Automobile welding jig parametric design system

An automotive welding fixture and parametric design technology, which is applied in computing, electrical digital data processing, special data processing applications, etc. The effect of setting up time, reducing technical requirements, and improving design efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

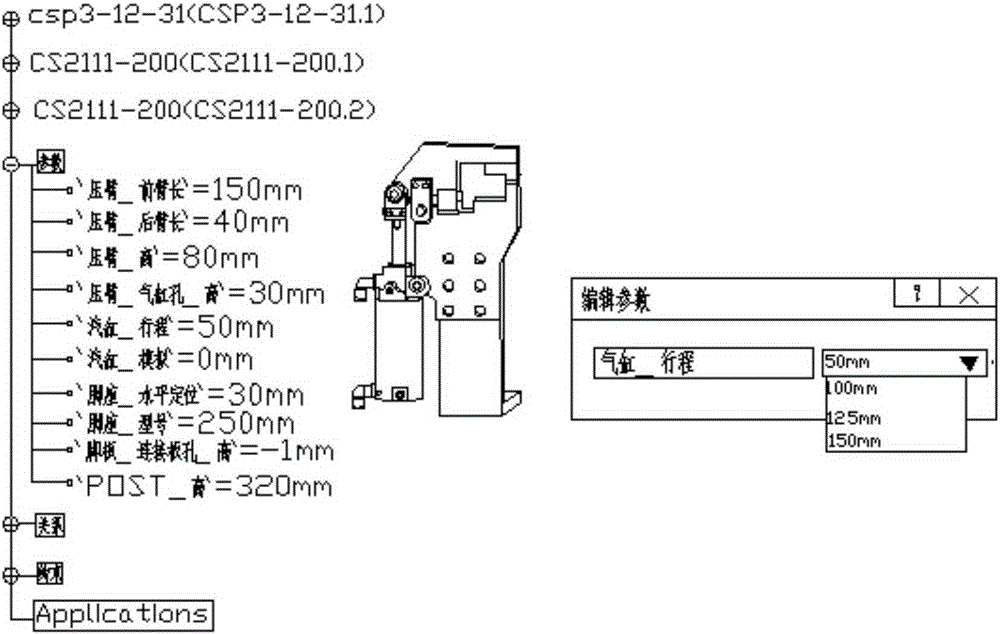

[0018] Such as figure 1 As shown, it includes a welding fixture unit and its structural parameter design system. The welding fixture unit transforms its structure by transforming its parameters. The structural parameter design system is set in the form of a tree diagram, and the welding fixture unit is divided into multiple A module, wherein the parameter is a module, and the welding fixture unit specifically includes parameters as follows:

[0019] a. Compression arm_forearm length = 150mm

[0020] b. Compression arm_rear arm length = 40mm

[0021] c. Compression arm_height = 80mm

[0022] d. Compression arm_cylinder hole_height = 30mm

[0023] e. Cylinder_stroke = 50mm

[0024] f.Cylinder_analog=0mm

[0025] g. Feet_horizontal positioning=30mm

[0026] h. Foot_Model=250mm

[0027] i. Type plate_ connection plate hole height = -3mm

[0028] j.POST_height = 320mm

[0029] The working process of the structural parameter design system is to select the part of the weldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com