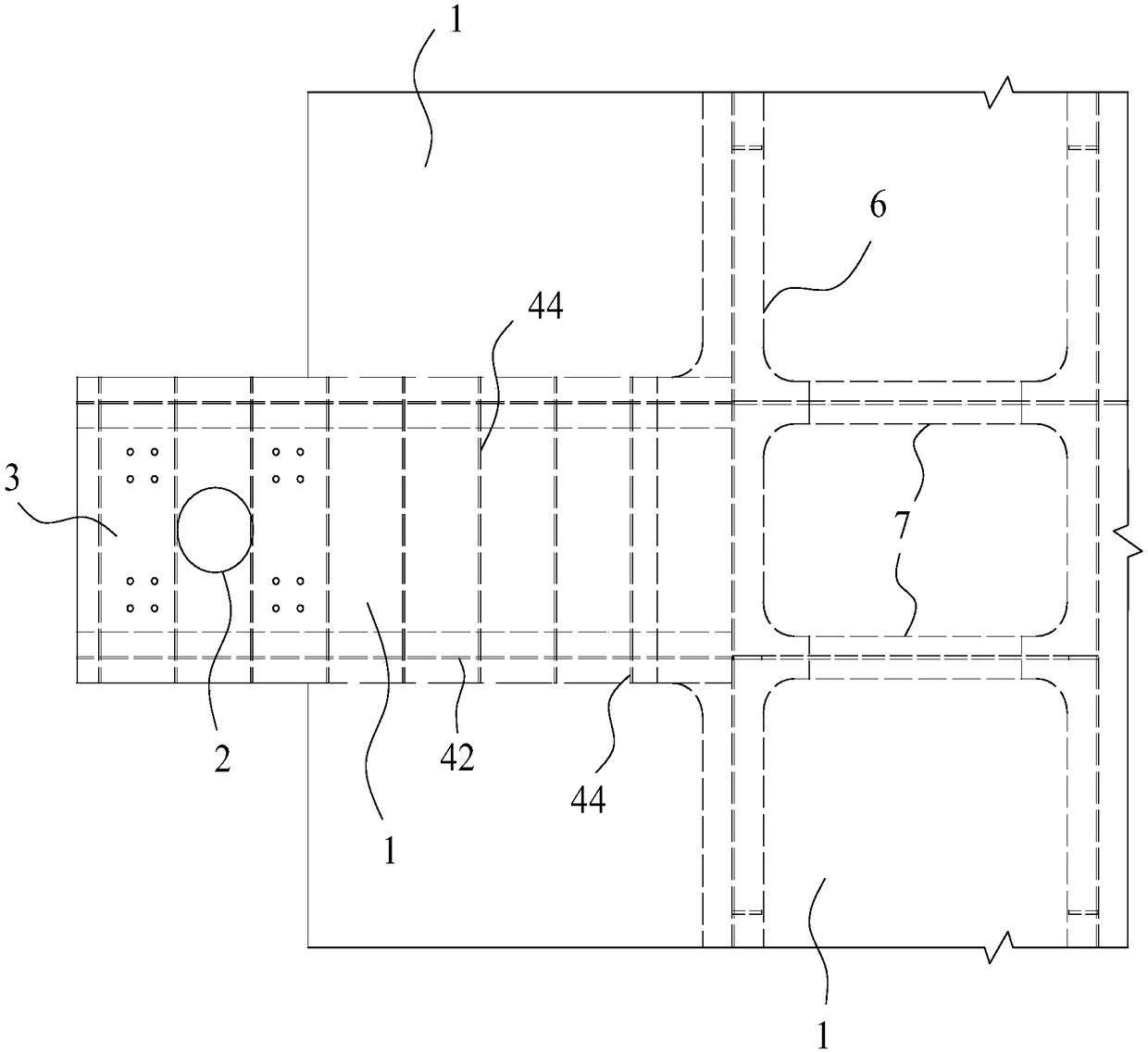

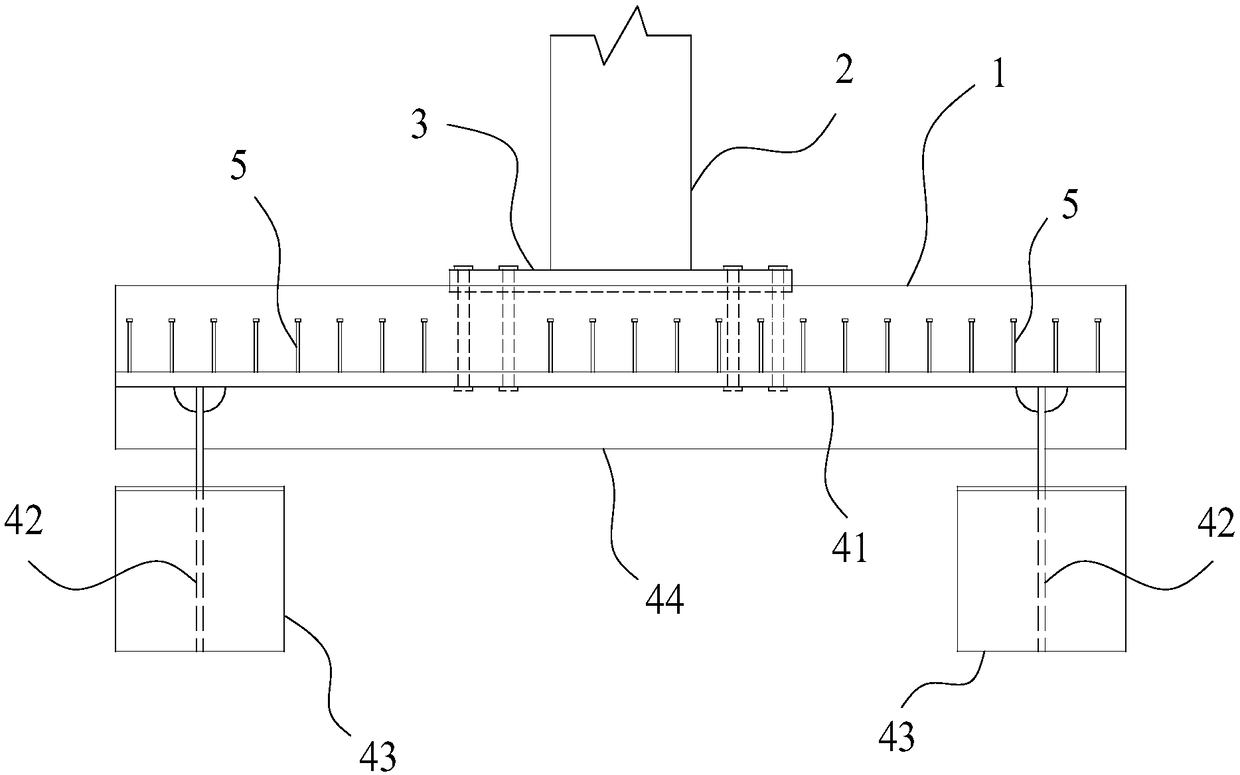

Active inclined dual pile row foundation pit supporting method

ActiveCN109440781AReduce distortionReduce bending momentExcavationsEngineeringStructural engineering

The invention discloses an active inclined dual pile row foundation pit supporting method. The method comprises the following steps that (1) front-row supporting piles inclined towards the interior ofa pit and back-row supporting piles inclined towards the outer portion of the pit are driven to the pile bottom design elevation along the inner side of a foundation pit edge, and meanwhile a waterproof curtain is arranged behind the back-row supporting piles; (2) a jack is arranged at the pile top of each front-row supporting pile; (3) crown beams are arranged on the front-row supporting piles and the back-row supporting piles, and the crown beams on the front-row supporting piles and the back-row supporting piles are connected into a whole through connecting beams; and (4) the soil definedby the front-row supporting piles is excavated to the pit bottom design elevation, and in the excavation process or before excavation, the jacks arranged in the step (2) are adopted for applying control expansion force to the front-row supporting piles so as to reduce displacement of the soil and the pile tops. By means of the method, the pile top displacement can be reduced to a large degree, thebending moment of pile bodies and the engineering cost can be reduced, the excavation depth can be increased, and the possibility of toppling damage happening to the foundation pit can be reduced.

Owner:TIANJIN UNIV

Active X-shaped double-row pile foundation pit supporting method

The invention discloses an active X-shaped double-row pile foundation pit supporting method. The active X-shaped double-row pile foundation pit supporting method comprises the following steps of (1) driving front-row vertical support piles to the pile bottom designed elevation along the inner side of the edge of a foundation pit, driving inclined rear-row support piles to the pile bottom designedelevation in the pit and meanwhile arranging a water isolation curtain behind the rear-row support piles; (2) arranging a jack on the pile top of each rear-row support pile; (3) arranging crown beamson the front-row vertical support piles and the rear-row support piles, and connecting the crown beams on the front-row vertical support piles and the rear-row support piles into a whole though connecting beams; and (4) excavating a soil body surrounded by the front-row vertical support piles and the rear-row support piles to the pit bottom designed elevation and applying control expansive force to the rear-row support piles through the jacks so as to reduce displacement of the soil body and the pile tops. Through the active X-shaped double-row pile foundation pit supporting method, the displacement of the pile tops can be reduced to a great extent, the bending moment of pile bodies can be reduced, the construction cost can be reduced, the excavation depth can be increased, and the possibility of collapse and damage to the foundation pit can be reduced.

