Heat-resistant aluminum alloy soldering composite material and preparation method thereof

A composite material and aluminum alloy technology, which is applied in the field of heat-resistant 3003 aluminum alloy brazing composite material and its preparation, can solve the problems affecting the yield and economic benefits, collapse and metal accumulation, and warping and deformation of workpieces, and improve the resistance to Collapse properties, strength increase, effects of mechanical properties optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

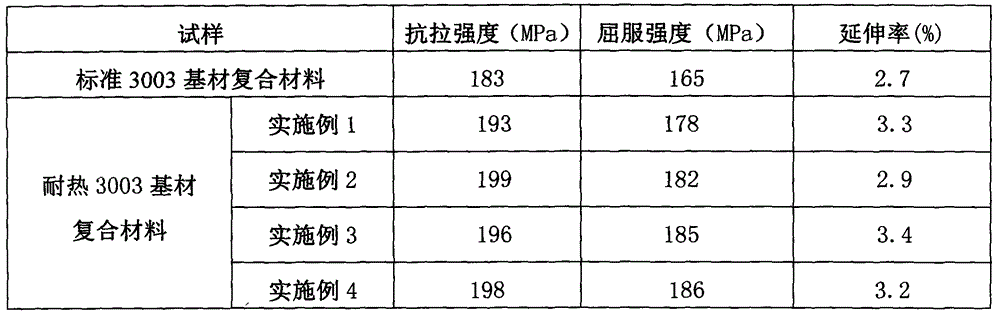

Embodiment 1

[0033] Core:

[0034] 3003 aluminum alloy, including the following composition by weight percentage: 0.70% Si, 0.4% Fe, 0.2% Cu, 1.5% Mn, 0.02% Mg, 0.1% Zr, 0.02% Cr, 0.12% Zn, 0.02% Ti, the balance is Al and unavoidable impurities.

[0035] Leather:

[0036] 4343 aluminum alloy, comprising the following composition by weight percentage: 8.7% Si, 0.2% Fe, 0.03% Cu, 0.04% Mn, 0.02% Mg, 0.08% Zr, 0.02% Cr, 0.08% Zn, 0.025% Ti, the balance is Al and unavoidable impurities.

[0037] The specific preparation method is as follows:

[0038] 1) Mix 3003 aluminum ingots with a weight fraction of 30-35% and molten aluminum with a weight fraction of 65-70% and a concentration of 99.7% at 740°C, put them into a guide furnace, put in a high-efficiency refining agent, and carry out at 680°C After the ingot casting is completed, cut the head and tail to ensure that the ingot is straight and free of casting segregation, and the thickness difference between the head, middle and tail and th...

Embodiment 2

[0046] Core:

[0047] 3003 aluminum alloy, comprising the following composition by weight percentage: 0.75% Si, 0.45% Fe, 0.1% Cu, 1.5% Mn, 0.02% Mg, 0.1% Zr, 0.02% Cr, 0.12% Zn, 0.02% Ti, the balance is Al and unavoidable impurities.

[0048] Leather:

[0049] 4045 aluminum alloy, comprising the following composition by weight percentage: 10.2% Si, 0.3% Fe, 0.02% Cu, 0.04% Mn, 0.02% Mg, 0.08% Zr, 0.02% Cr, 0.08% Zn, 0.025% Ti, the balance is Al and unavoidable impurities.

[0050] The preparation method is the same as in Example 1.

Embodiment 3

[0052] Core material, skin material composition are with embodiment 1.

