Installation method of column foundation of overhead contact system on railway steel-concrete composite girder

A technology of steel-concrete combined beam and installation method, which is applied in basic structure engineering, construction and other directions, can solve the problems of high construction difficulty, low construction efficiency and many restrictive conditions, so as to improve the quality of pouring and forming, facilitate hoisting and installation, increase safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

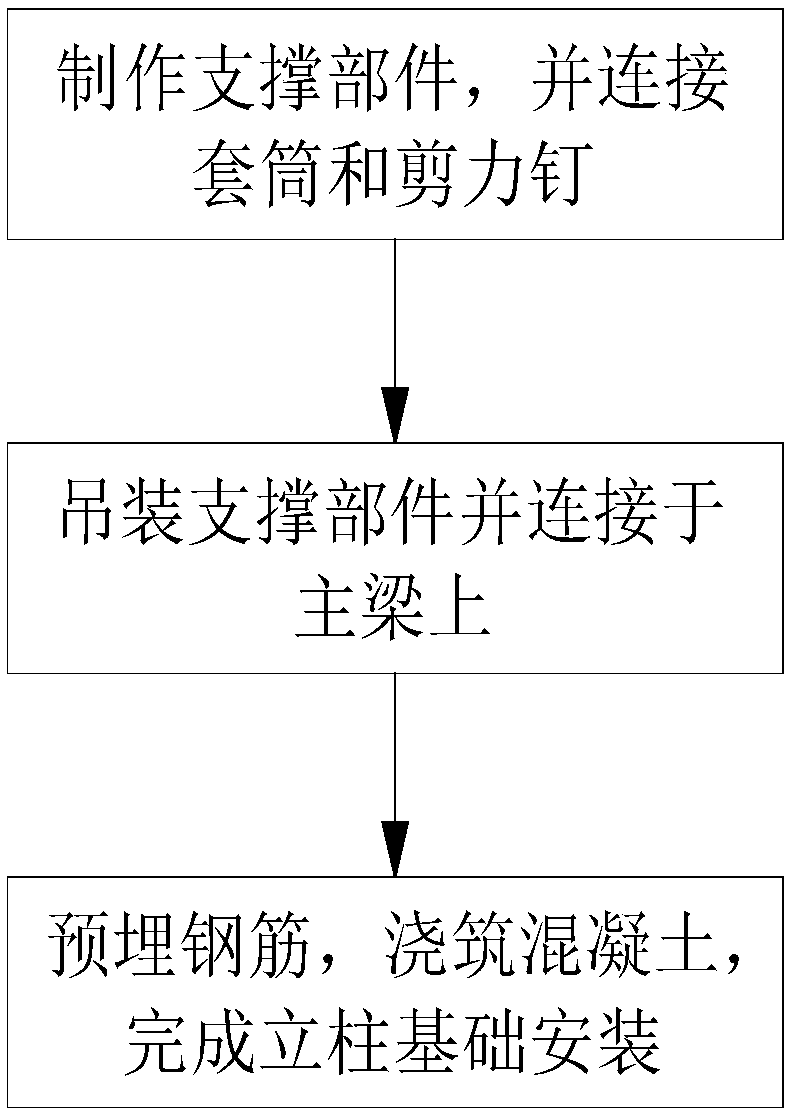

[0037] Such as figure 1 As shown, the installation method of catenary column foundation on a kind of railway steel-concrete combined beam of the present invention comprises the following steps:

[0038] Step 1, making a supporting part, connecting several sleeves and several shear nails 5 to the top of the supporting part, and all the sleeves are arranged around the installation place of the column 1;

[0039] Step 2, hoisting and connecting all the supporting components to the main beam 2;

[0040] Step 3: Set up pre-embedded steel bars on the tops of all the supporting components and the top of the main beam 2, and pour concrete on the tops of the supporting components and the top of the main beam 2 to form a reinforced concrete layer 3, and complete the installation of the column foundation.