Owner:TIANJIN UNIV

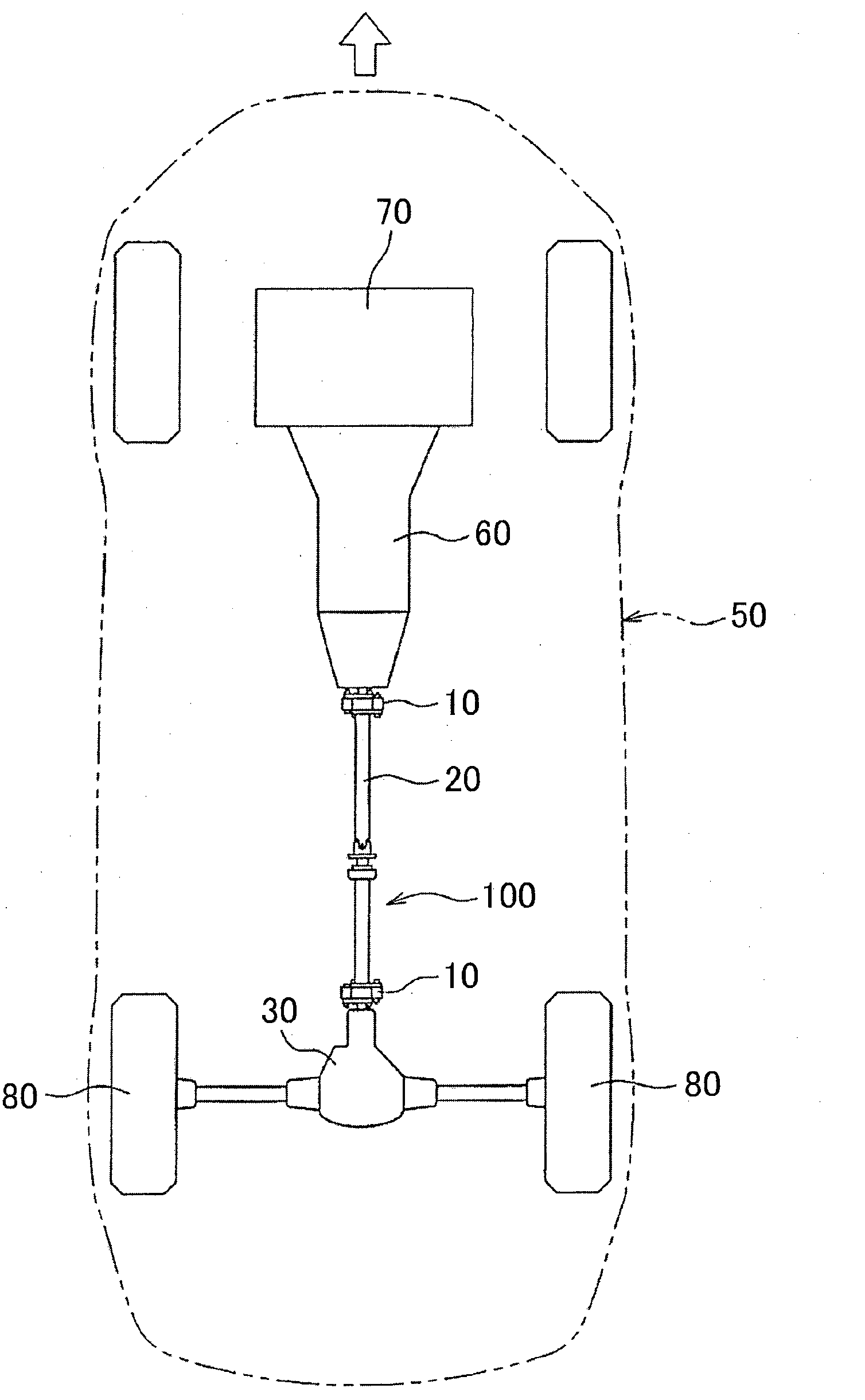

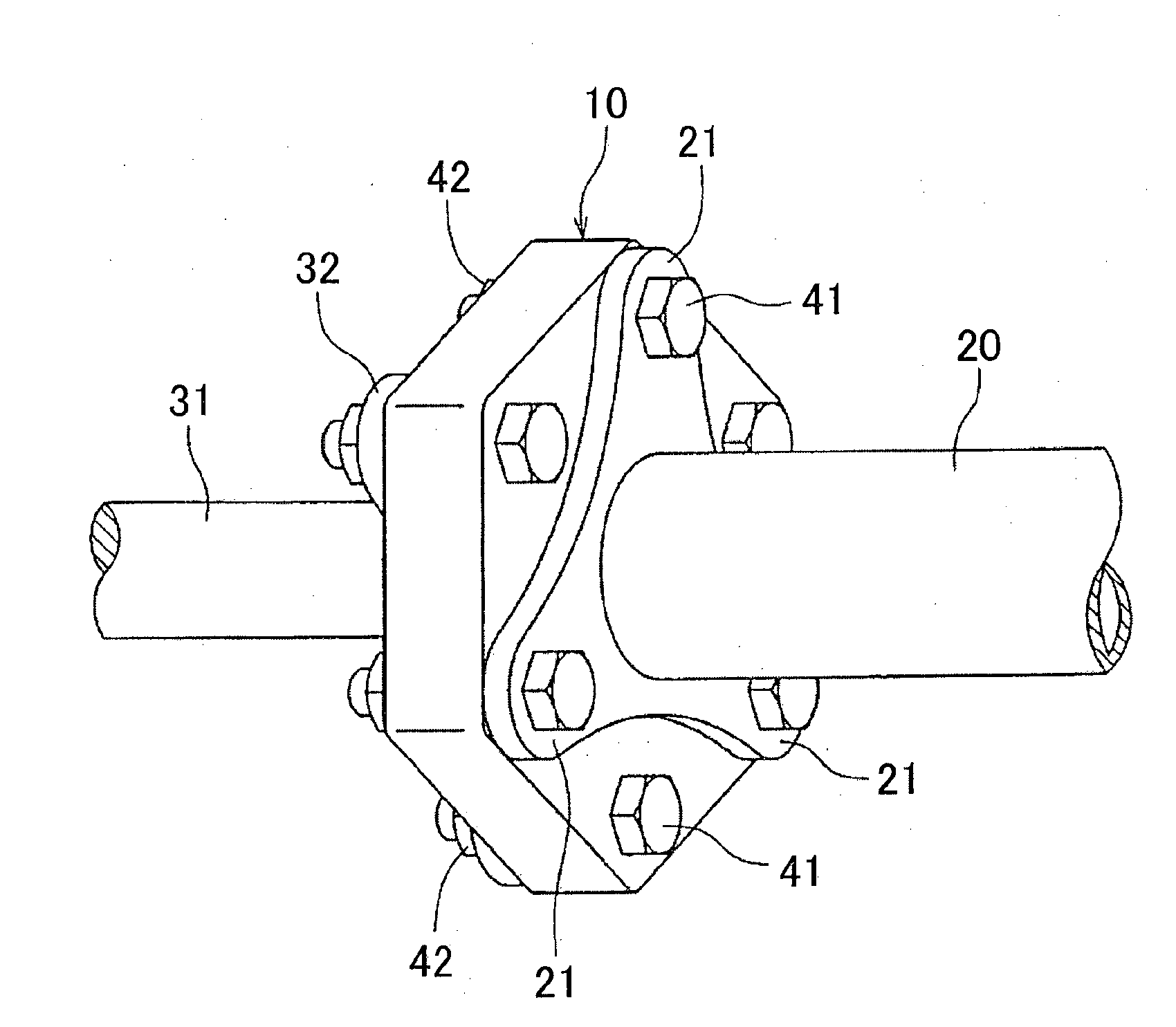

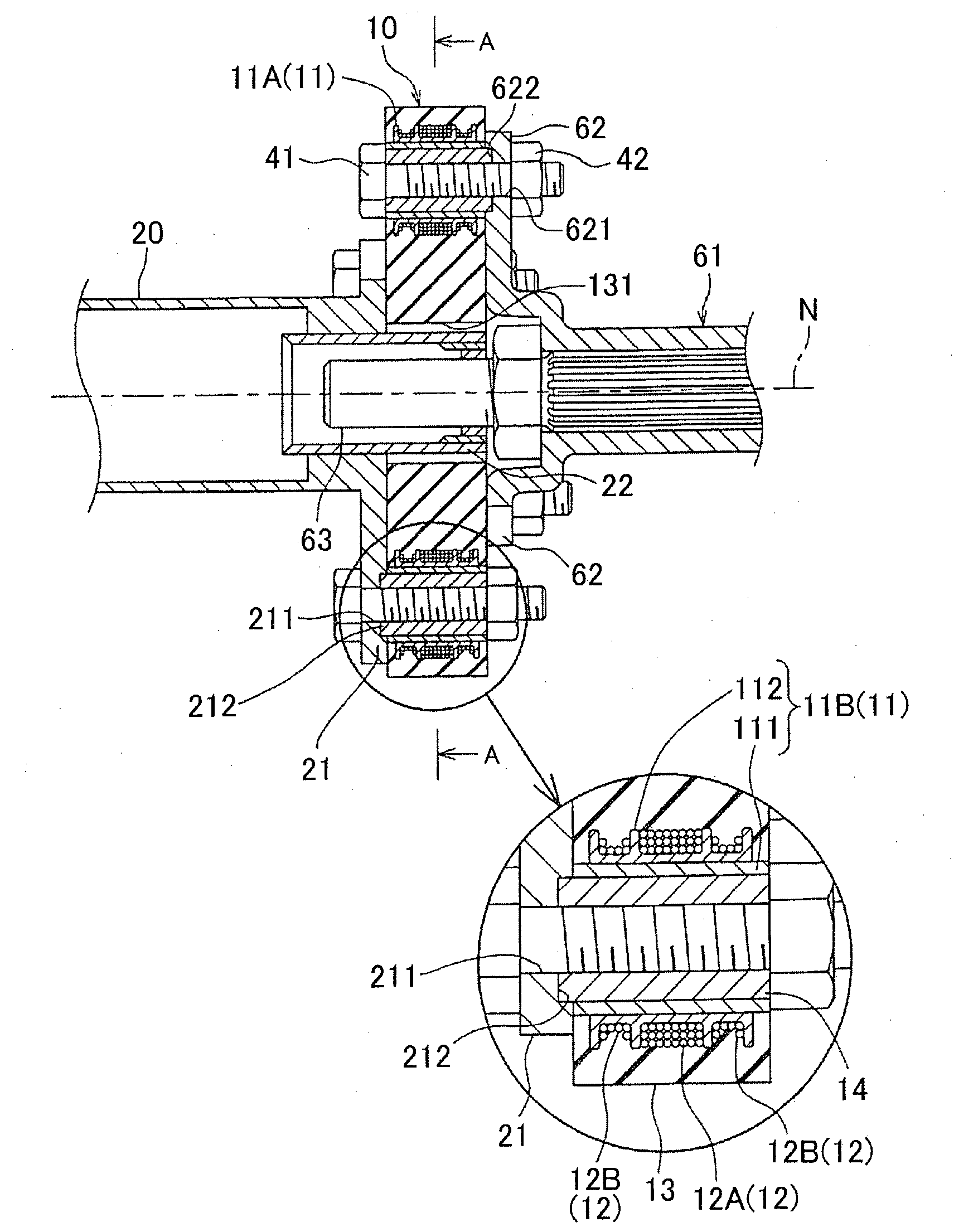

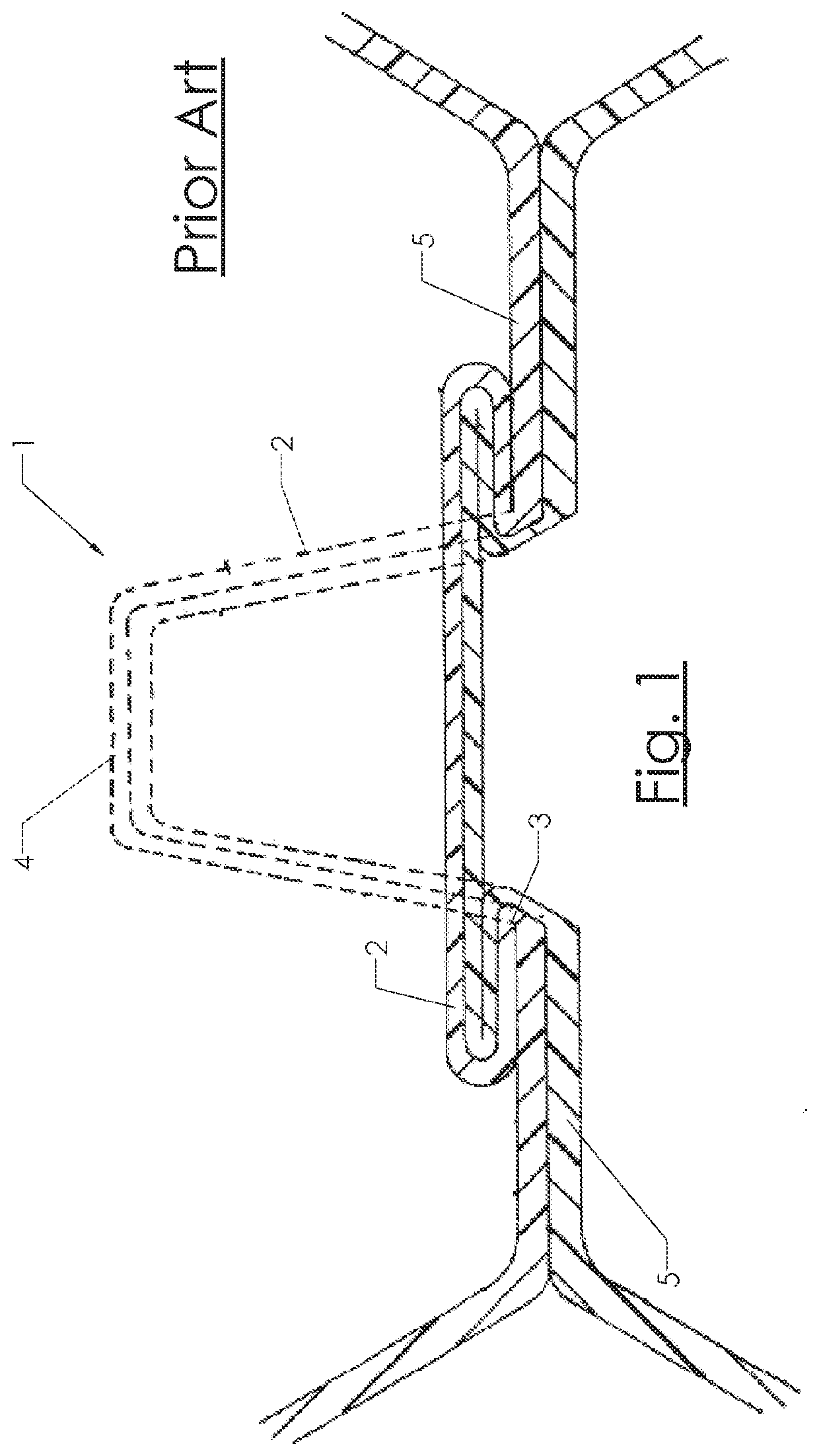

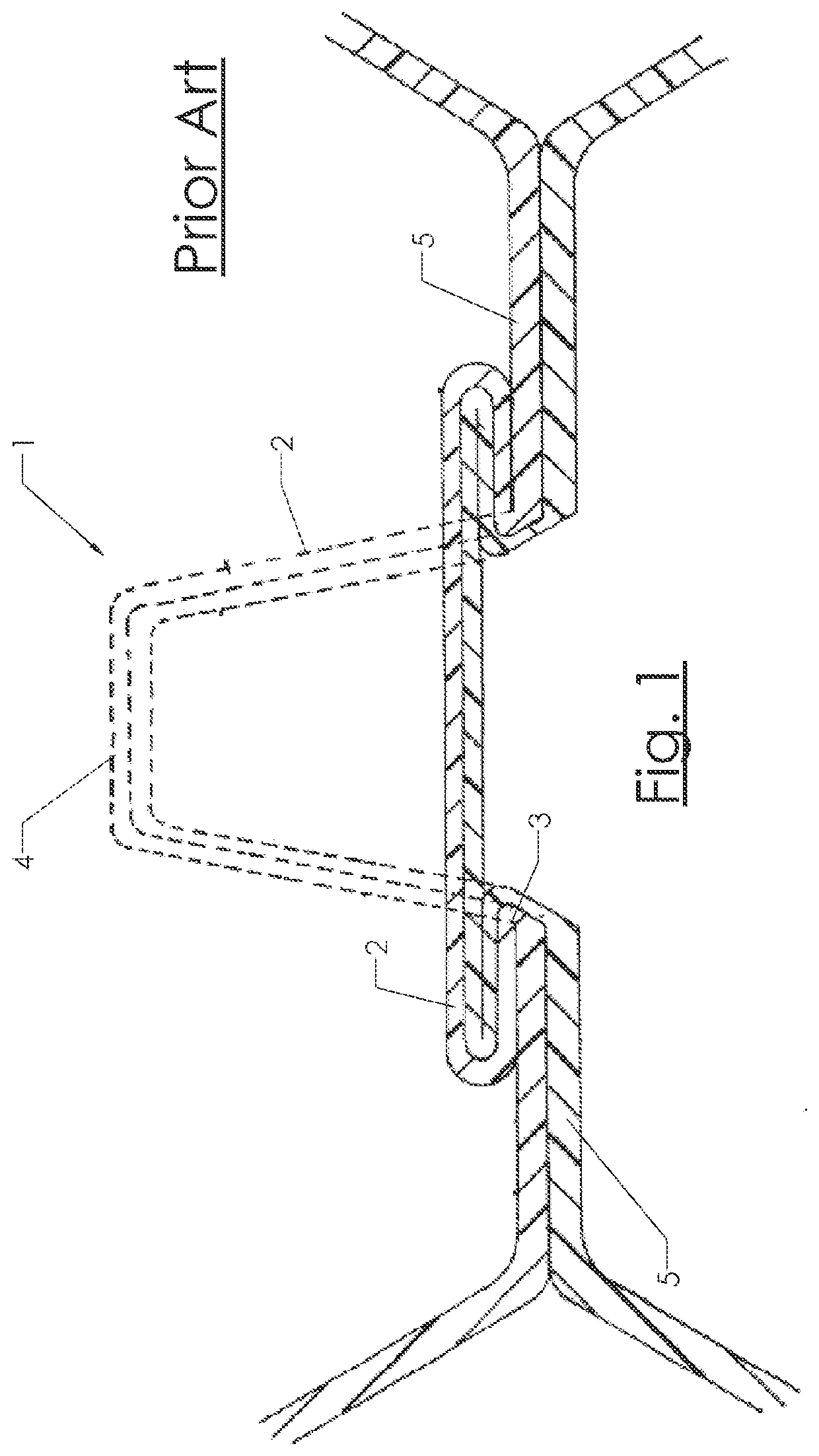

Flexible coupling and vehicle motive power transmission apparatus

A flexible coupling (10) includes: spool members (11) disposed equidistantly on a circumference; torque transmission lines (12) disposed around adjacent pairs of the spool members (11); and an annular elastic body (13) in which the spool members (11) and the torque transmission lines (12) are embedded. The torque transmission lines (12) consist of first torque transmission lines (12A), and second torque transmission lines (12B) whose total sum of cross-sectional area is a half of that of the first torque transmission lines (12A).; The flexible coupling (10) is constructed so that the first torque transmission lines (12A) transmit positive torque and the second torque transmission lines (12B) transmit negative torque, and is incorporated into a vehicle motive power transmission apparatus that has a hypoid gear whose mesh transmission error is greater during transmission of negative torque than during transmission of positive torque.

