Patents

Literature

92results about How to "Delayed buckling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

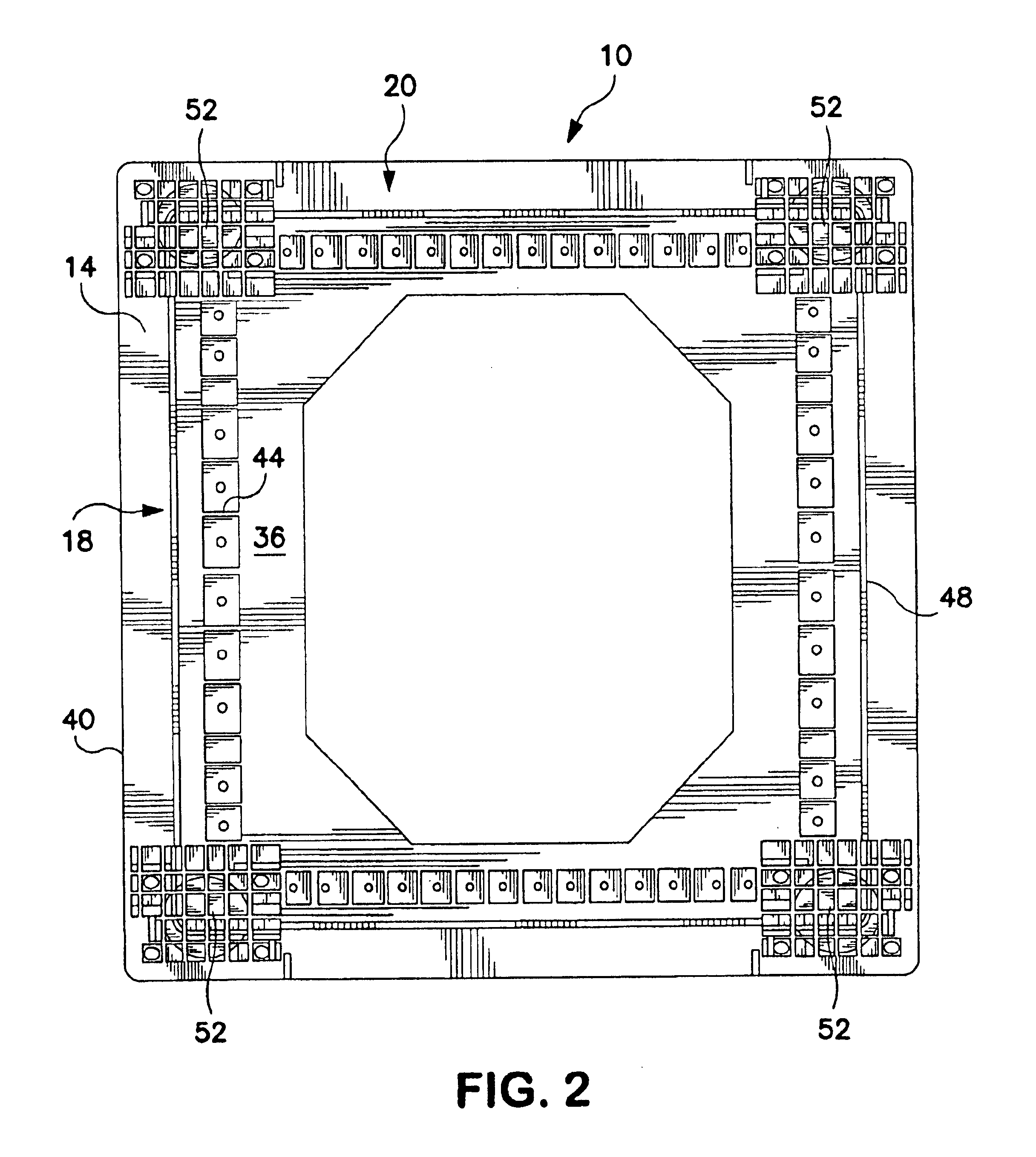

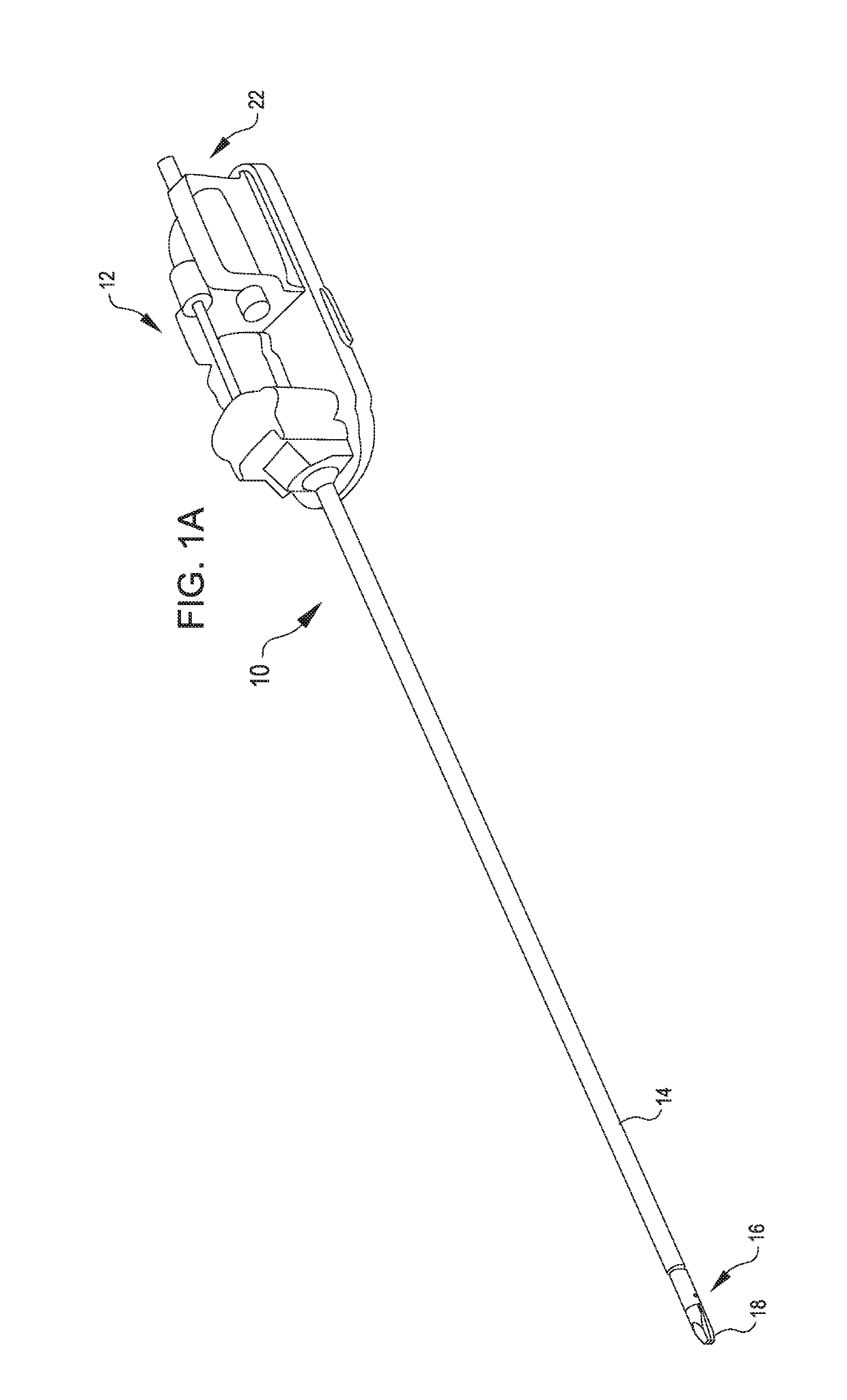

Wrist architecture

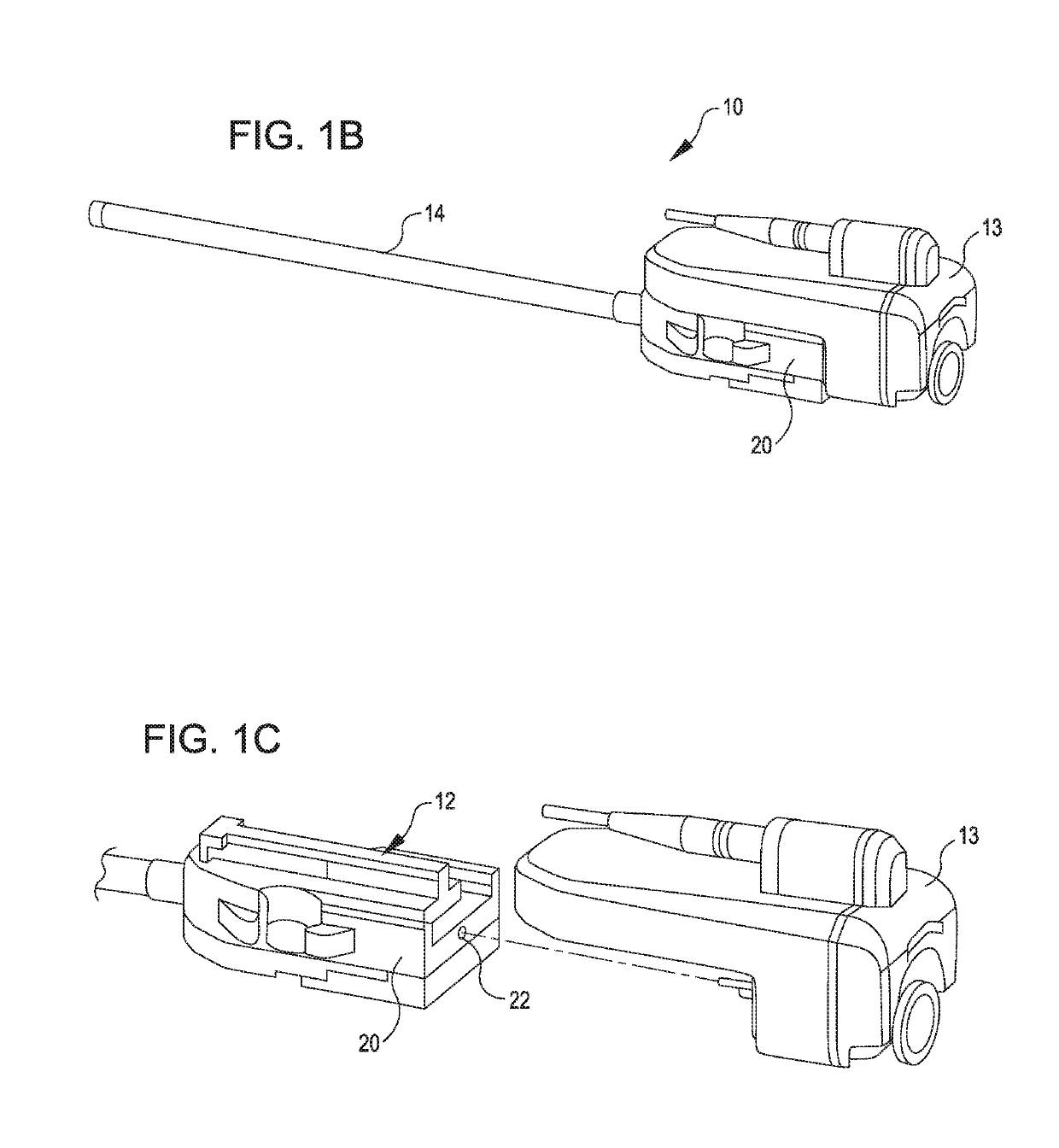

ActiveUS11234700B2Highly compressibleLow efficiencySurgical manipulatorsSurgical robotsPhysical medicine and rehabilitationEngineering

A surgical device includes an elongated shaft, an end effector, and a wrist assembly. The wrist assembly includes a first outer link, a first inner link, and a second outer link. The first outer link is connected to the shaft and includes first gear teeth. The first inner link is pivotally coupled with the first outer link. The second outer link is pivotally coupled with the first inner link. The second outer link includes second gear teeth that interface with the first gear teeth and control orientation of the first inner link relative to the first outer link and the first outer link throughout a range of orientations of the wrist assembly.

