Buckling-restrained steel pipe-FRP confined concrete combined member and construction method

A technology of restrained concrete and -FRP, which is applied in the direction of building components, earthquake resistance, and building construction, can solve the problems of composite structure bearing capacity failure, low compressive stiffness of fiber cloth, and interface detachment, so as to avoid corrosion and improve The overall stiffness and ultimate bearing capacity, the effect of slowing buckling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

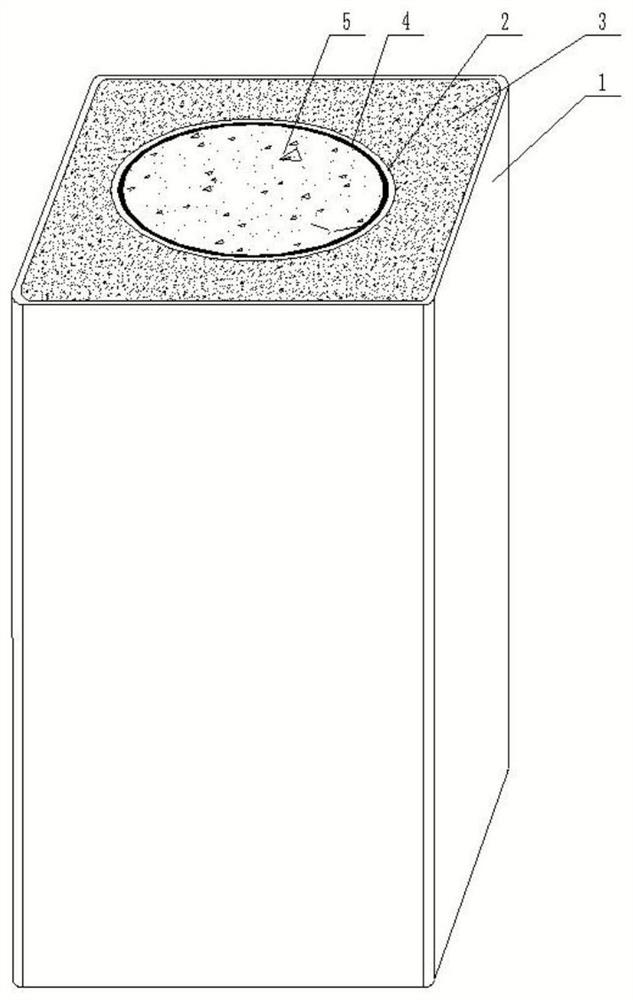

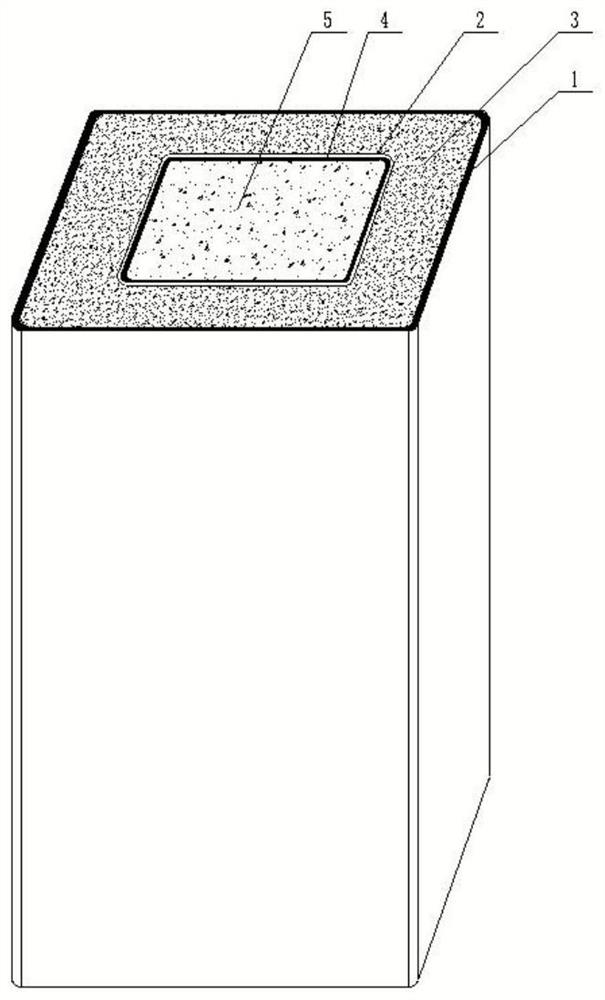

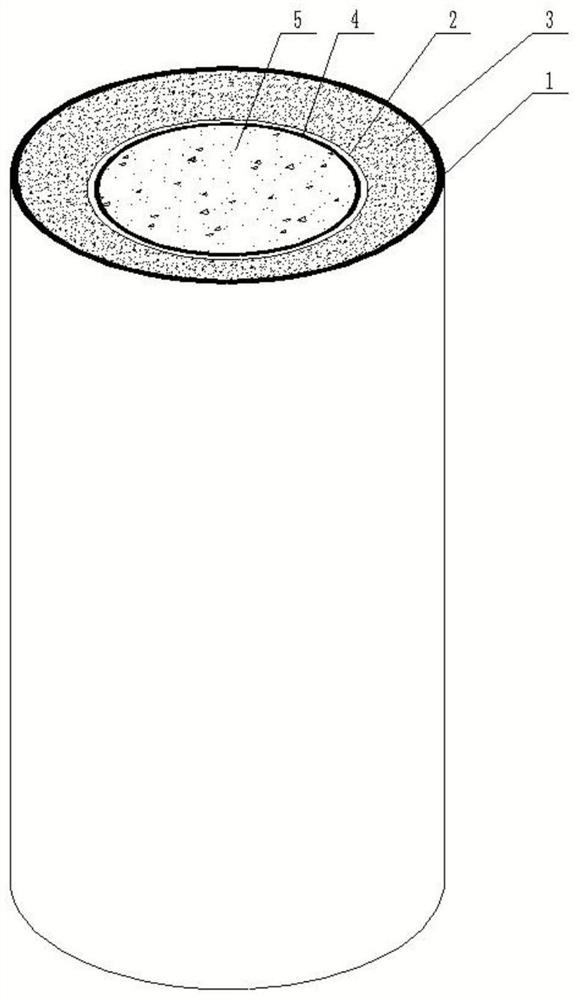

[0050] like Figure 1-14 , an anti-buckling steel pipe-FRP constrained concrete composite member, comprising a FRP winding forming pipe 1, and also comprising a steel pipe 2, which is arranged in the FRP winding forming pipe 1, and a high-strength mixing pipe is poured between the steel pipe 2 and the FRP winding forming pipe 1 Material layer 3; Circumferential fiber FRP layer 4, the fiber direction is arranged in the circumferential direction of the pipe, fixed on the inner wall of the steel pipe 2, a core concrete layer 5 is poured in the steel pipe 2, and the circumferential fiber FRP layer 4 is located between the core concrete and the inner wall of the steel pipe 2. ; Reinforcing keys are provided with several, one side of several reinforcing keys is fixed on the outer wall of the steel pipe 2, the reinforcing keys extend into the high-strength mixture layer 3, and the reinforcing keys are fixed to the high-strength mixture layer 3, and the other side of the reinforcing ke...

Embodiment 2

[0075] like Figure 14 , the difference from Embodiment 1 is that the outer casing of the steel pipe 2 is provided with a number of reinforcement rings 11, the outer wall of the reinforcement ring 11 has the same structure as the outer wall of the steel pipe 2, and the reinforcement ring 11 is provided with a number of through holes, the hook edges, and the ends pass through the through holes. The reinforcement ring 11 is fixed, and the hook edge is fixedly connected with the reinforcement ring 11 . By setting the reinforcement ring 11 , the purpose is to further improve the connection strength between the reinforcement key and the high-strength mixture layer 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com