Owner:TOYOTA JIDOSHA KK

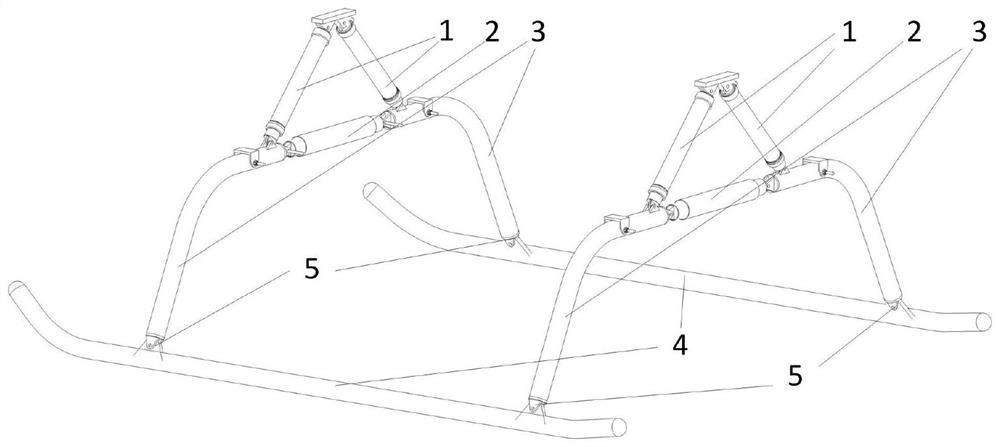

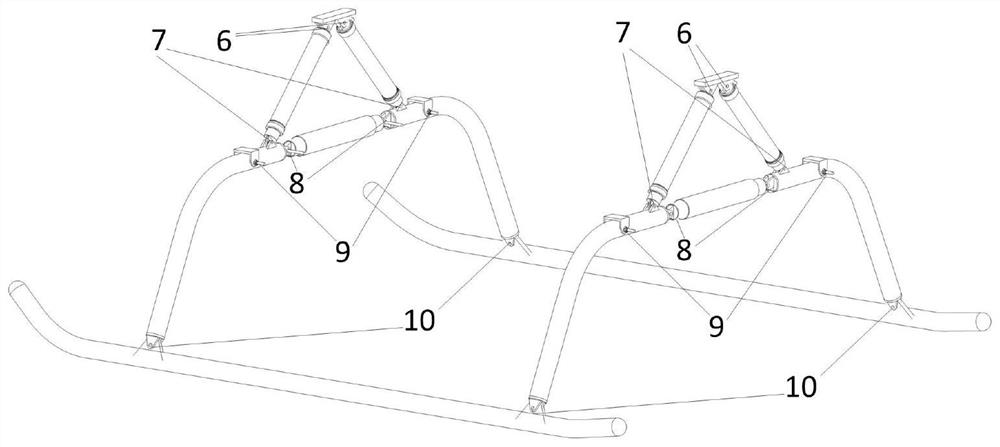

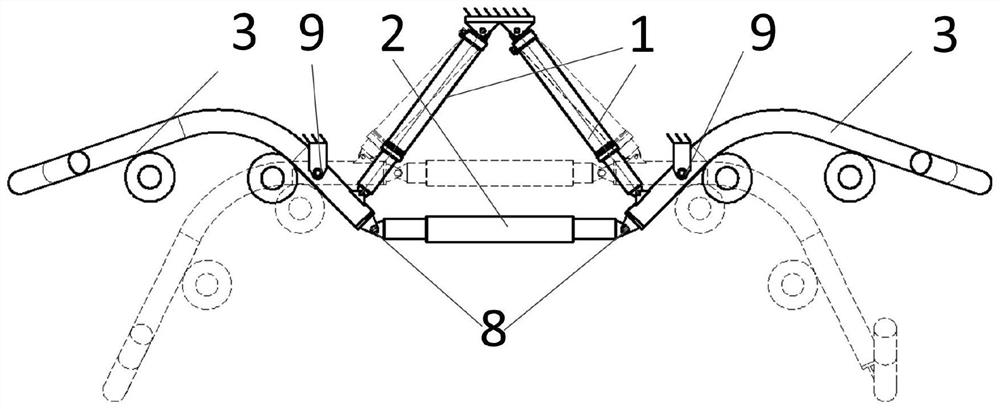

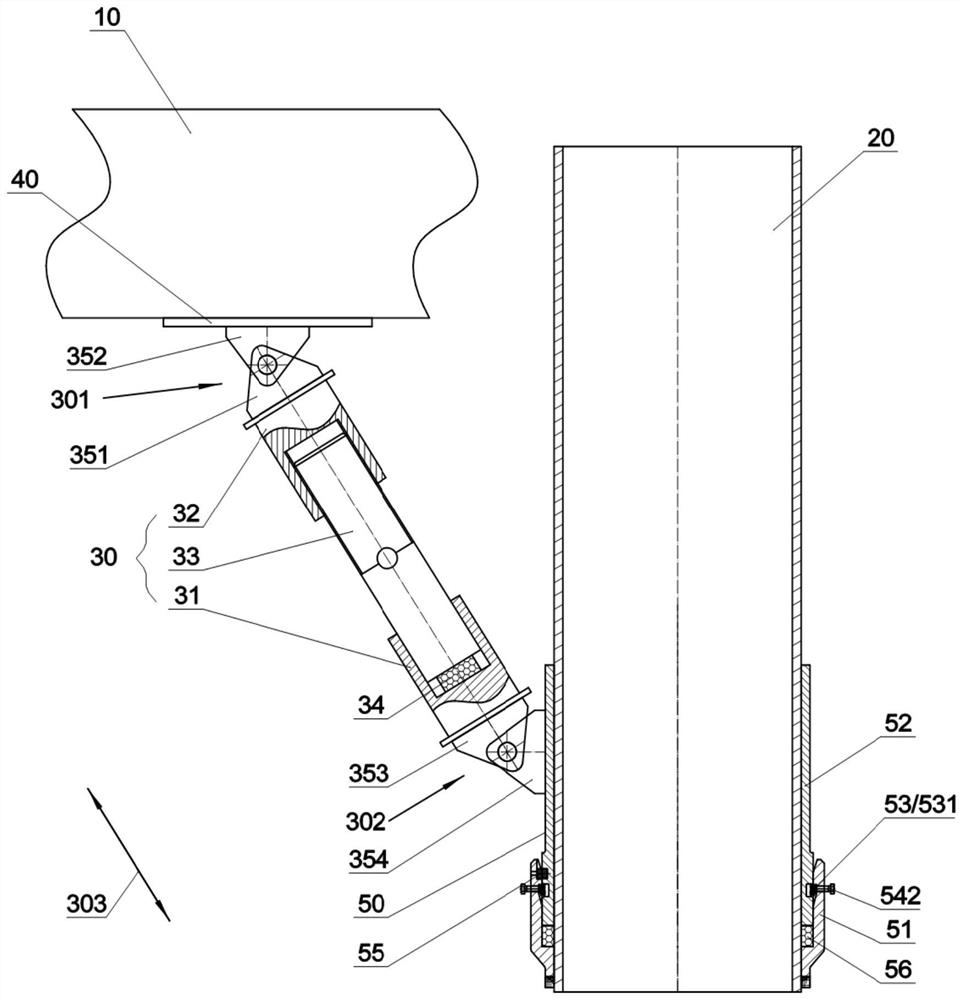

Adjustable skid undercarriage for unmanned helicopter

ActiveCN113386950AEliminate or mitigate distractionsSolve the problem of difficult landingSkis/runnersUndercarriagesControl theoryDynamic energy

The invention discloses an adjustable skid undercarriage for an unmanned helicopter. The adjustable skid undercarriage comprises a high-damping telescopic actuating rod, a bidirectional equal-rigidity tension-compression type buffer, a split bow beam and a variable-length skid; wherein the top ends of the two high-damping telescopic actuating rods in the same group are hinged to the unmanned helicopter body, and the bottom ends of the two high-damping telescopic actuating rods in the same group are hinged to the split bow beams on the two sides respectively. The two ends of the two-way equal-rigidity tension-compression type buffer are hinged between the split type bow beams on the two sides; the two-way equal-rigidity tension-compression type buffer and the two high-damping telescopic actuating rods form a stable triangular mechanism; the split type bow beams are hinged to the unmanned helicopter body around the longitudinal axis of the unmanned helicopter, and the split type arch beam and the variable-length skid are connected through a connecting spherical hinge. The arched beam can be rotationally folded and unfolded along the longitudinal horizontal line of the helicopter, passive absorption impact kinetic energy of the undercarriage is reduced, the landing angle of the undercarriage is freely adjusted, so that the adaptability of the undercarriage and task equipment such as a photoelectric pod is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

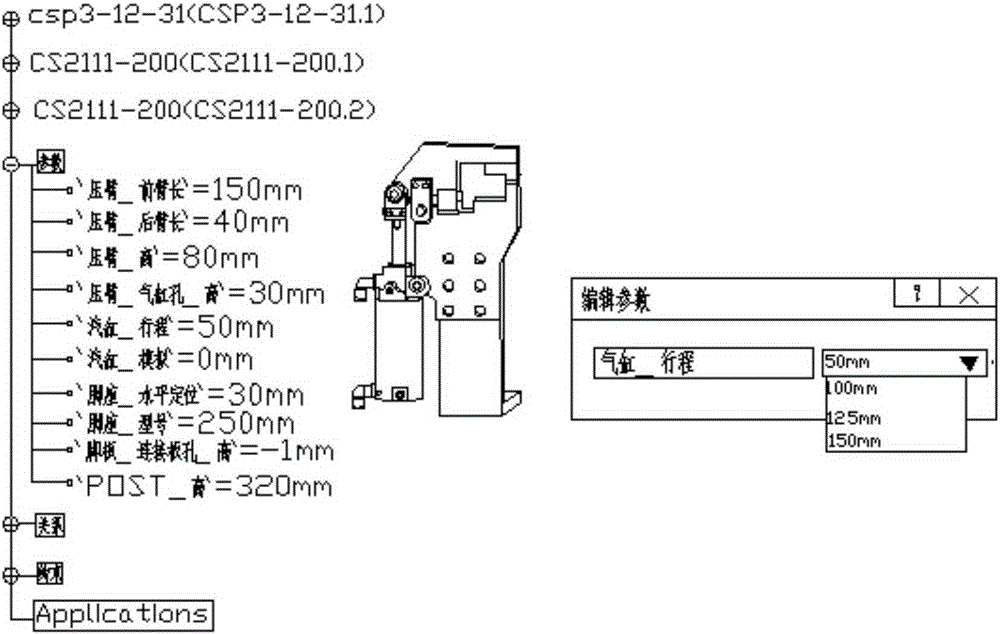

Automobile welding jig parametric design system

InactiveCN105302982AAchieve modularityLow technical requirementsSpecial data processing applicationsModularityEngineering

The invention discloses an automobile welding jig parametric design system. The system comprises a welding jig unit and a structure parameter designing system of the welding jig unit, wherein the structure of the welding jig unit is changed through the change of the parameters of the welding jig unit, the structure parameter designing system is arranged in the form of a tree diagram, the welding jig unit is divided into multiple modules, parameters form one module, and the structure parameter designing system works in the way of selecting the part, needing to be edited, of the welding jig unit and then directly editing parameters to change parameter values. By the adoption of the system, modularization of the jig unit is achieved, so that design strength is reduced, setting time is shortened, design efficiency is improved, support is provided for designing better welding jigs with higher level, manufacturing quality, accuracy and profitability are further improved, and the technical requirement for employees is reduced.

