Supporting system and supporting method of slant cement soil mixing pile foundation pit

A cement-soil mixing pile and foundation pit support technology, which is applied in excavation, sheet pile walls, foundation structure engineering, etc., can solve problems such as prone to overturning damage, endangering the surrounding environment, and broken slope protection piles, and achieve the design strength of the pile body Effects of reduction, good technical value, and increased excavation depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the following embodiments in no way limit the present invention.

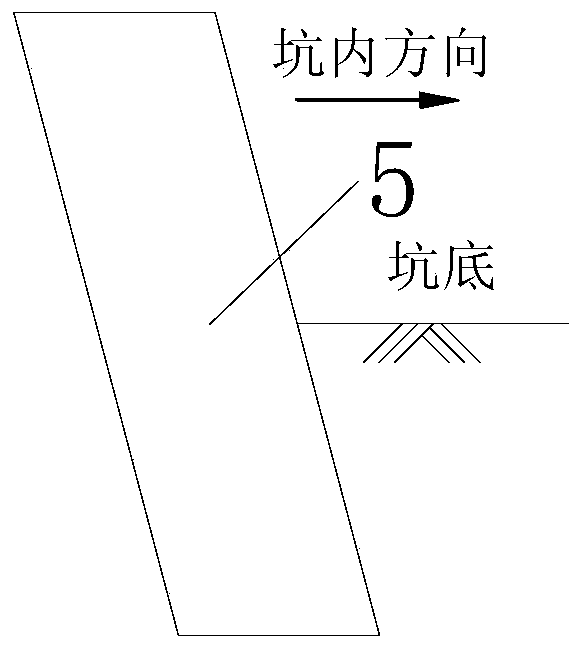

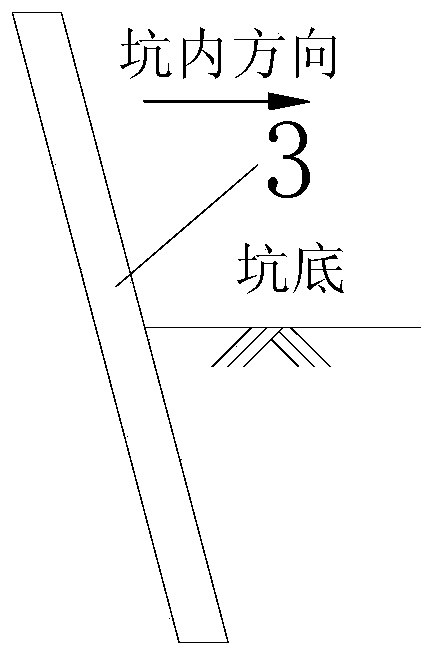

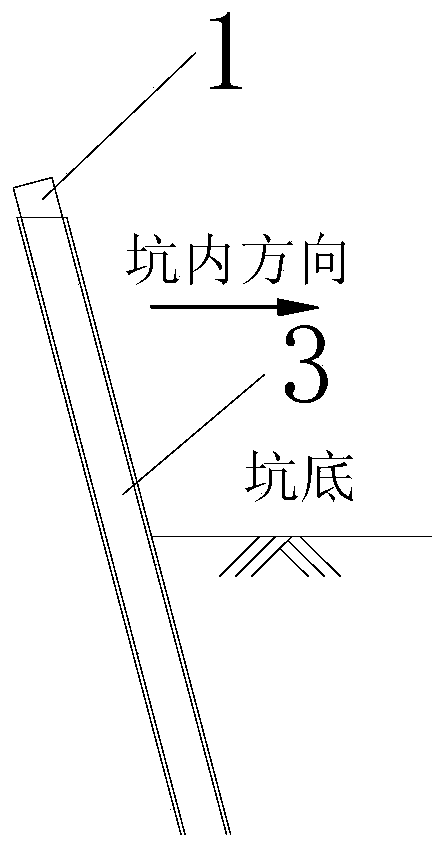

[0036] In the method of the invention, the foundation pit is supported by rows of piles with a certain inclination under the condition that the site permits. When inclined piles are used for foundation pit support, the wedge-shaped body with sliding tendency behind the pile is smaller than the wedge-shaped body when the pile is vertical, because the wedge-shaped body behind the pile is partly less due to the slope. Therefore, the force of the soil on the pile will be greatly reduced, so that the displacement of the pile top and the force of the pile body will be greatly reduced. Theoretically speaking, the larger the slope of the pile, the smaller the force of the pile and the displacement of the pile top, which is more economical, but the slope of the pile cannot be increased...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com