Multi-pier system high in durability and resistant to earthquake collapsing and construction method

A durable and anti-seismic technology, used in bridge parts, erection/assembly of bridges, bridges, etc., can solve the problems of difficult seismic design of multi-column piers, difficult seismic damage control design, lack of safety confidence, etc., and achieve good earthquake resistance. Collapse ability, convenient construction and good repairability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

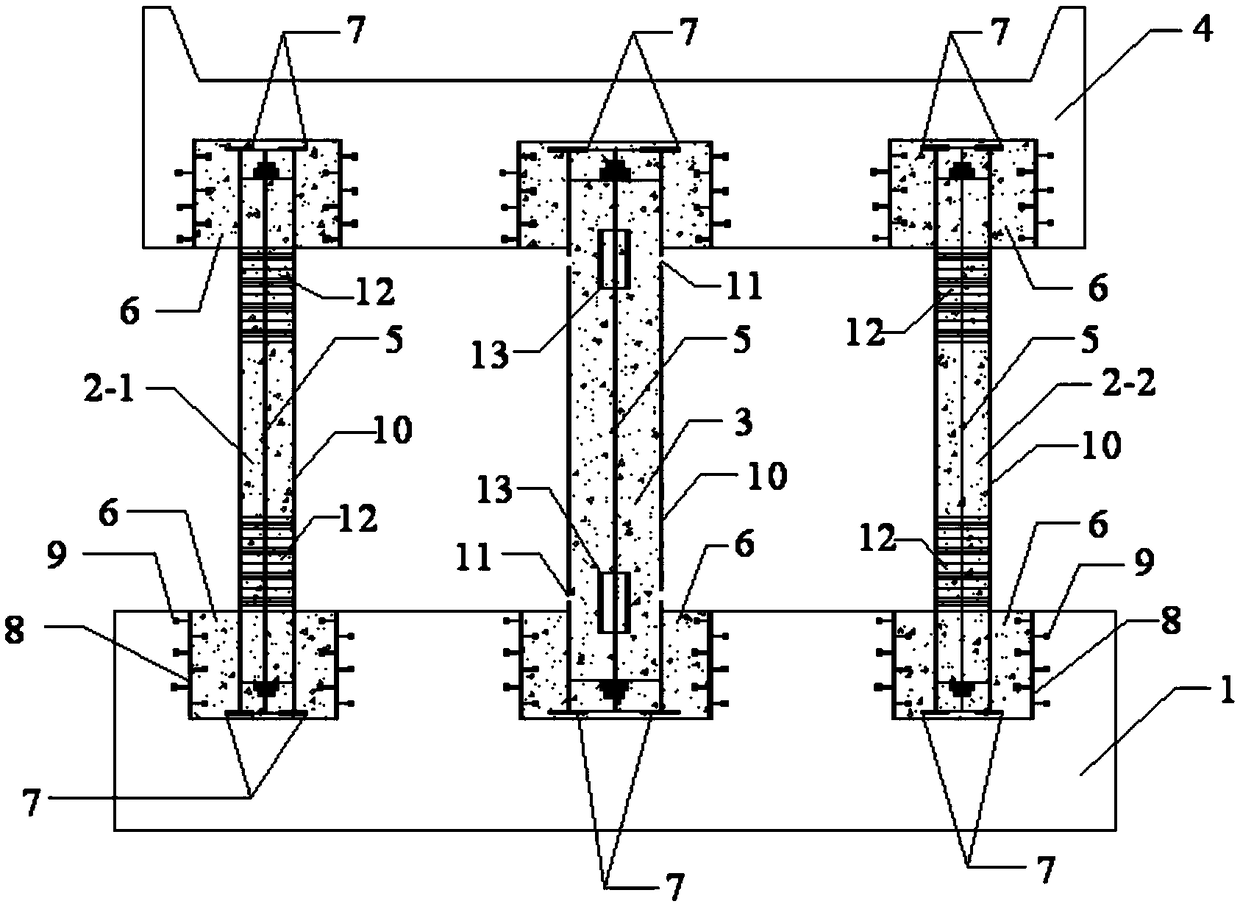

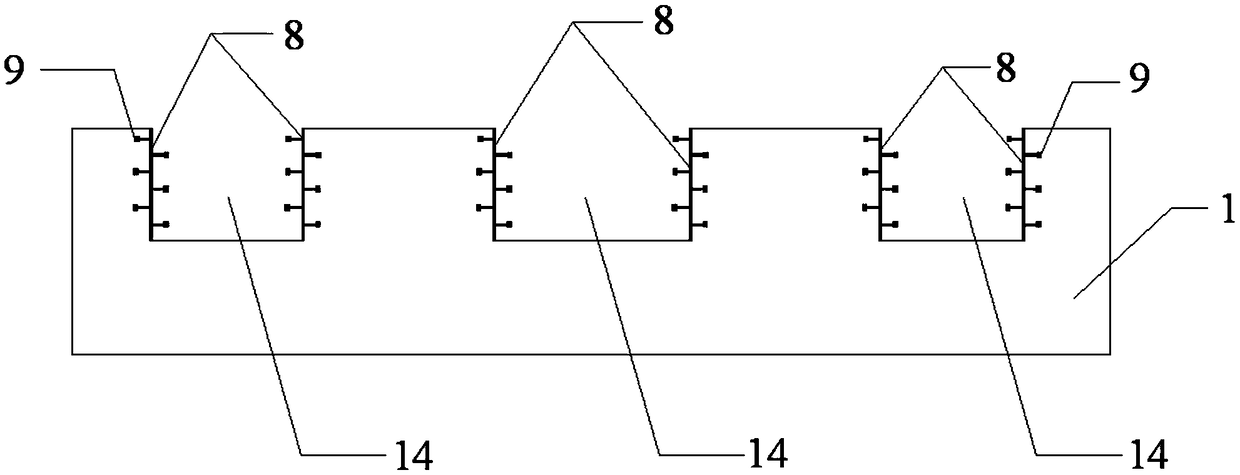

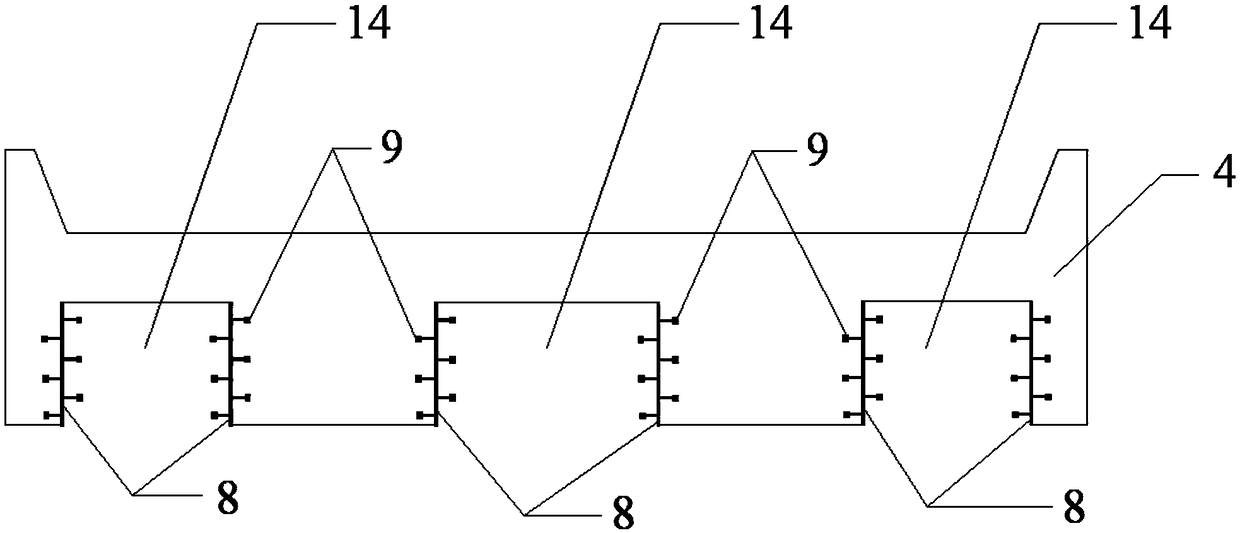

[0044] As shown in the figure, a multi-column pier system with high durability and anti-earthquake collapse consists of cap (1), left pier (2-1), right pier (2-2), middle pier (3), and prefabricated cover Beams (4), unbonded prestressed tendons (5), self-compacting micro-expansion high-strength concrete (6), pullout rings (7), ring-shaped steel plates (8), studs (9), stainless steel pipes (10), It consists of a truncated ring (11), a circular CFRP (12), a shear key (13), and a reserved slot (14).

[0045] A left pier (2-1) and a right pier (2-2) are respectively arranged on the left and right sides of the upper part of the cap (1), a middle pier (3) is arranged in the middle, and a prefabricated cover beam (4) is arranged on the top of the pier. The cross-sectional size of the middle pier (3) is obviously larger than that of the left pier (2-1) and the right pier (2-2), and the cross-sectional dimensions of the left pier (2-1) and the right pier (2-2) are equal.

[0046] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com