Owner:CHONGQING IND POLYTECHNIC COLLEGE

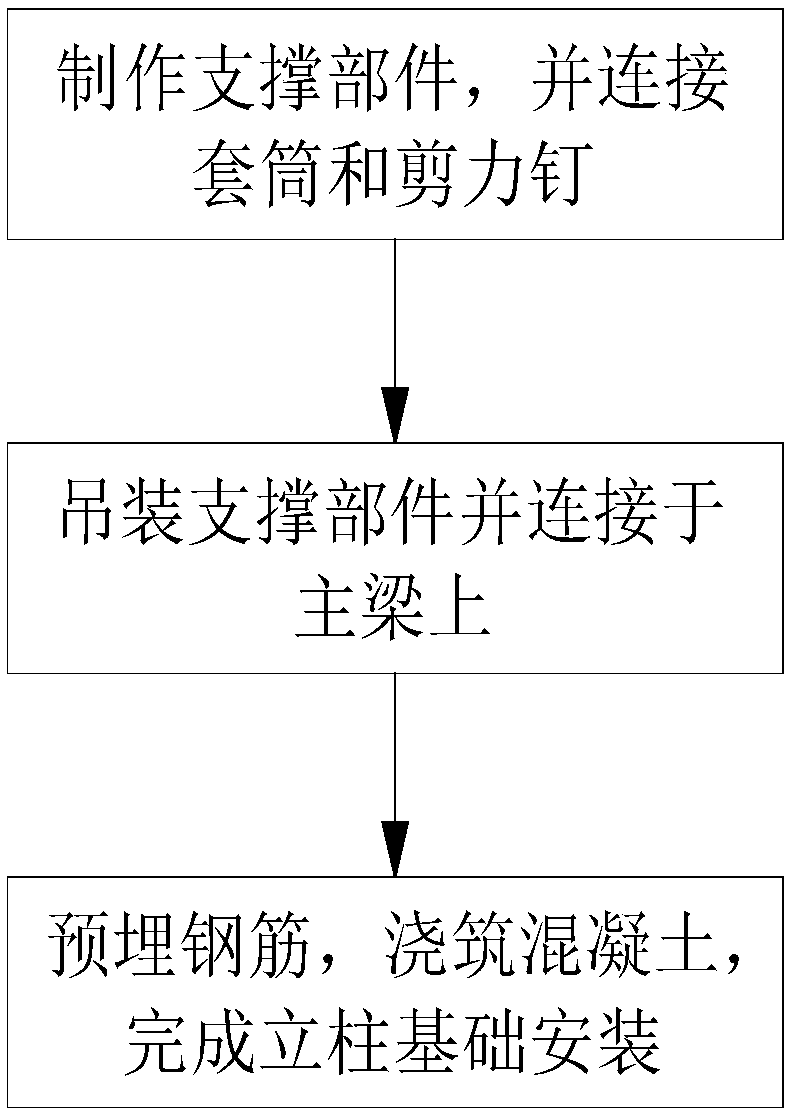

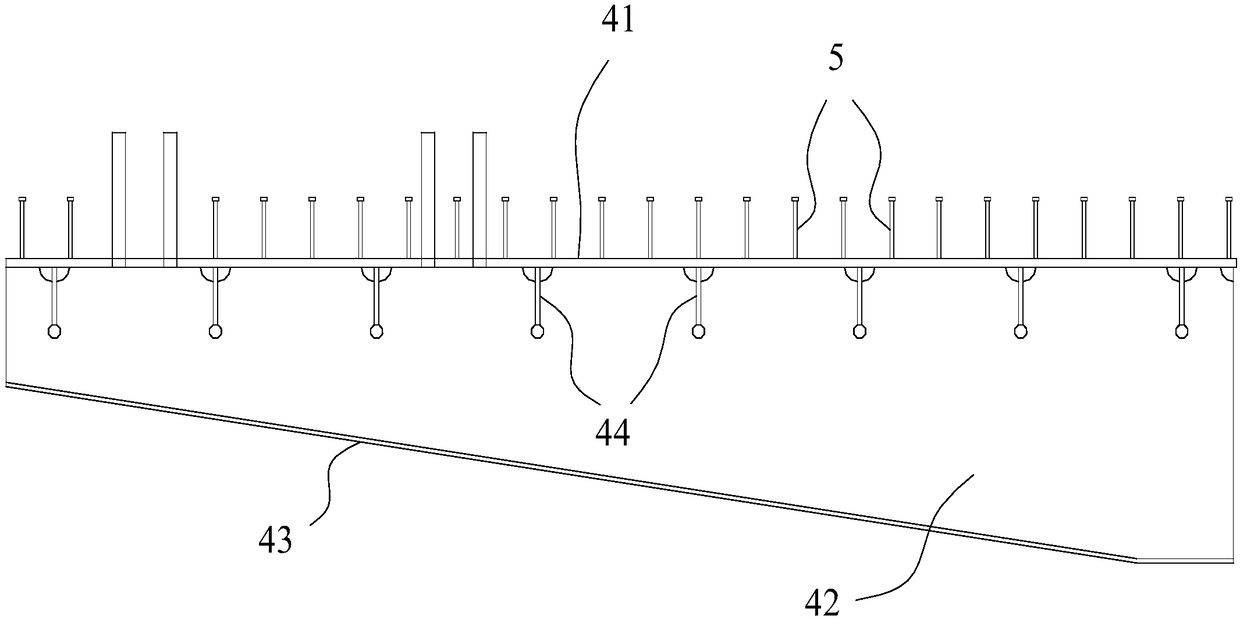

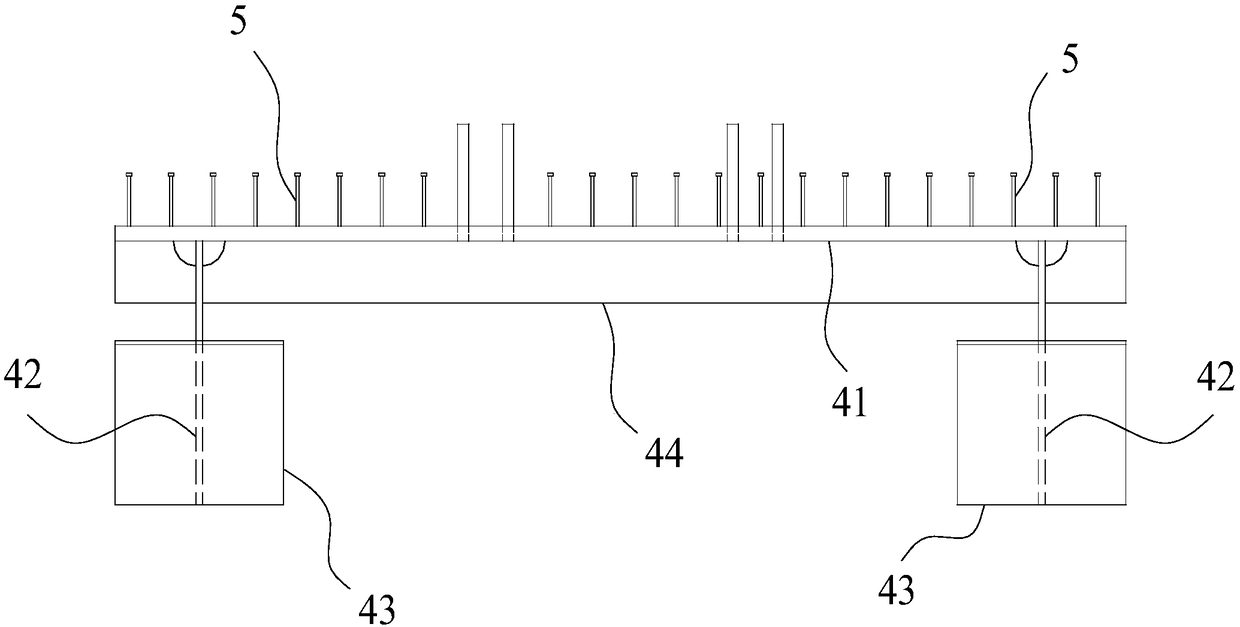

Installation method of column foundation of overhead contact system on railway steel-concrete composite girder

ActiveCN108487291AImprove pouring molding qualityImprove installation efficiency and qualityFoundation engineeringRebarPower transmission

The invention discloses an installation method of a column foundation of an overhead contact system on a railway steel-concrete composite girder. The installation method of the column foundation of the overhead contact system on the railway steel-concrete composite girder comprises the steps of assembling, lifting and installing supporting parts, then embedding reinforcing steel bars on the top parts of the all supporting parts and the top part of a main girder, pouring, and accomplishing the installation of the column foundation. By adopting the method, the column foundation of the overhead contact system can be conveniently constructed, the pouring forming quality of a concrete layer is effectively improved, temporary construction measures such as independently arranging a template are reduced, the installation efficiency and the quality of the column foundation are effectively improved, the construction period is shortened, the lifting and the installing of follow-up stand columns can be carried out conveniently, the perpendicularity and the stability of the stand columns are favorably ensured, the occurrence of the phenomena of rod collapse and sedimentation is avoided, reinforcing steel bars on flanges of a bridge floor have no need to be densified, the design strength and the construction difficulty are effectively reduced, materials are favorably saved, the increase of the construction cost of bridge engineering is avoided, installation positions of the stand columns can be planned conveniently, the operating quality of the contact system is improved, the economicalefficiency is improved, and the safety of a railway power transmission line is improved.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

