Hydrokinetic type supersonic wave air-conditioning spray chamber

A fluid power and ultrasonic technology, applied in air conditioning systems, heating methods, air humidification systems, etc., can solve the problems of poor purification effect of fine dust, achieve the effect of improving water removal efficiency, good flow equalization effect, and reducing air resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

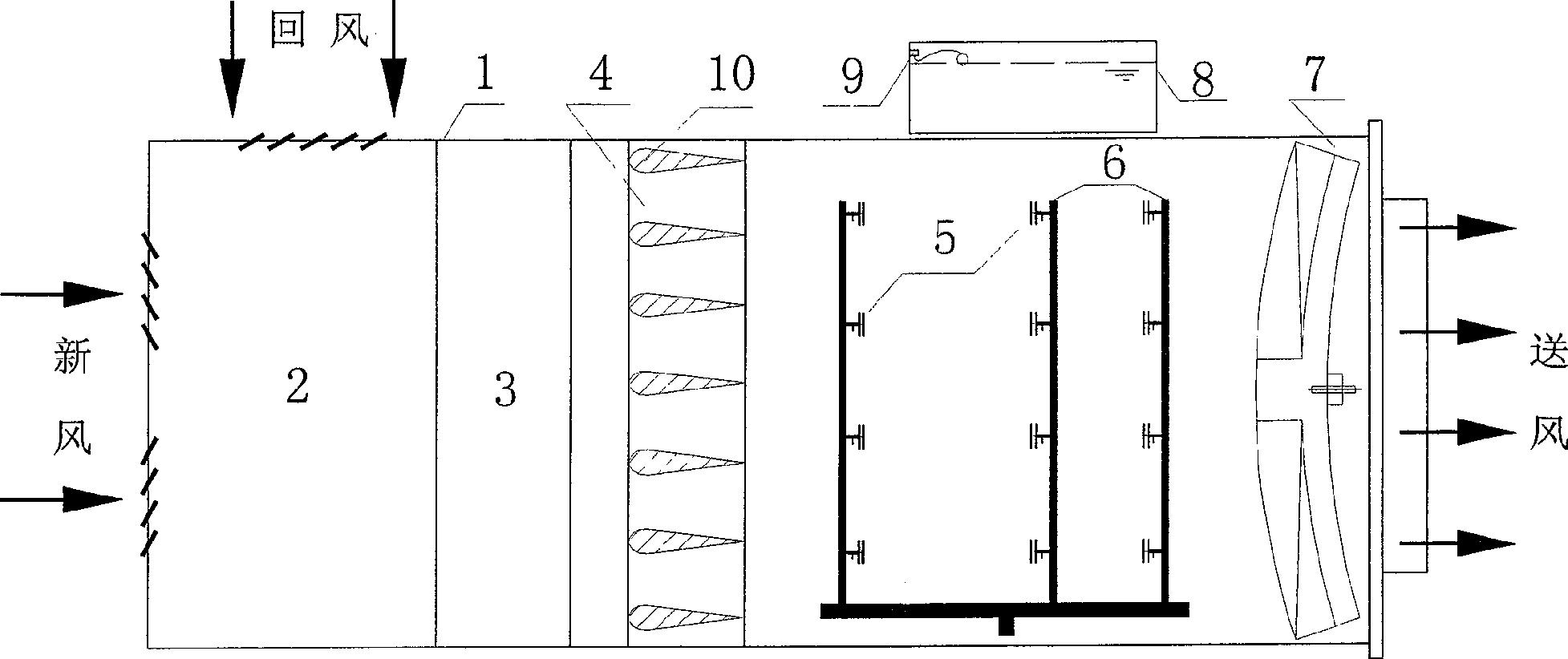

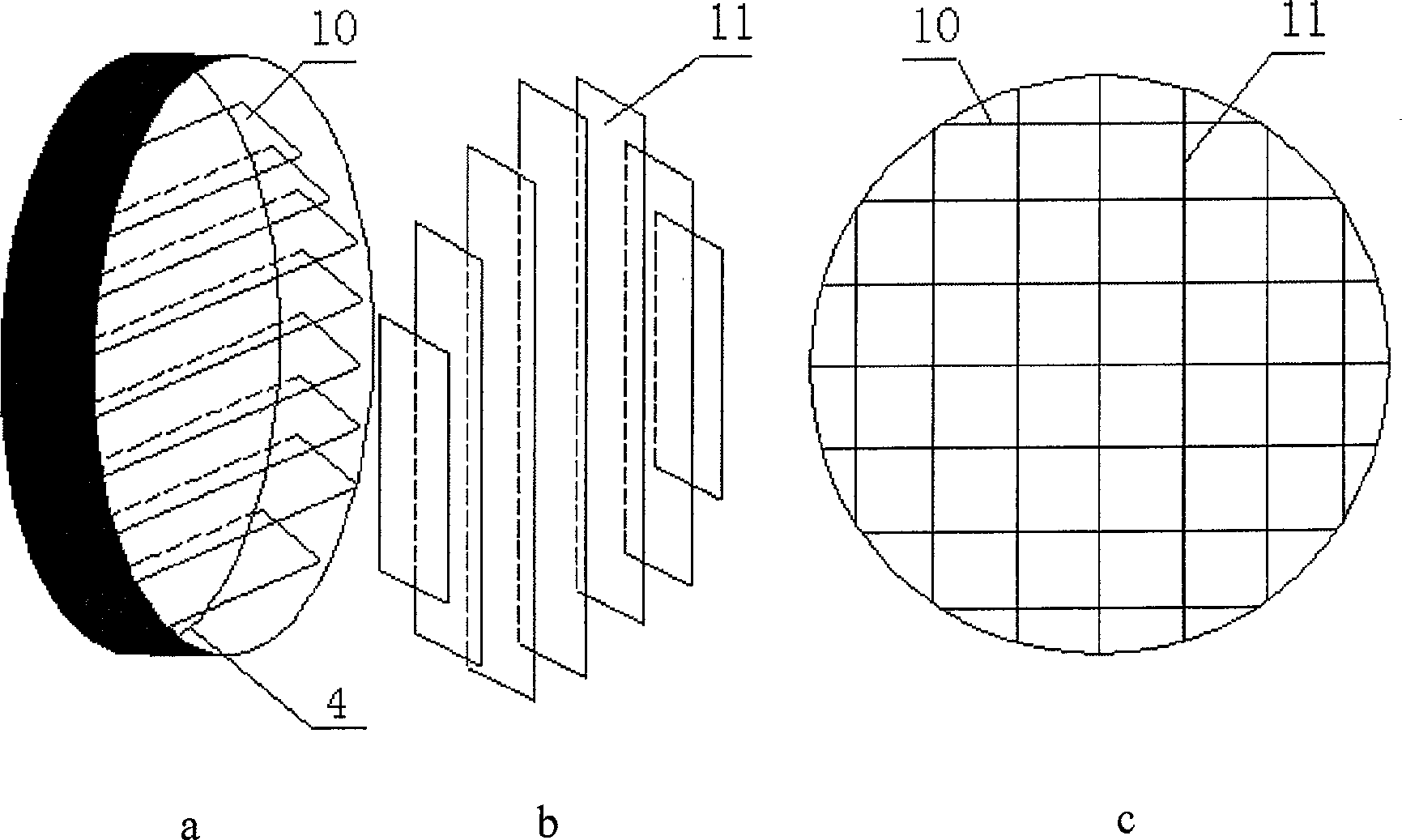

