Ship propeller hub with front oil cylinder

A front-mounted propeller technology, which is applied to ship propulsion, propulsion components, ship components, etc., can solve problems such as adding hydraulic systems, increasing ship operation risks, leakage, etc., and achieves large pressure area, compact structure, and improved reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

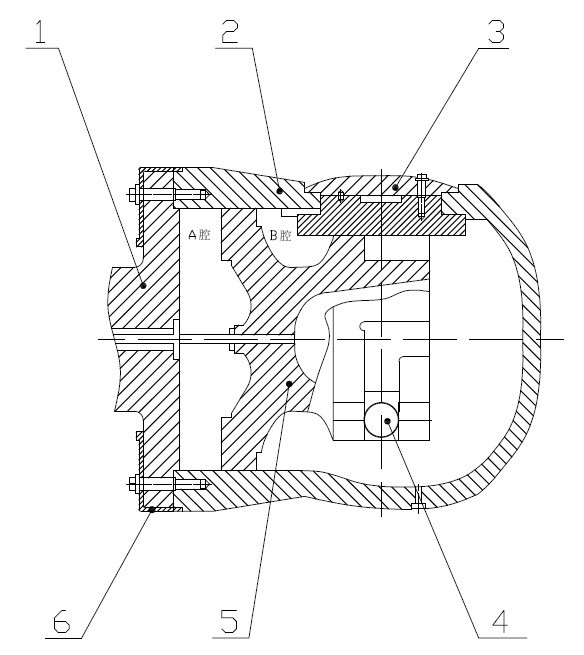

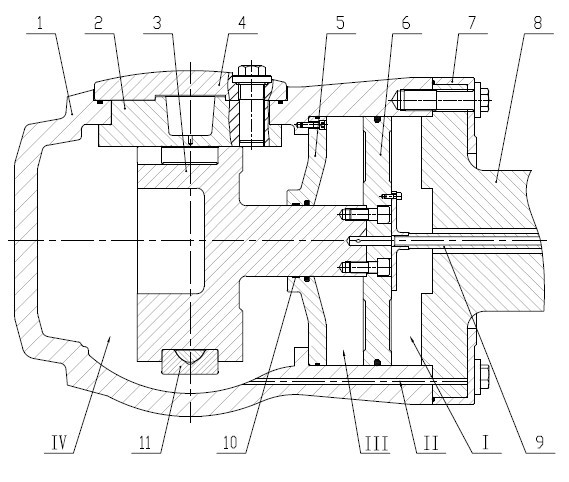

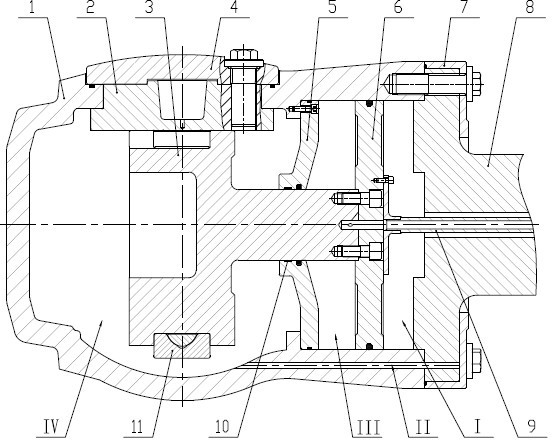

[0016] The present invention includes a propeller hub body 1, a propeller seat 2, a guide frame 3, a propeller 4, an oil cylinder supporting partition 5, a piston 6, a propeller shaft protection cover 7, a propeller shaft 8, an inner pipe part 9, and a guide wear-resistant ring 10 , slider 11, wherein: the propeller hub body 1 is integrated with the front end oil cylinder, and its front end is connected to the propeller shaft by flange bolts; the propeller hub body 1 is provided with a guide frame 3, and the guide frame 3 is connected to the piston through bolts; the oil cylinder The support partition 5 is installed on the propeller hub body by screws, and its inner hole is equipped with a guide wear-resistant ring 10; the disc root of the propeller seat 2 is provided with a crank pin, and the slider 11 is set on the crank pin, and then put into the guide In the chute in the middle of the frame 3, the slider 11 is movably connected with the crank pin and the chute; the piston 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com