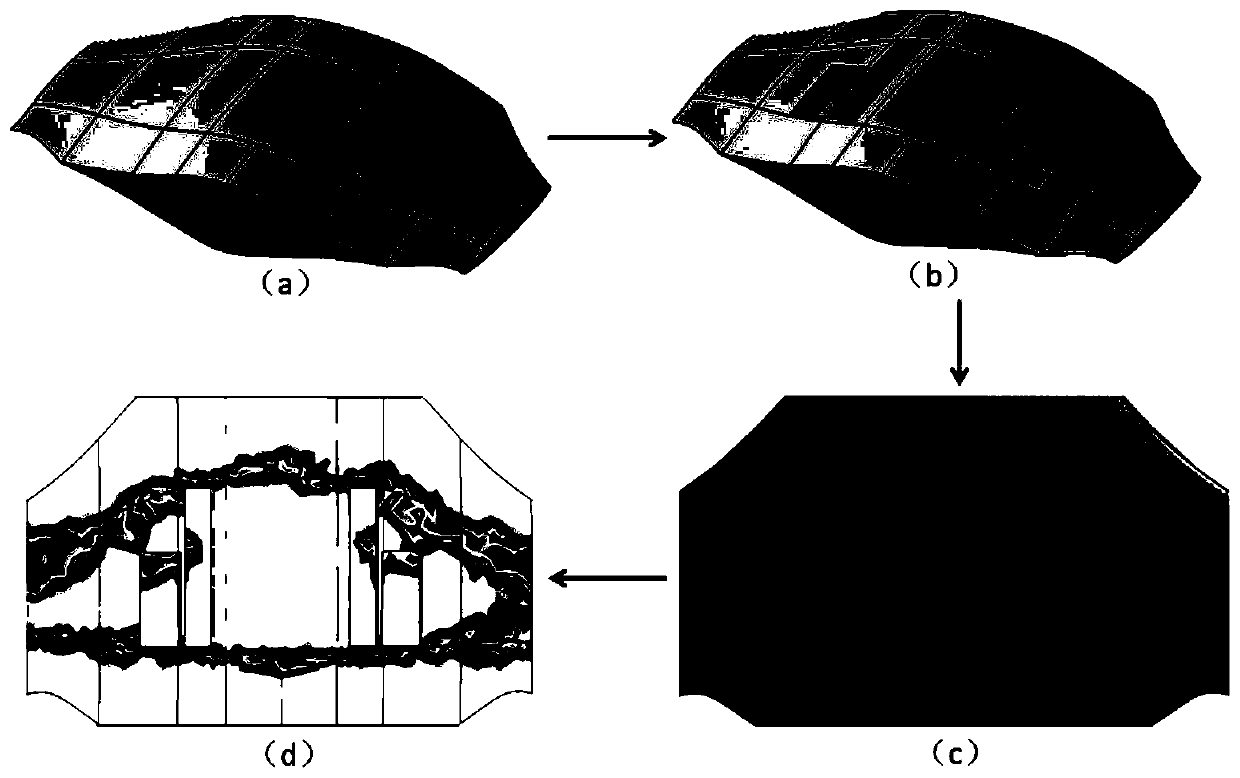

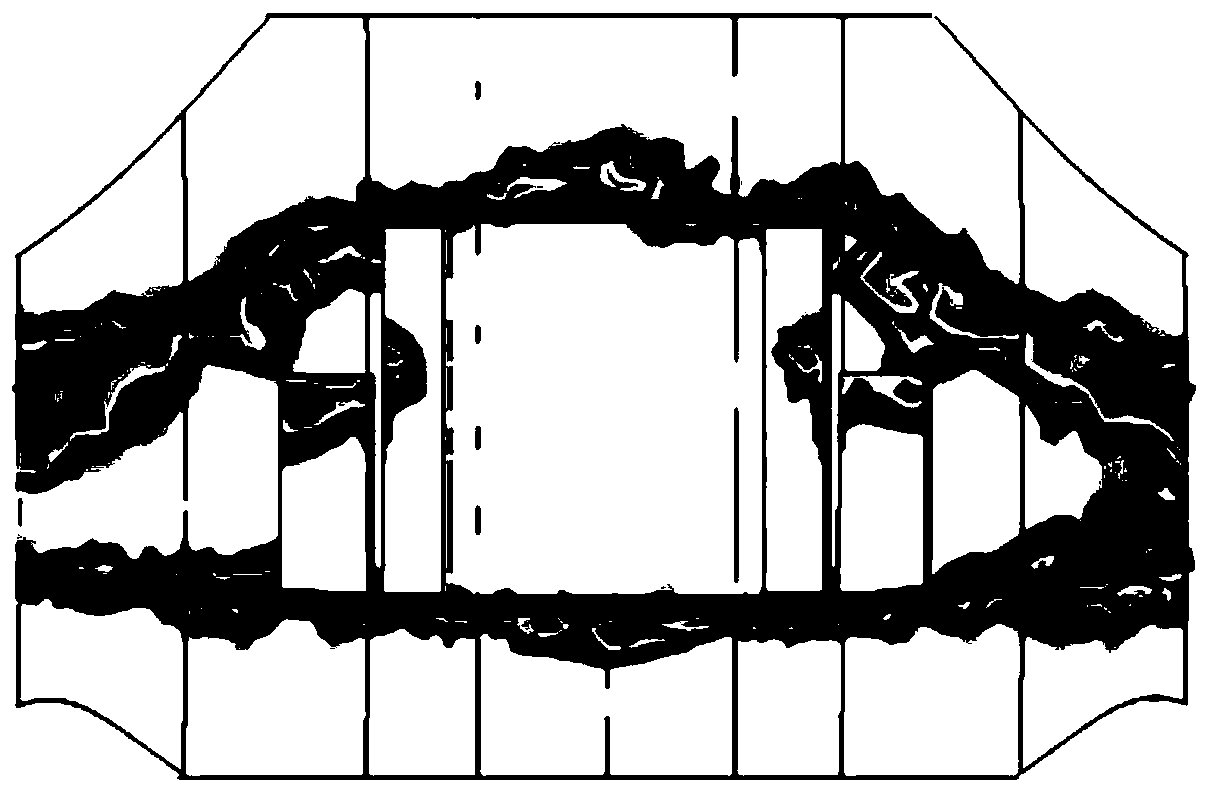

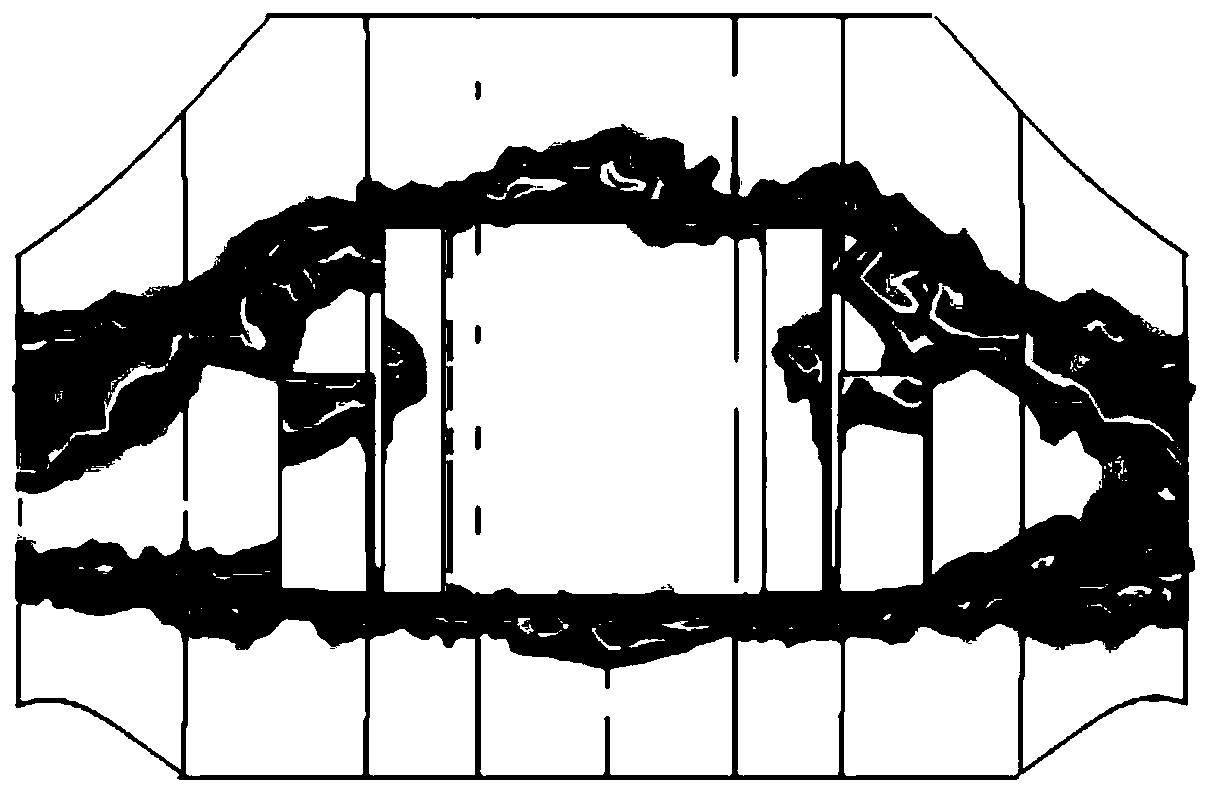

A method for determining the position of a main beam of a wing-body fusion body aircraft

ActiveCN109710988AReduced design structureReduced design strengthSustainable transportationSpecial data processing applicationsTopology optimizationEngineering

The invention belongs to the technical field of aircraft structure design, and particularly relates to a method for determining the position of a wing body fusion body aircraft main beam. The method comprises the following steps: 1) making a necessary cabin body opening on the entity, such as an undercarriage cabin and an equipment cabin, and forming a wing body fusion area with an opening; 2) carrying out finite element entity modeling, setting a unified material attribute, setting a boundary condition, and applying a load; 3) performing topological optimization analysis, and setting the minimum structural weight as an optimization target to obtain an optimization analysis result; and (4) determining the positions of the front beam and the rear beam according to an optimization analysis result. Compared with the traditional structure design, the method has the advantages that the iteration process of the structure design and strength checking can be greatly reduced, the design periodis shortened, the design efficiency is improved, the cost is saved, and the determined position of the main beam is more accurate.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

Offshore oil production platform, and bearing capacity transfer method and transfer device of drilling platform

PendingCN111810063AIncrease ultimate bearing capacityReduce design costArtificial islandsDrilling rodsWell drillingOil production

The invention provides an offshore oil production platform, and a bearing capacity transfer method and transfer device of a drilling platform. The bearing capacity transfer device of a riser and the drilling platform comprises a connecting rod body, a drilling platform connecting plate and a riser connecting structure, wherein the connecting rod body can transfer vertical load; the drilling platform connecting plate is connected to the first end of the connecting rod body and can be fixedly connected to the drilling platform; and the riser connecting structure is connected to the second end ofthe connecting rod body and can be fixedly connected to the riser. Through the offshore oil production platform, the ultimate bearing capacity of the drilling platform is increased, and safety guarantee is provided for subsequent development.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