Owner:INTUITIVE SURGICAL OPERATIONS INC

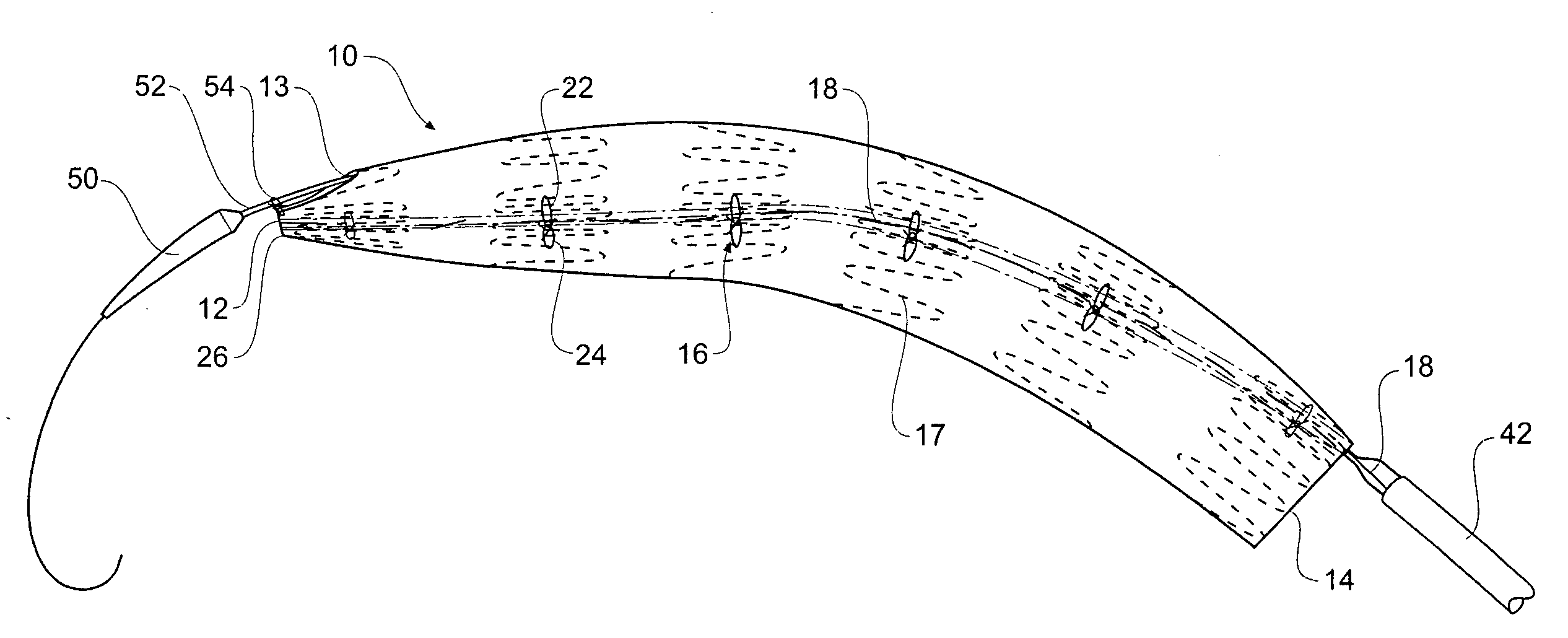

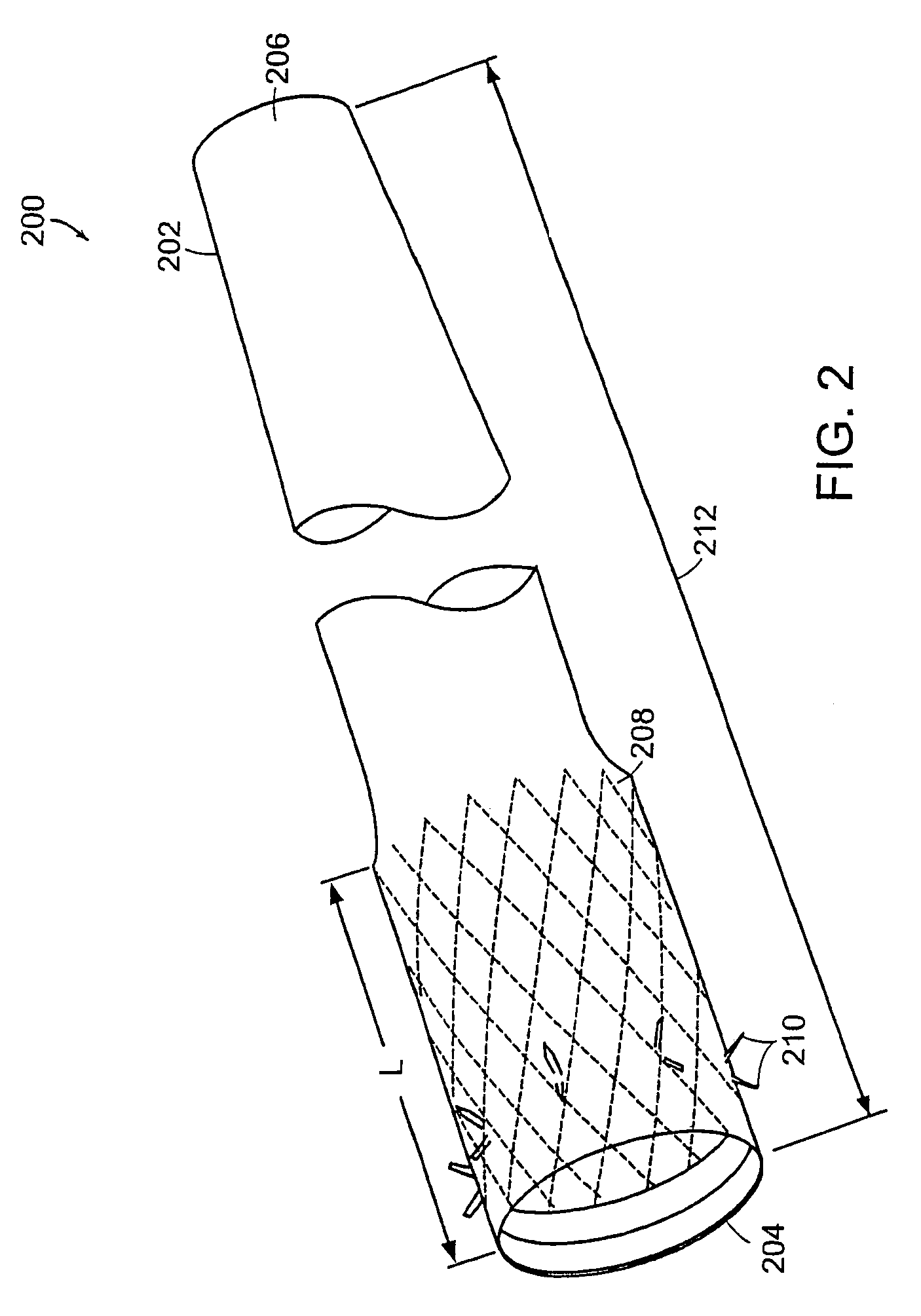

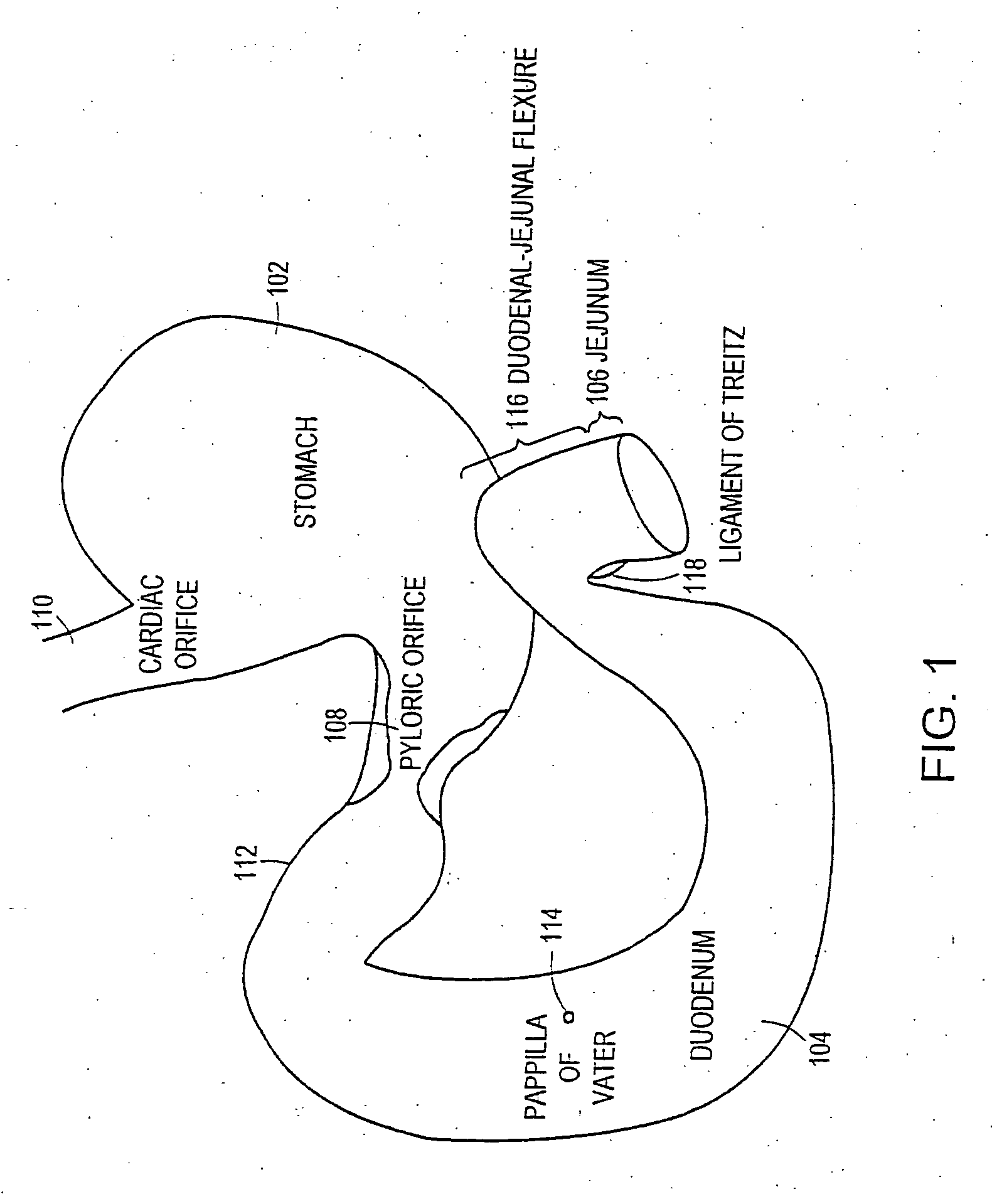

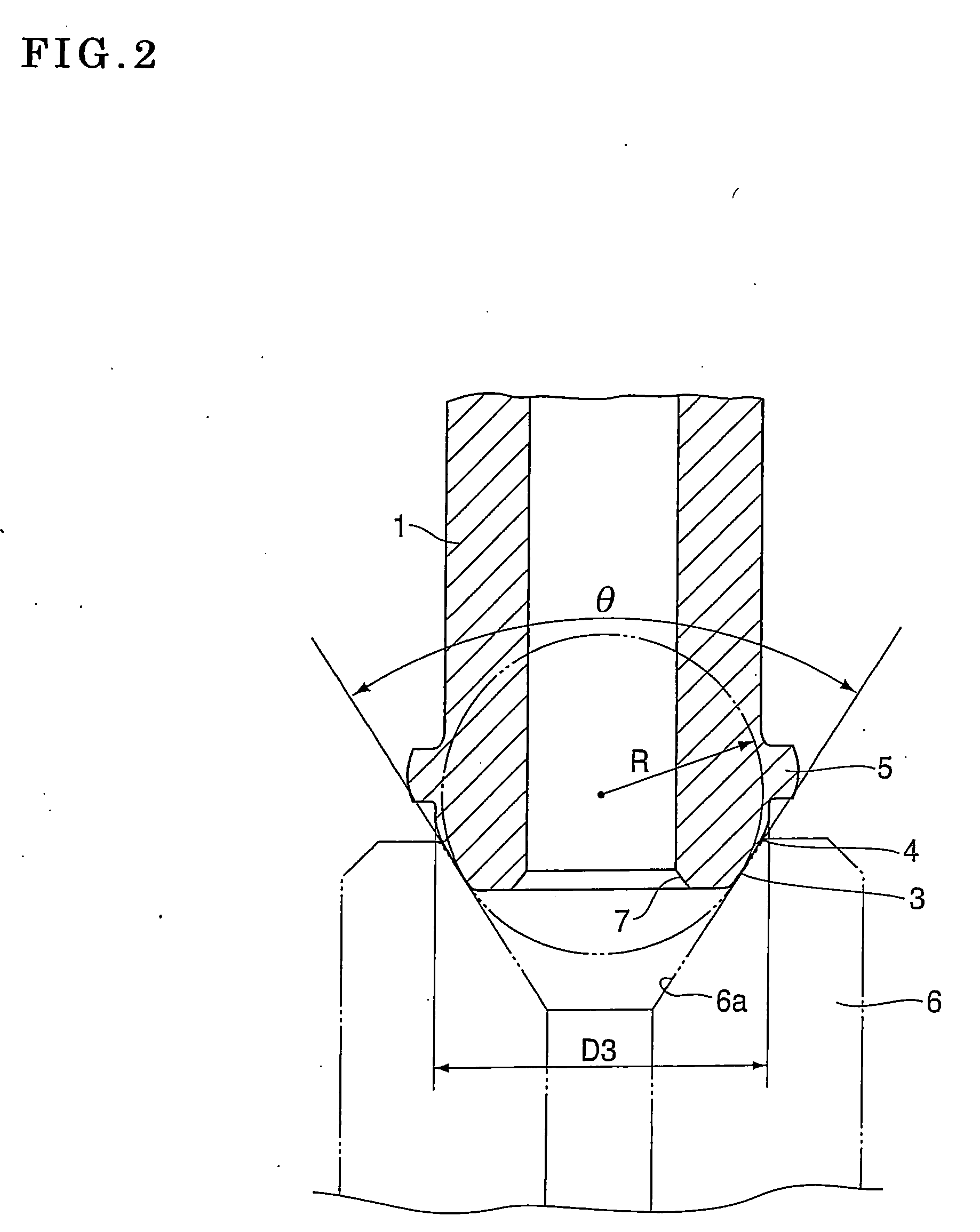

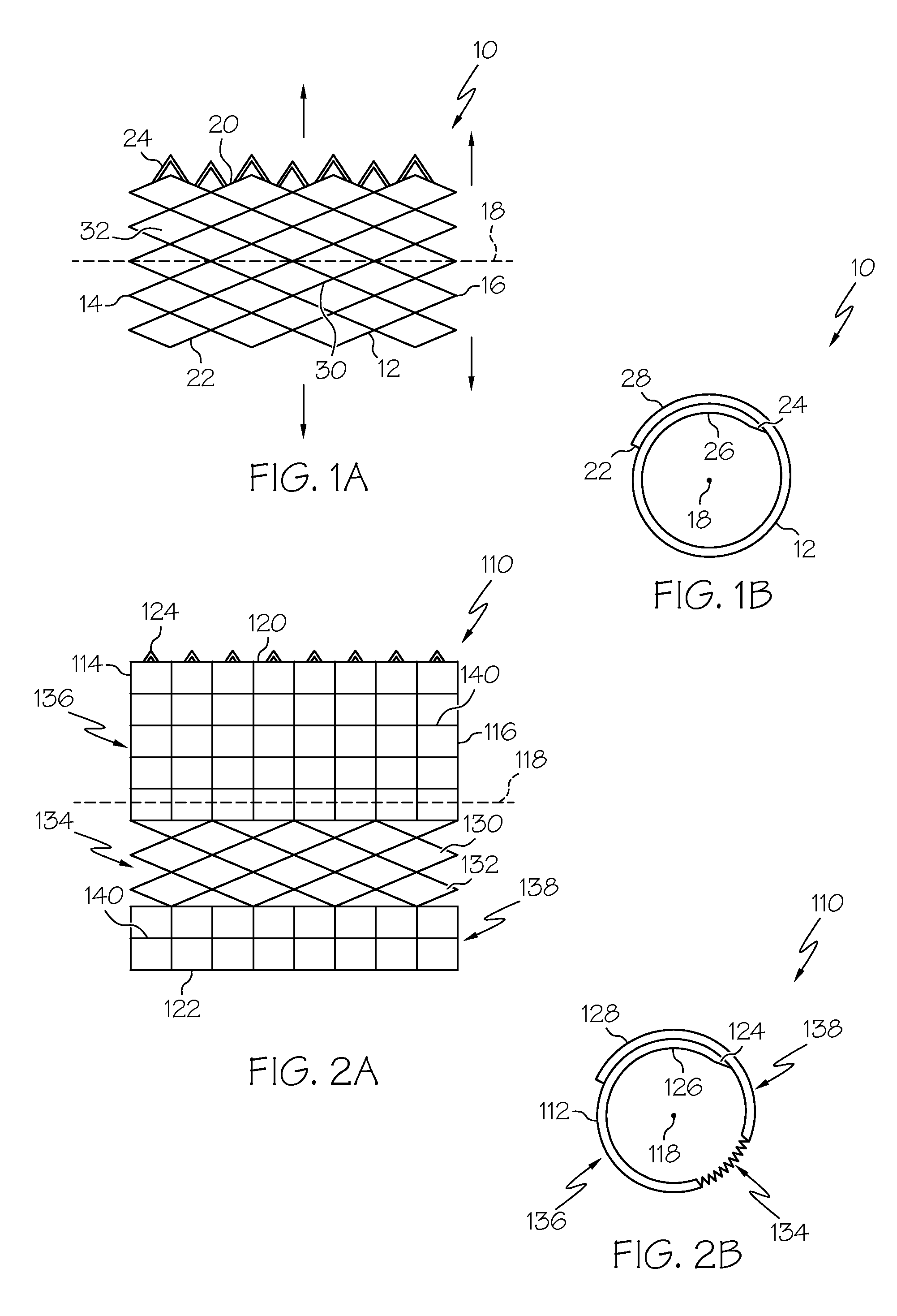

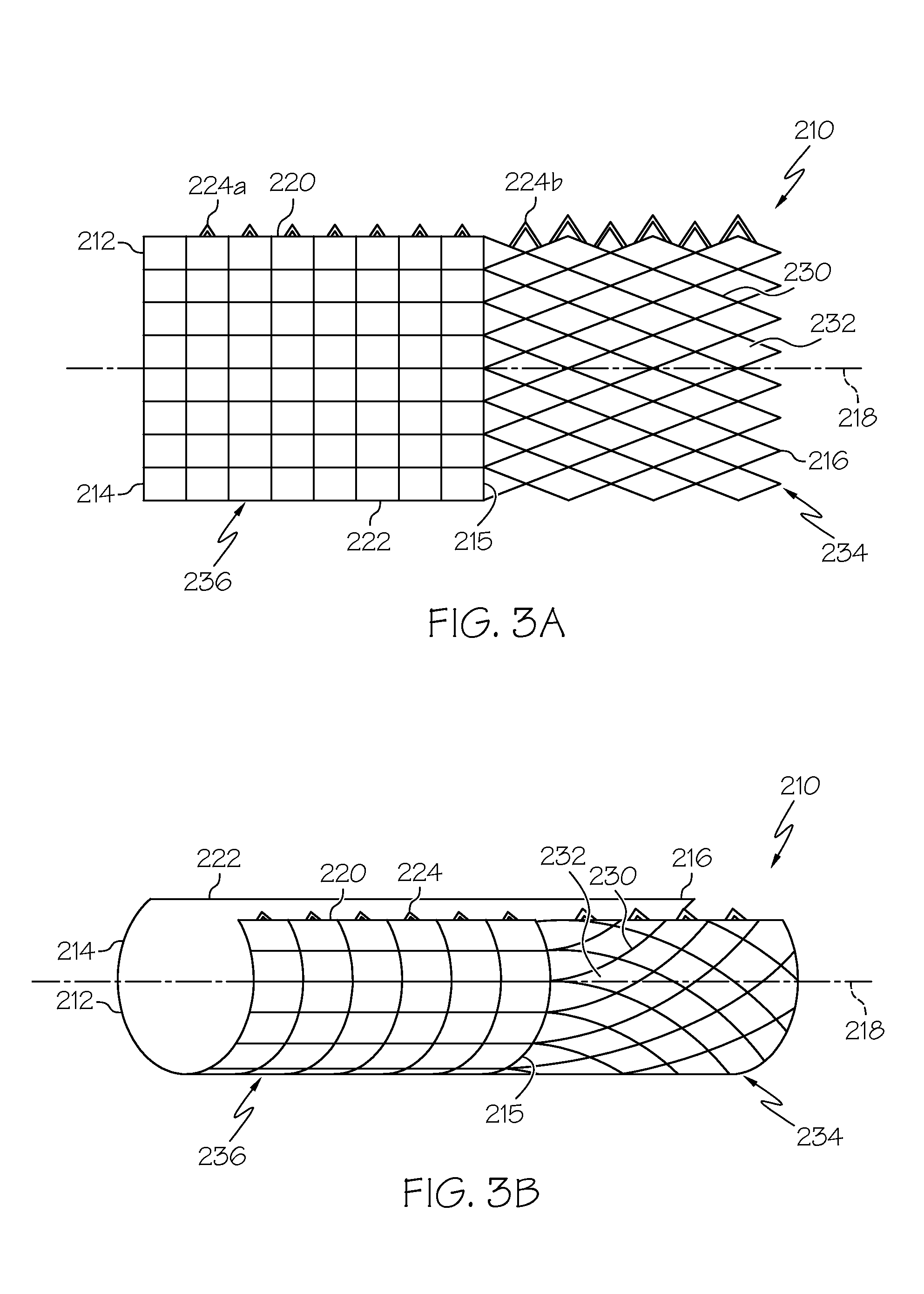

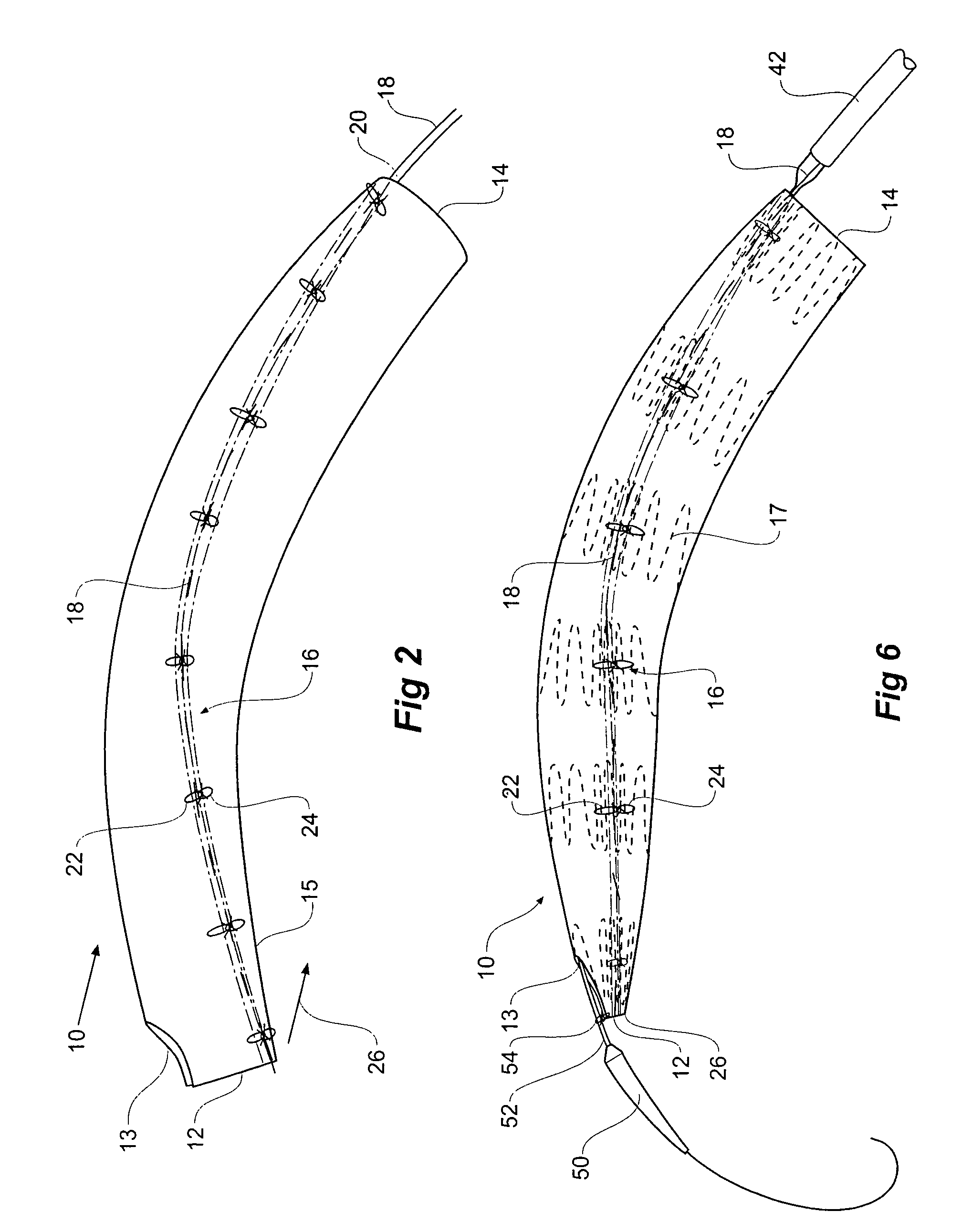

Stent grafts for the thoracic aorta

ActiveUS20080294234A1Reduce the overall diameterReduce distanceStentsBlood vesselsThoracic aortaStent grafting

Owner:COOK MEDICAL TECH LLC

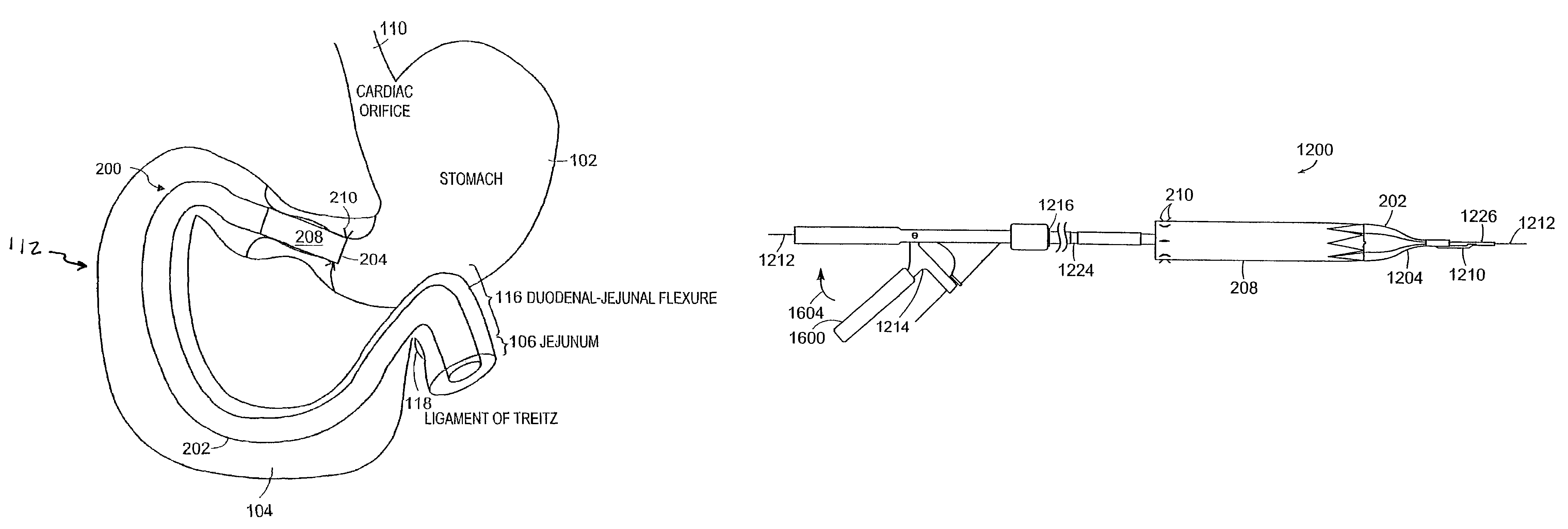

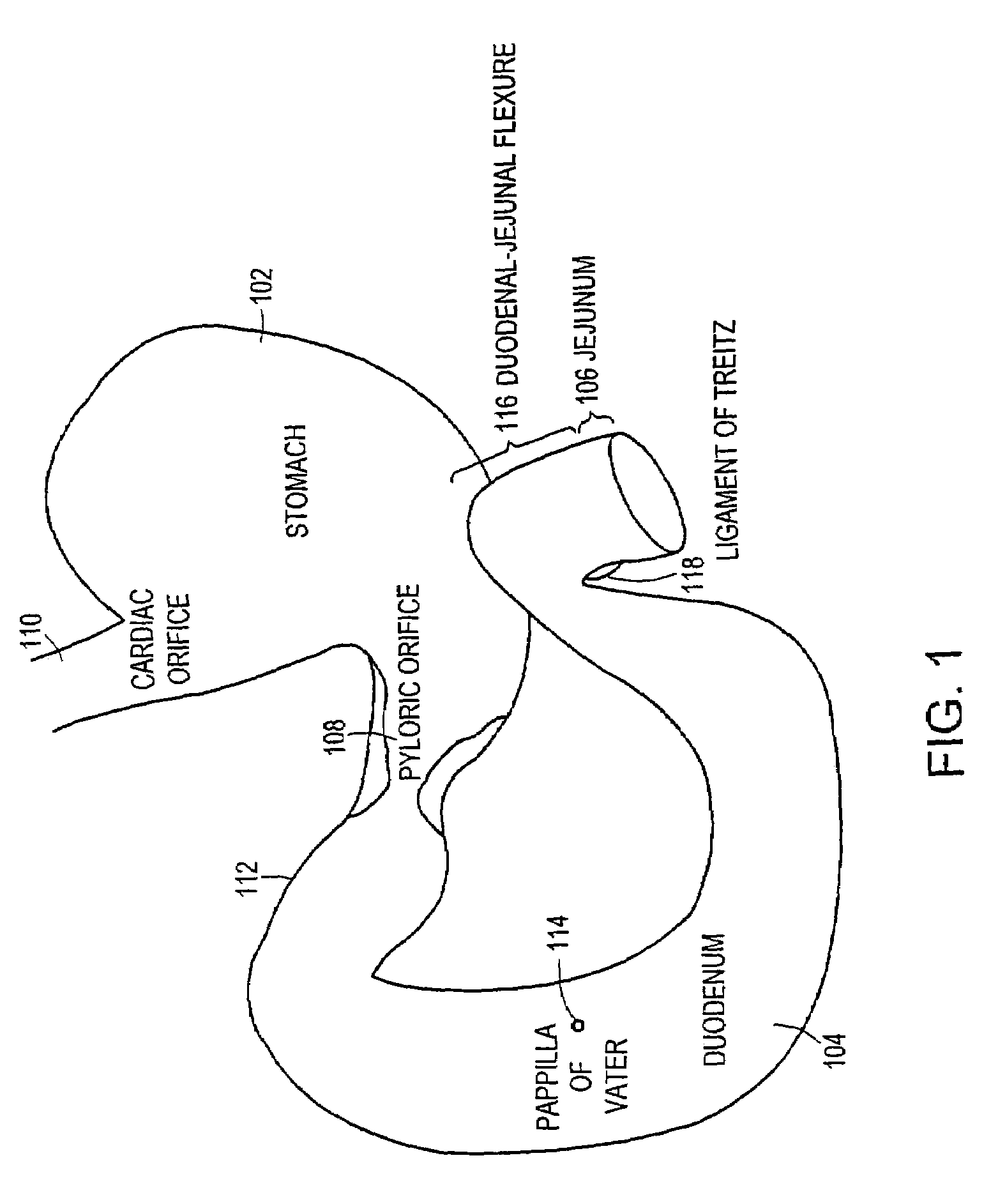

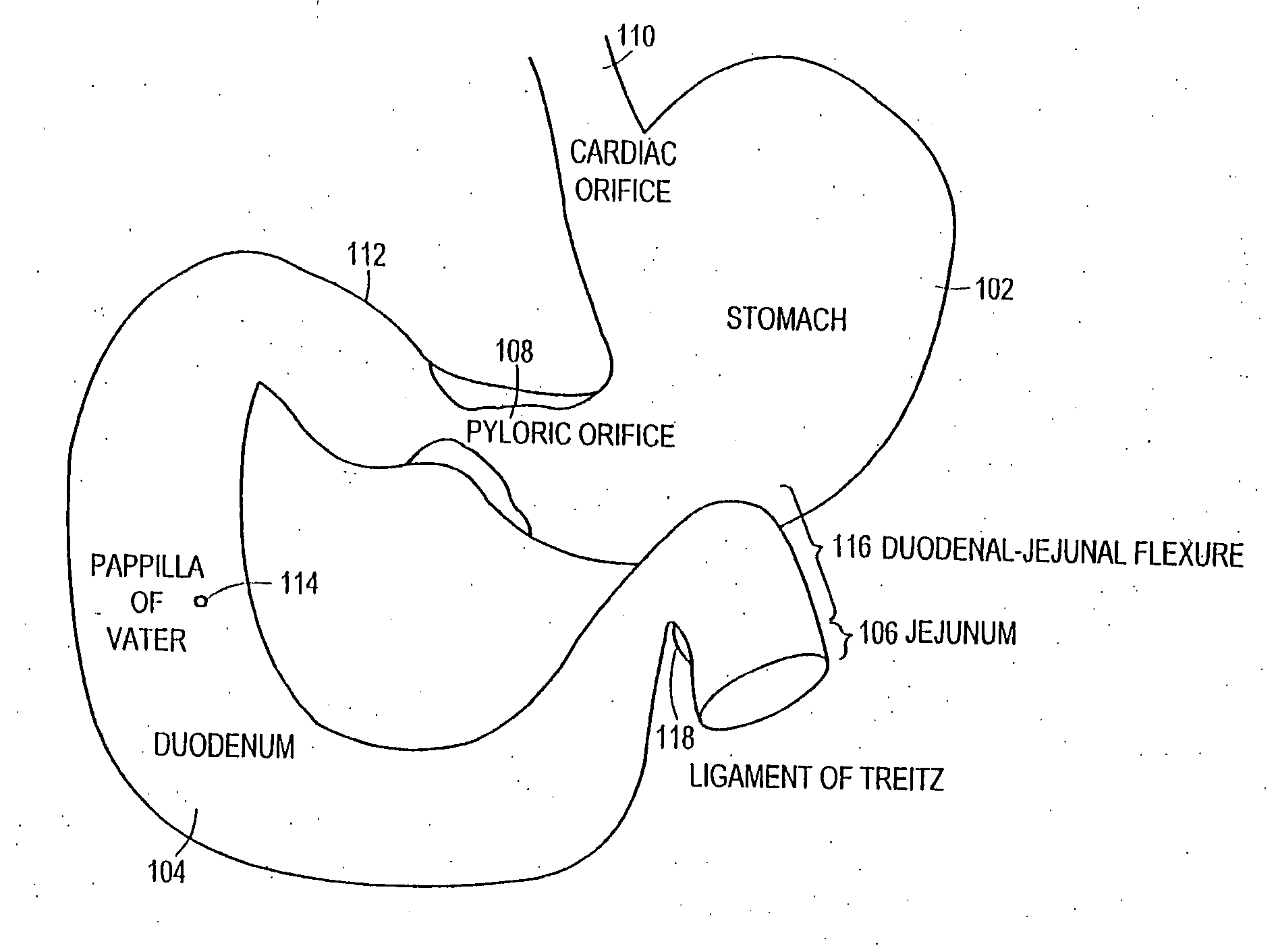

Methods of treatment using a bariatric sleeve

ActiveUS7695446B2Promote healingControlled absorptionSuture equipmentsStentsDiseaseIntestinal structure

Methods of treatment using a gastrointestinal implant device removably anchored within an animal's gastrointestinal tract. For example, the implant device includes a collapsible anchor for anchoring the device coupled to a proximal end of a flexible sleeve. The implant device can be anchored within the stomach, within the pyloric orifice, and / or distal to the pylorus and extended into the duodenum. All partially-digested food, or chyme, exiting the stomach is funneled through the device. Methods of treatment include treating obesity by one or more of: limiting the absorption of nutrients within the duodenum; delaying the mixing of chyme with digestive enzymes; alter hormonal triggers; and providing negative feedback. Alternatively or in addition, the desired result includes treating a diseases, such as diabetes, or temporarily shielding a portion of the intestine to promote healing within the intestine.

