A structure-optimized marine electric control cabinet

A technology for electric control cabinets and ships, which is applied in the direction of electrical equipment shells/cabinets/drawers, electrical components, casings/cabinets/drawer parts, etc., which can solve the problems of slowing down the production and processing efficiency of electric control cabinets and welding quality Guarantee, welding deformation of sheet metal parts and other issues, achieve the effect of structural design and processing and assembly process optimization, improve efficiency, and facilitate disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

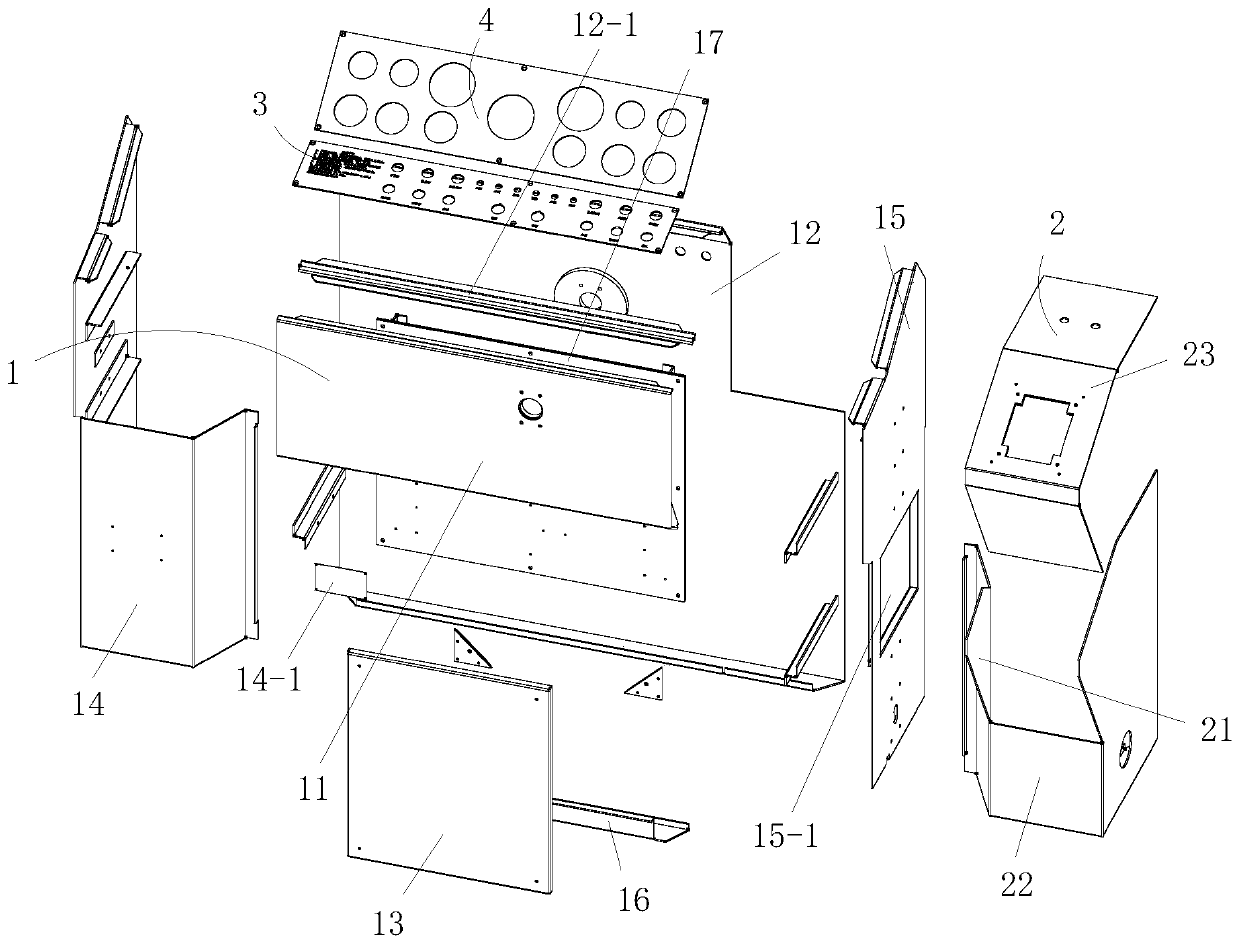

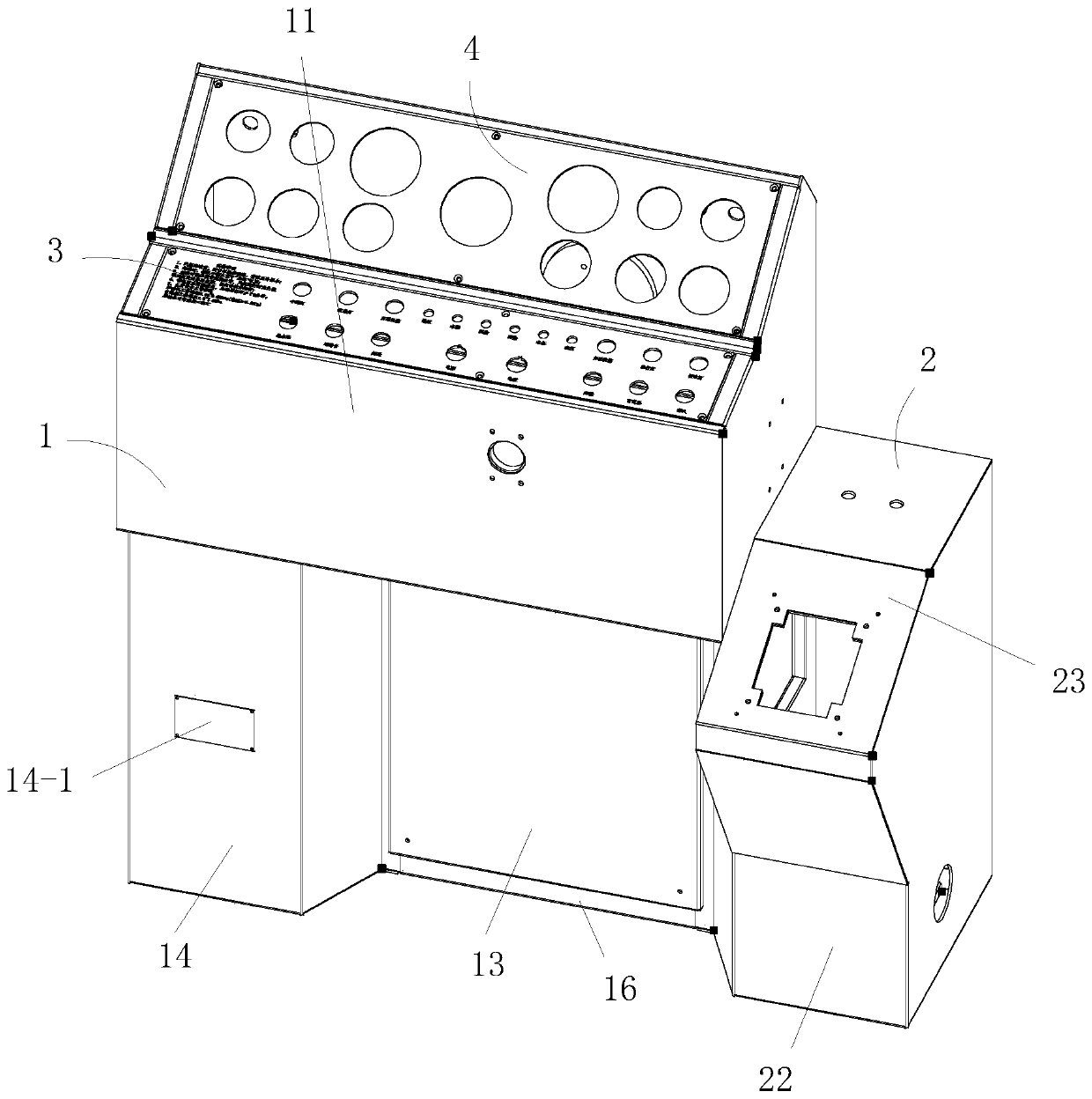

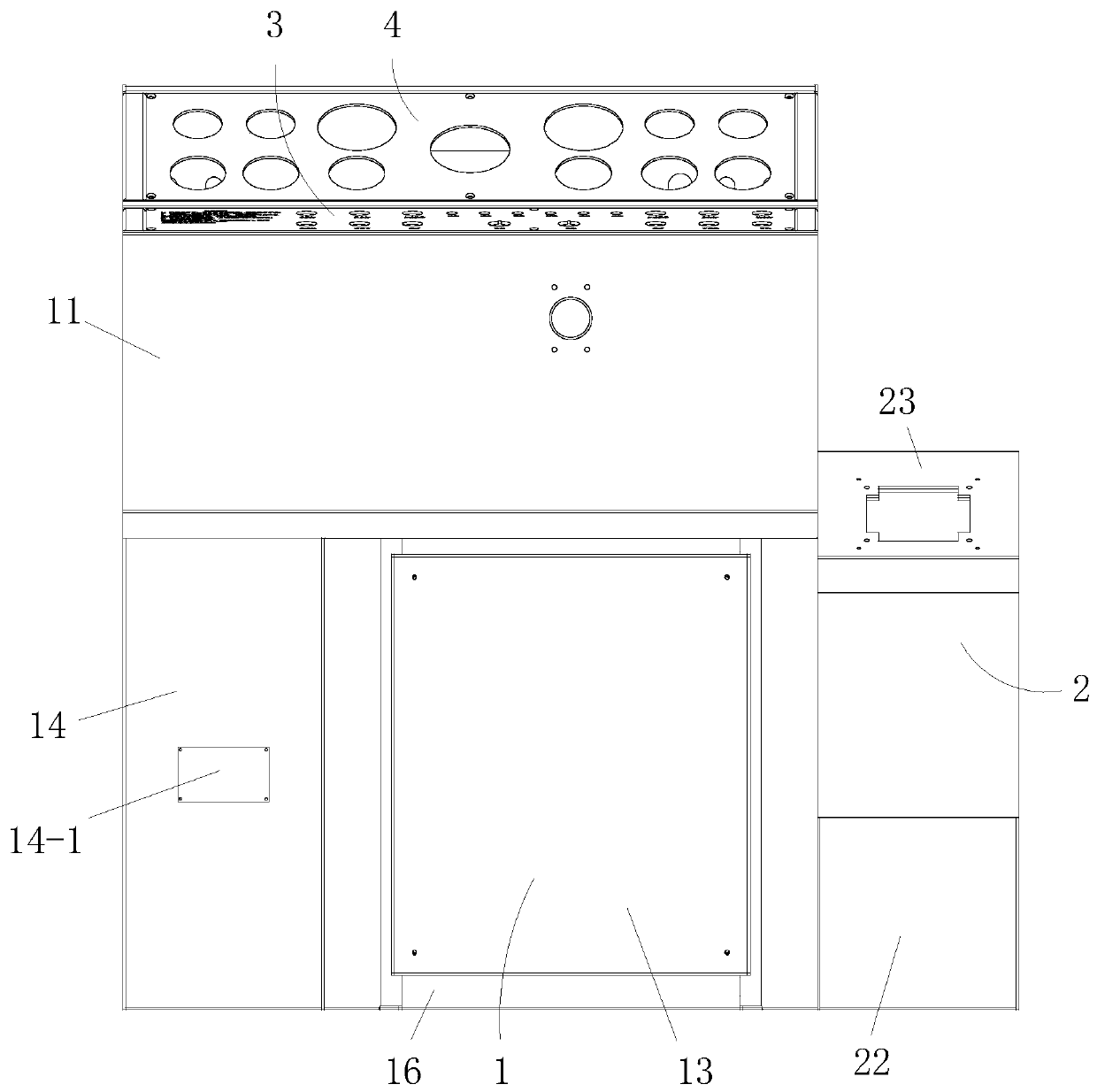

[0016] Figure 1 to Figure 3 The specific embodiment of the present invention is shown: a structurally optimized marine electric control cabinet, including an electric cabinet 1, a control cabinet 2, a switch indicating panel 3 and an instrument panel 4, and the control cabinet 2 is fixed and installed on the side of the electric cabinet 1 by rivets. At the side end, the switch indicating panel 3 is fixedly installed on the upper end of the electrical cabinet 1 through rivets, the instrument panel 4 is fixedly installed on the upper end of the electrical cabinet 1 through rivets, and the switch indicating panel 3 and the instrument panel 4 are fixedly connected through rivets .

[0017] In this embodiment, the electrical cabinet 1 is composed of a front panel 11, a rear panel 12, a cover plate 13, a left side panel 14, a middle side panel 15, a bottom brace 16 and an electrical installation panel 17. The left side panel 14 Fixedly connected with the rear panel 12 through rive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com