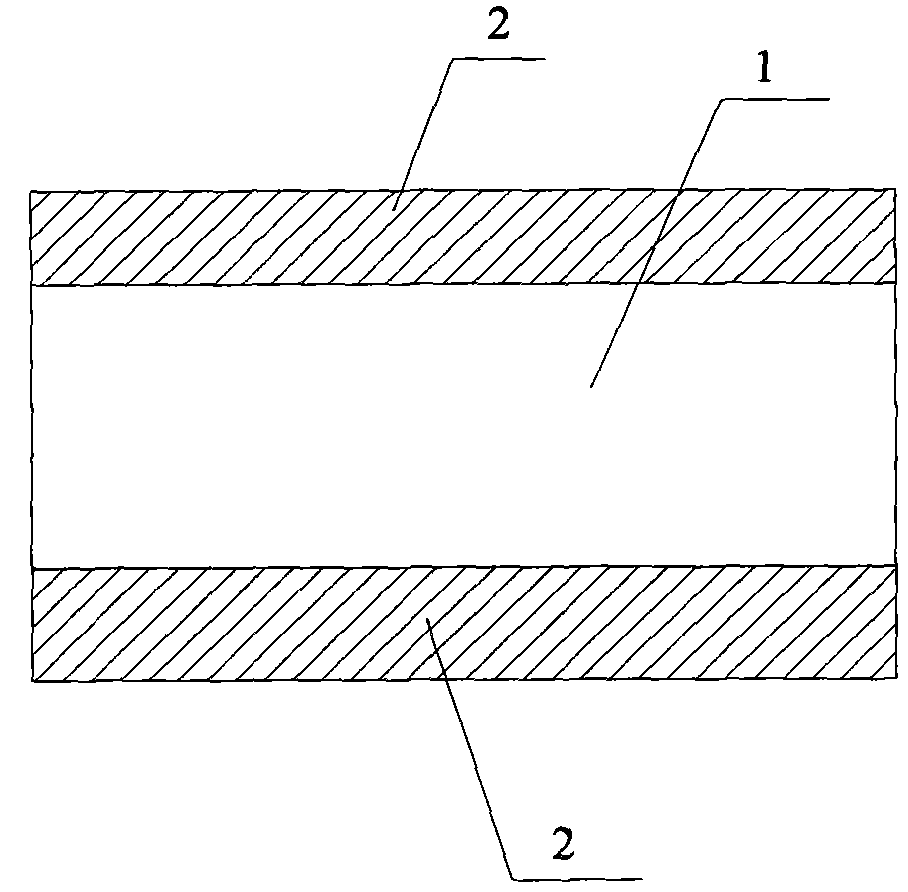

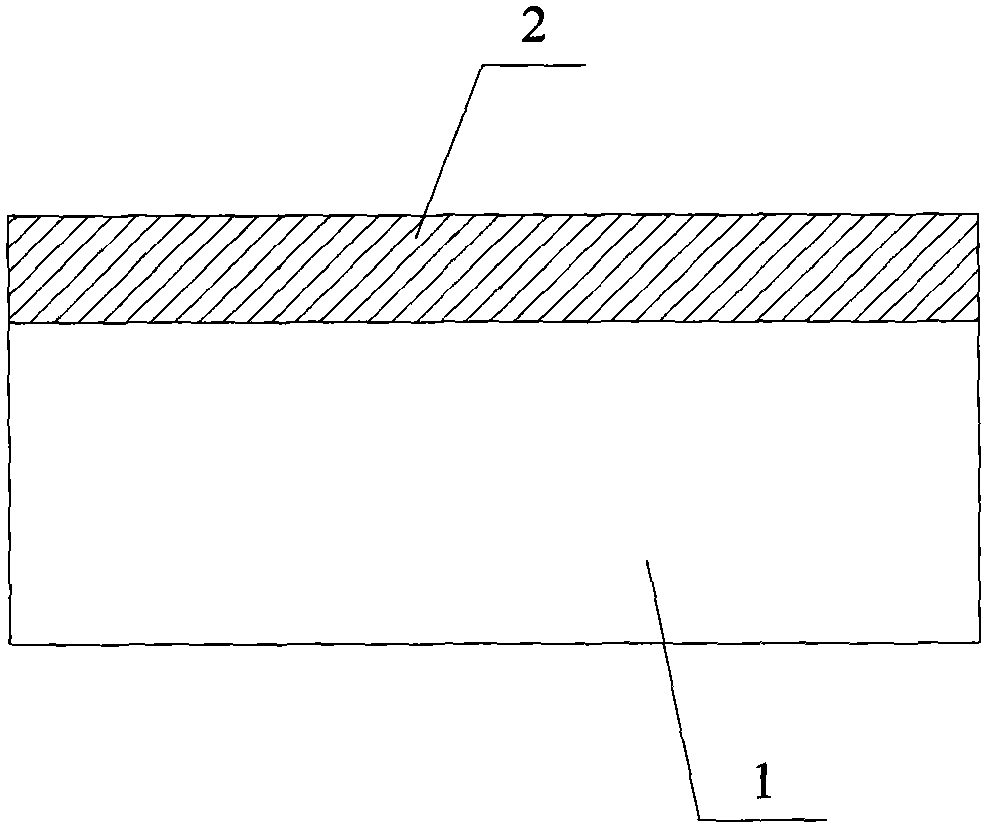

[0053] When preparing, as figure 2 As shown, each layer of core material 1 and skin material 2 is fastened and welded, and the remaining methods are the same as in embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com