Owner:GI DYNAMICS INC

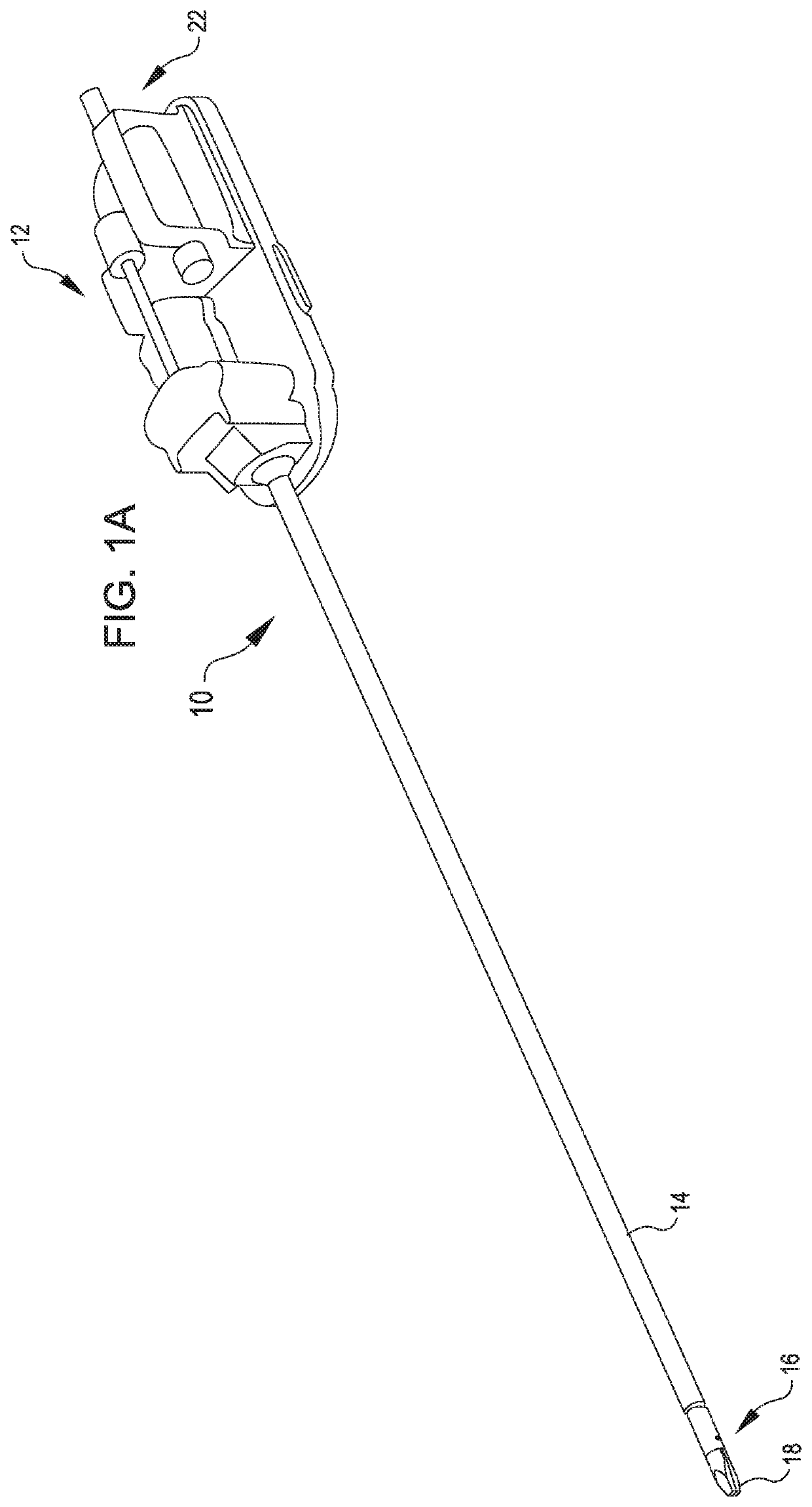

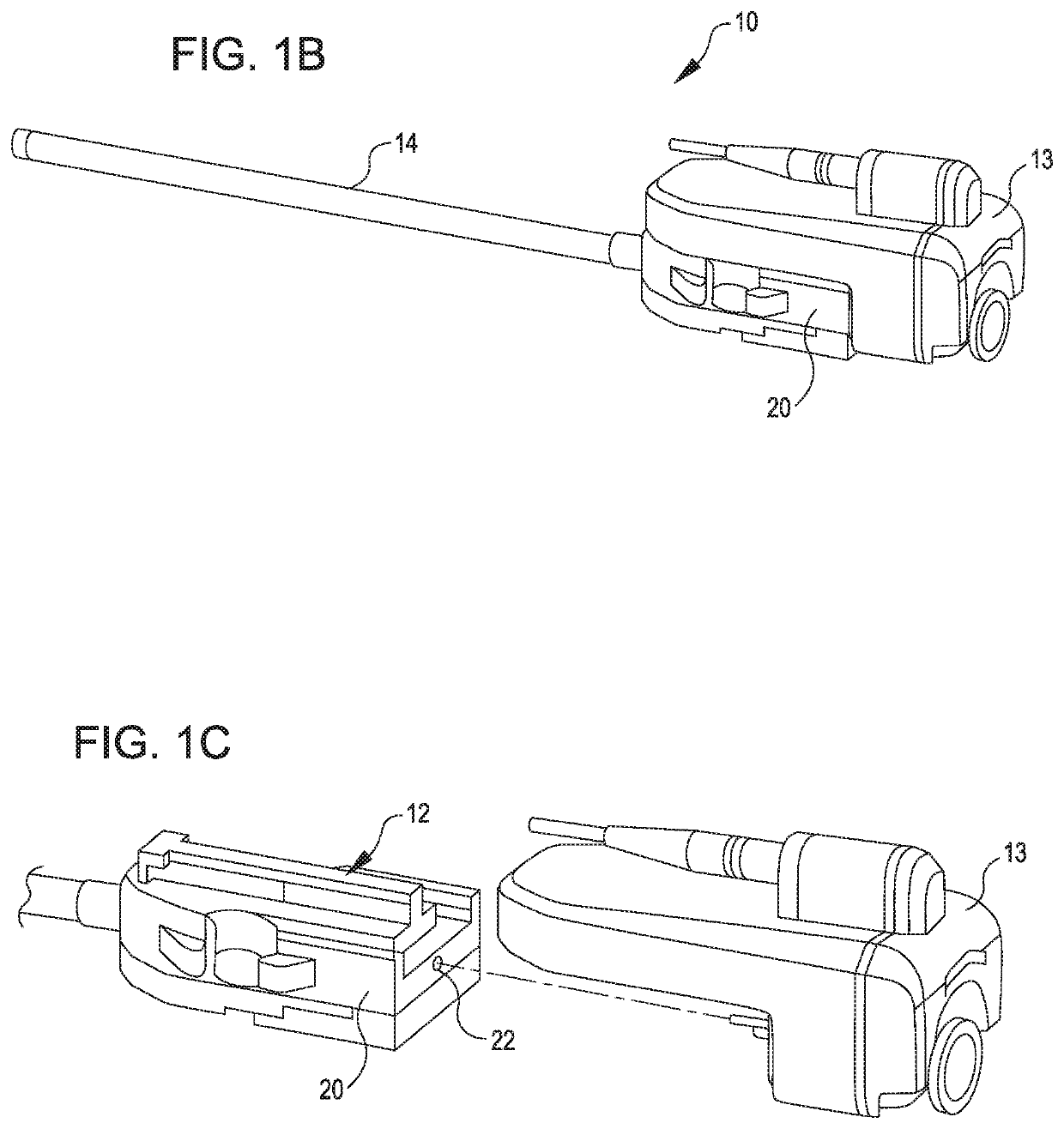

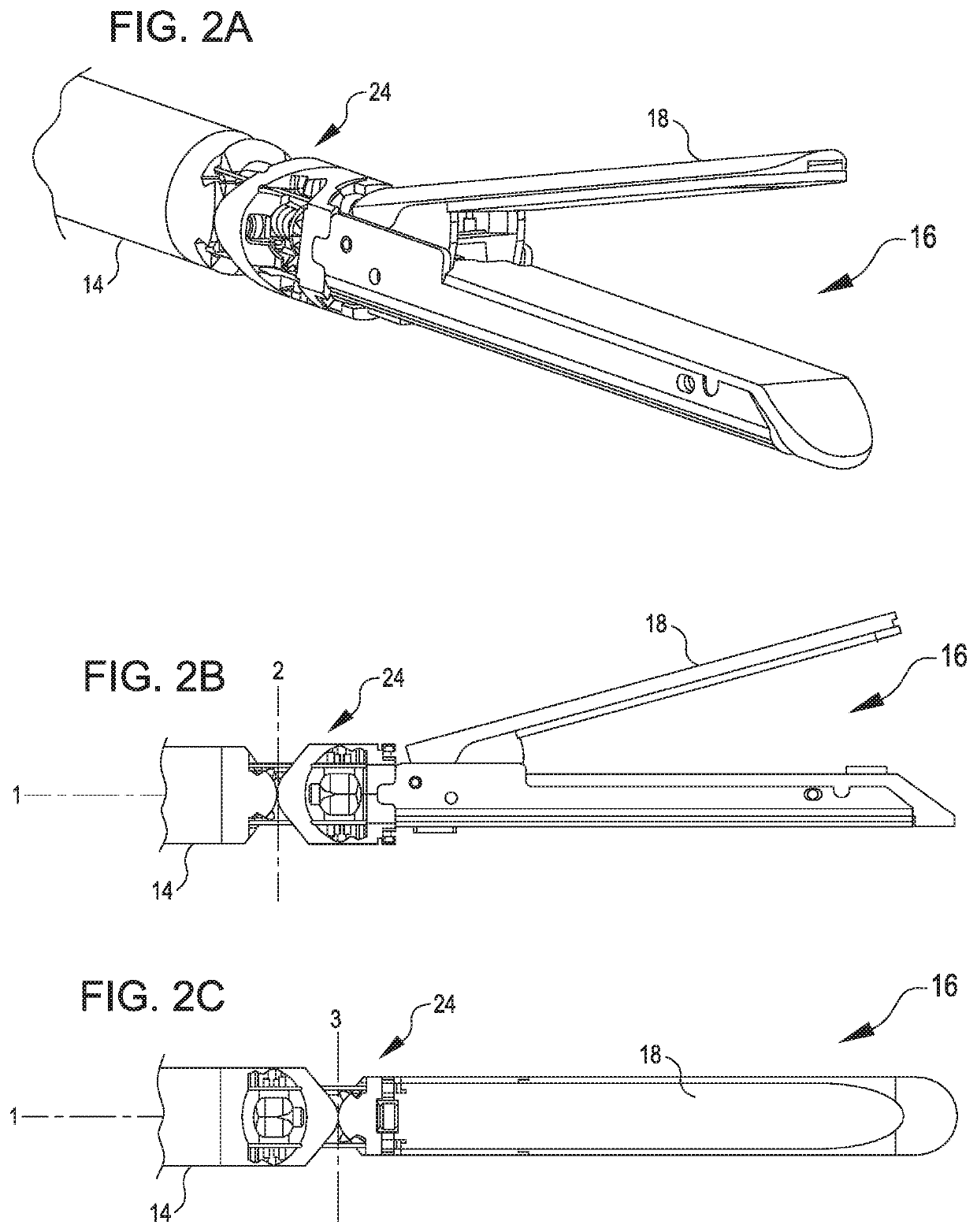

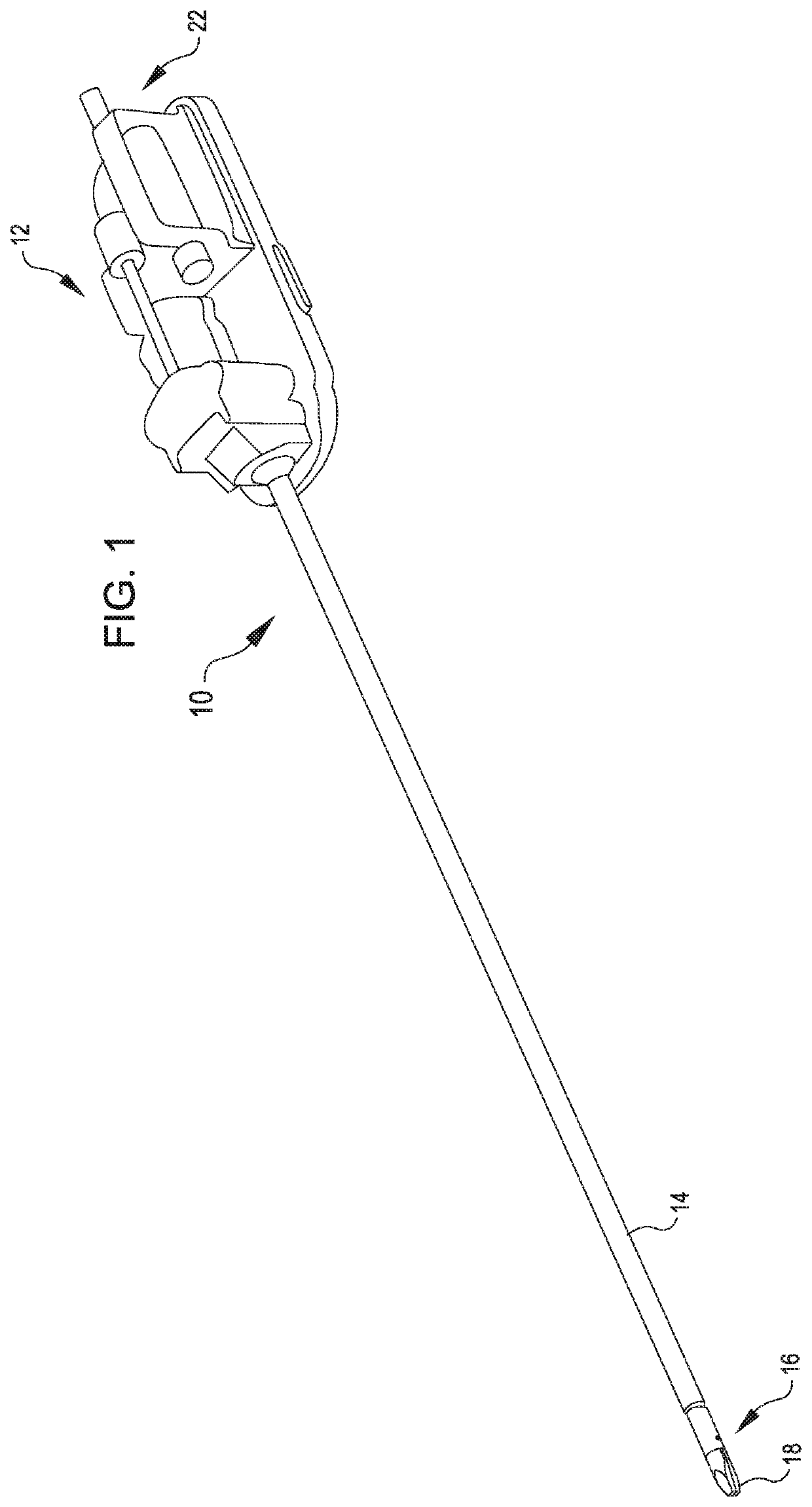

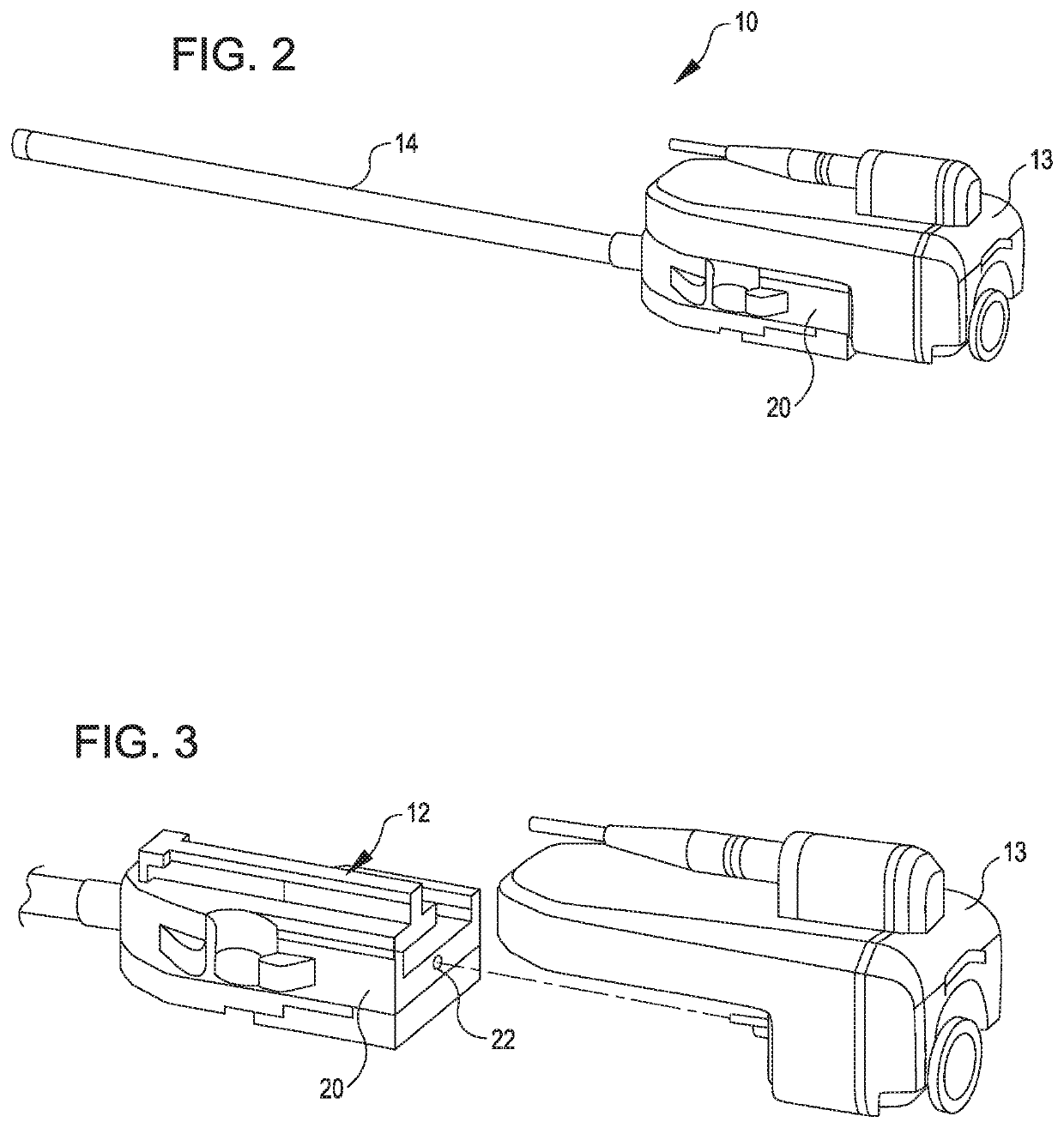

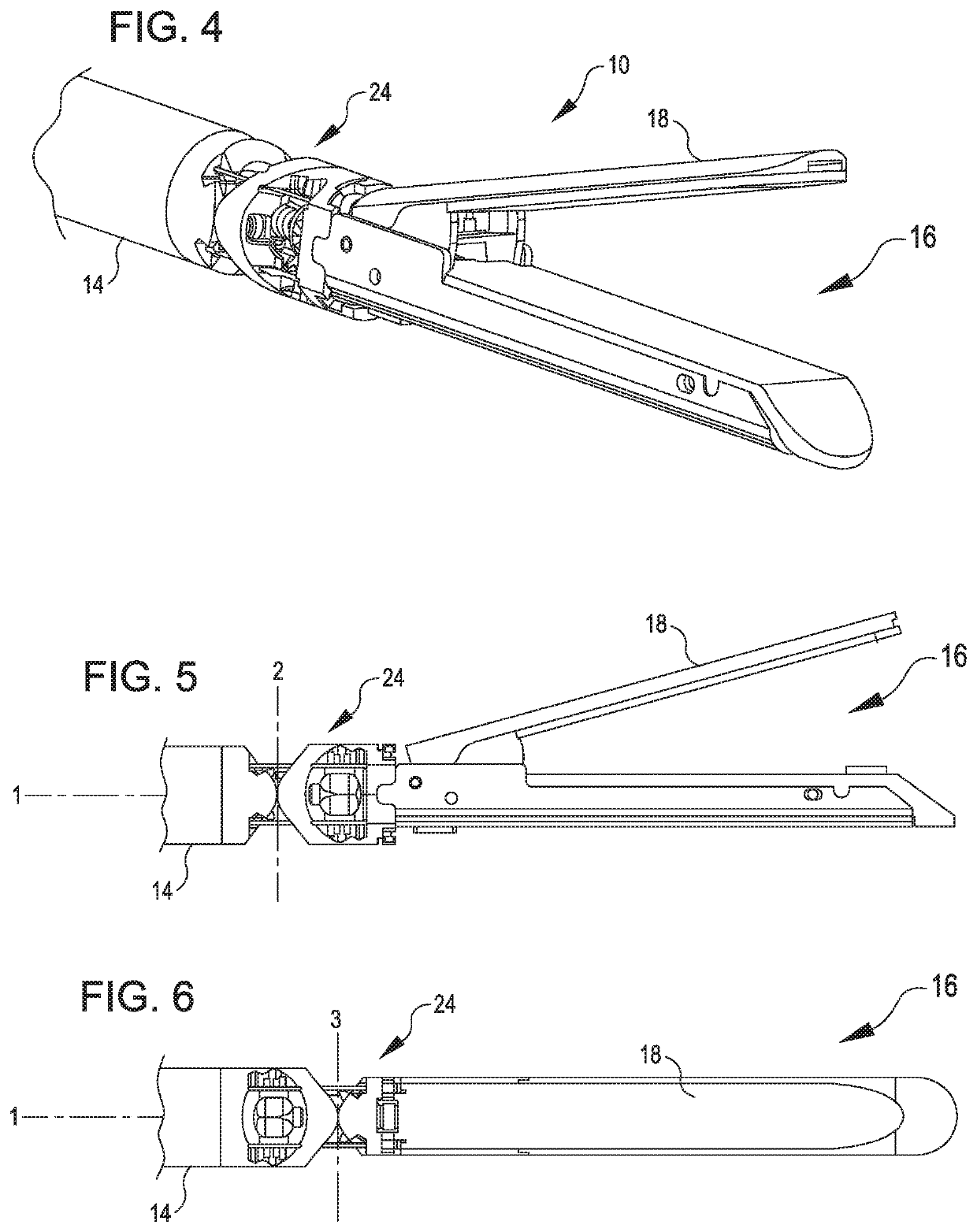

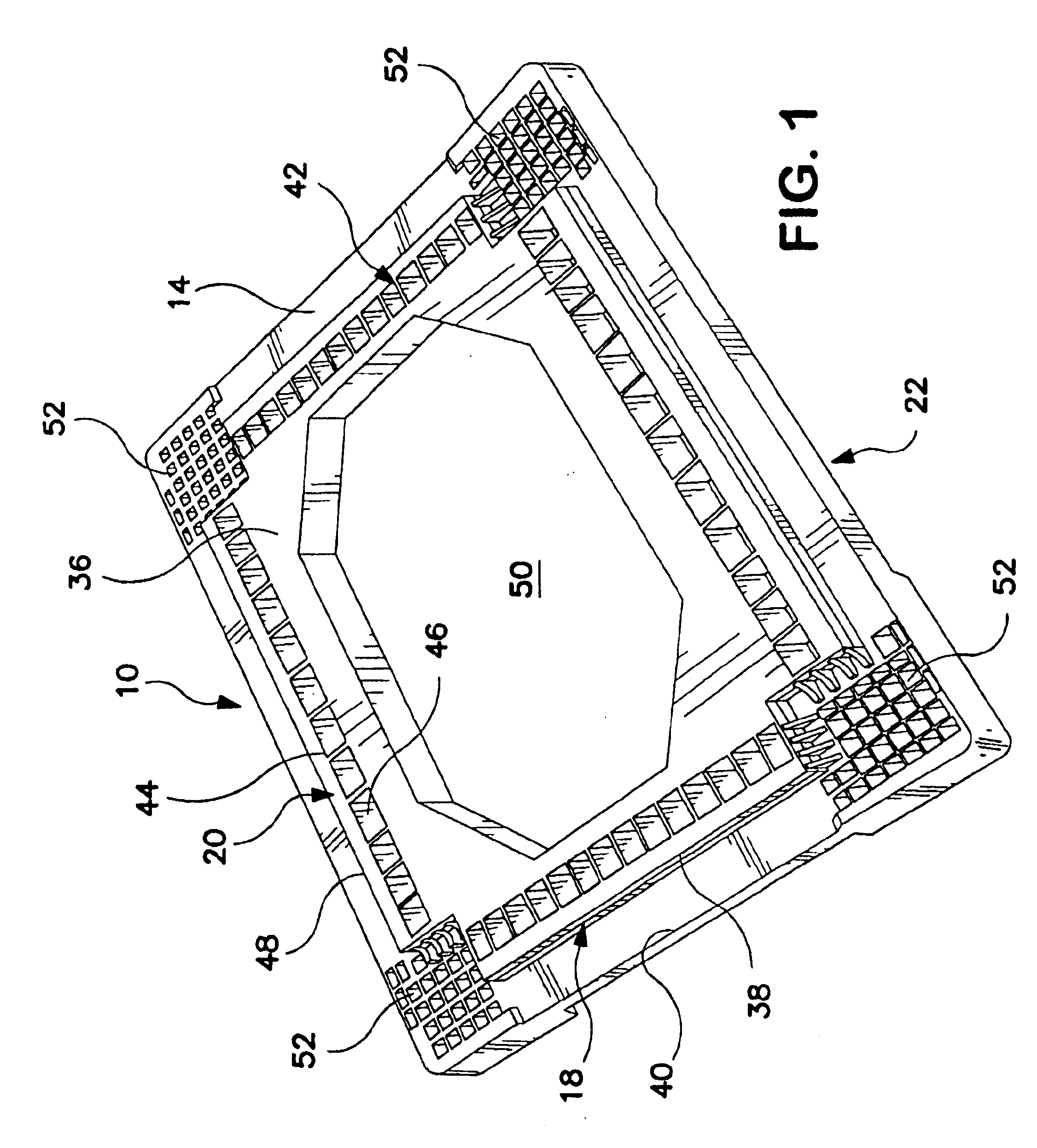

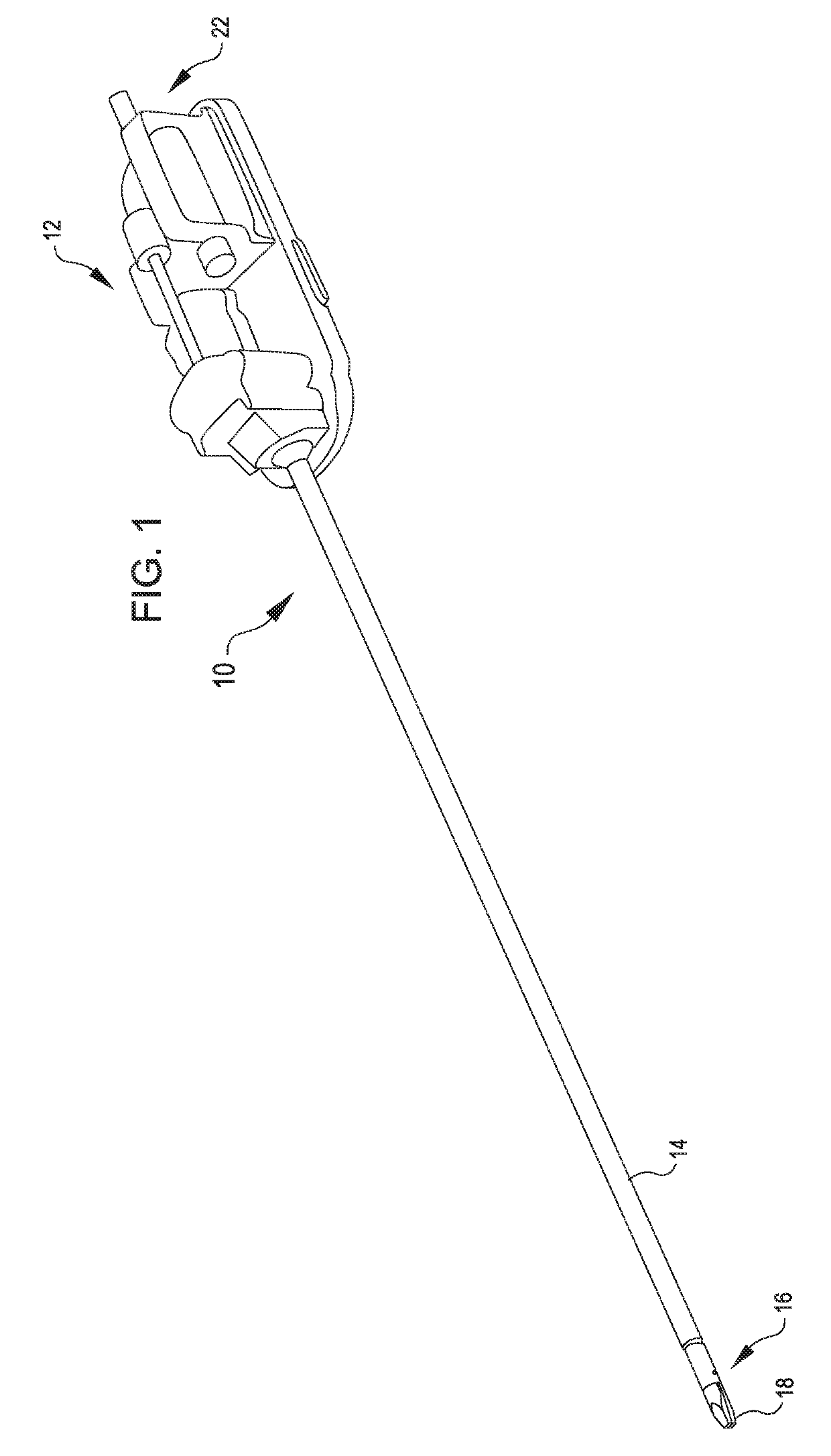

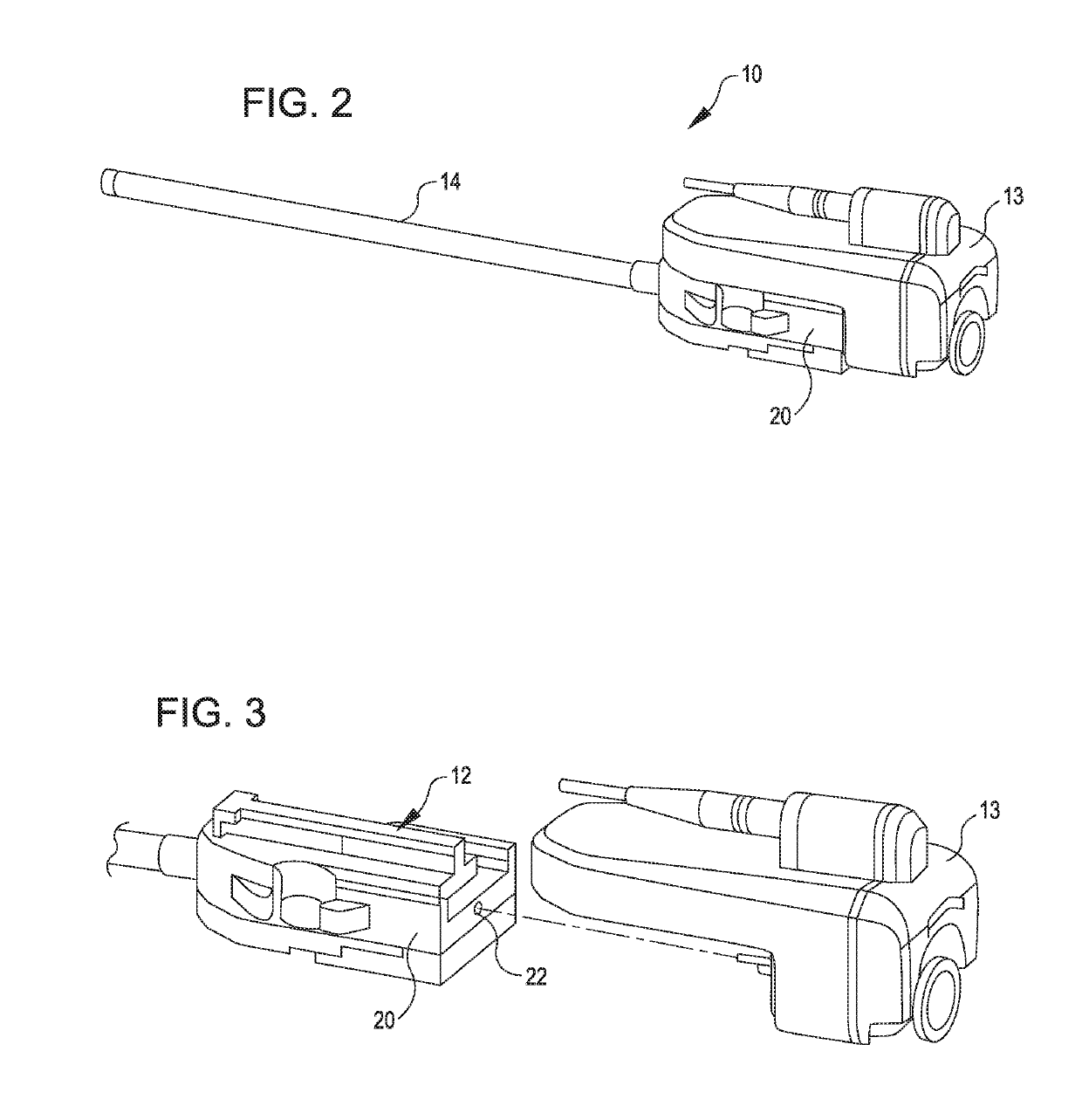

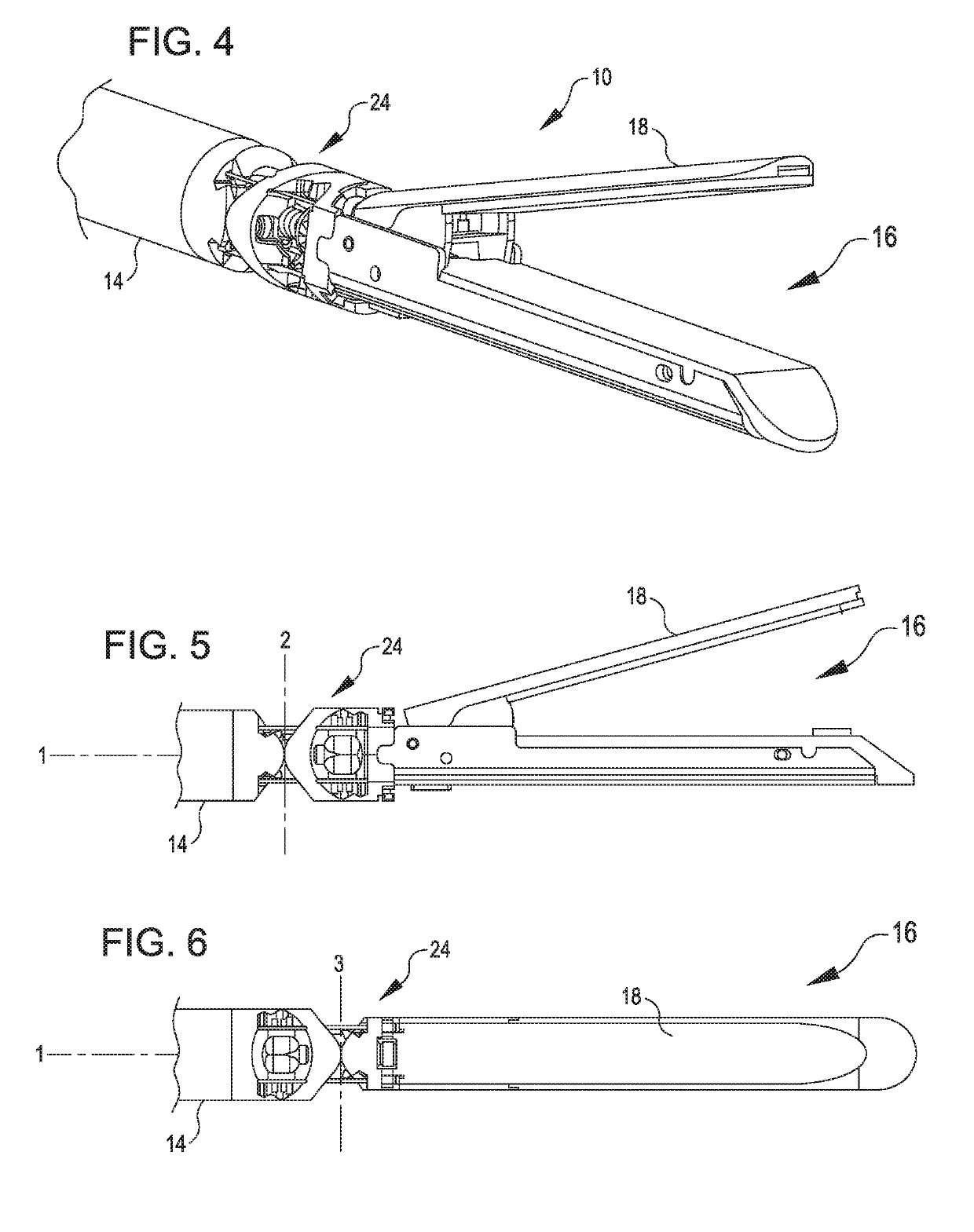

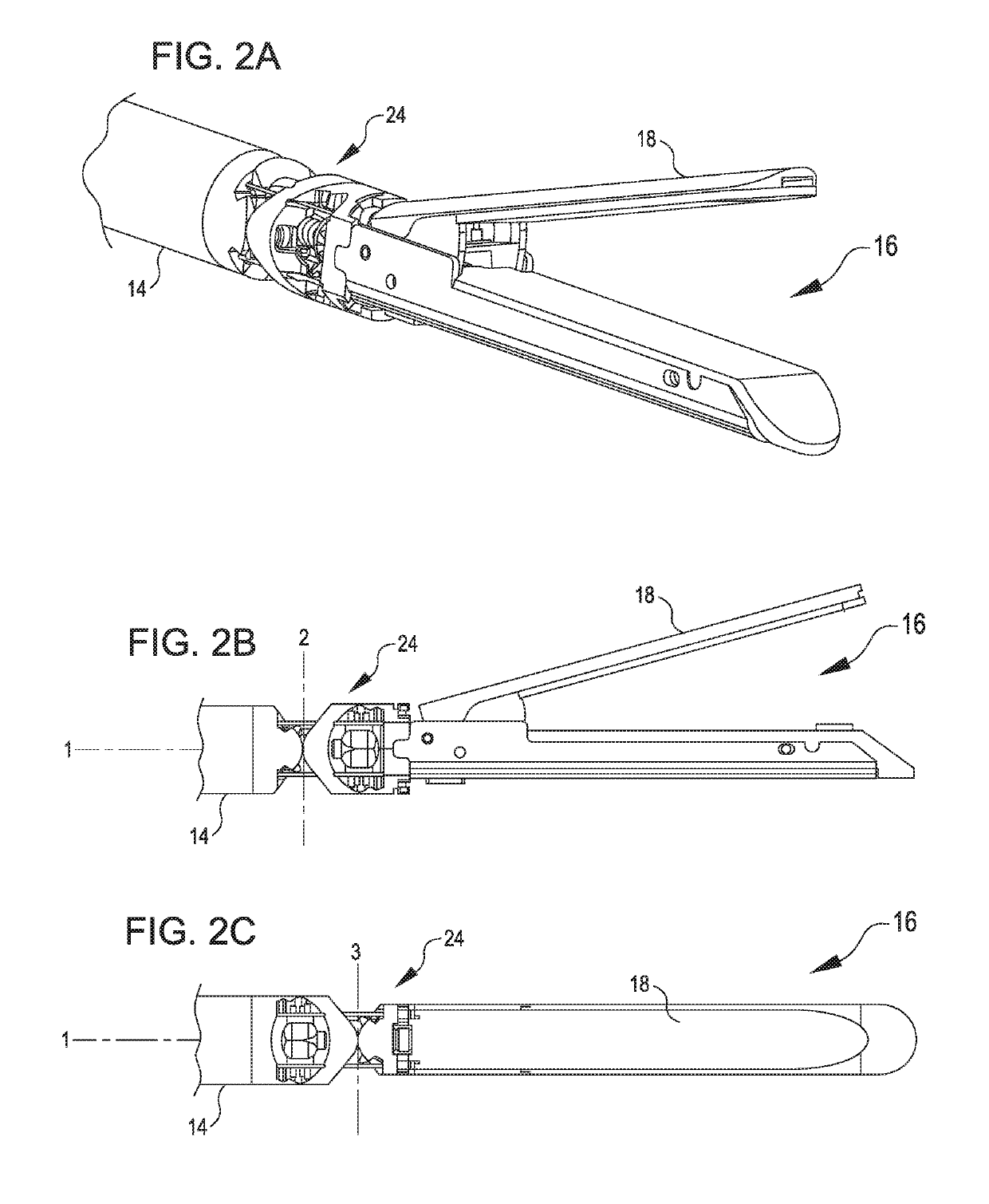

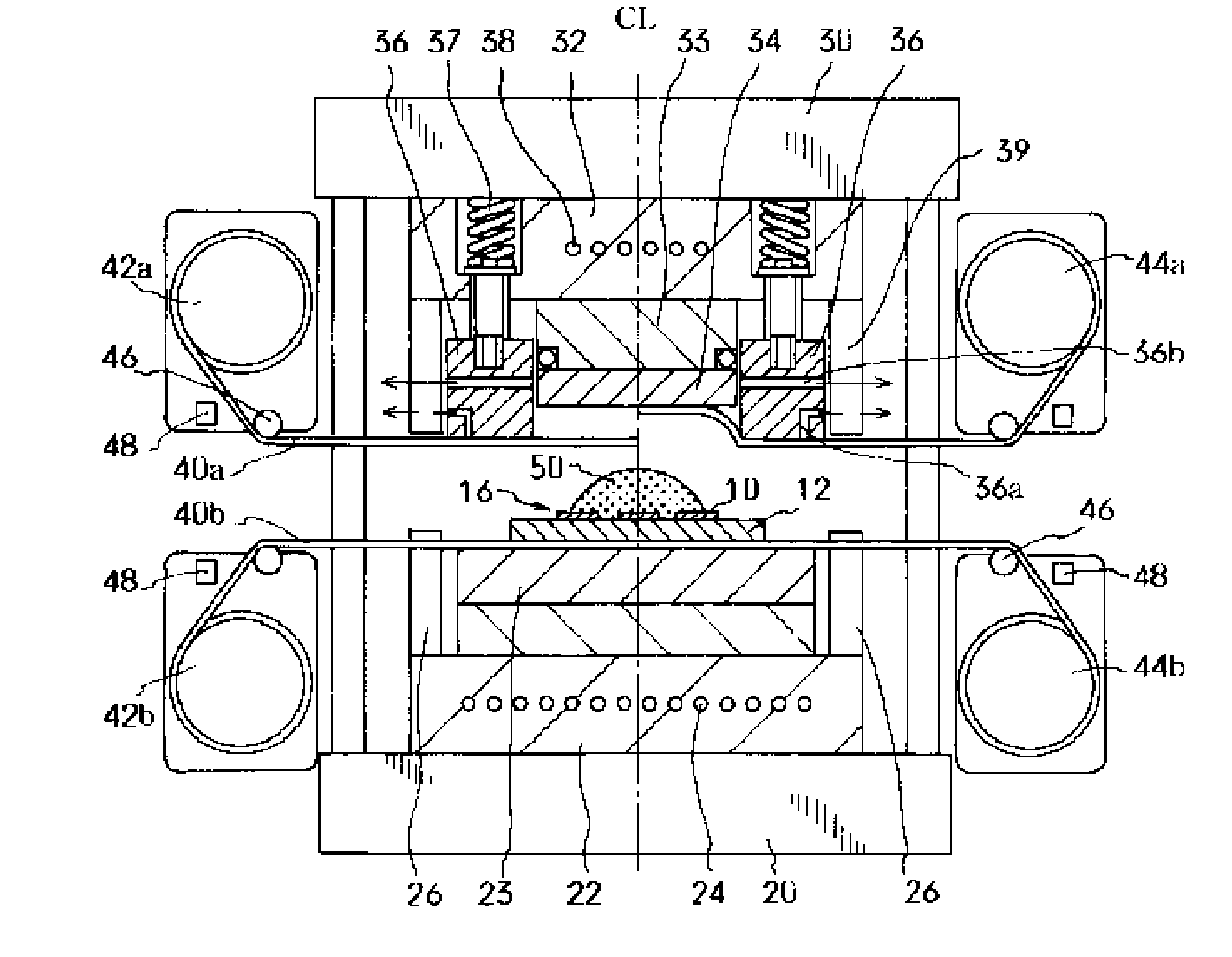

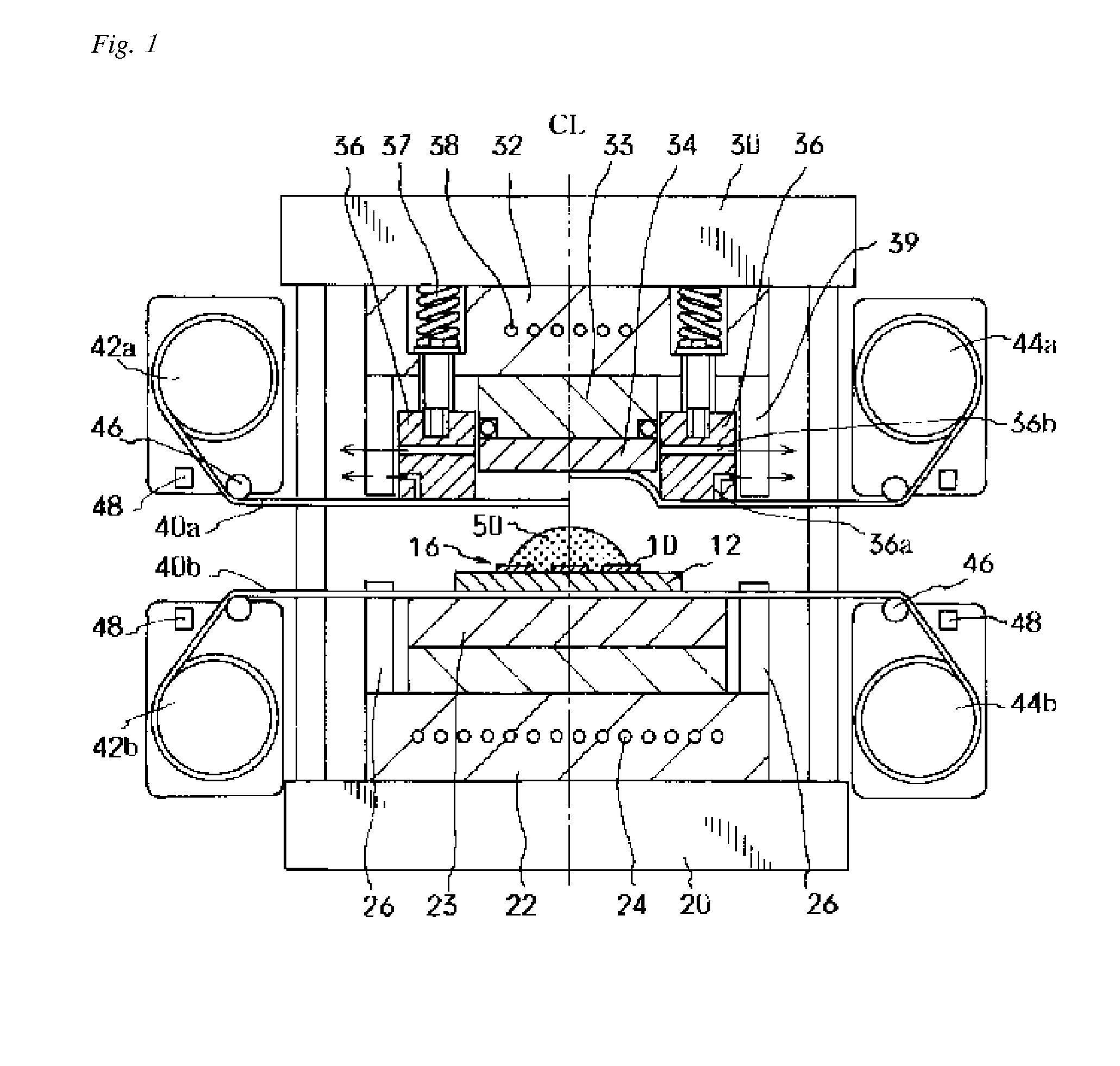

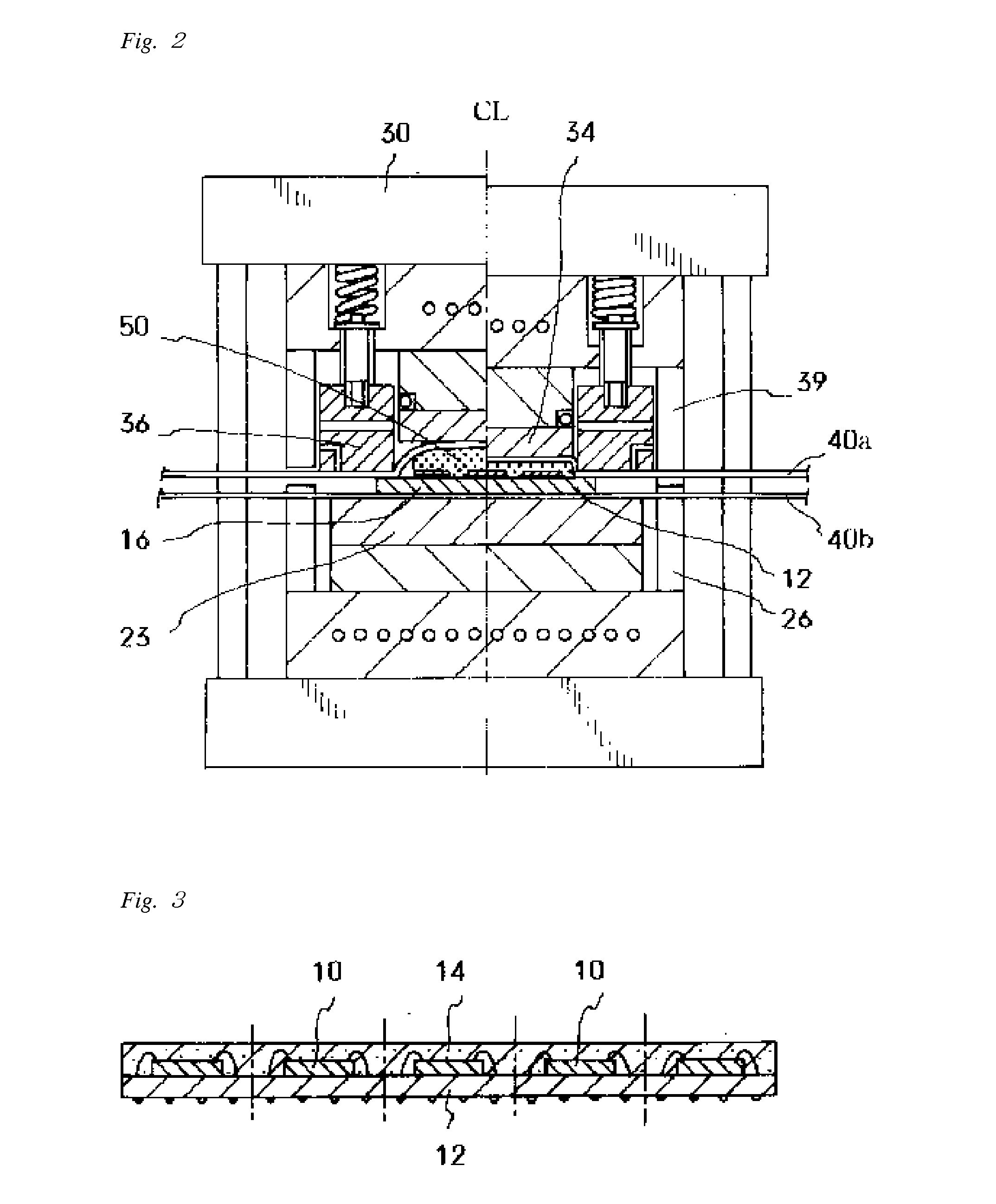

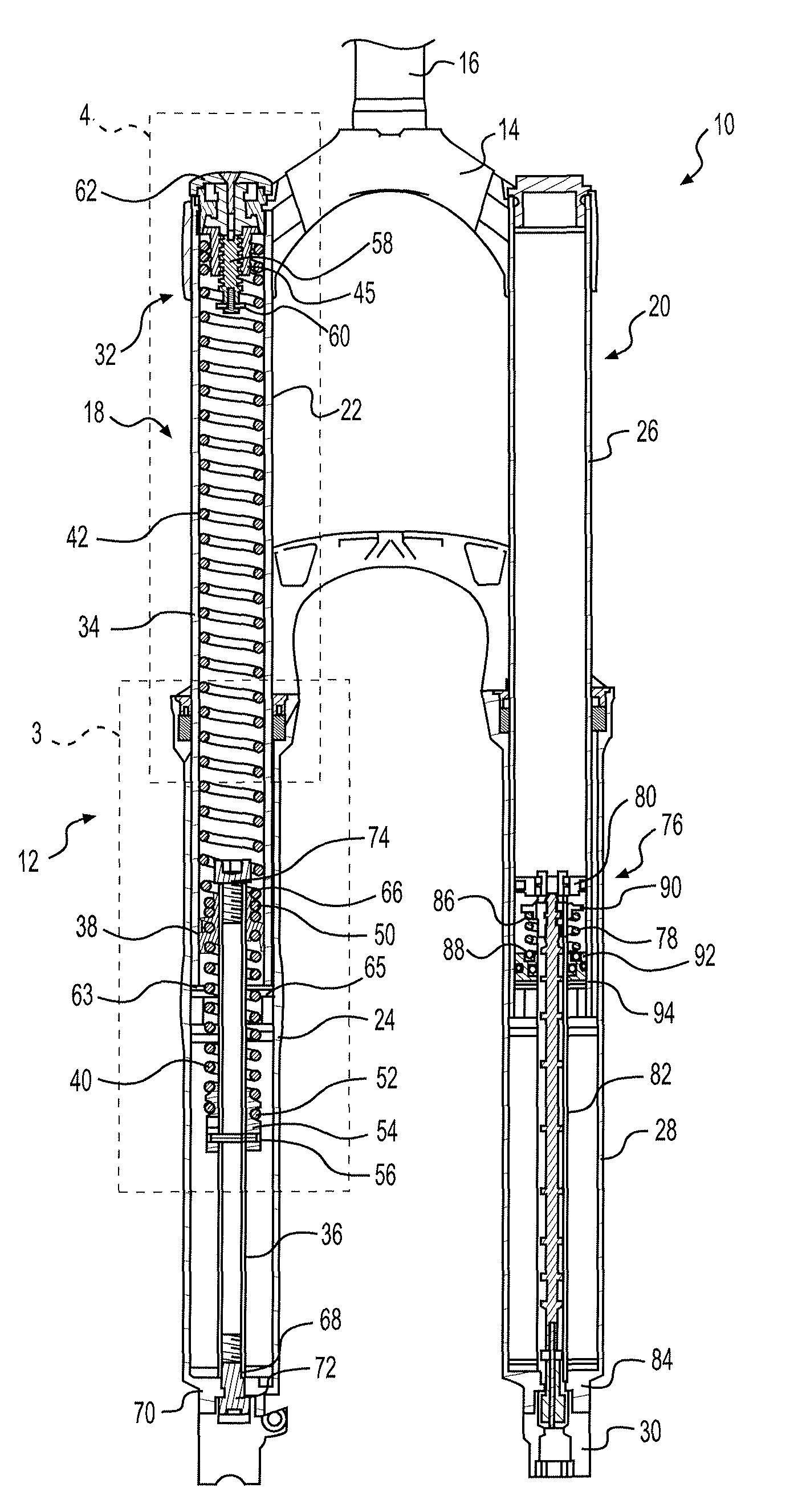

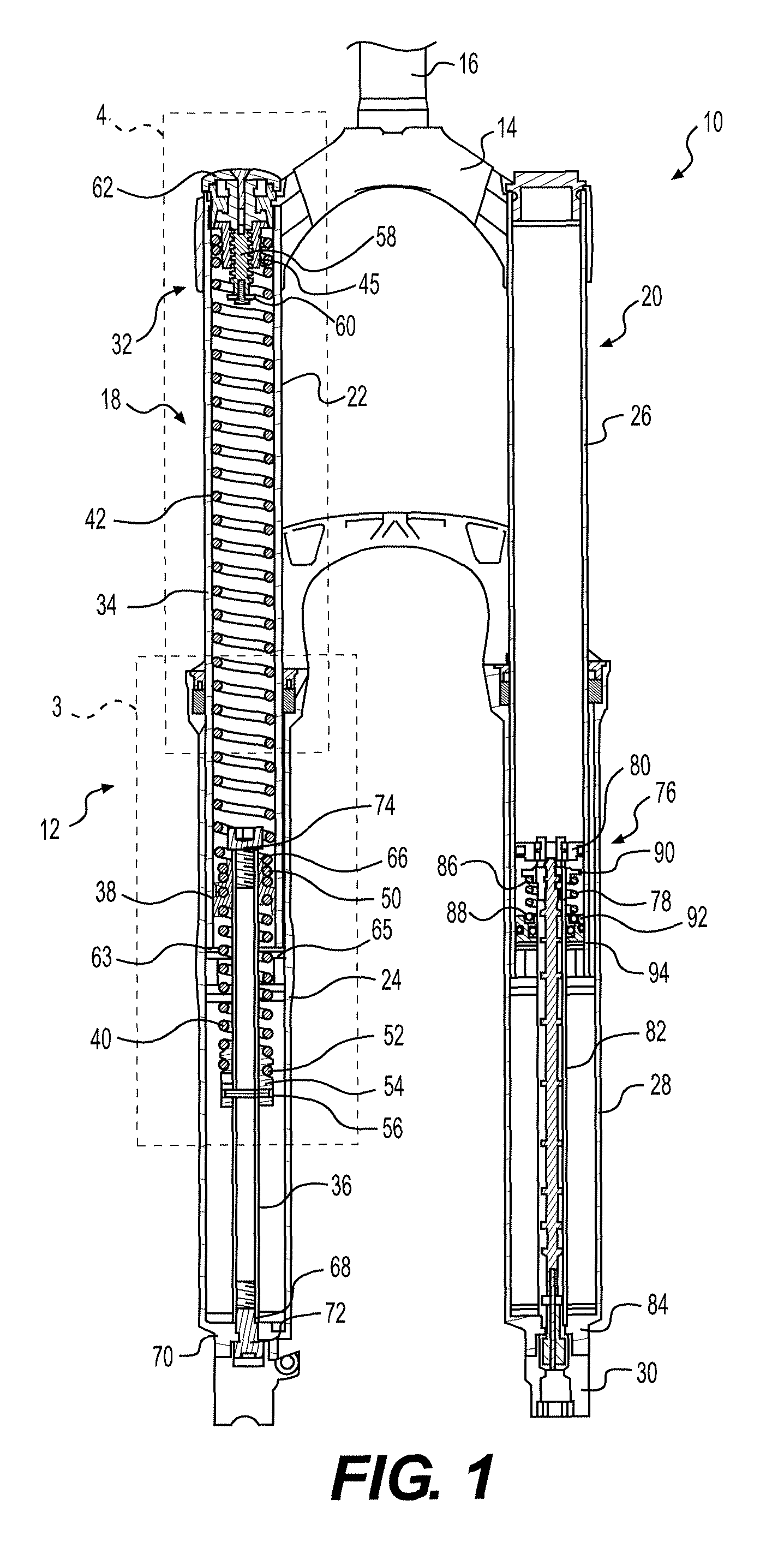

