Continuous pouring processing production method for cement products

A production method and technology for cement products, which are applied in the field of cement product pouring, can solve the problems of poor covering air forming quality, being located under cement, and cement surging, etc., and achieve the effects of high pouring forming quality, stable discharging and less air covering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

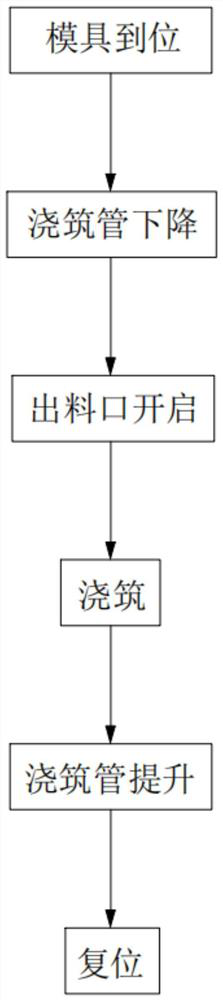

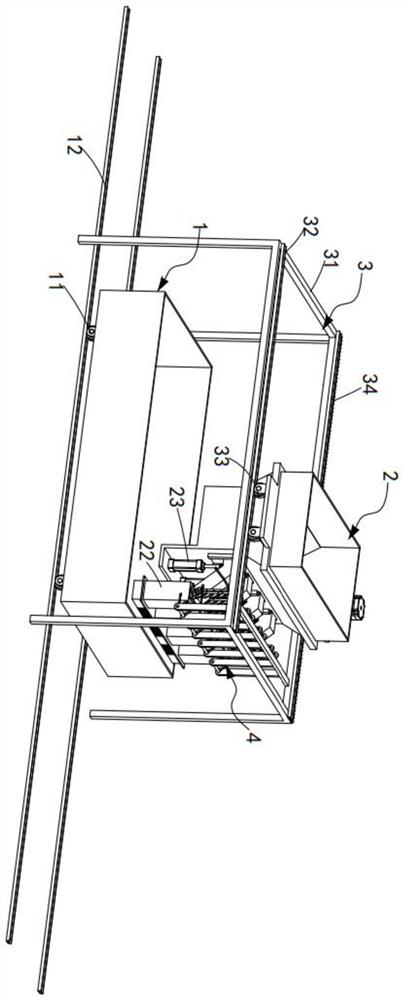

[0063] Such as Figures 1 to 13 Shown, a kind of cement products continuous pouring processing production method, comprises the following steps:

[0064] Step 1. The mold is in place, and the pouring mold 1 with rollers 11 installed at the bottom is moved along the laid track 12 by a tractor to the bottom of the pouring bin 2 to wait for pouring of cement;

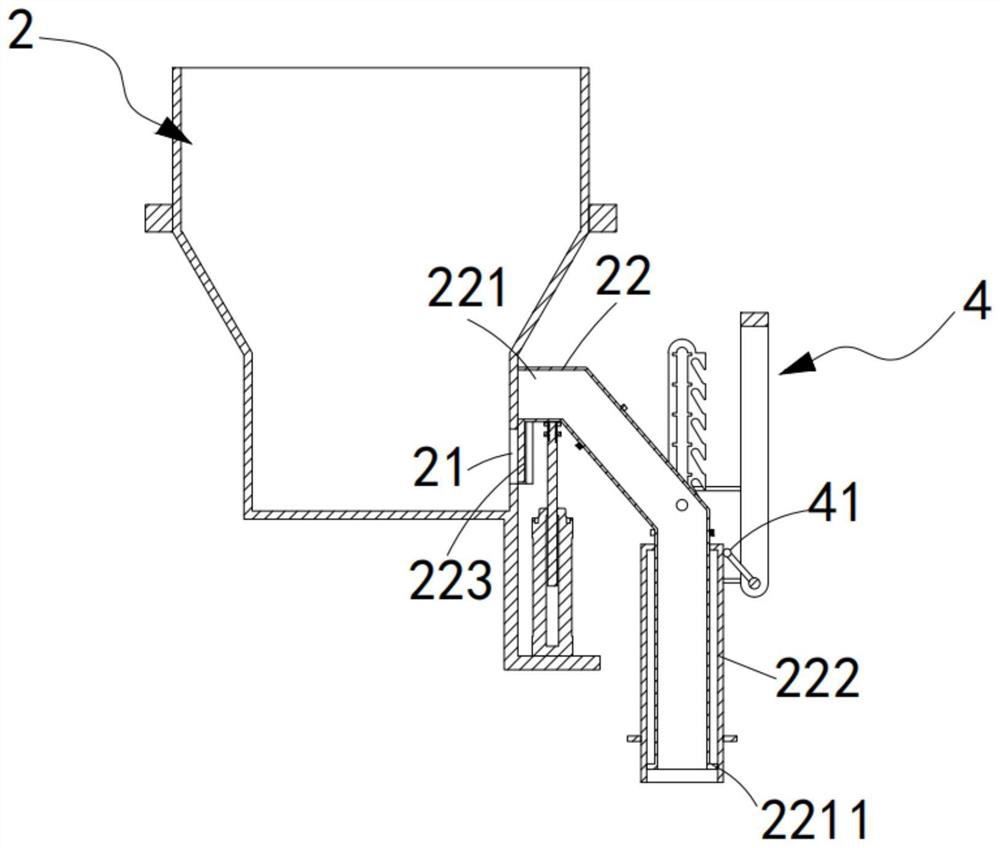

[0065] Step 2: the pouring pipe is lowered, and after the pouring mold 1 is in place, the pouring pipe 22 located at the outlet 21 of the pouring bin 2 slides and extends into the pouring mold 1;

[0066] Step 3, the discharge port is opened, after the pouring pipe 22 extends into the pouring mold 1, the control cabinet controls the hydraulic cylinder 23 located at the discharge port 21 to start, the discharge port 21 is opened, and the pouring chamber 2, the cement in the pouring pipe 22 is discharged into the pouring mold 1;

[0067] Step 4, pouring, after the discharge port 21 is opened, the walking mechanism 3 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com