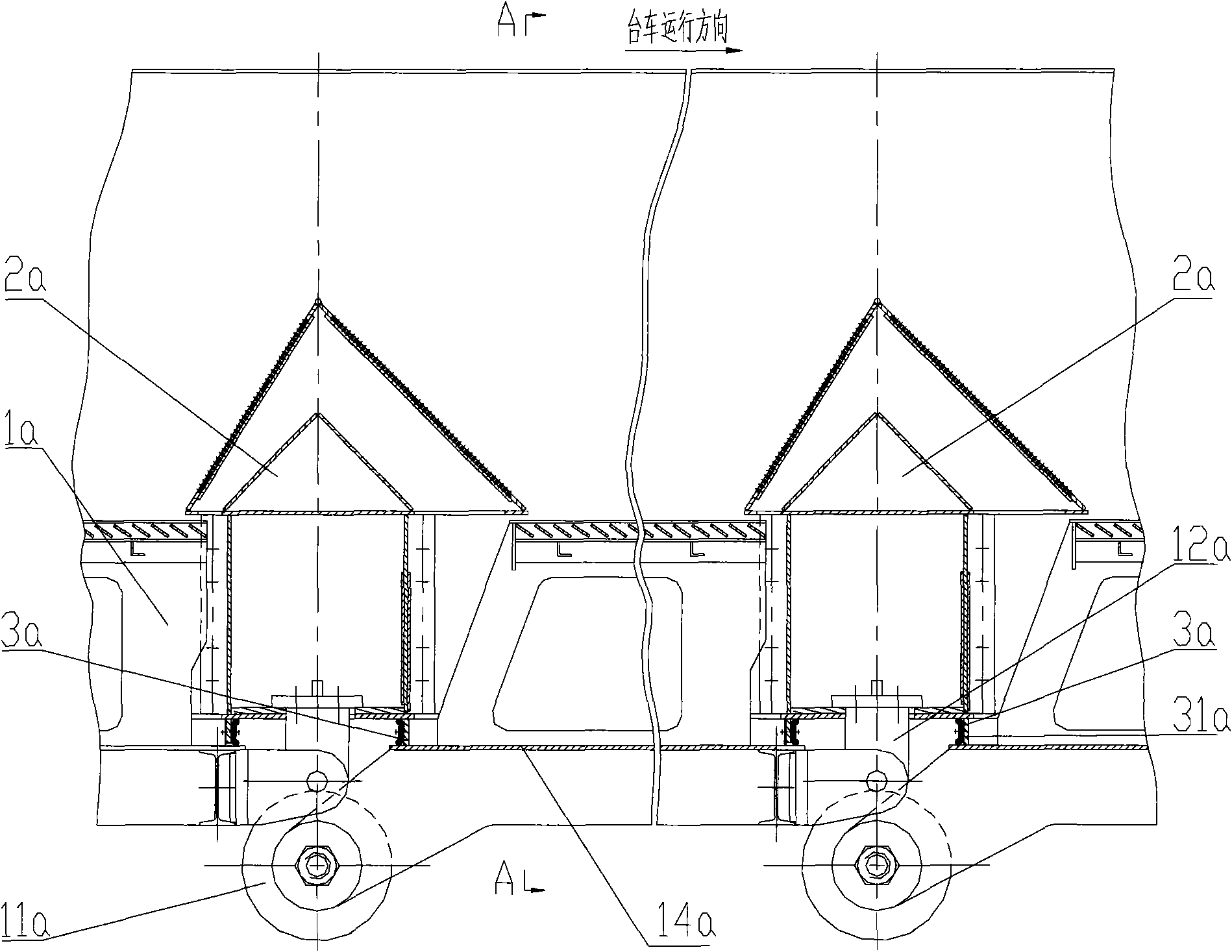

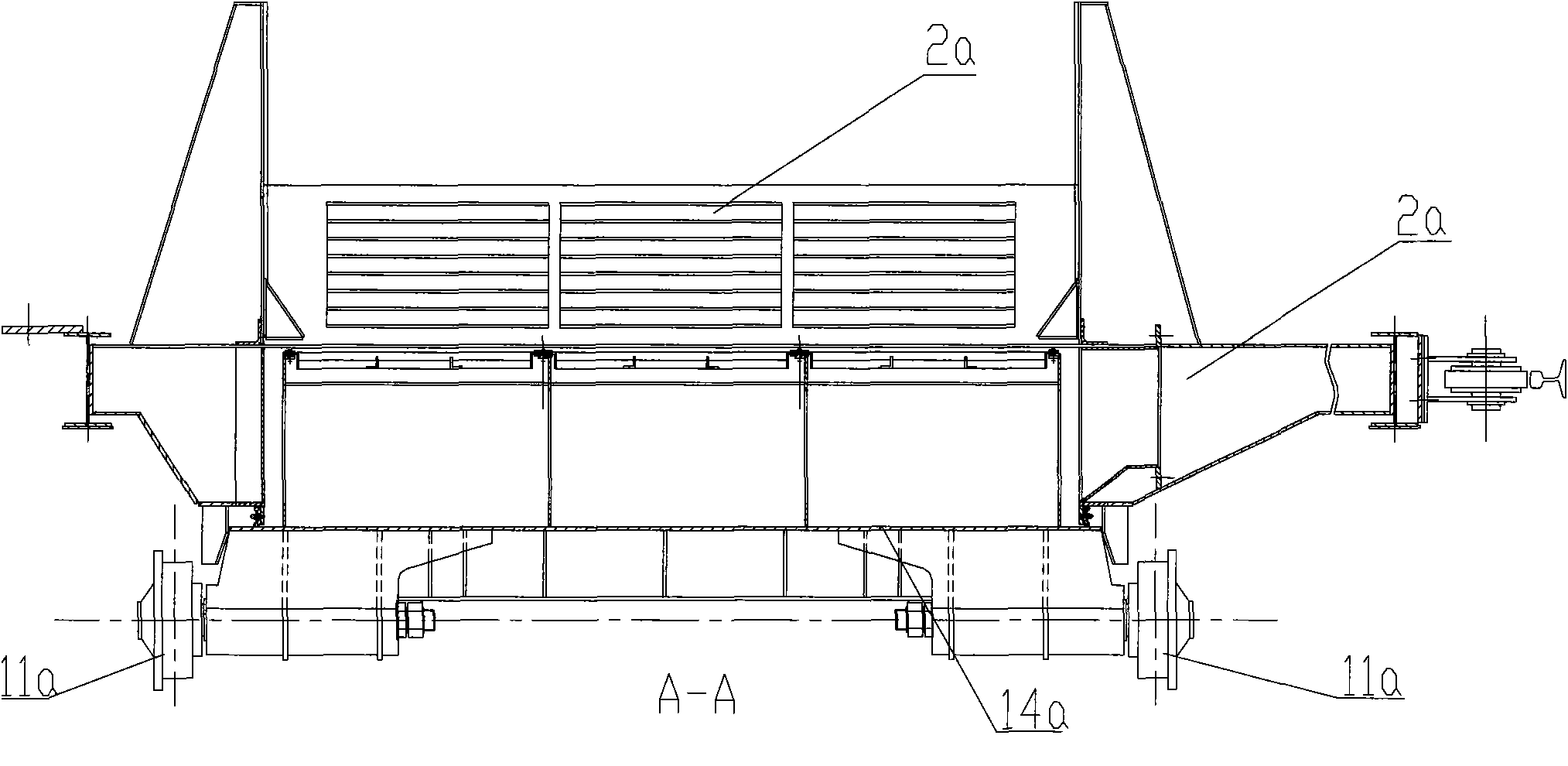

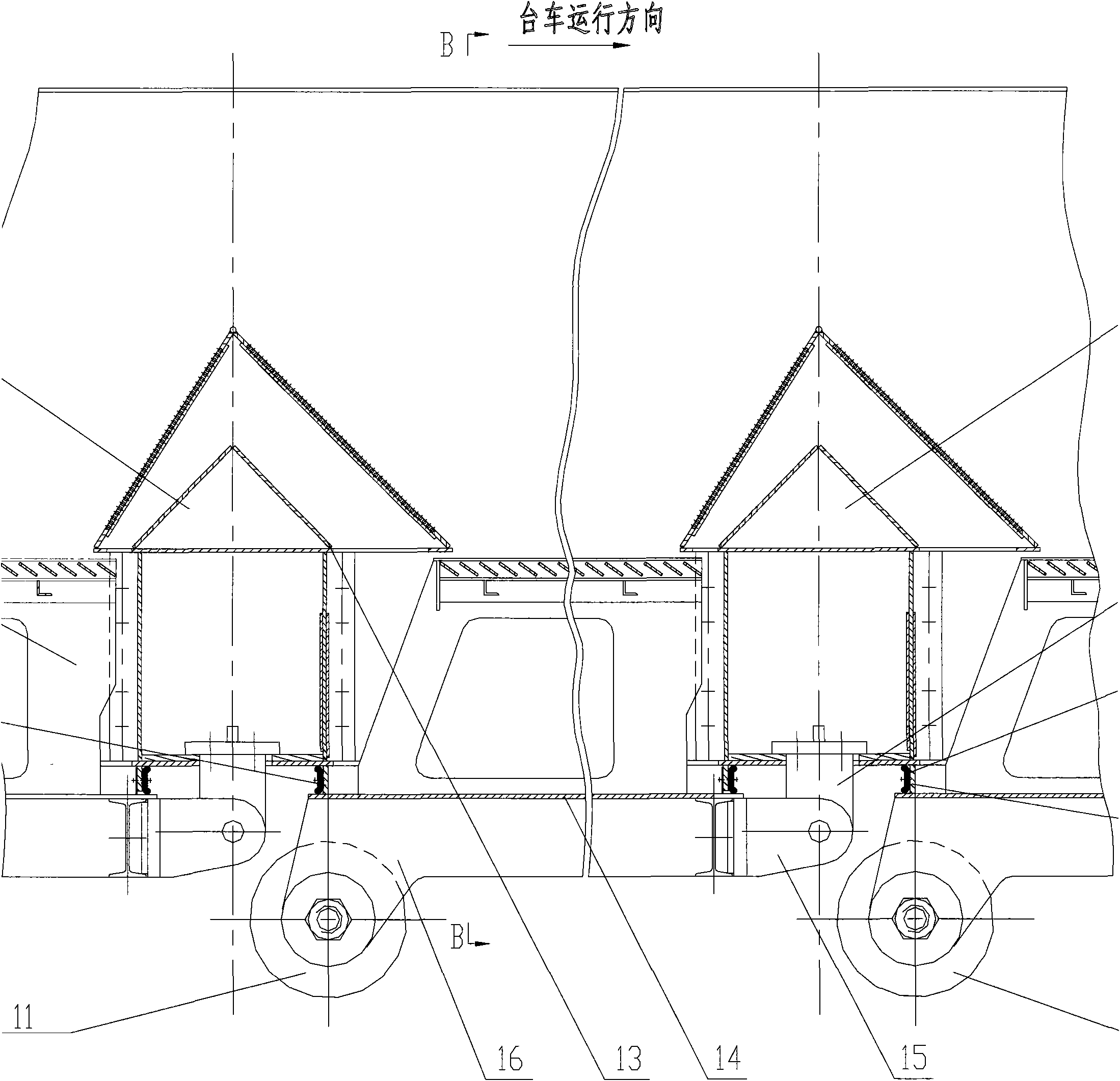

Rotary trolley body of ring cold machine and rotary trolley

ActiveCN101929805AReduce additional torqueReduce weightHandling discharged materialEngineeringMechanical engineering

The invention relates to a rotary trolley body which is supported by trolley support beams of a trolley rotary frame; the rotary trolley body and the trolley support beams are arranged along a ring cold machine at intervals in sequence. The rotary trolley body comprises a trolley preposed end and a trolley postpose end which are arranged on the trolley rotary frame, and also comprises a spherical hinge seat arranged on the trolley preposed end and trolley support wheels arranged on the trolley postpose end; the spherical hinge seat is mounted on the support beam of a preposed trolley; hard contact is arranged between the bottom of the front support plate of the support beam of a postpose trolley and a trolley lower flat through a sealing member installation support plate; and the centre line of the wheel axle of the trolley support wheels is vertically arranged below the installation support plate. The invention also provides the rotary trolley body and a rotary trolley, which are used for reducing the strength and rigidity of the trolley support beams, an inner toroidal beam and an outer toroidal beam and reducing the weight of the rotary frame on the premise of meeting application, wherein the inner toroidal beam and the outer toroidal beam are connected with the two ends of the trolley support beams.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Active bidirectional inclined pile row foundation pit supporting method

ActiveCN109440778AReduce distortionReduce bending momentExcavationsStructural engineeringEngineering

The invention discloses an active bidirectional inclined pile row foundation pit supporting method. The method comprises the following steps that (1) inward-inclined supporting piles inclined towardsthe interior of a pit and outward-inclined supporting piles inclined towards the outer portion of the pit are driven to the pile bottom design elevation in a staggered manner along the inner side of afoundation pit edge, and meanwhile a waterproof curtain is arranged behind the outward-inclined supporting piles; (2) a jack is arranged at the pile top of each inward-inclined supporting pile; (3) acrown beam for connecting all the inward-inclined supporting piles and all the outward-inclined supporting piles into a whole is arranged on a bidirectional inclined pile row formed by all the inward-inclined supporting piles and all the outward-inclined supporting piles; and (4) the soil defined by the inward-inclined supporting piles is excavated to the pit bottom design elevation, and in the excavation process or before excavation, the jacks arranged in the step (2) are adopted for applying control expansion force to the inward-inclined supporting piles so as to reduce displacement of thesoil and the pile tops. By means of the method, the pile top displacement can be reduced to a large degree, the bending moment of pile bodies and the engineering cost can be reduced, the excavation depth can be increased, and the possibility of toppling damage happening to the foundation pit can be reduced.