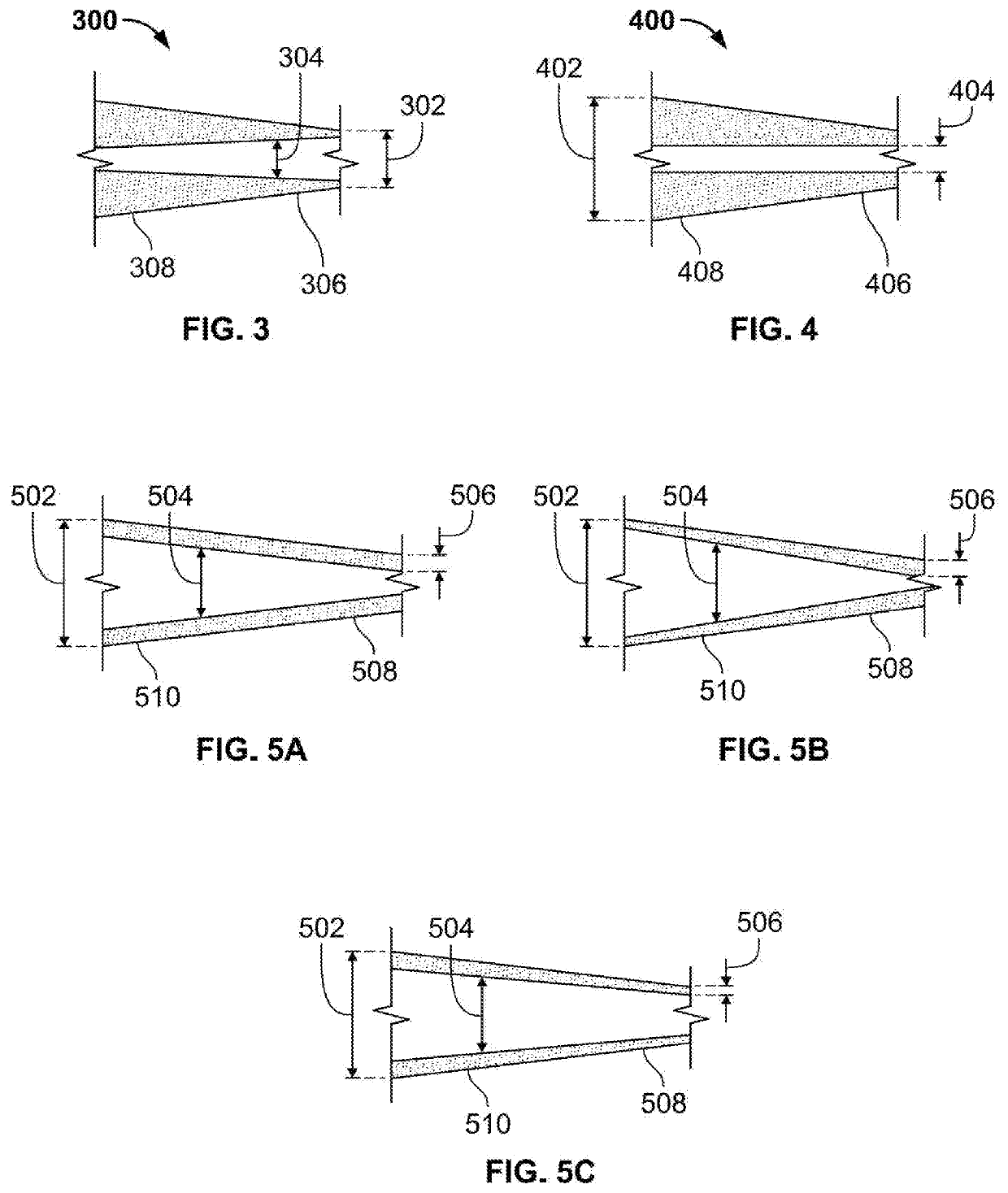

Stapler beam architecture

ActiveUS11166773B2Low efficiencyHigh degreeSurgical robotsSurgical staplesMedicineMechanical engineering

An end effector that can have an upper jaw and a lower jaw. A wrist can connect the end effector to an elongated shaft. A beam member can be arranged to translate within the upper and lower jaw. An actuation assembly can have a pushing assembly configured to transfer compressive force to the beam member and a pulling assembly configured to transfer tensile force to the beam member.

Owner:INTUITIVE SURGICAL OPERATIONS INC

Bariatric sleeve

InactiveUS20090240340A1Limit absorptionReducing hormone triggersSuture equipmentsStentsGastrointestinal deviceIntestinal structure

Method and apparatus for limiting absorption of food products in specific parts of the digestive system is presented. A gastrointestinal implant device is anchored in the stomach and extends beyond the ligament of Treitz. All food exiting the stomach is funneled through the device. The gastrointestinal device includes an anchor for anchoring the device to the stomach and a flexible sleeve. When implanted within the intestine, the sleeve can limit the absorption of nutrients, delay the mixing of chyme with digestive enzymes, altering hormonal triggers, providing negative feedback, and combinations thereof. The anchor is collapsible for endoscopic delivery and removal.

