Hydroxyapatite-silk fibroin composite reinforced calcium phosphate bone cement and preparation method thereof

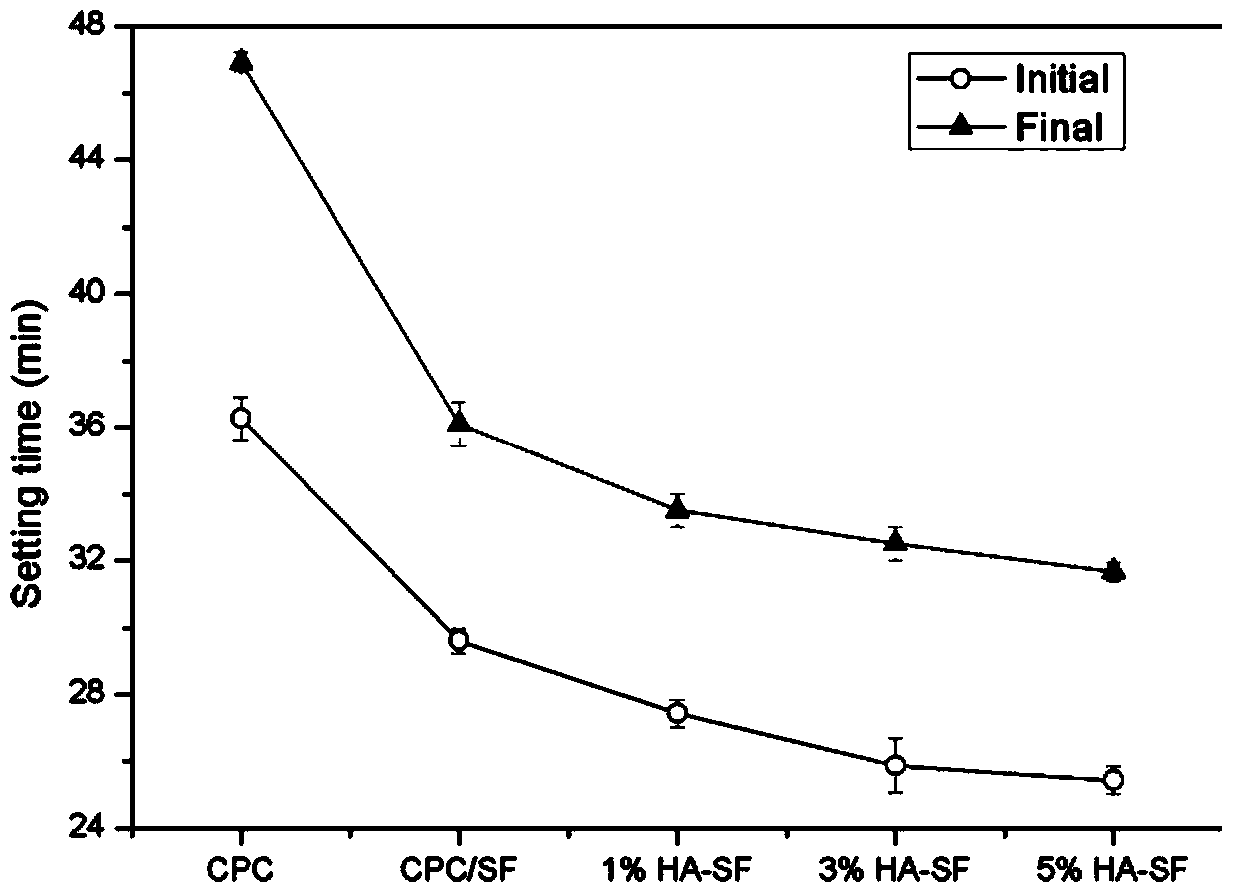

A technology of calcium phosphate bone cement and hydroxyapatite, applied in the field of medicine, can solve the problems of difficult CPC mechanical strength, exothermic damage to surrounding tissues, toxic polymer biocompatibility, etc. Collapse resistance and the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Preparation of silk fibroin

[0033] Add silk to 0.02mol / L Na 2 CO 3 Boil in the solution for 20 minutes, and scrub with deionized water several times to remove sericin. After drying, dissolve in 9.3mol / L LiBr solution, dissolve at 60°C for 4 hours, dialyze with deionized water for 48 hours, remove silk fibroin aggregates by high-speed centrifugation, and obtain concentrations of 5wt.% and 20wt.% after concentration or dilution silk fibroin solution.

[0034] (2) Preparation of hydroxyapatite-silk fibroin composite

[0035] Weigh 7.37g Ca(OH) 2 Dissolved in 38mL water to prepare 16wt.% Ca(OH) 2 solution, after it dissolves, add 12.5mL of 20wt.% SF solution and mix well. Measure 4mLH 3 PO 4 Dilute slightly with 6mL of water, and slowly drop it into the aforementioned mixed solution while stirring at high speed, and find that the solution gradually becomes cloudy. Finally with NH 3 ·H 2 O adjust the pH to 9.0 and continue stirring for 3h. The product is fi...

Embodiment 2

[0039] (1) Preparation of silk fibroin

[0040]Add silk to 0.02mol / L Na 2 CO 3 Boil in the solution for 40 minutes, and scrub with deionized water several times to remove sericin. After drying, it was dissolved in 9.3mol / L LiBr solution, dissolved at 60°C for 4 hours, dialyzed in deionized water for 48 hours, and centrifuged at high speed to remove silk fibroin aggregates to obtain a silk fibroin solution with a concentration of 5wt.%.

[0041] (2) Preparation of hydroxyapatite-silk fibroin composite

[0042] Weigh 5.16g Ca(OH) 2 Dissolve in 30mL water to make Ca(OH) 2 solution, after it dissolves, add 60mL of 5wt.% SF solution and mix well. Measure 3.0mL H 3 PO 4 Slightly diluted with 5 mL of water, and slowly dropped into the aforementioned mixed solution while stirring at high speed, it was found that the solution gradually became cloudy. Finally with NH 3 ·H 2 O adjust the pH to 9.0 and continue stirring for 3h. The product is filtered, washed, dried and ground ...

Embodiment 3

[0046] (1) Preparation of silk fibroin

[0047] Add mulberry silk to 0.02mol / L Na 2 CO 3 Boil in the solution for 30 minutes, and scrub with deionized water several times to remove sericin. After drying, dissolve in 9.3mol / L LiBr solution, dissolve at 60°C for 4 hours, dialyze with deionized water for 48 hours, and centrifuge at high speed to remove silk fibroin aggregates, and prepare silk fibroin solutions with a concentration of 5wt.% and 10wt.%. .

[0048] (2) Preparation of hydroxyapatite-silk fibroin composite

[0049] Weigh 4.45g Ca(OH) 2 Dissolve in 25mL water to make Ca(OH) 2 solution, after it dissolves, add 40mL of 10wt.% SF solution and mix well. Measure 2.5mL H 3 PO 4 Slightly diluted with 5 mL of water, and slowly dropped into the aforementioned mixed solution while stirring at high speed, it was found that the solution gradually became cloudy. Finally with NH 3 ·H 2 O adjust the pH to 9.0 and continue stirring for 3h. The product is filtered, washed,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com