Owner:TIANJIN UNIV

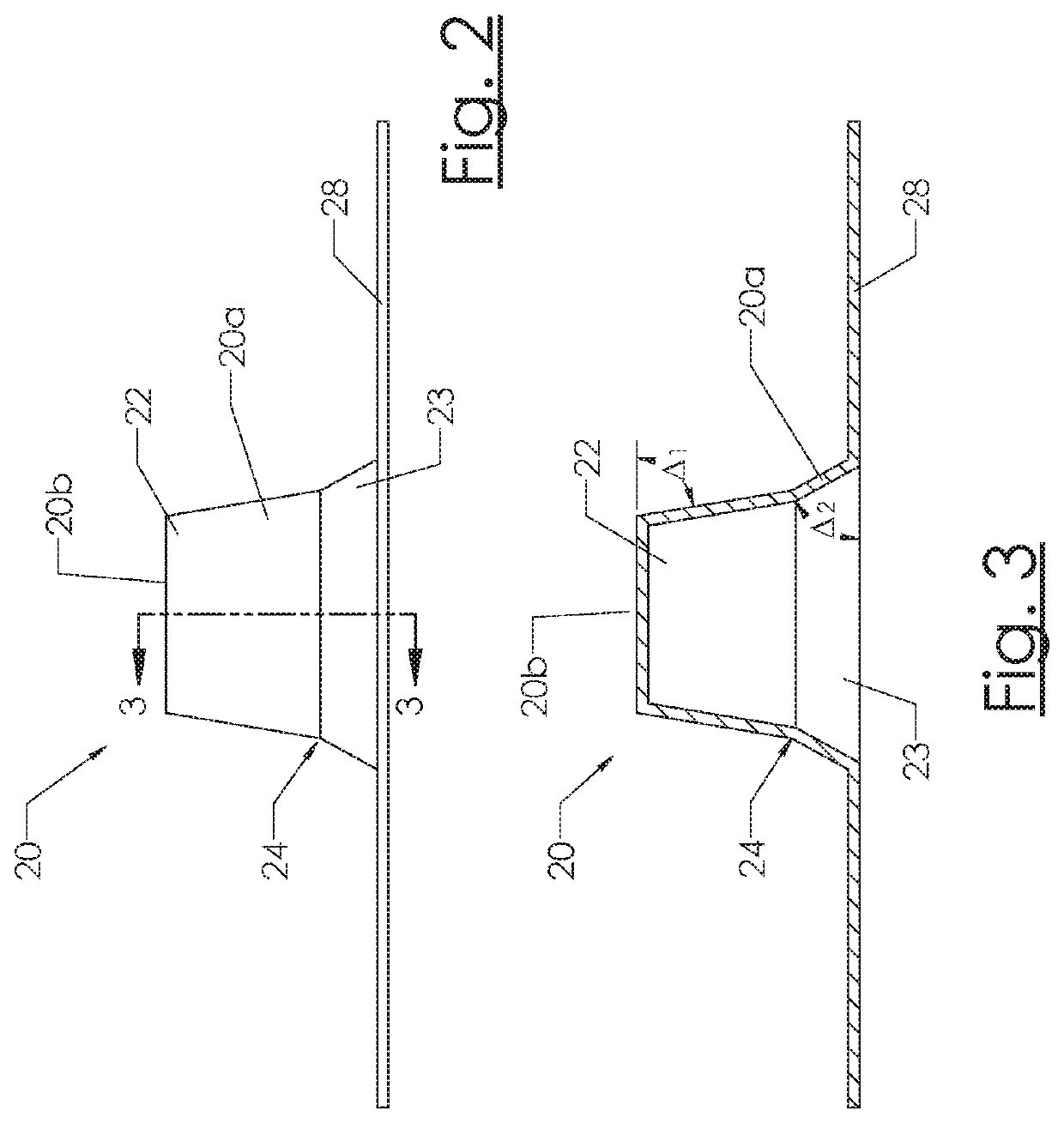

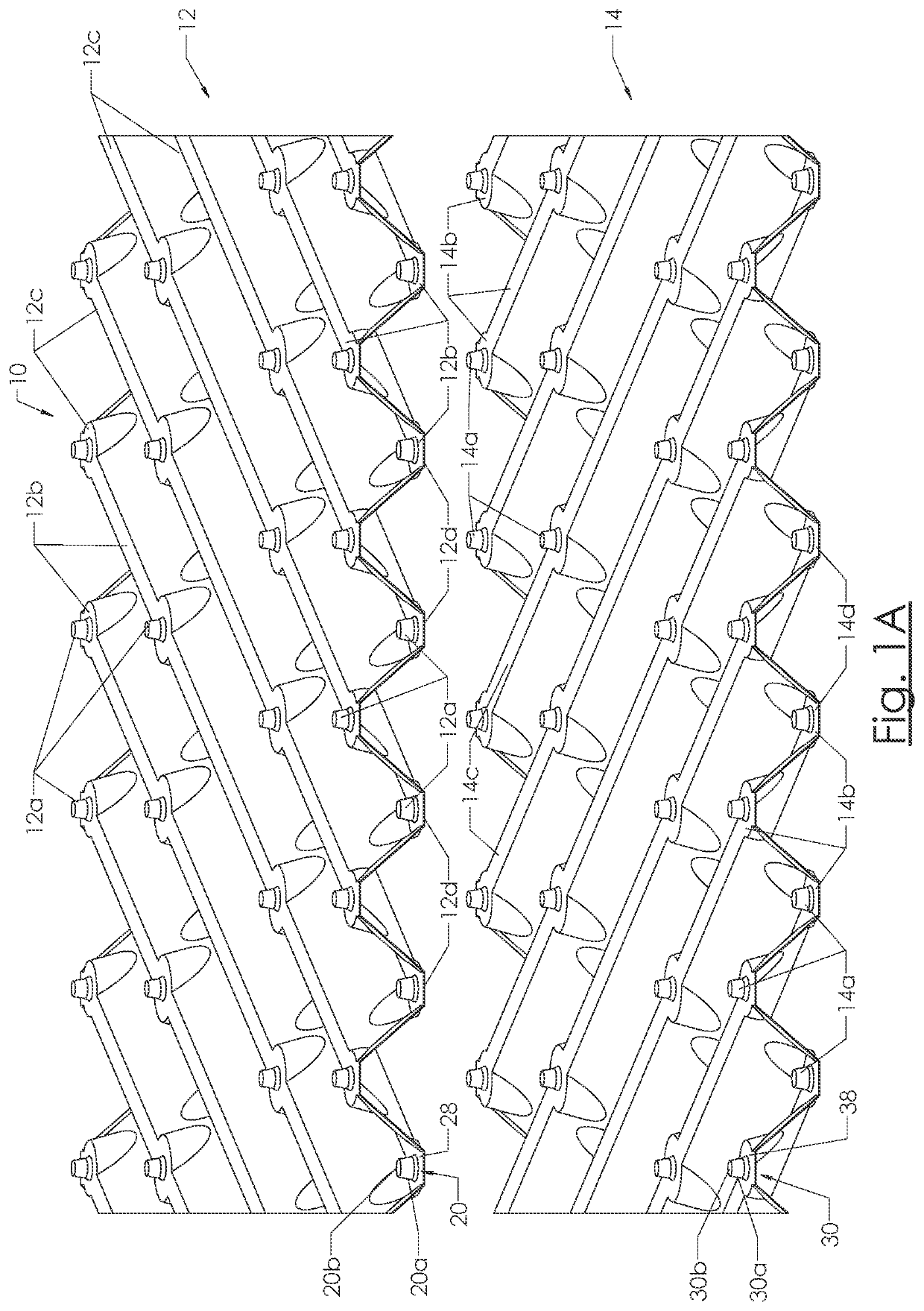

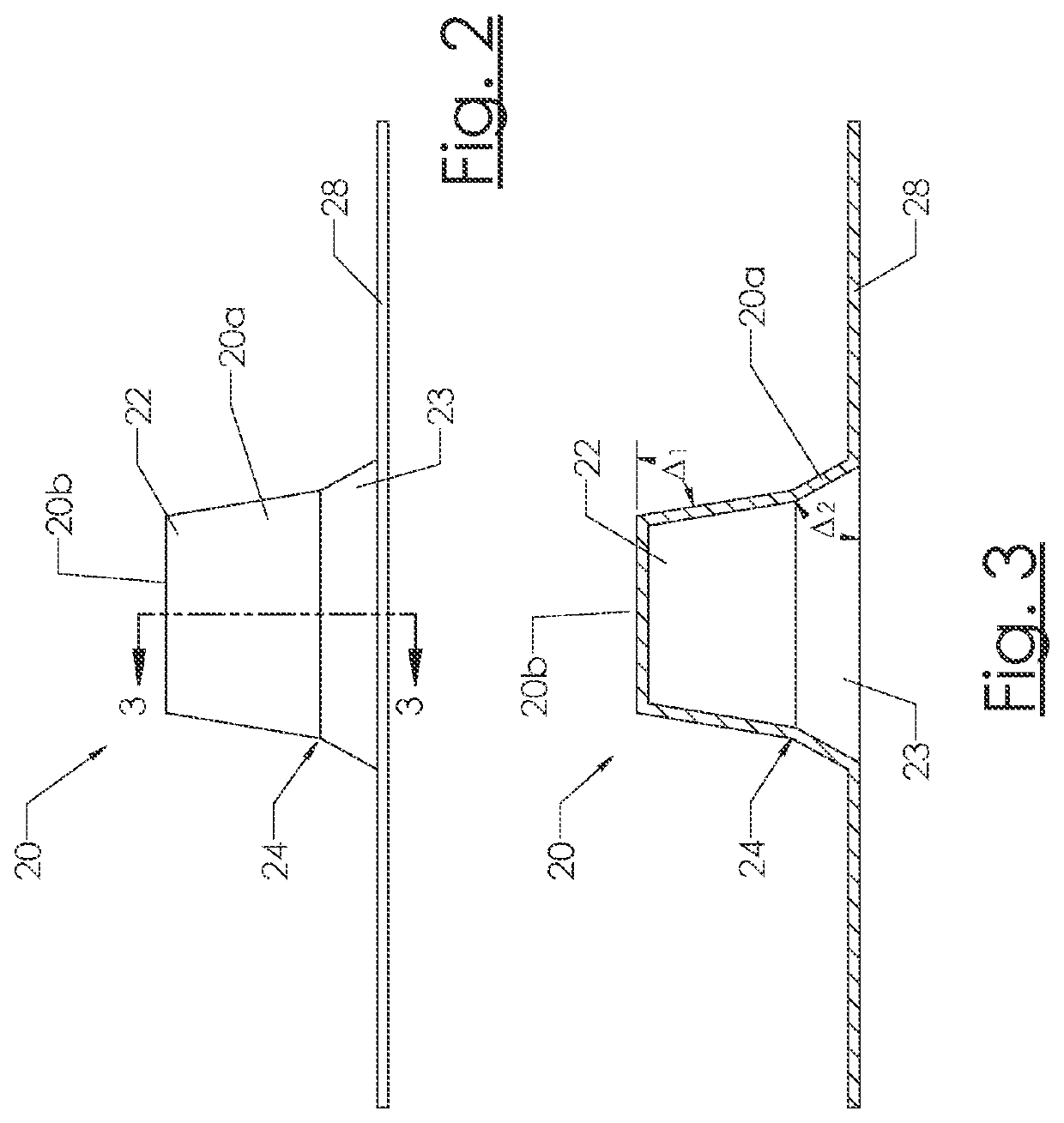

Mechanical assembly for securing sheets and related method

ActiveUS20210040968A1Increase strength of connectionReduce connectionLayered productsSheet joiningAcute angleEngineering

A mechanical assembly for securing a first sheet to a second sheet includes a first projection having a first sidewall and a first top wall. The first sidewall extends from the first top wall at a first acute angle. The first sidewall includes a first top end and a first bottom end. A first discontinuity is defined in the first sidewall between the first top end and the first bottom end. A first base wall extends from the first bottom end. The first base wall extends generally parallel to the first top wall.