Owner:GI DYNAMICS

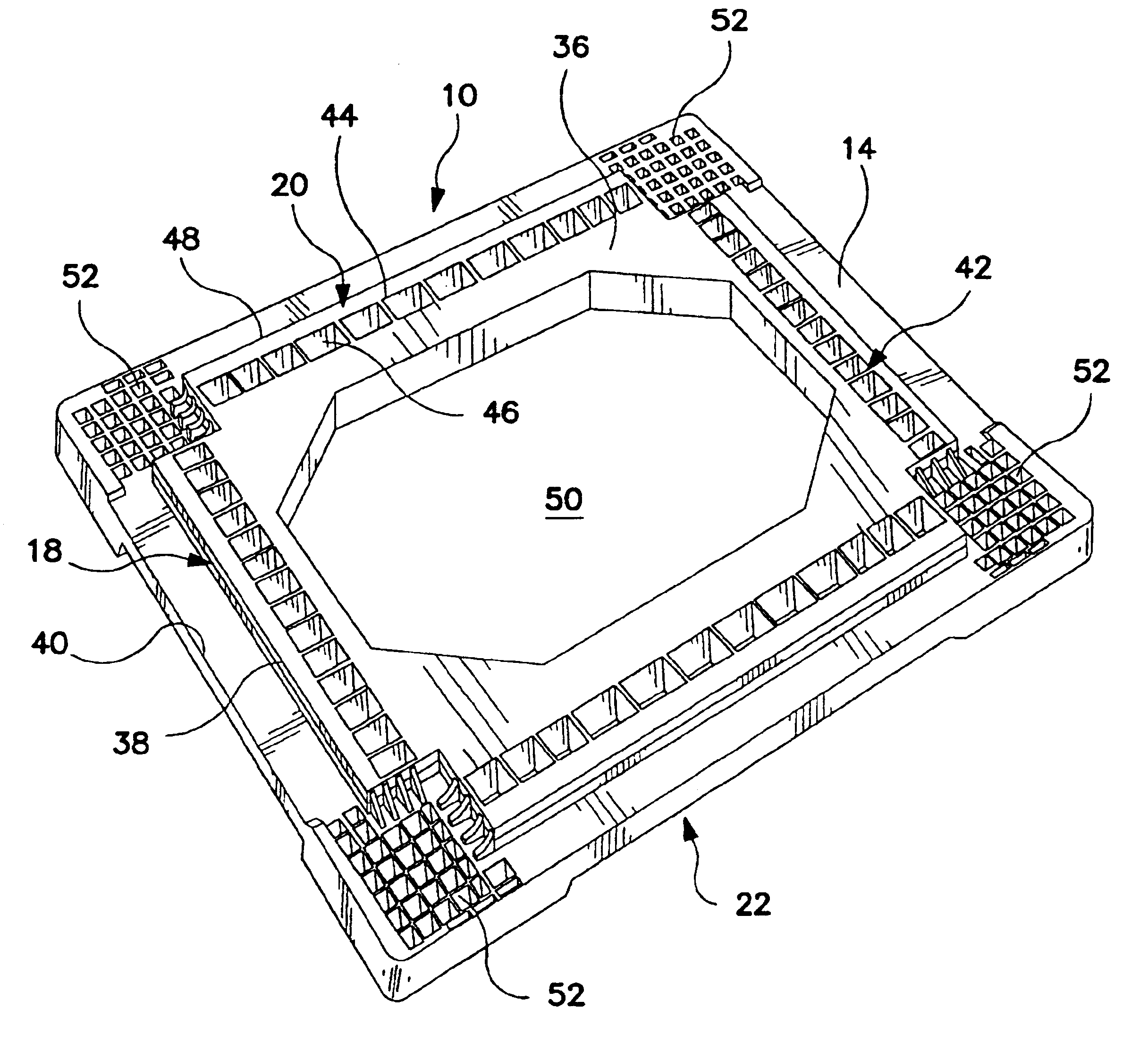

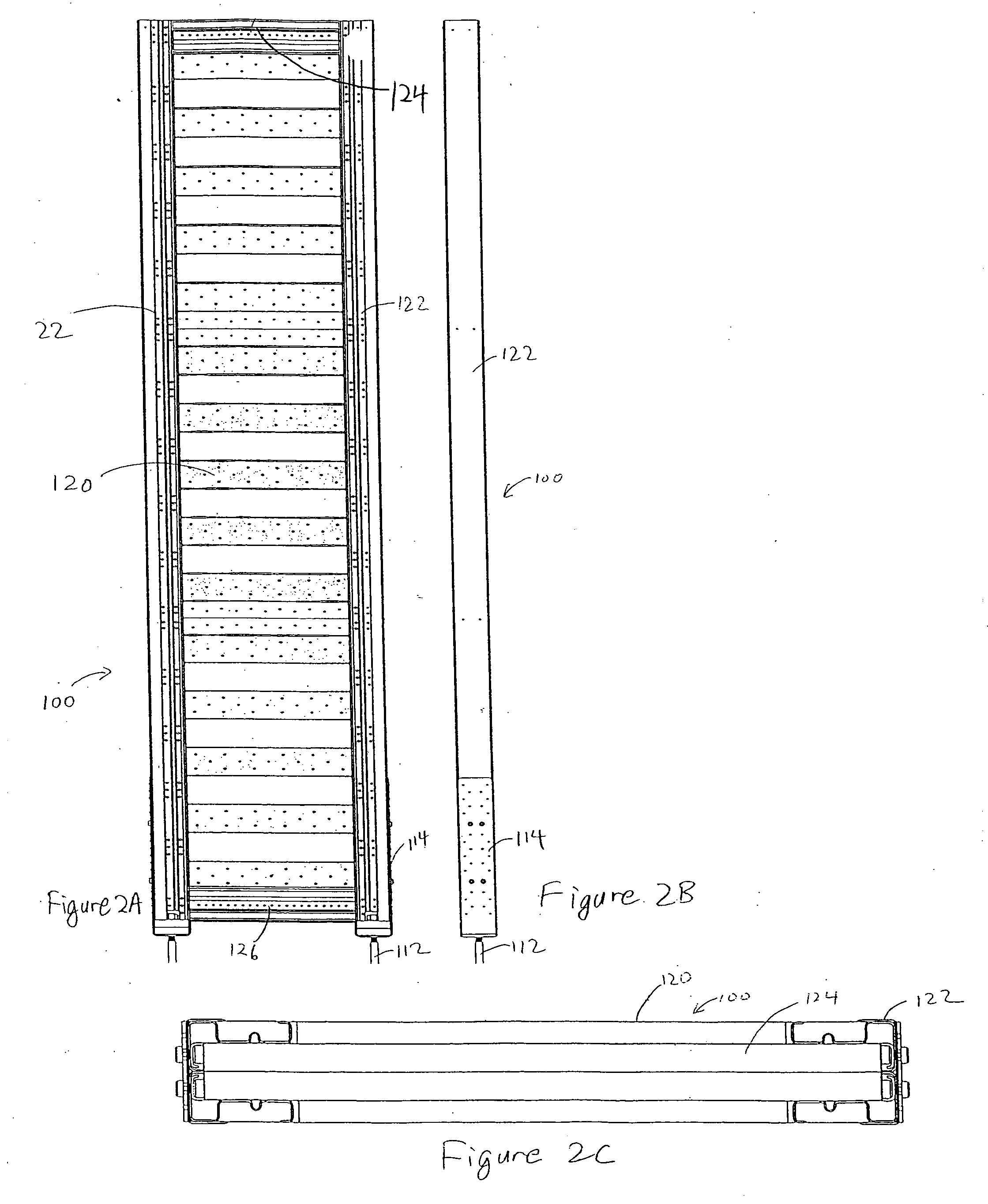

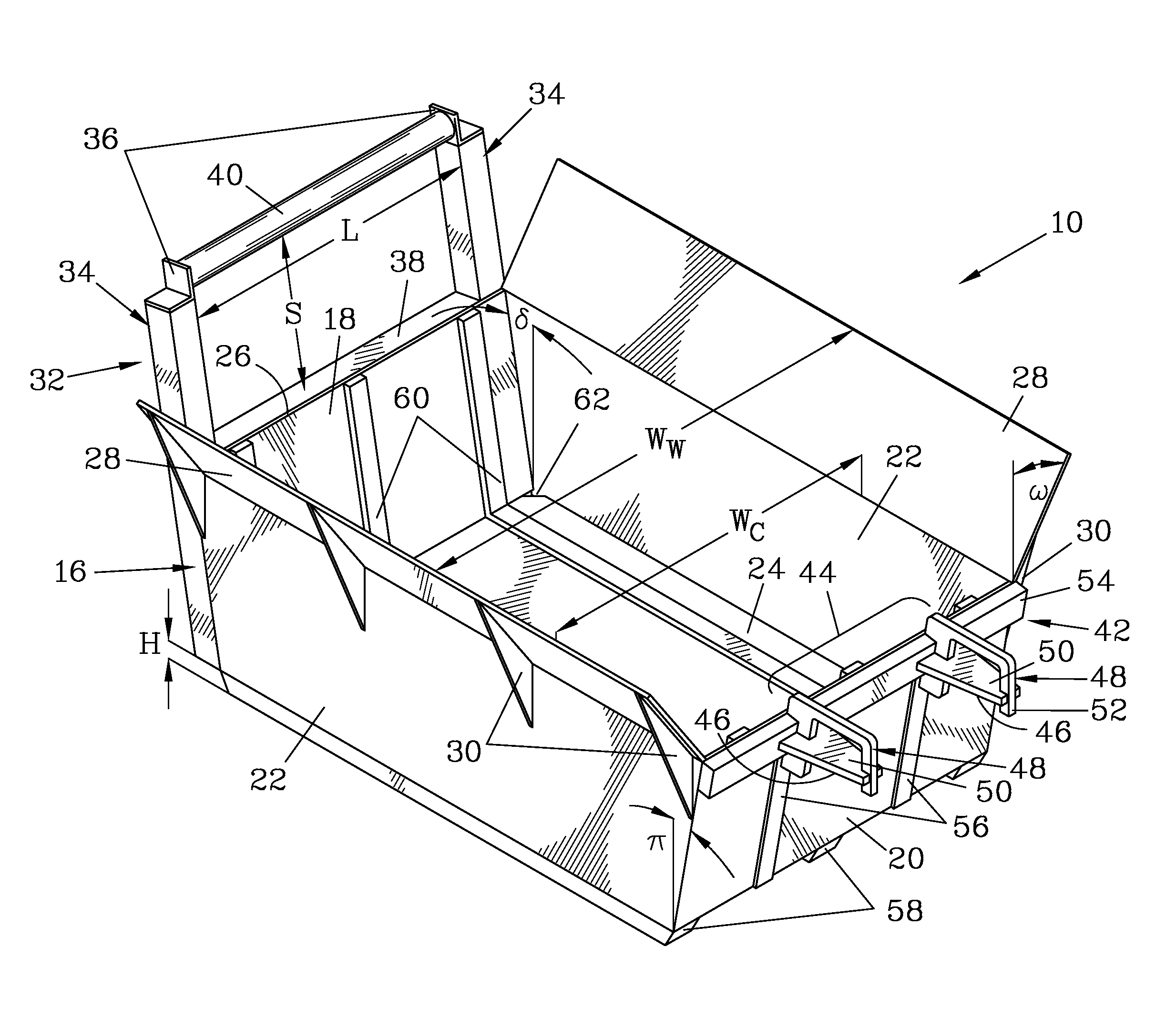

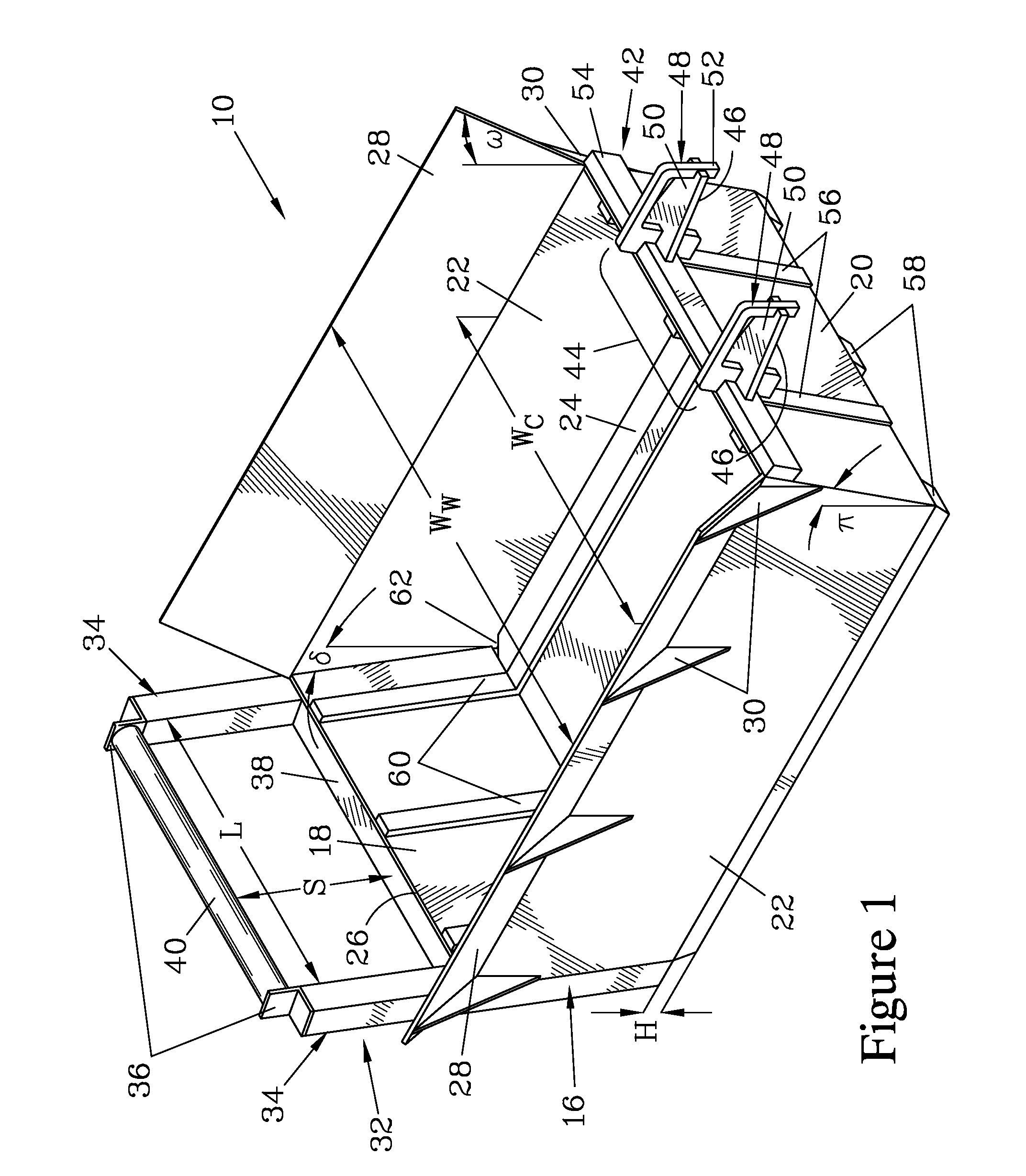

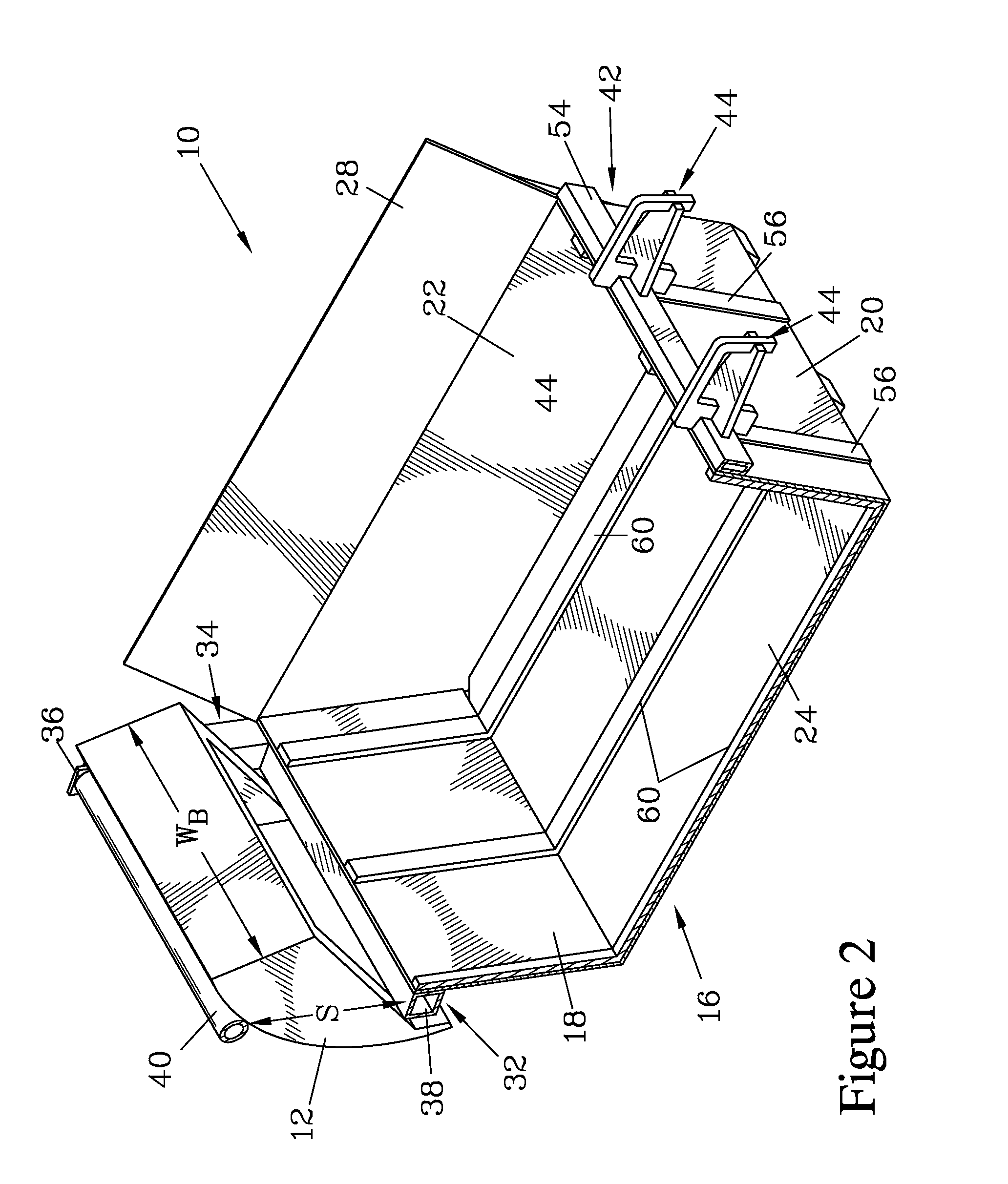

Dolly for supporting and transporting bakery trays

A load carrying device configured to support and transport a tray comprising a platform configured to support the tray, rolling means depending from the platform, and a retainer disposed on the platform and configured to loosely abut the tray to limit movement of the tray across the platform when the tray is supported on the platform. The retainer limits movement of the tray in all directions across the platform when the tray is supported on the platform. The retainer projects upwardly from the platform and presents a surface opposing horizontal movement of the tray when the tray is supported on the platform. The tray includes a bottom surface, a first pair of opposed walls projecting upwardly from the bottom surface, a second pair of opposed walls projecting upwardly from the bottom surface and integrally joined with the first pair of opposed walls, and a plurality of support members projecting below the bottom surface and configured to be supported by the platform, wherein the bottom surface is configured to clear the retainer when the support members are supported on the platform, and wherein the support members oppose and loosely abut the retainer when the support members are supported on the platform.

