Tractor axle with planetary speed reducing mechanism

A planetary deceleration and planetary gear deceleration technology, which is applied in the field of tractor transmission system manufacturing, can solve the problems of increasing the arrangement of surrounding accessories, difficulty in reducing the structural size, and difficulty, and achieve the effect of compact structure, reduced design strength, and large transmission torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific implementation.

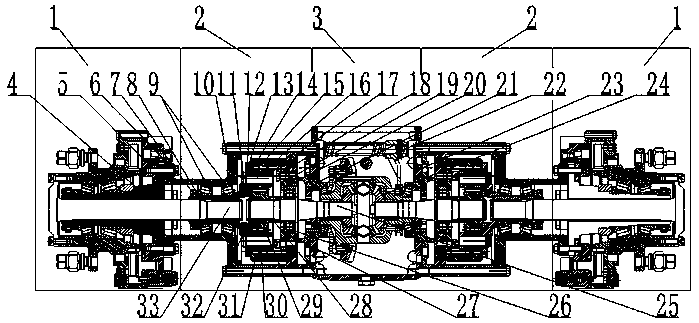

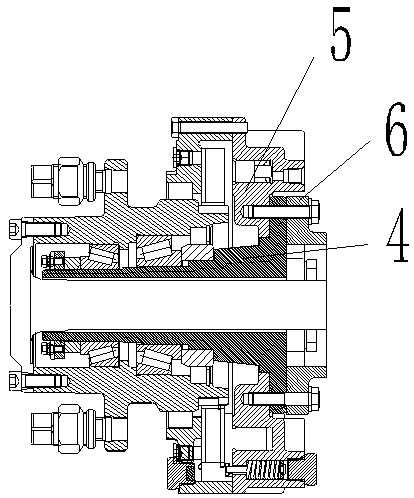

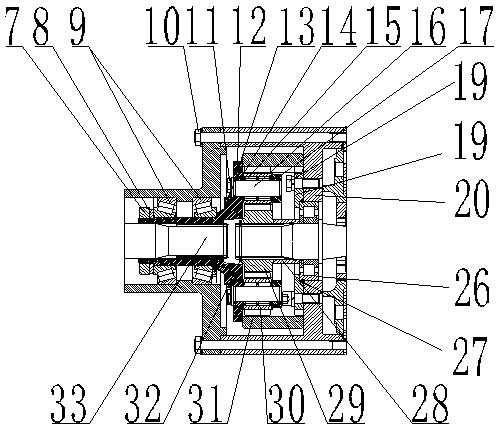

[0016] Such as Figure 1-4 As shown, an axle for a tractor with a planetary reduction mechanism is composed of three major components: an axle main reduction mechanism assembly 3 , a planetary gear reduction mechanism assembly 2 , and a hub mechanism assembly 1 . Main deceleration mechanism assembly 3 is equipped with main deceleration assembly 24 and main deceleration differential lock operating mechanism 22, main deceleration assembly 3 can realize deceleration effect, main deceleration differential lock operating mechanism 22 can realize synchronous driving of left and right wheels, enhance Off-road passing performance; the planetary gear reduction mechanism assembly 2 is equipped with a planetary gear reduction assembly, and the power is output from the planet carrier to realize deceleration; the wheel hub mechanism assembly 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com