Manual hole digging pile concrete protection wall pouring construction system and construction method thereof

A technology of concrete retaining wall and artificial digging pile, which is applied in construction, sheet pile wall, infrastructure engineering and other directions, can solve the problems of complicated concrete pouring process, high labor intensity and long pouring period of concrete retaining wall, so as to reduce the concrete pouring period. , the construction pace is fast, the effect of simplifying the construction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

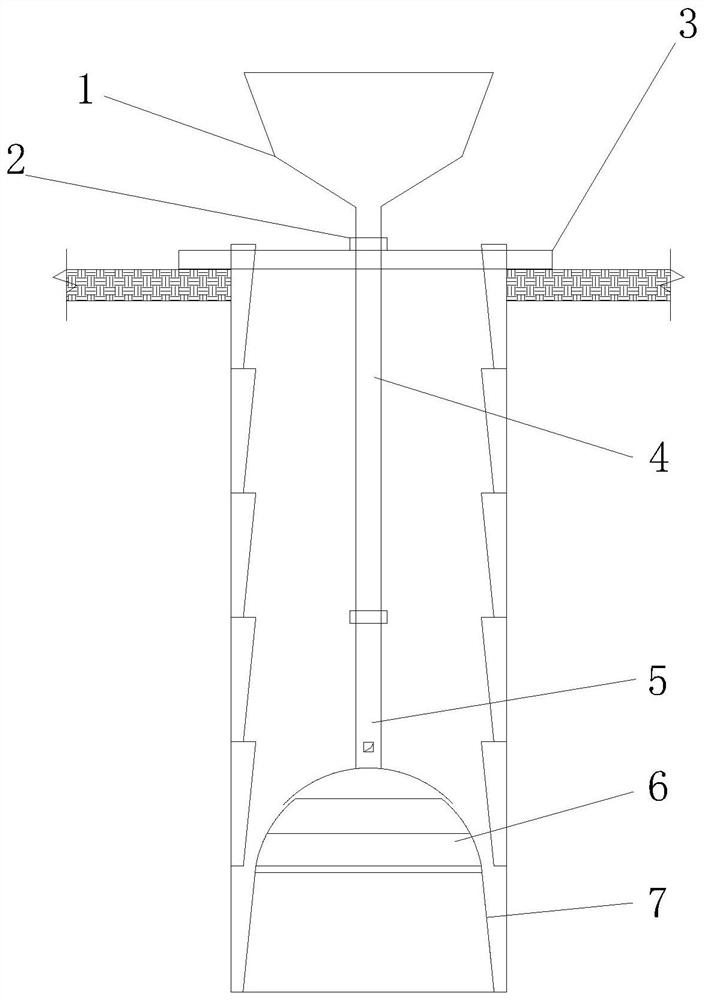

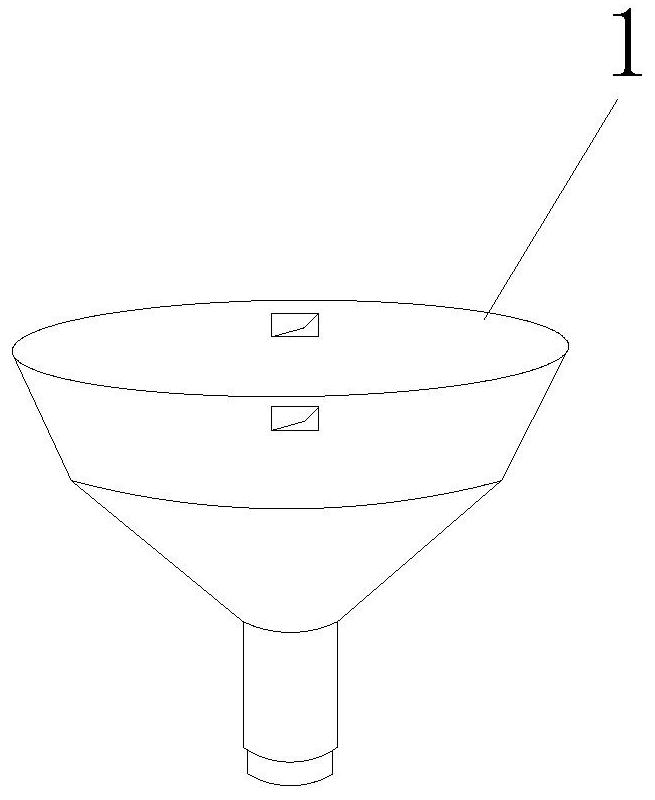

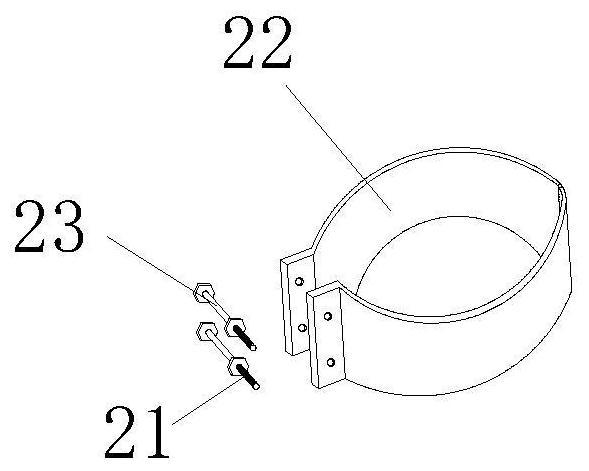

[0042] From Figure 1-8 It can be seen that the concrete pouring construction system for artificial excavation piles in this embodiment includes a hopper 1, the bottom of the hopper 1 is provided with a connecting buckle 2 and a conduit 4, the hopper 1 communicates with the conduit 4, and the outer ring of the conduit 4 is arranged There is a steel shelf 3, the connection between the hopper 1 and the conduit 4 is fixed by the connecting buckle 2, the connecting buckle 2 is supported on the steel shelf 3, the bottom of the conduit 4 is provided with a customized conduit 5, and the outer ring of the customized conduit 5 is opened There is a hole 51, and the bottom of the customized conduit 5 is provided with a concrete splitter 6 and a shaped steel casing 7. The concrete splitter 6 is composed of a first frustum-shaped steel retaining wall 61, a second frustum-shaped steel retaining wall 62, and a spherical custom-made steel plate 63. A shaped steel casing 7 is arranged at the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com