Owner:ORBIS CANADA

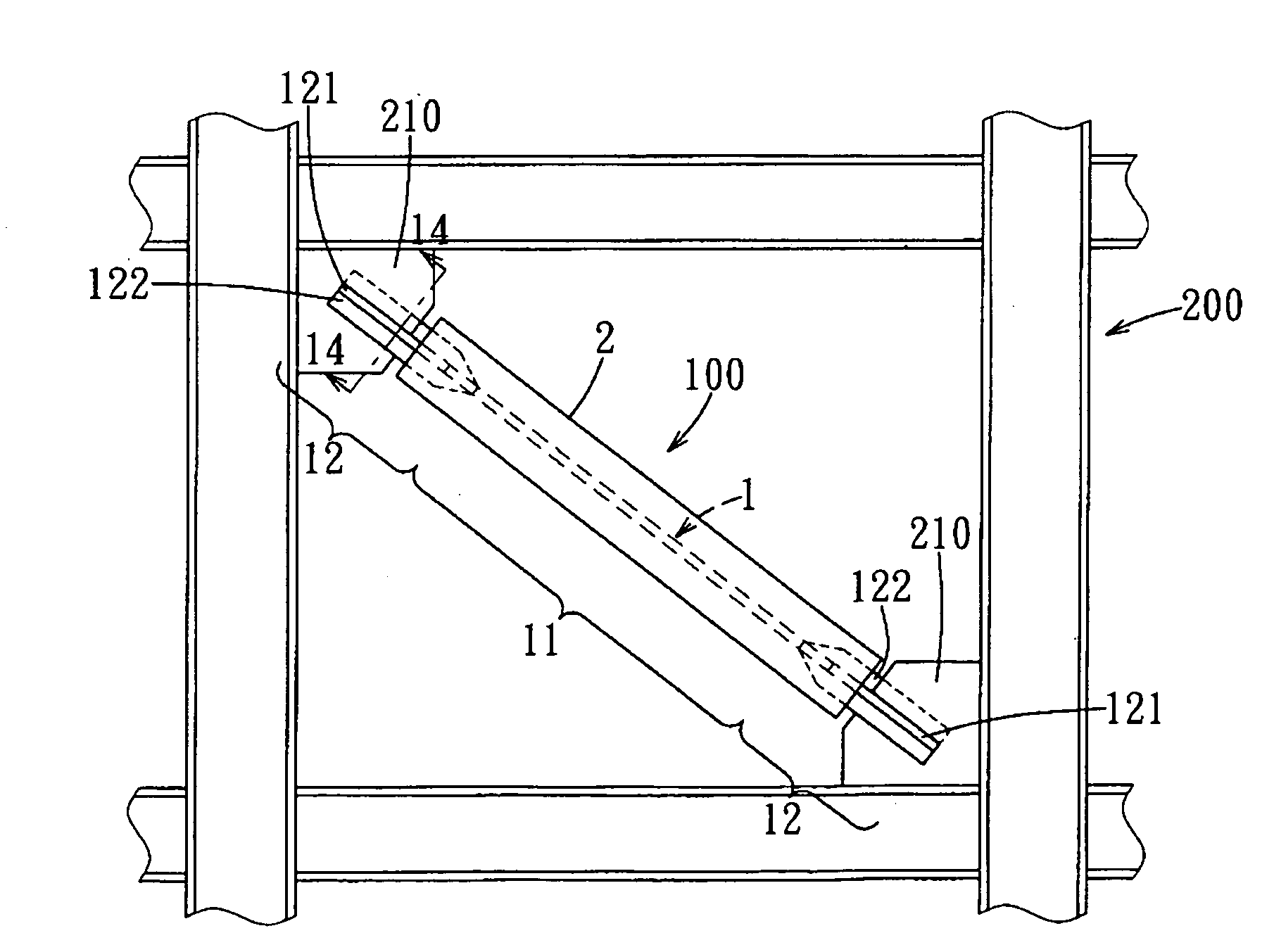

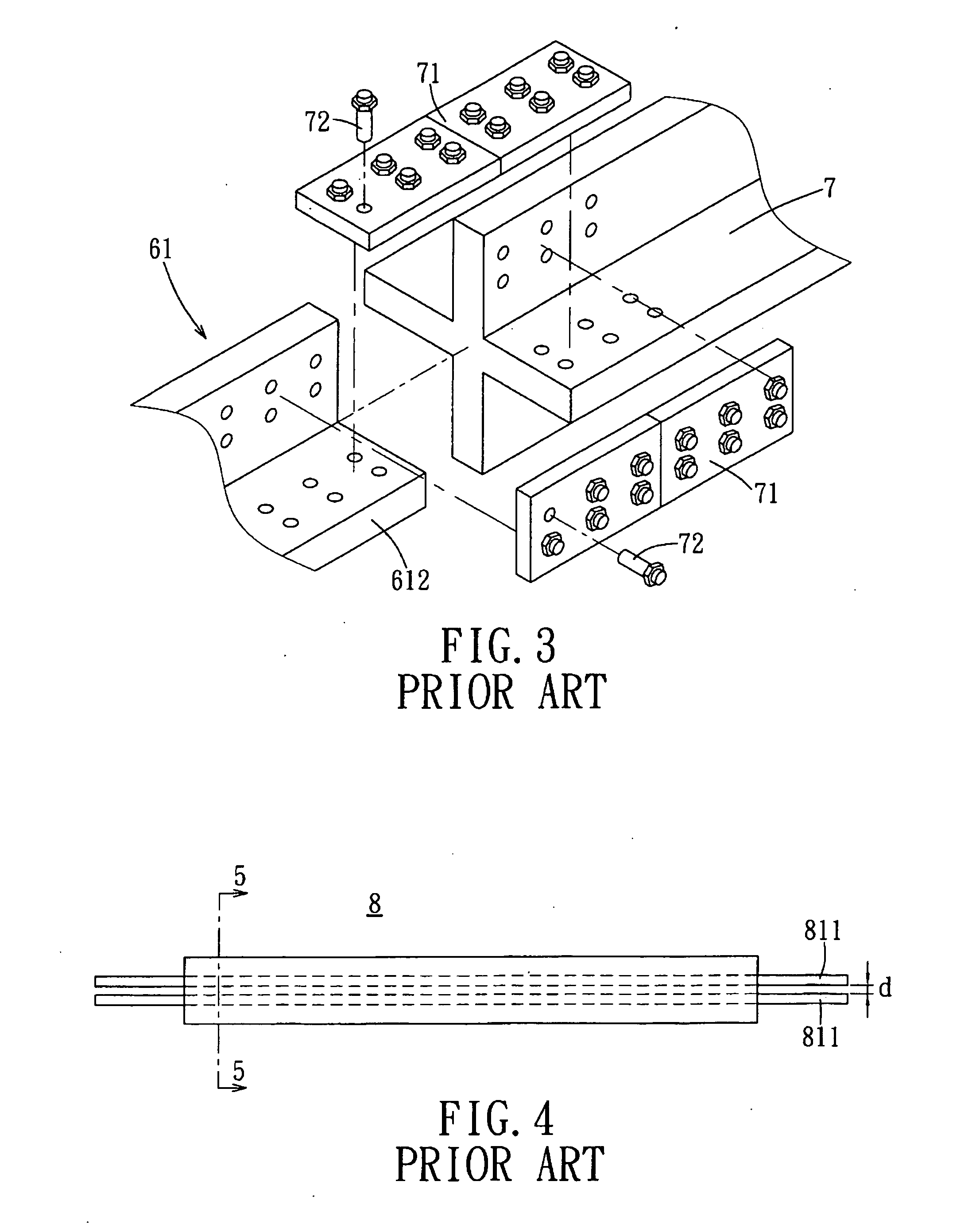

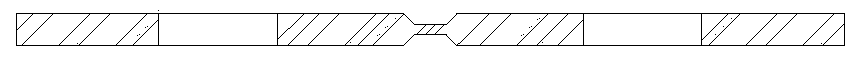

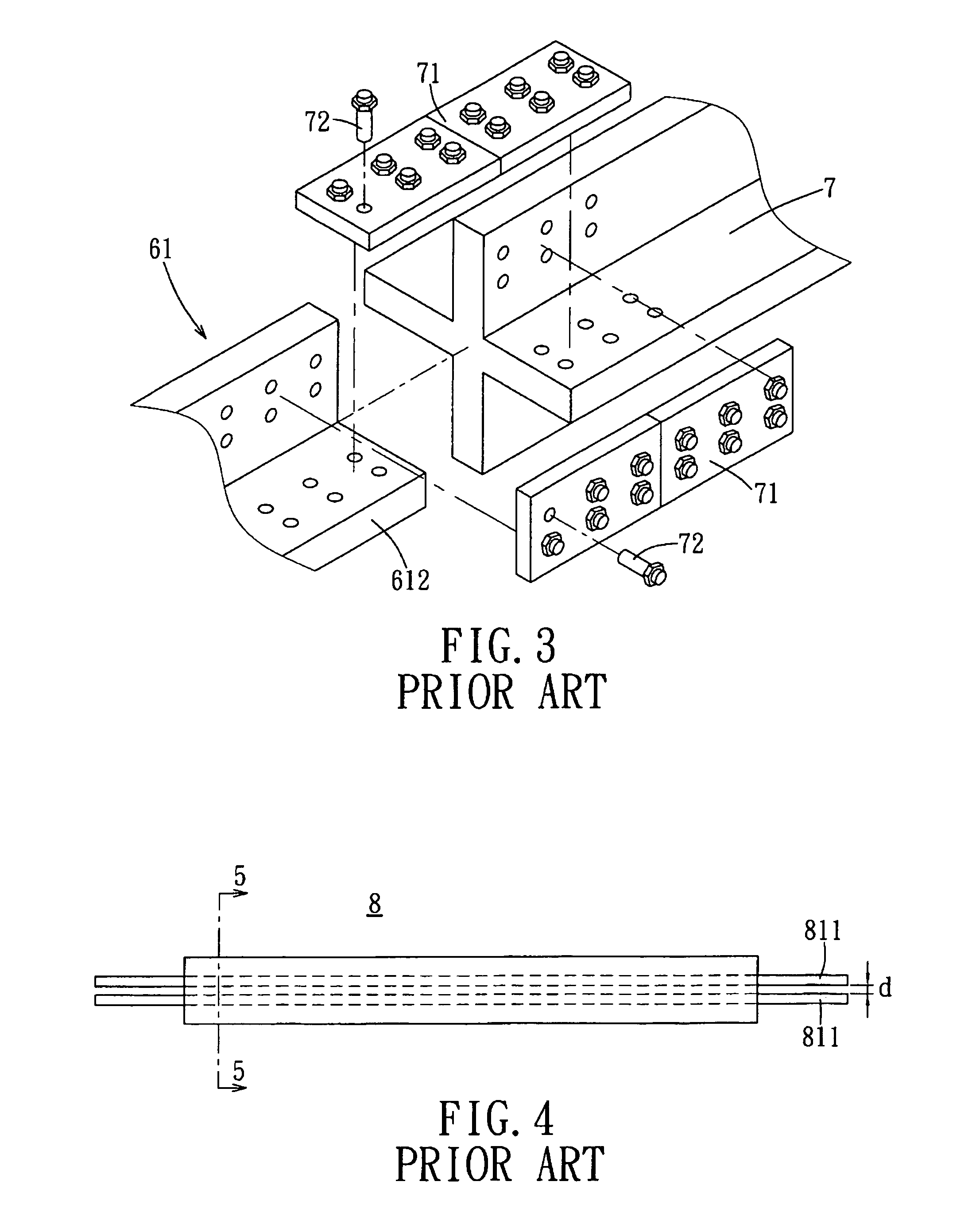

Buckling restrained brace

ActiveUS20100005737A1Easily connectBuckling of be reduceProtective buildings/sheltersBuilding reinforcementsBuckling-restrained braceCoupling

A buckling restrained brace includes an axial member and a restraining unit. The axial member extends along an axial direction, and has two coupling sections for connecting respectively to two connecting plates of a framework of a building, and a middle section connected between the coupling sections. Each coupling section has a supplying plate portion coplanar with an elongated plate body of the middle section, and a contacting plate portion extending perpendicularly from the supporting plate portion. An outer end of the supplying plate portion of each coupling section has a groove formed therethrough along a transverse direction of the axial member, extending along the axial direction, and permitting a respective one of the connecting plates to engage fittingly therewith and contact the corresponding contacting plate portion.

Owner:NAT APPLIED RES LAB

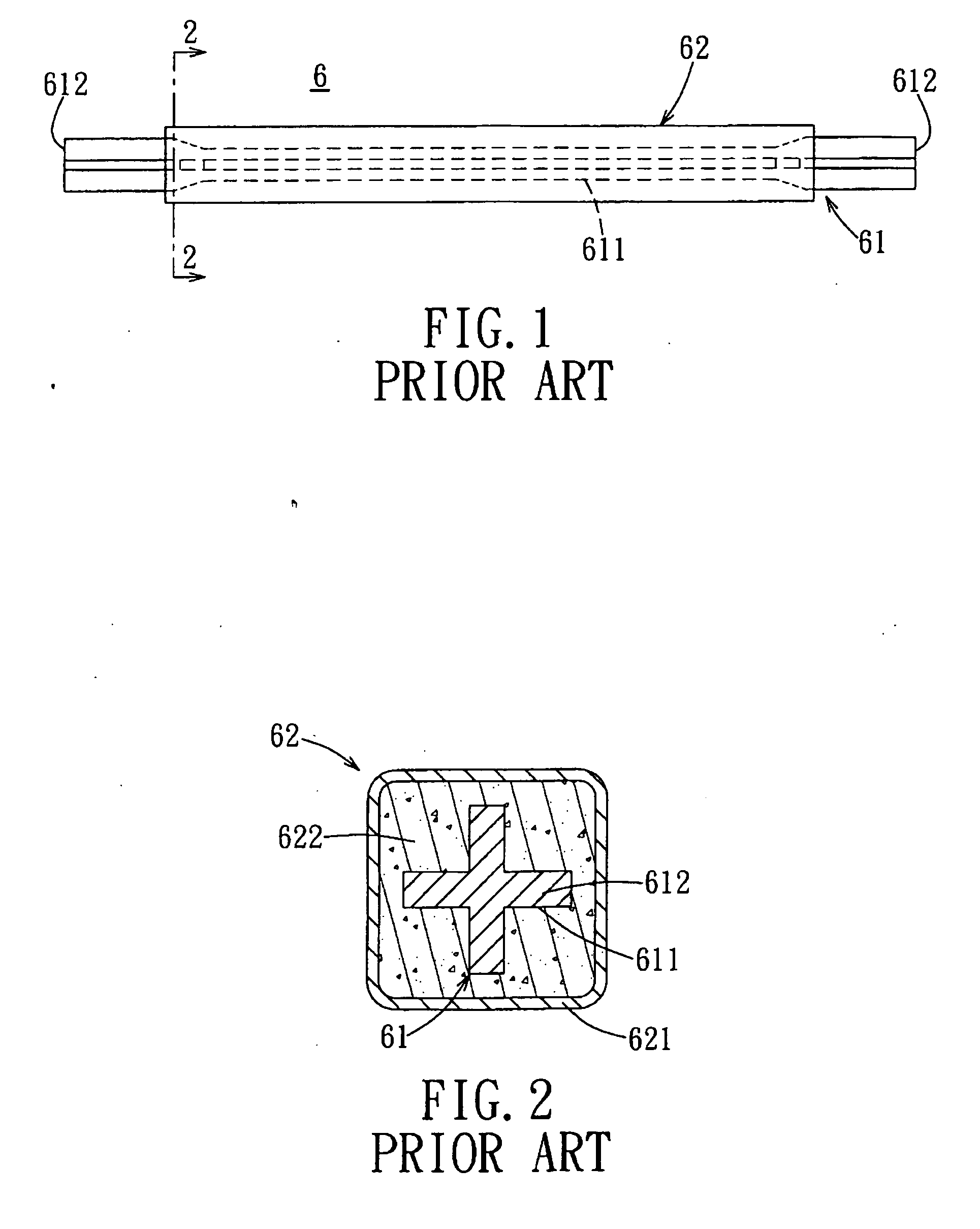

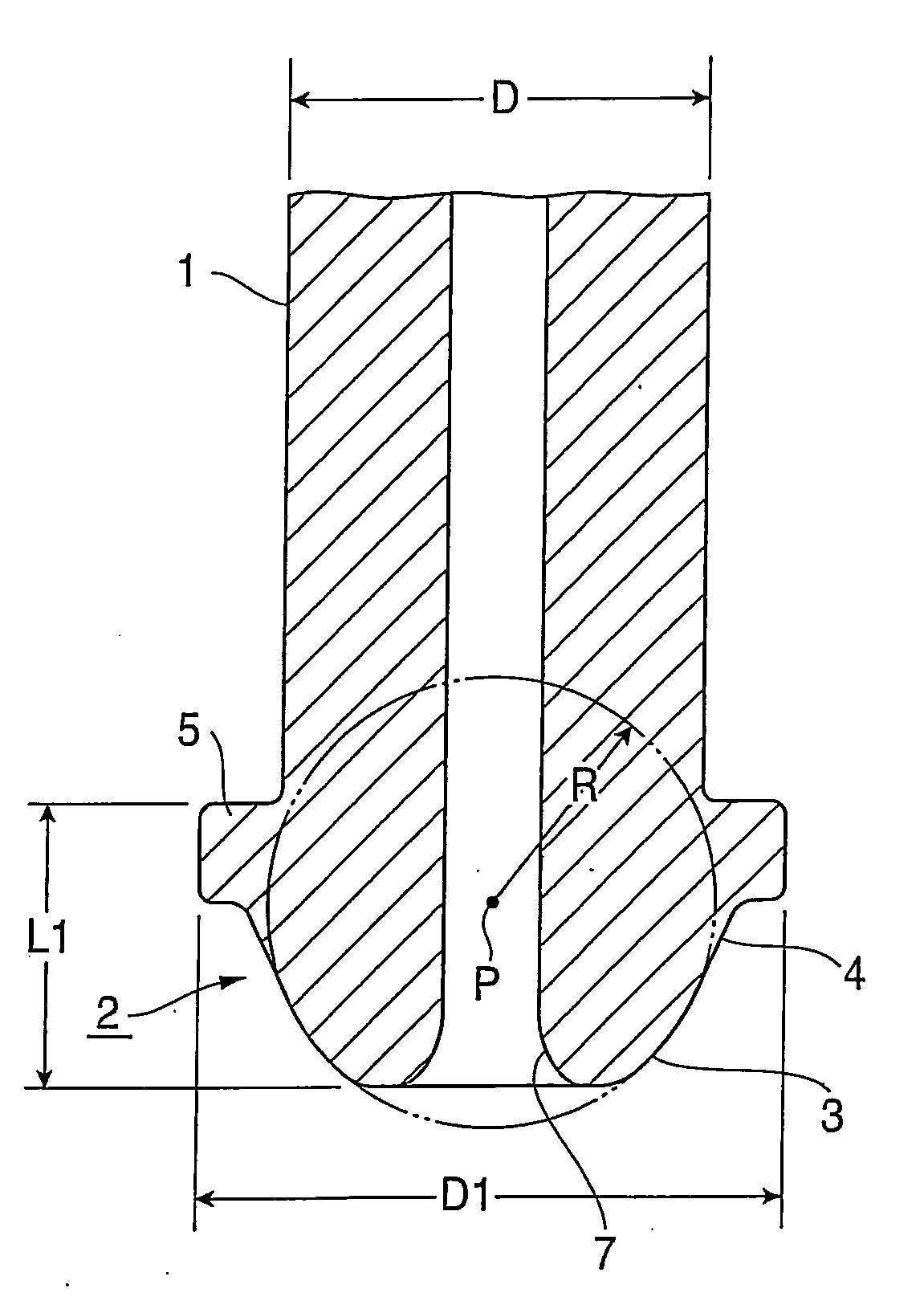

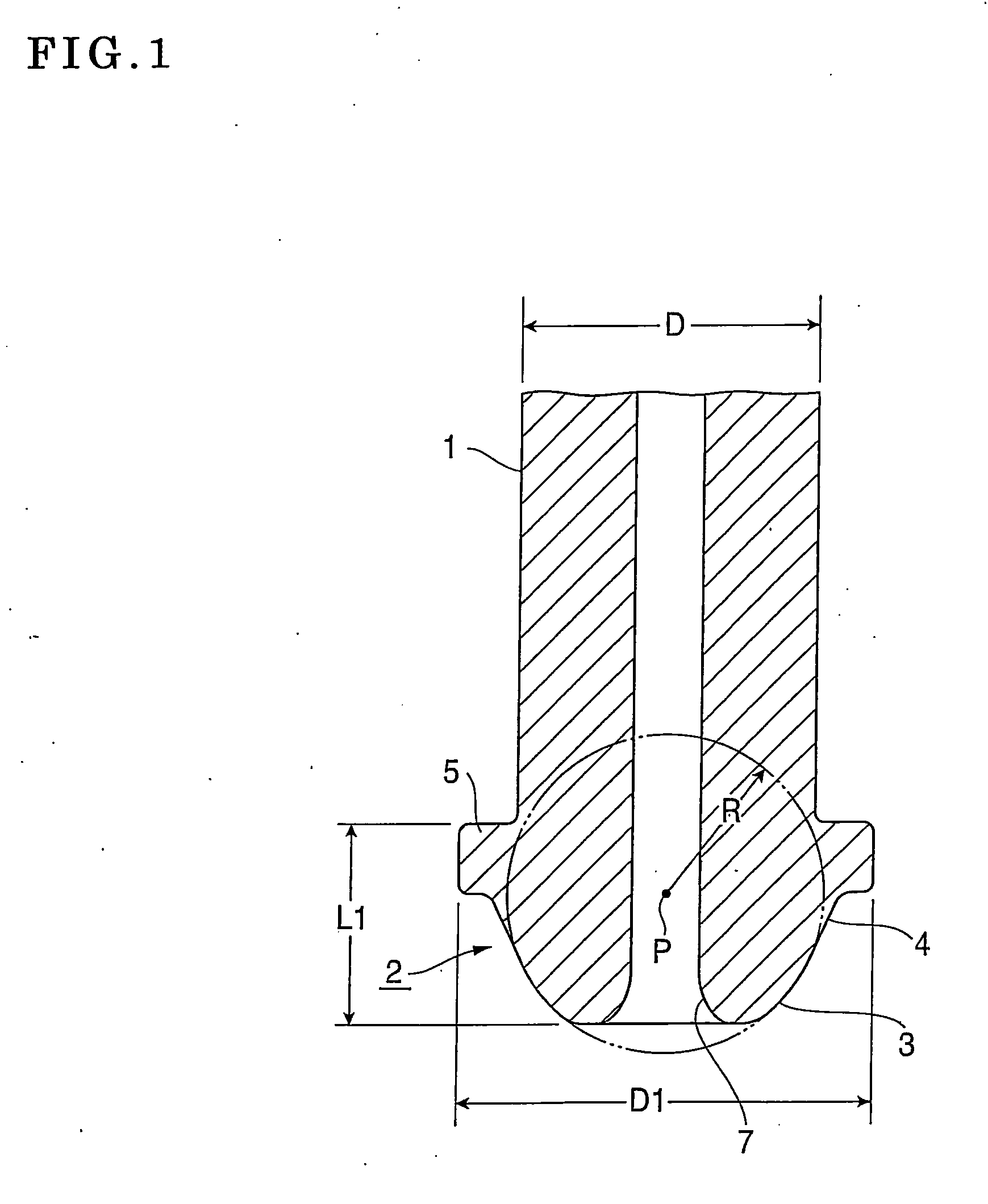

Connecting Head Stucture For High-Pressure Fuel Injection Pipes

ActiveUS20090139595A1Increase the diameterImprove stress conditionJoints with sealing surfacesMachines/enginesEngineeringThick wall

A thick-wall small-diameter high-pressure fuel injection pipe has a spherical seat surface, an annular flange, and a conical surface continued from the seat surface at a connecting end of the pipe. If the pipe is configured so that t (thickness) / D (outer diameter)<0.3, then an axial distance from the connecting head end to the back face of the annular flange is 0.38D to 0.6D, a spherical radius of the seat surface is 0.45D to 0.65D, the annular flange outer diameter is 1.2D to 1.4D, and an inner peripheral surface of the head has a substantially flat cylindrical surface or a conical surface. If the pipe is configured so that t (thickness) / D (outer diameter)≧0.3, then the axial distance from the connecting head end to the back face of the annular flange is 0.38D to 0.7D.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

Stapler Beam Architecture

ActiveUS20190239967A1Low bending stiffnessSufficient axial stiffnessSurgical robotsSurgical staplesPull forceEngineering

An end effector that can have an upper jaw and a lower jaw. A wrist can connect the end effector to an elongated shaft. A beam member can be arranged to translate within the upper and lower jaw. An actuation assembly can have a pushing assembly configured to transfer compressive force to the beam member and a pulling assembly configured to transfer tensile force to the beam member.

Owner:INTUITIVE SURGICAL OPERATIONS INC

Wrist Architecture

ActiveUS20190239877A1Prevent bucklingHighly compressibleSurgical manipulatorsSurgical robotsEngineeringGear tooth

A surgical device includes an elongated shaft, an end effector, and a wrist assembly. The wrist assembly includes a first outer link, a first inner link, and a second outer link. The first outer link is connected to the shaft and includes first gear teeth. The first inner link is pivotally coupled with the first outer link. The second outer link is pivotally coupled with the first inner link. The second outer link includes second gear teeth that interface with the first gear teeth and control orientation of the first inner link relative to the first outer link and the first outer link throughout a range of orientations of the wrist assembly.

Owner:INTUITIVE SURGICAL OPERATIONS INC

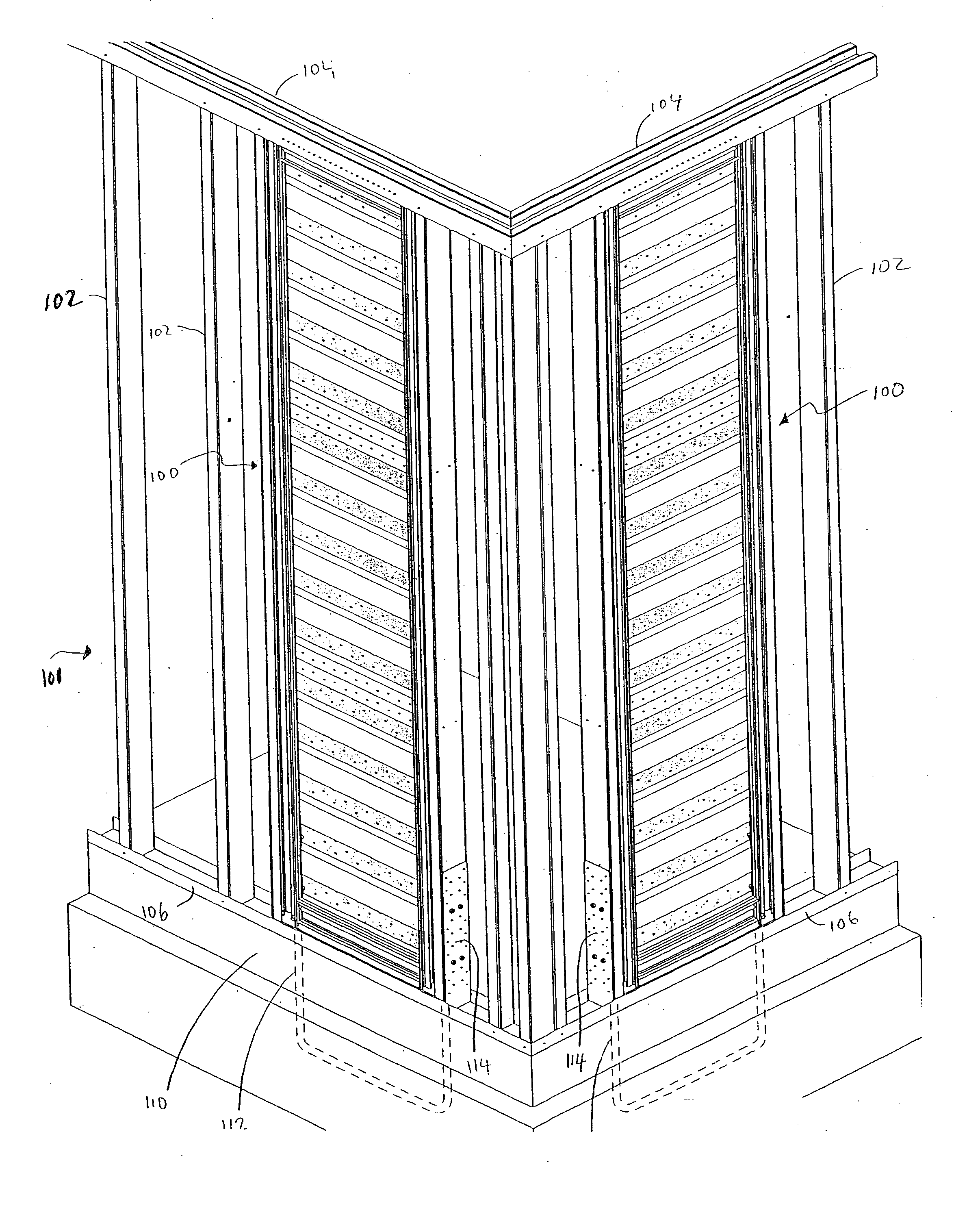

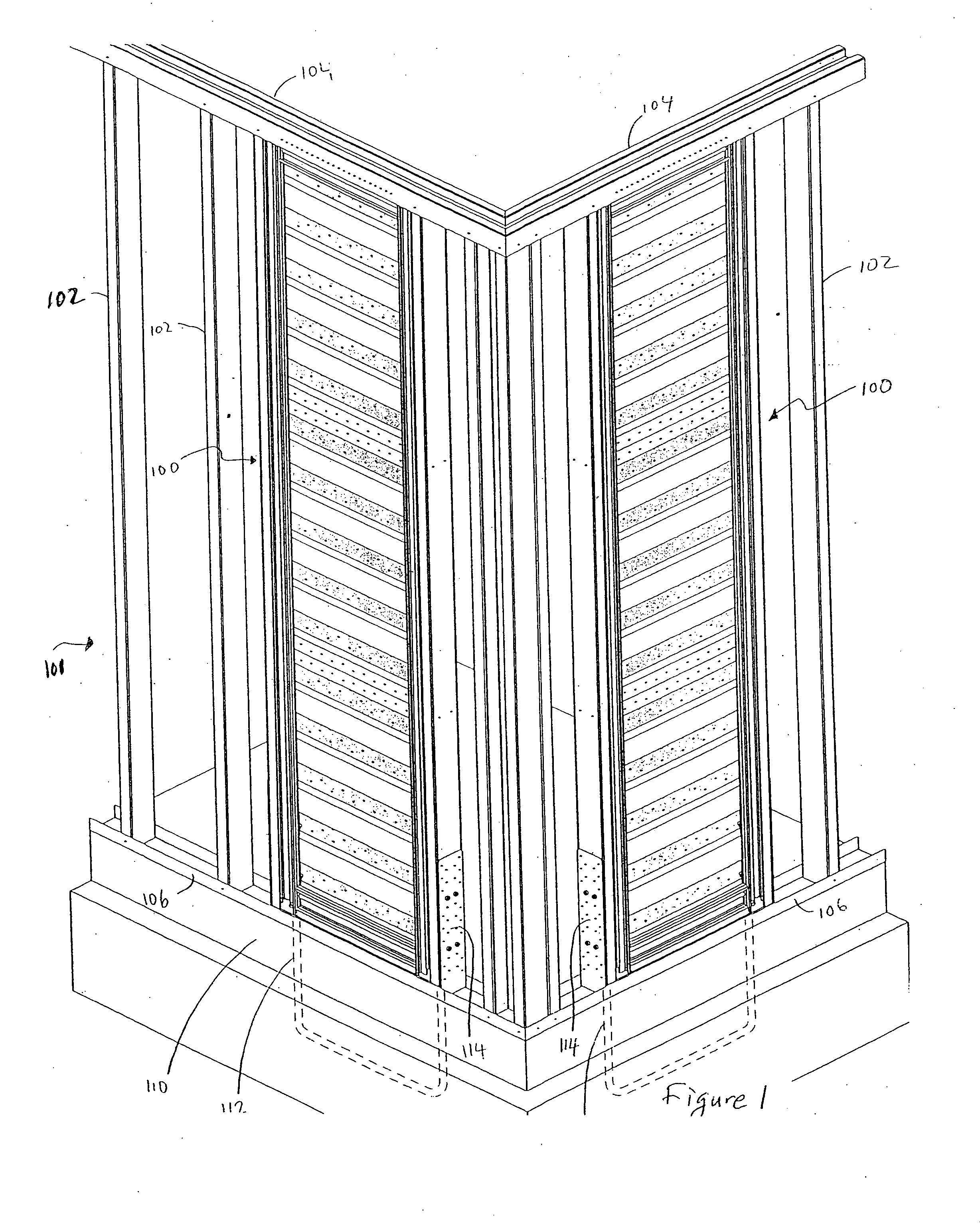

Corrugated shear panel and anchor interconnect system

InactiveUS20070062135A1Increase shear forceImprove shear resistanceProtective foundationEngineeringDistortion

A system for inhibiting unwanted movement between a building and an underlying foundation, the system including at least one shear panel assembly including corrugated portions and configured to resist bending and twisting distortion and at least one hold-down assembly configured to attach to the at least one shear panel assembly and to attach to at least one anchor member rigidly engaged with an underlying building foundation so as to resist uplift, downward movement, and lateral movement of the at least one attached shear panel assembly, the at least one hold-down assembly configured to provide a range of vertical attachment adjustment to accommodate a range of extended length of the at least one anchor member.