Owner:BRENTWOOD INDS

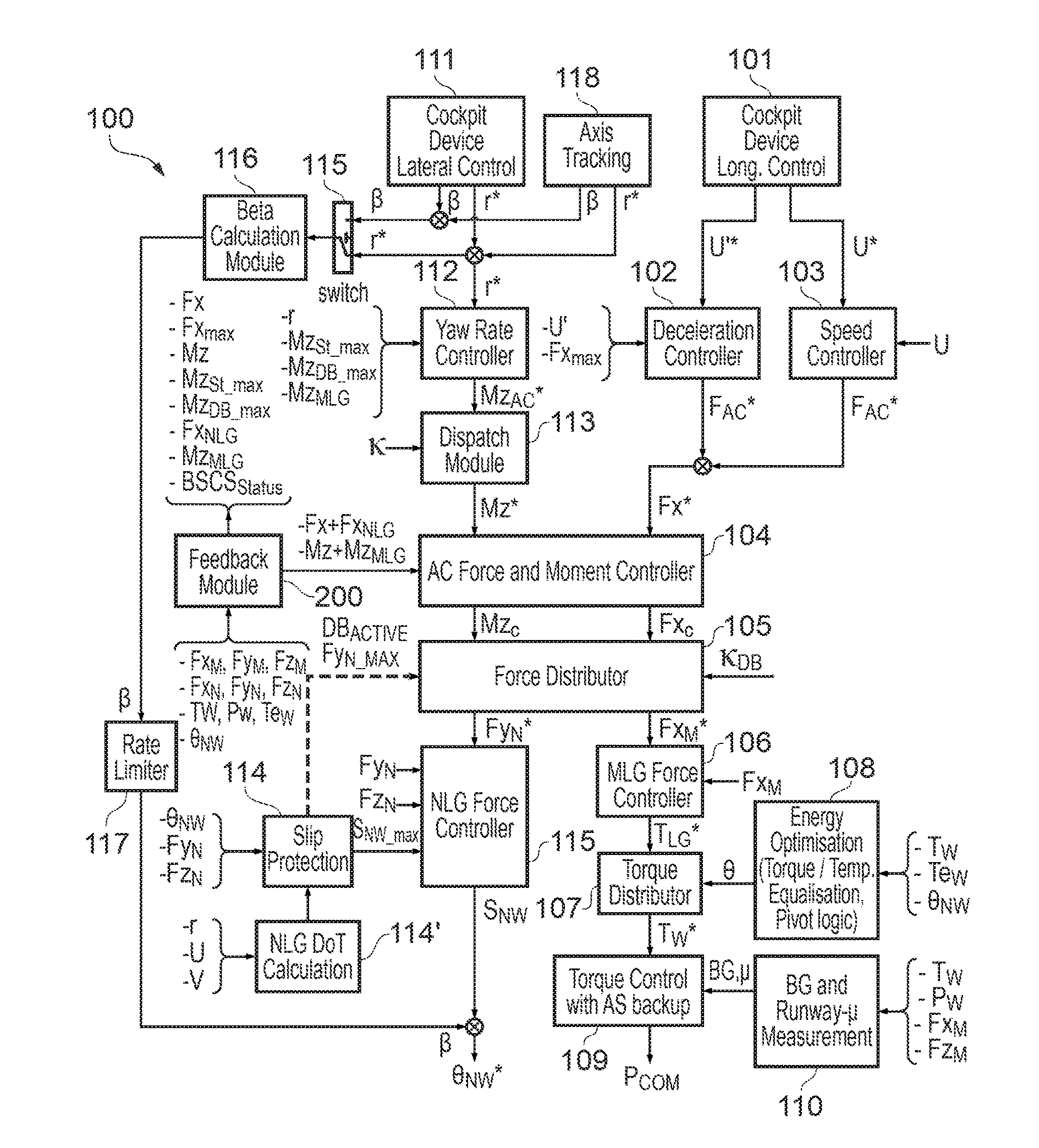

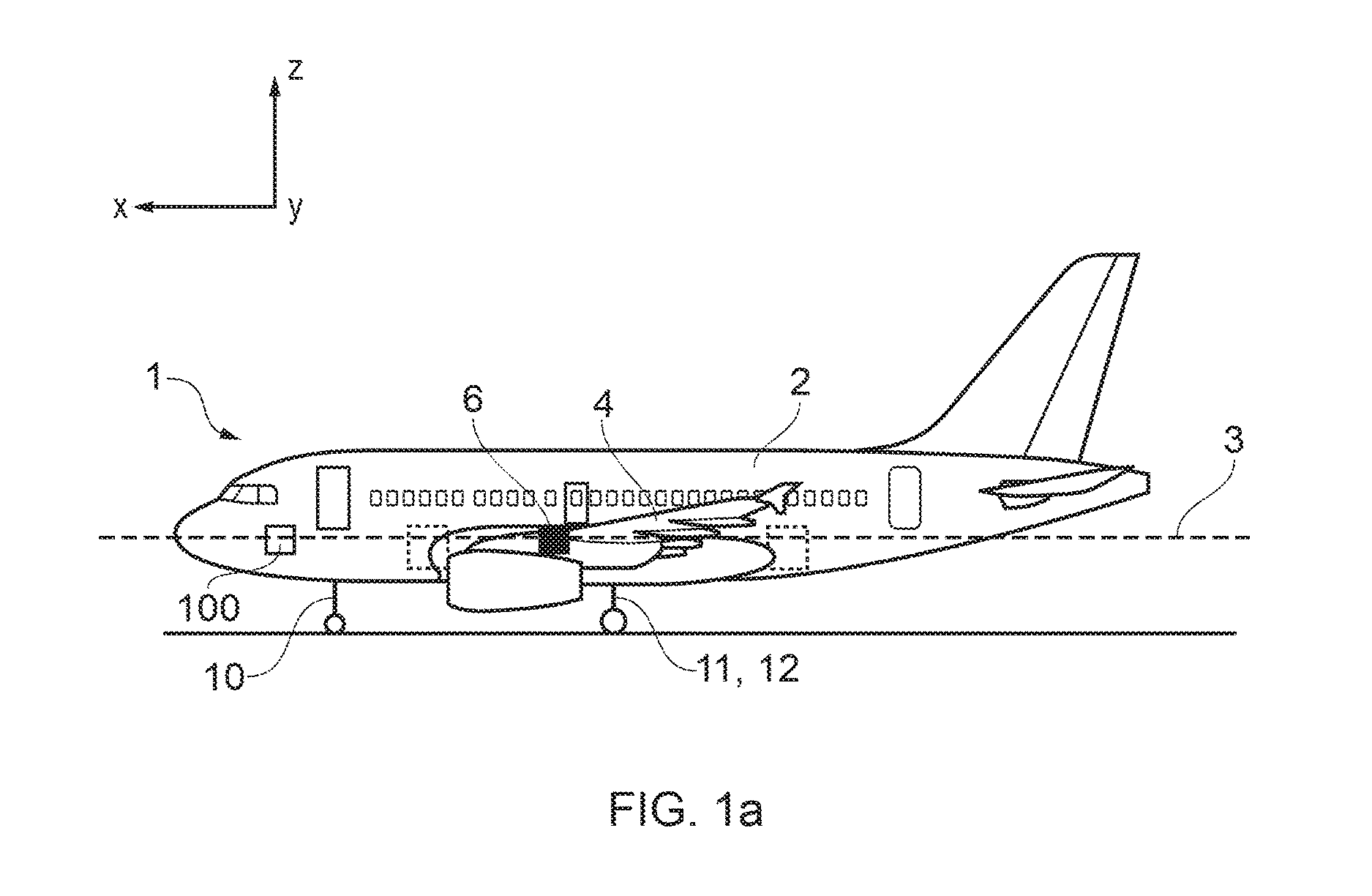

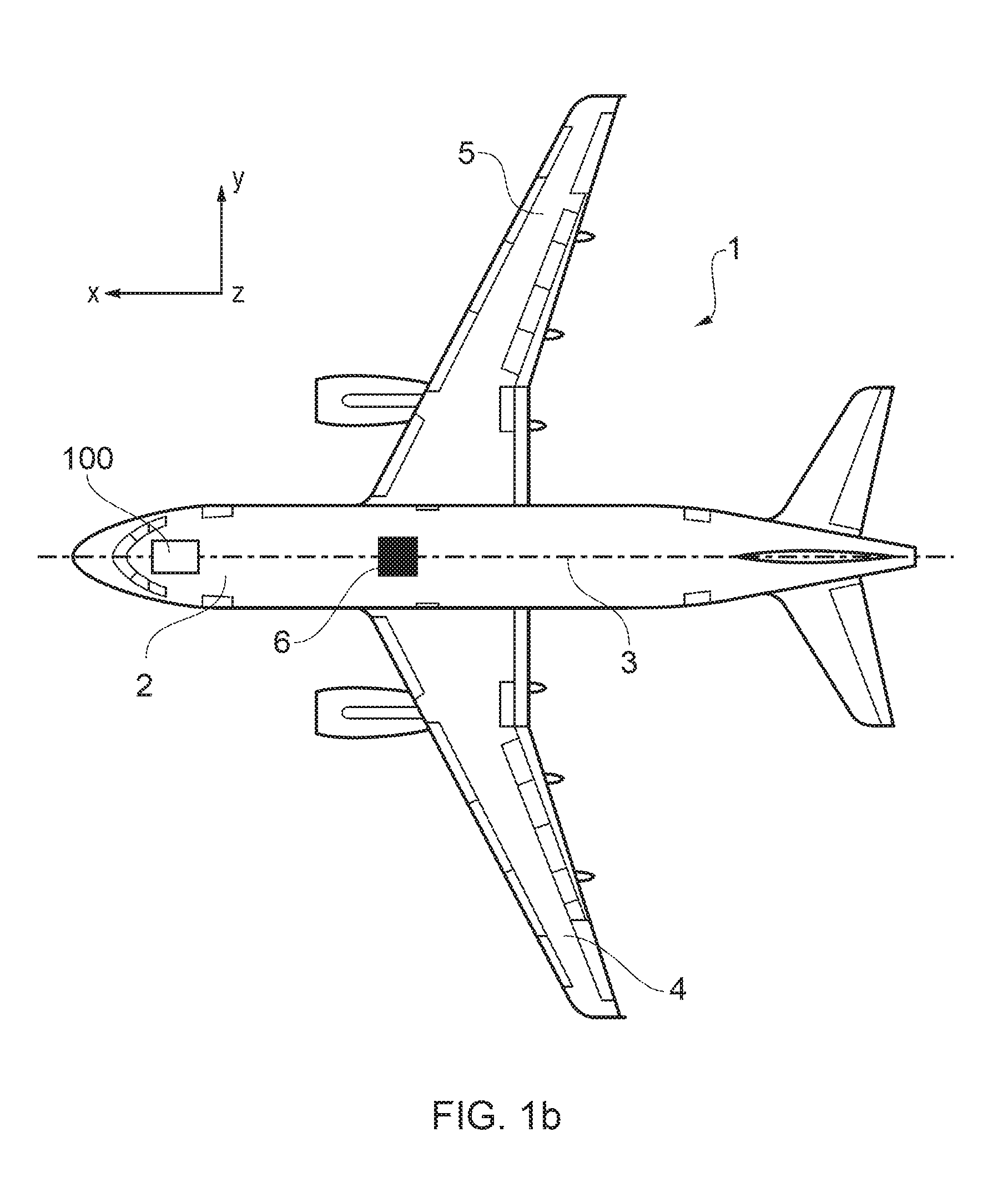

Aircraft steering system controller

ActiveUS20170008619A1Maximize effectivenessAdjustment is limitedActuated automaticallyWeight reductionEngineeringActuator

A controller for an aircraft steering system, the controller being configured to receive a steering input representative of a desired direction of travel of a steerable nose landing gear, and to receive one or more force-based inputs representative of lateral forces acting upon the nose landing gear, wherein the controller is adapted to automatically adjust the steering input based upon the force-based input(s) so as to output an adjusted steering command for a steering actuator of the nose landing gear.

Owner:AIRBUS OPERATIONS LTD +1

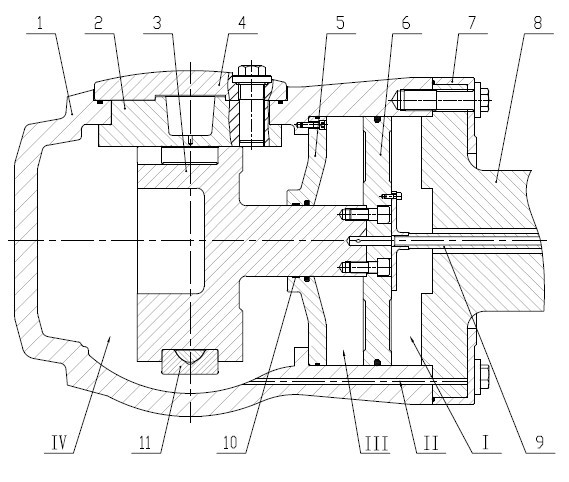

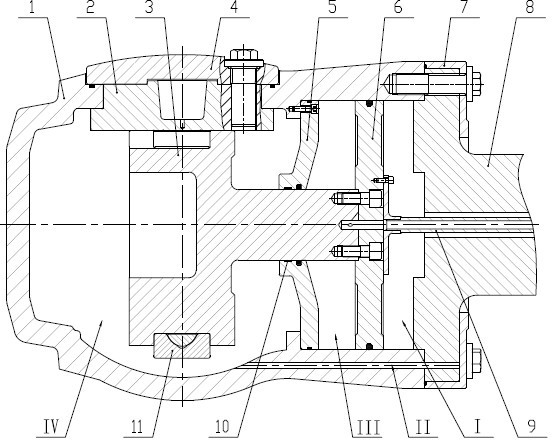

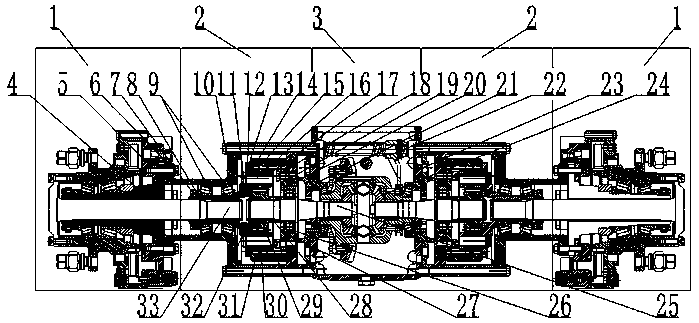

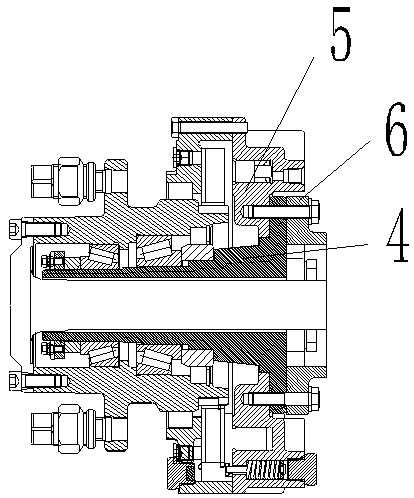

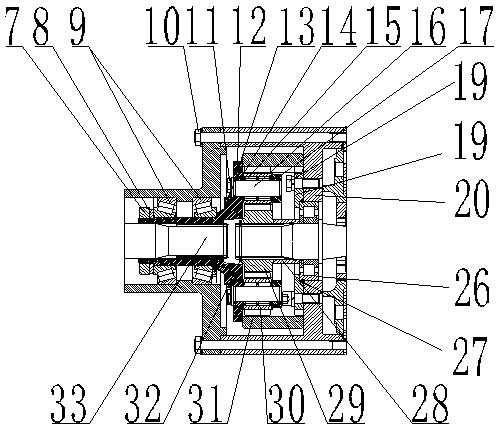

Tractor axle with planetary speed reducing mechanism

PendingCN109532475AReduced design strengthSmall and compact designGearingAxle unitsEngineeringBraking system

The invention discloses a tractor axle with a planetary speed reducing mechanism, which consists of an axle main speed reducing mechanism assembly, a planetary gear speed reducing mechanism assembly and a wheel hub mechanism assembly. The main speed reducing mechanism assembly is internally provided with a main speed reducing assembly and a main speed reducing differential lock operating mechanism; the planetary gear reducing mechanism assembly is respectively designed at two ends of the axle main reducing mechanism assembly and is internally provided with the planetary gear reducing assembly;and the wheel hub mechanism assembly is provided with a brake system mechanism and a wheel hub seat. The planetary speed reducing mechanism assembly is designed at two sides of the axle main speed reducing mechanism assembly, so that a second deceleration can be realized after the main deceleration of the axle; the planetary gear speed reducing transmission and coaxial output are adopted; and theplanetary speed reduction mechanism assembly is compact in structure, high in strength and large in transmission torque. Under the condition of the same wheel edge output torque, the design strengthof the transmission system and the main reducing gear can be reduced, so that the transmission system and the main reducing gear assembly can be designed to be smaller and more compact, and the purposes of reliable use and light weight manufacture can be achieved.

Owner:广西合浦县惠来宝机械制造有限公司

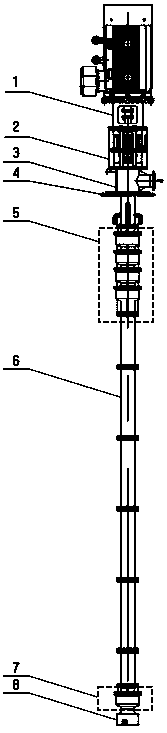

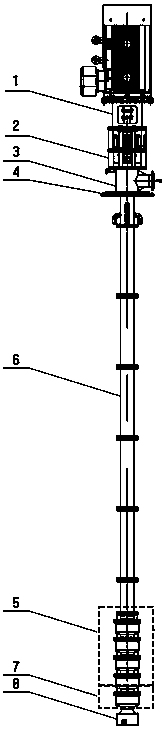

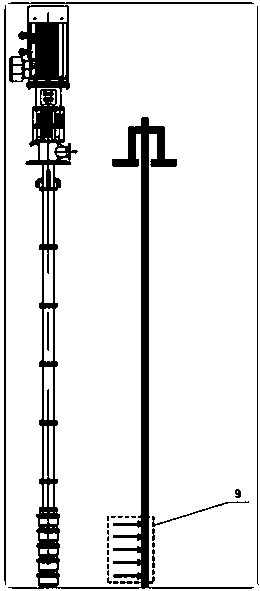

Long-shaft molten salt pump

InactiveCN109798247ASolve the problem of too concentrated mass distributionImprove the stability of installation and fixingSpecific fluid pumpsPump componentsImpellerStress point

The invention discloses a long-shaft molten salt pump which comprises a motor frame, a bearing box, a bearing box bracket, a water outlet seat, a mounting bottom plate, a connecting pipe, a pump section and a water inlet and is characterized in that the pump section is divided into a first-stage pump section and a second-stage pump section; the first-stage pump section is arranged at the lower endof the pump shaft; the lower part of the first-stage pump section is connected with the water inlet; the secondary pump section is arranged below the mounting bottom plate; the first-stage pump section is internally provided with a group of impellers and guide blades; and the secondary pump section is internally provided with four groups of impellers and guide blades. With the structure, the existing structural form that the pump section is arranged at the lower end of the pump shaft is improved into a structural form that the secondary pump section is arranged below the mounting bottom plate, and mass distribution of the pump and a stress point of an unbalanced force are changed, so that reasonable mass distribution and unbalanced stress point are realized, and improvement on operation stability of the long-shaft molten salt pump is realized.

Owner:JIANGSU FEIYUE PUMP GRP

Combined crushing granulation dryer

ActiveCN106422974BAchieve maximum surfaceAchieve superficialityGranulation by pressingForeign matterSoft materials

A combined granulator, comprising a multilayer combined box body (11), a temporary feed storage bin (01), and multiple layers and groups of rolling mills. Each group of rolling mills is provided with a rotary joint (04), a cleaning blade (05), an elastic stripping frame (14), a material baffle (07), and a guide plate. The box body is further provided with a waste gas evacuation port (03), and a support is provided with an air inlet (12) at the lowest layer of the granulator. The tooth surface linear velocity and the volumetric flow rate of a rotating drum of each rolling mill (08) at the second layer are higher than those of a rotating drum of each rolling mill (02) at the first layer; the ratios of the tooth surface linear velocities and the volumetric flow rates of the rotating drums having meshed tooth slots or individual radial tooth slots of adjacent rolling mills at the lower layer can be adjusted according to the volume of materials in the region. The granulator can not only strip hard foreign matters, but also simply granulate a soft material, such as cream, paste, and slurry. In addition, the granulator can also directly pull caky and blocky materials into monomer granules, so that soft and hard materials can simultaneously enter the granulator, and granules at an outlet are porous and irregular in shape.

Owner:张元才

Active x-shape double-row pile foundation pit support method

ActiveCN109440779BReduce distortionReduce bending momentExcavationsArchitectural engineeringStructural engineering

Owner:TIANJIN UNIV

Mechanical assembly for securing sheets and related method

ActiveUS20210317853A1Little strengthImprove connection strengthLayered productsSheet joiningAcute angleClassical mechanics

Owner:BRENTWOOD INDS

Prefabricated built-in thermal insulation layer foamed concrete composite wall-light steel frame-floor connection node

InactiveCN108643346BImprove seismic performanceHigh design strengthWallsFloorsFoam concreteInsulation layer

The invention belongs to the technical field of wall joint connection fabrication in building structure engineering, and particularly relates to a prefabricated built-in thermal insulation layer foamed concrete composite wall-light steel frame-floor slab connecting joint. A composite wall is installed in a semi-embedded mode, a built-in thermal insulation layer and inner page foamed concrete are embedded into a light steel frame, and outer page foamed concrete externally covers light steel frame beams and columns. Compared with a traditional prefabricated wall, the wall of the prefabricated built-in thermal insulation layer foamed concrete composite wall-light steel frame-floor slab connecting joint can be used as a structural force-bearing member to transfer loads between the frame beamsand columns, participates in the structural stress of a house and improves the bearing capacity and seismic capacity of the house, and a wall panel is externally wrapped with the steel frame beams andcolumns to effectively reduce the corrosion of steel. According to the composite wall-light steel frame-floor slab joint, bolt holes are prefabricated between components, and bolts are connected intothe bolt holes in a penetrating mode during assembly to realize the connection. The joint is simple in structure form, the connection is reliable, the construction is easy, and the joint can be usedin practical engineering to effectively shorten the construction period and is suitable for widespread popularization and application in low-rise multi-storey light steel frame structures.

Owner:BEIJING UNIV OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com