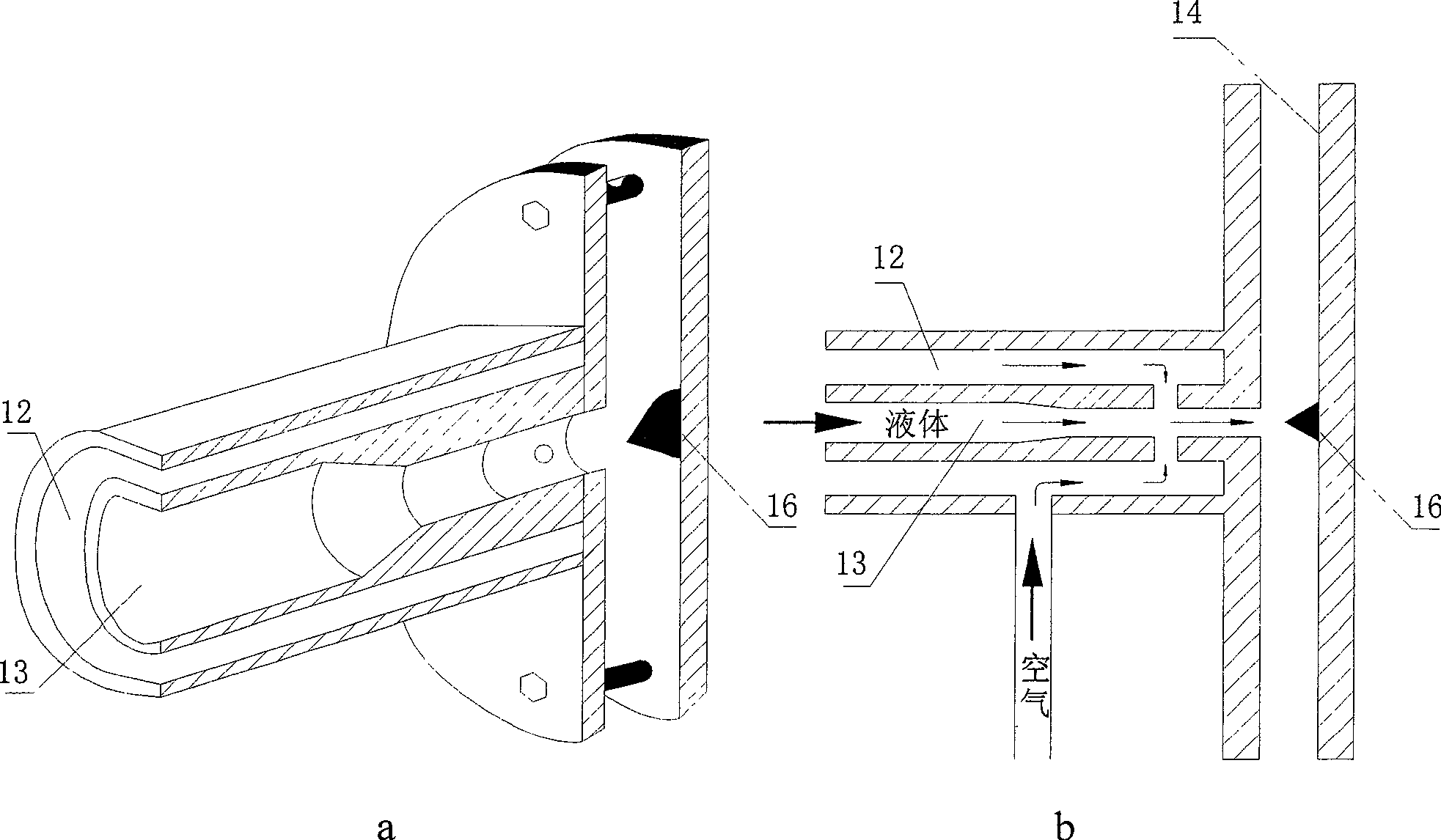

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0028] In order to achieve the purpose of improving the dust removal efficiency of the water spray chamber, it is necessary to destroy the air film on the surface of the fine dust to increase the wettability between the dust and water droplets. The method of destroying the air film can be achieved by increasing the partial pressure of water vapor on the air side and by physical destruction. In addition, physical methods can be used to increase the collision and agglomeration between fine dust and between fine dust and water droplets, so that the fine dust forming "coal ash yarn" becomes larger particles and then removed through the spray section, which can also significantly improve The efficiency of the water spray booth to remove fine dust. The fluid dynamic ultrasonic water spray chamber of the present invention is a comprehensive applica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com