A method for determining the position of a main beam of a wing-body fusion body aircraft

A technology for determining methods and fusion, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as cumbersome iterative process, long design cycle, low design efficiency, etc., to reduce the iterative process, save costs, The effect of improving design efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

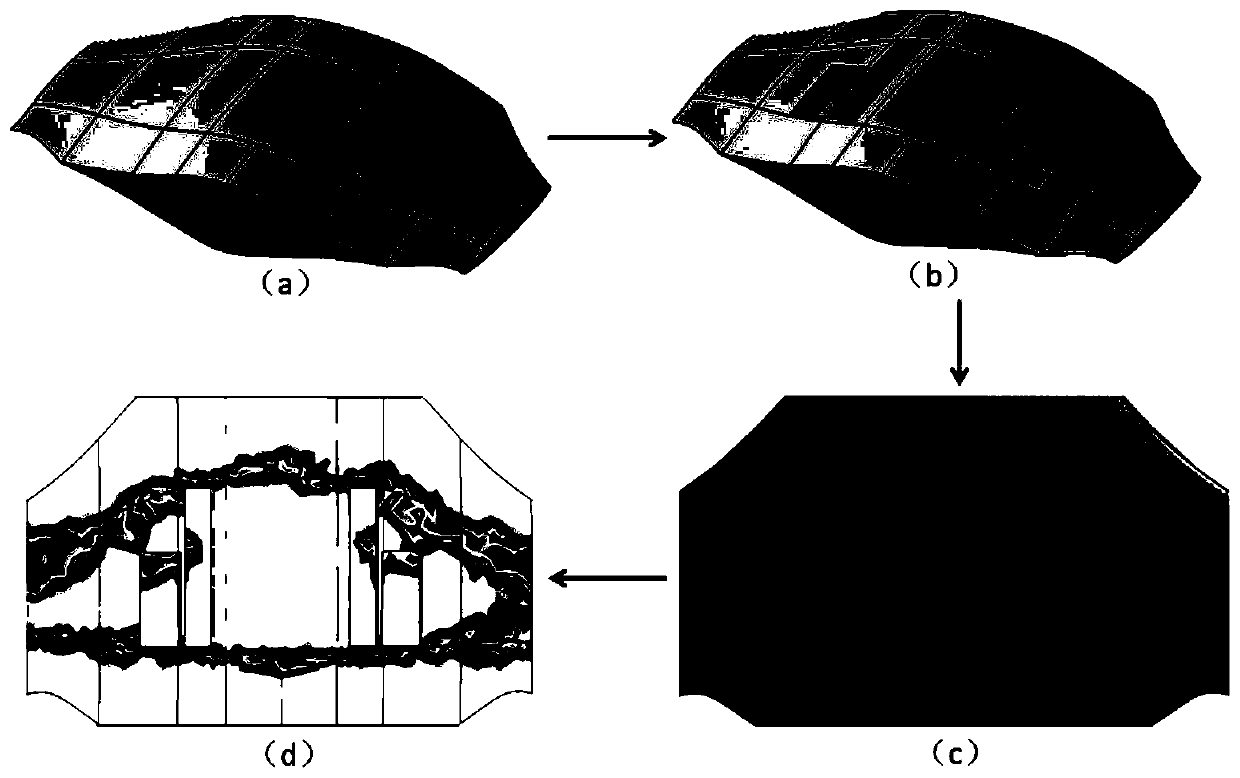

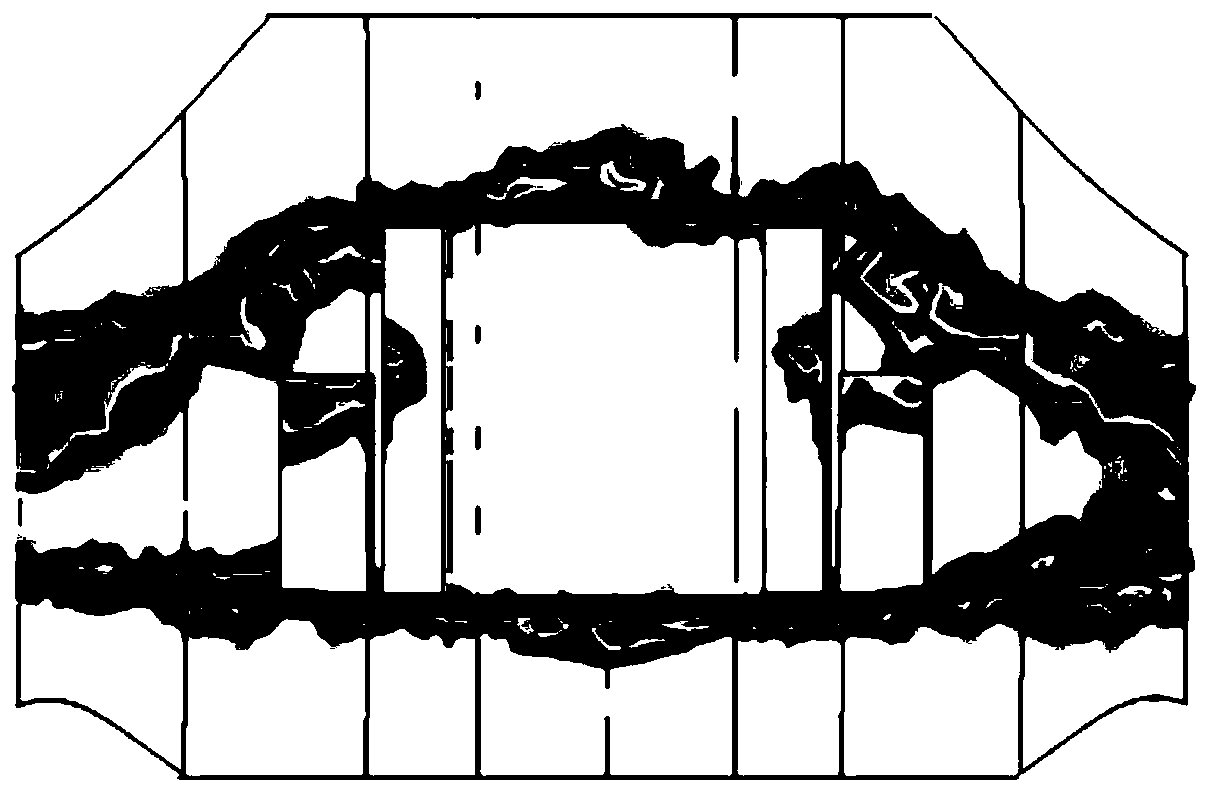

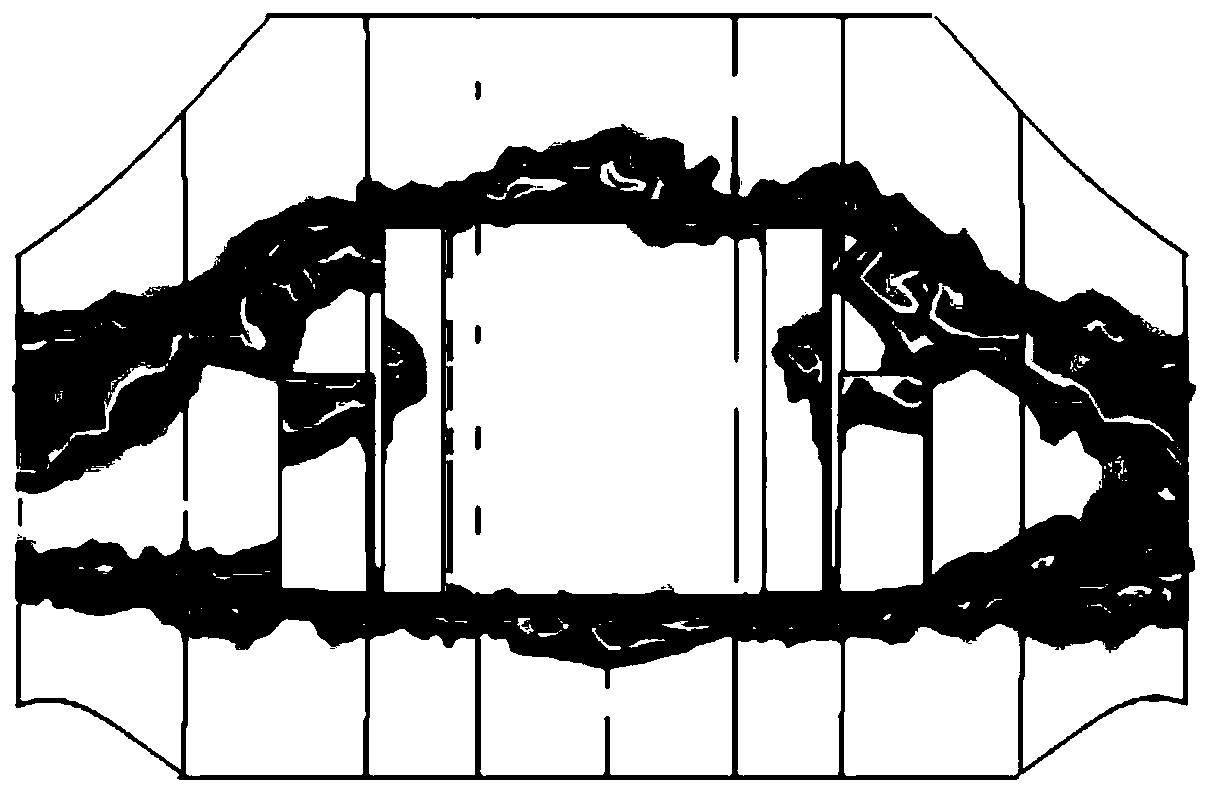

[0011] See attached Figure 1-2 , The invention provides a method for determining the position of the main girder in the fusion area of a wing-body fusion aircraft. by figure 1 The solid structure of the fusion body shown as an example, the steps to determine the position of the main beam are as follows: first step, make the necessary cabin openings on the entity, such as the landing gear compartment and the equipment compartment, to form the wing-body fusion area with openings ,Such as figure 1 (a)-(b); The second step is to carry out finite element solid modeling, set uniform material properties, set boundary conditions, and apply loads, such as figure 1 (c); The third step is to conduct topology optimization analysis, set the minimum structural weight as the optimization goal, and obtain the optimization analysis results, such as figure 1 (d), the darker the color in the figure, the more load transfer; the fourth step is to determine the positions of the front beam and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com