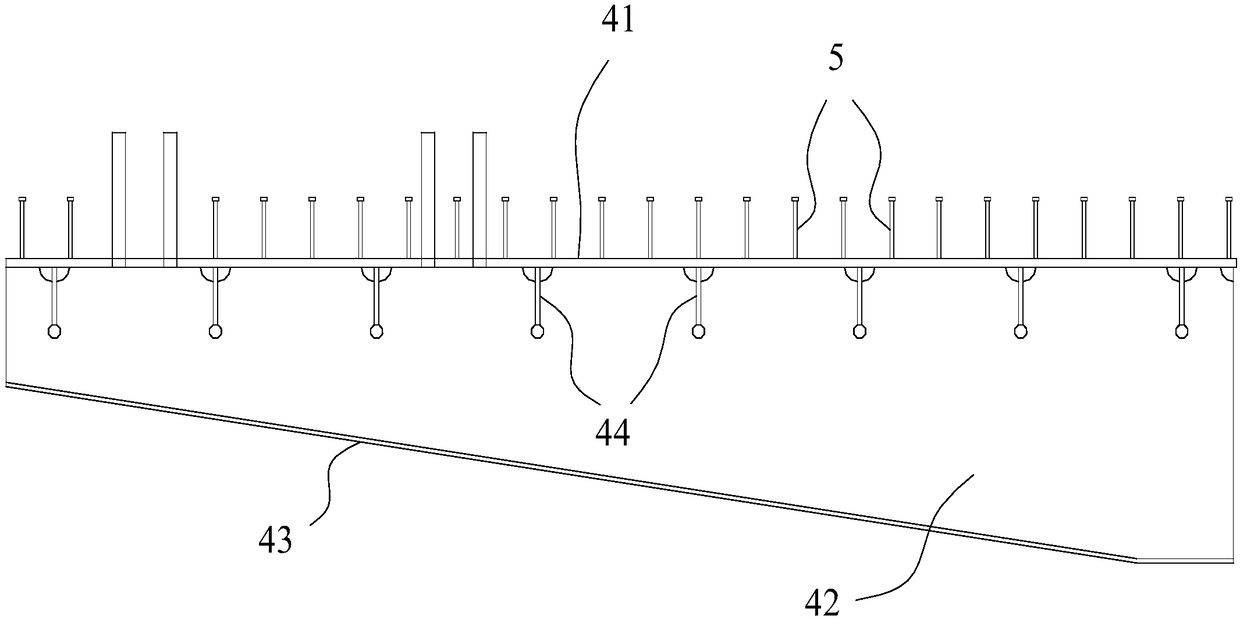

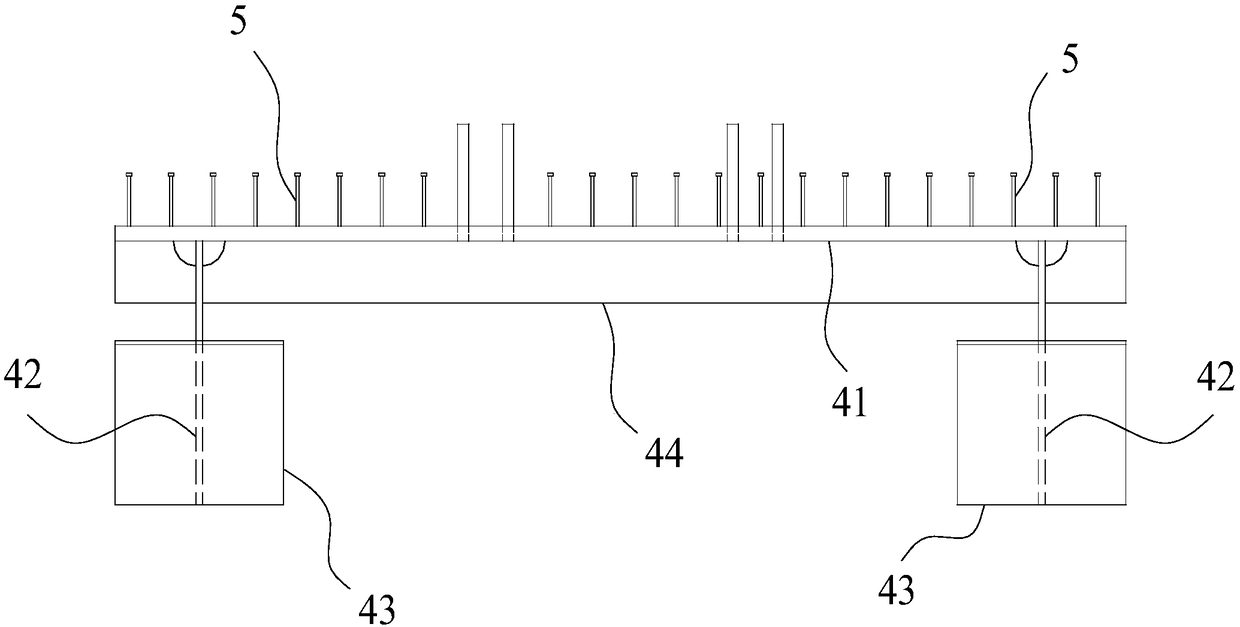

[0041] First assemble the supporting parts, the supporting parts include a top plate 41, a web 42 and a bottom plate 43 of steel structure, two of the webs 42 are arranged below the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com