Owner:MUELLER LEE W

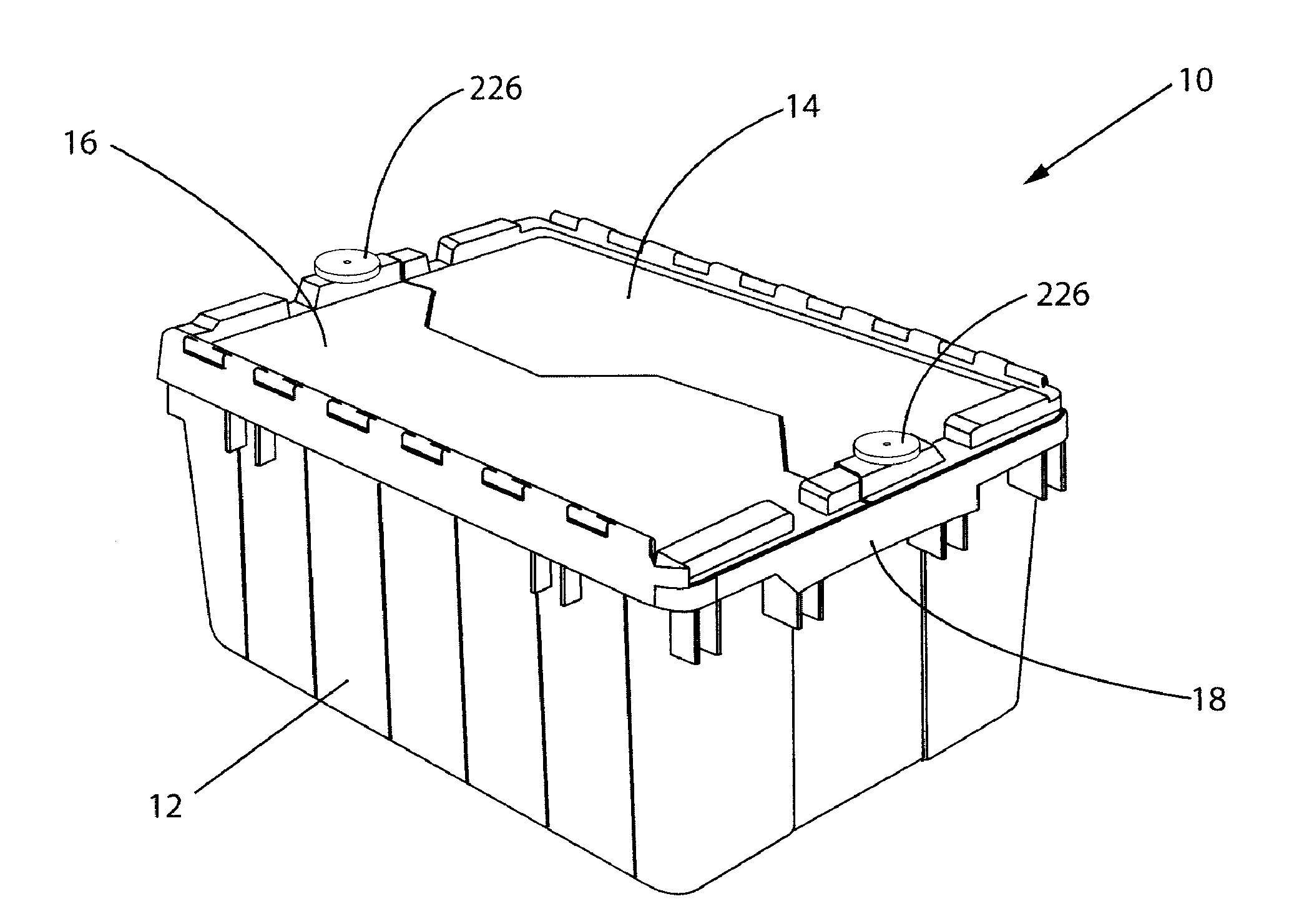

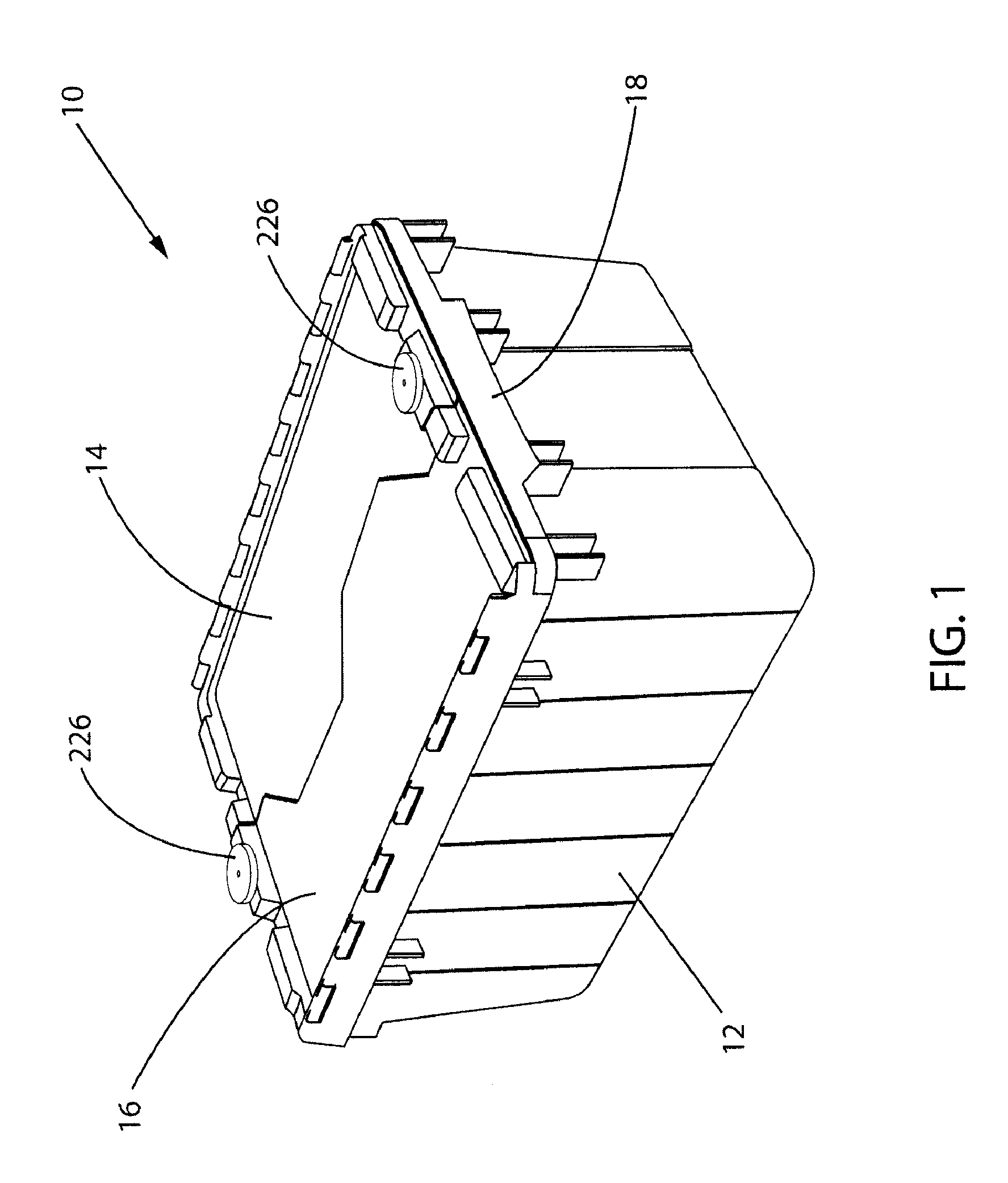

Locking device for tote bin

InactiveUS20100133126A1Effective and reliableDelayed bucklingNon-mechanical controlsLarge containersEngineeringMechanical engineering

A locking device is provided for locking a container having sidewalls and at least one lid defining an open position and a closed position. The locking device may include an elongate lock member configured to engage the lid(s) and a lock housing that is associated with at least one of the sidewalls. The lock housing may be configured to at least partially receive the elongate lock member. The locking device may be designed to be installed on the container in the field, or the locking device may be integrally formed with the container. The lock housing may include a security element that is detectable by a security system to guard against theft of the container. In some cases, a security module is provided that releasably attaches to the lock housing to provide further alarm functionality.

Owner:CHECKPOINT SYST INC

Method Of Manufacturing A Semiconductor Device And A Semiconductor Device Produced Thereby

InactiveUS20100213623A1Delayed bucklingImprove the immunitySemiconductor/solid-state device detailsSolid-state devicesEpoxyCompression molding

A method of manufacturing a semiconductor device sealed in a cured silicone body by placing an unsealed semiconductor device into a mold and subjecting a curable silicone composition which is fed into the space between the mold and the unsealed semiconductor device to compression molding, the method being characterized by the fact that the aforementioned curable silicone composition comprises at least the following components: (A) an epoxy-containing silicone and (B) a curing agent for an epoxy resin; can reduce warping of the semiconductor chips and circuit board, and improve surface resistance to scratching.

Owner:DOW CORNING TORAY CO LTD

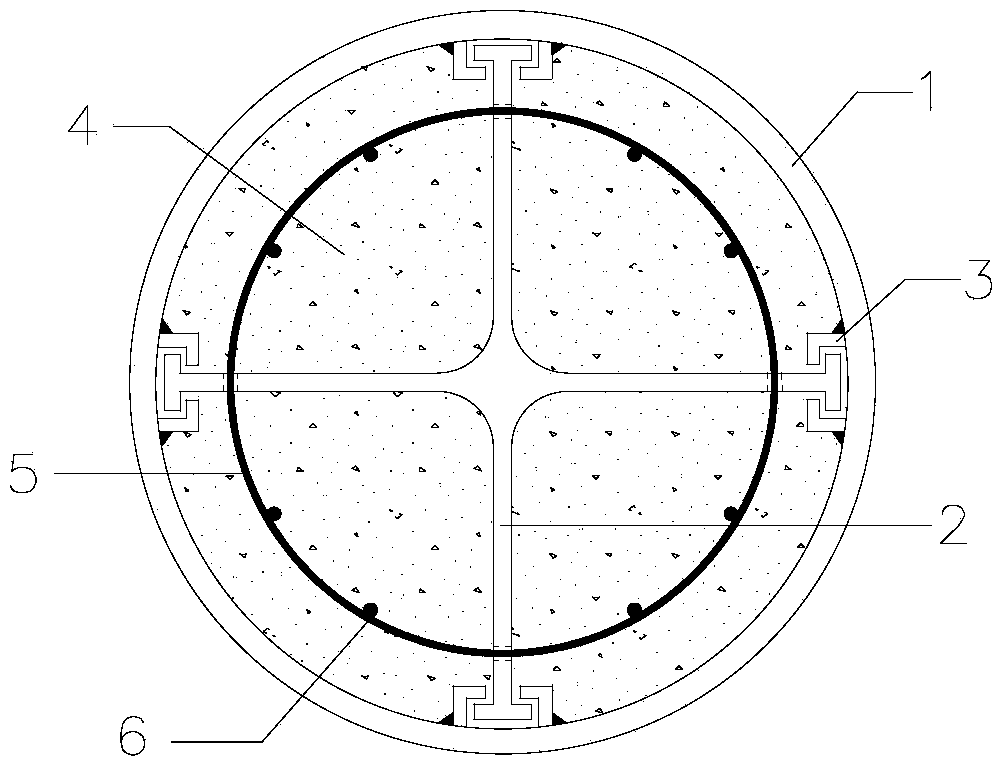

Fiber reinforce plastic (FRP) reinforced concrete-filled steel tube combination column

ActiveCN103899040AEnhanced binding effectDelayed bucklingStrutsBuilding reinforcementsFiberReinforced concrete

The invention aims at providing a fiber reinforce plastic (FRP) reinforced concrete-filled steel tube combination column which comprises a steel tube, a hoop rib, an FRP reinforced rib and a longitudinal reinforcement, wherein the hoop rib and the FRP reinforced rib are arranged in the steel tube; the inner wall of the steel tube is provided with fixed angle iron; the end part of the FRP reinforced rib is fixed on the angle iron; the FRP reinforced rib is provided with a hole, and the hoop rib passes through the hole in the FRP reinforced rib; the longitudinal reinforcement is fixed on the hoop rib; the steel tube is filled with concrete. An FRP reinforced rib plate internally provided with the hoop rib and the longitudinal reinforcement is arranged in the FRP reinforced concrete-filled steel tube combination column, and the concrete can be separated again, so that the restraint effect of the concrete is improved, the bearing capacity of the concrete is improved, and the tube wall on the stressed side is effectively prevented from being bended. By adopting a structure of enabling reinforced concrete, the FRP reinforced rib and the steel tube to cooperative work, the FRP reinforced concrete-filled steel tube combination column is simple in structure and convenient to construct, and has the characteristics of being light in weight, high in carrying capacity and good in ductility and shock resistance.

Owner:HARBIN ENG UNIV

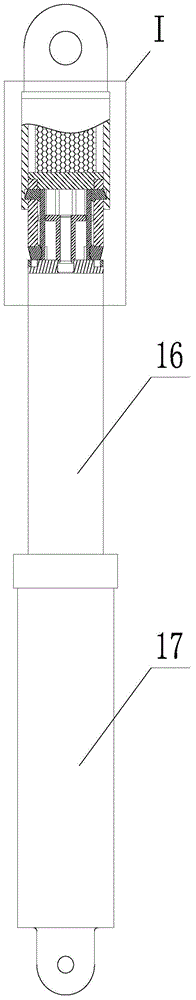

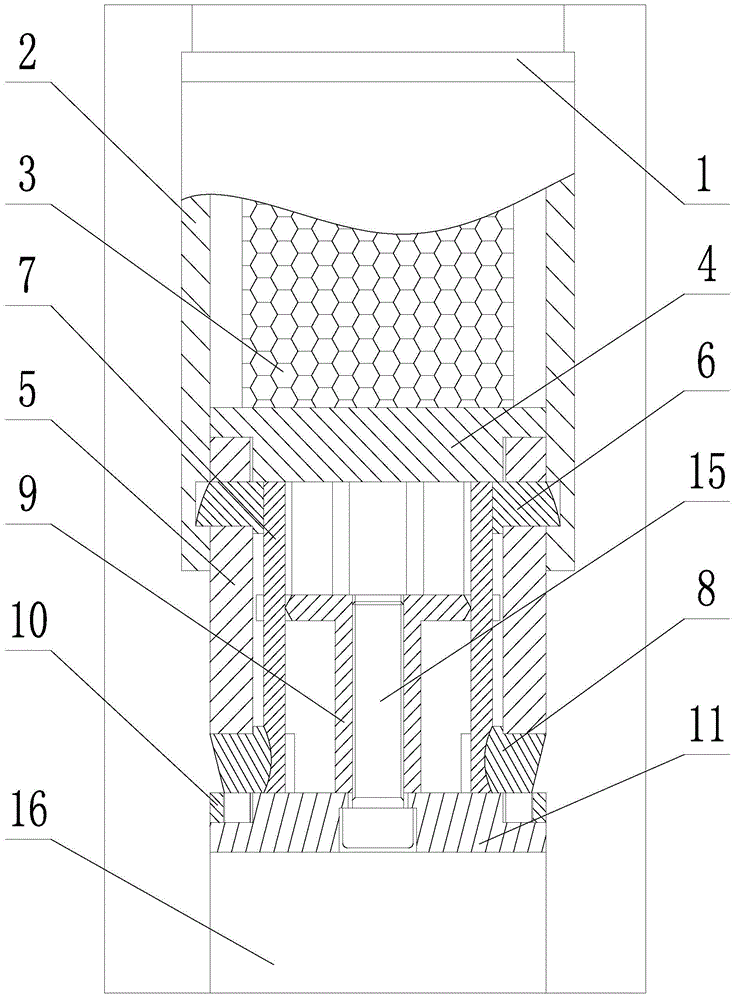

Hydraulic prop having anchoring force energy-absorbing buffering function

ActiveCN105041350AImprove impact resistanceMitigate excess impactProps/chocksSupporting systemInstability

A hydraulic prop having an anchoring force energy-absorbing buffering function comprises a prop main body part. An anchoring force energy-absorbing buffering mechanism part is arranged at the end of a movable column of the prop main body part, so as to overcome the shortcoming that an existing hydraulic prop is weak in impact resistance. When the hydraulic prop is subjected to impact of an external load and when the loading force is not enough to break open a clamping pin in an anchoring force supporting state, the impact load can be resisted through the rigid supporting of the clamping pin; and when the loading force exceeds the anchoring force supporting force of the clamping pin, the clamping pin cannot support an outer sleeve any longer and is obliged to retract towards an inner sleeve. While the clamping pin retracts, an energy-absorbing block is compressed in first time to absorb energy, precious buffering time is provided for the opening of a hydraulic prop safety valve, the safety valve is prevented from being damaged in an instant by huge impact force, the occurrence probability of cylinder explosion, sealing ring crushing and prop instability and bending is reduced, the impact resistance of the hydraulic prop is improved, and the safety factor of the hydraulic prop and a supporting system where the hydraulic prop is located is improved.

Owner:LIAONING TECHNICAL UNIVERSITY

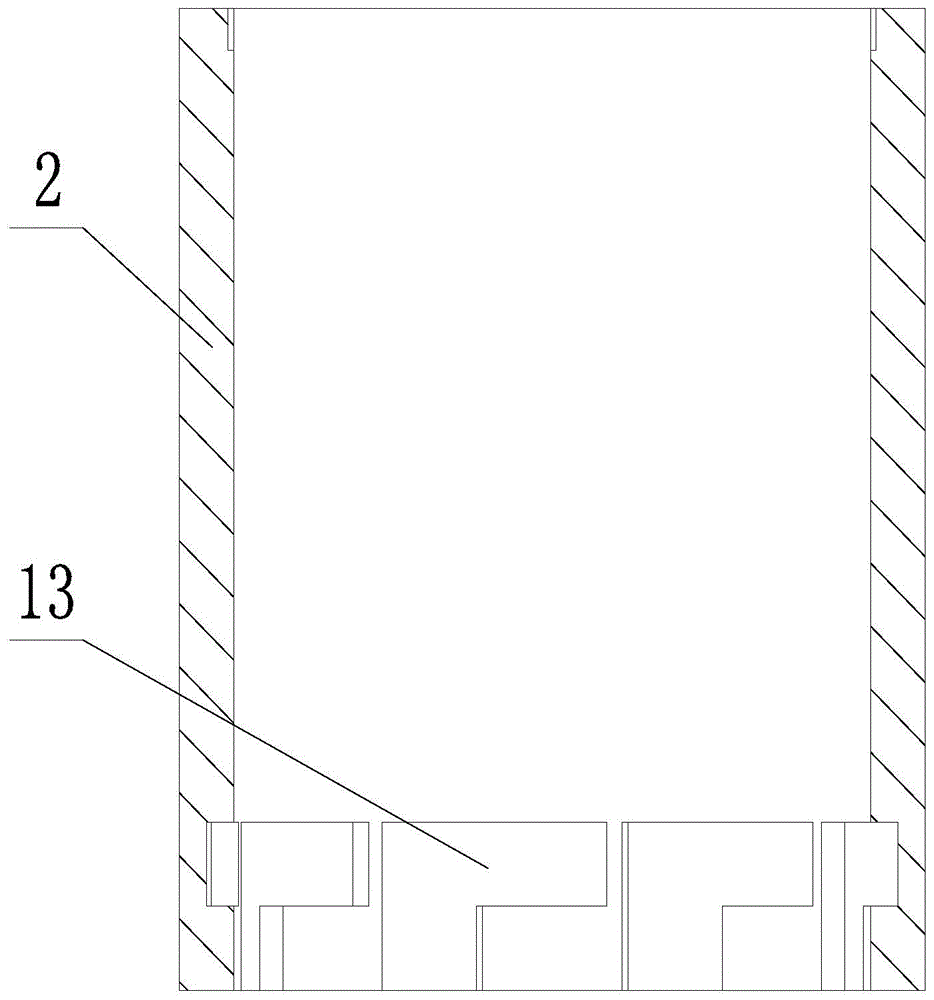

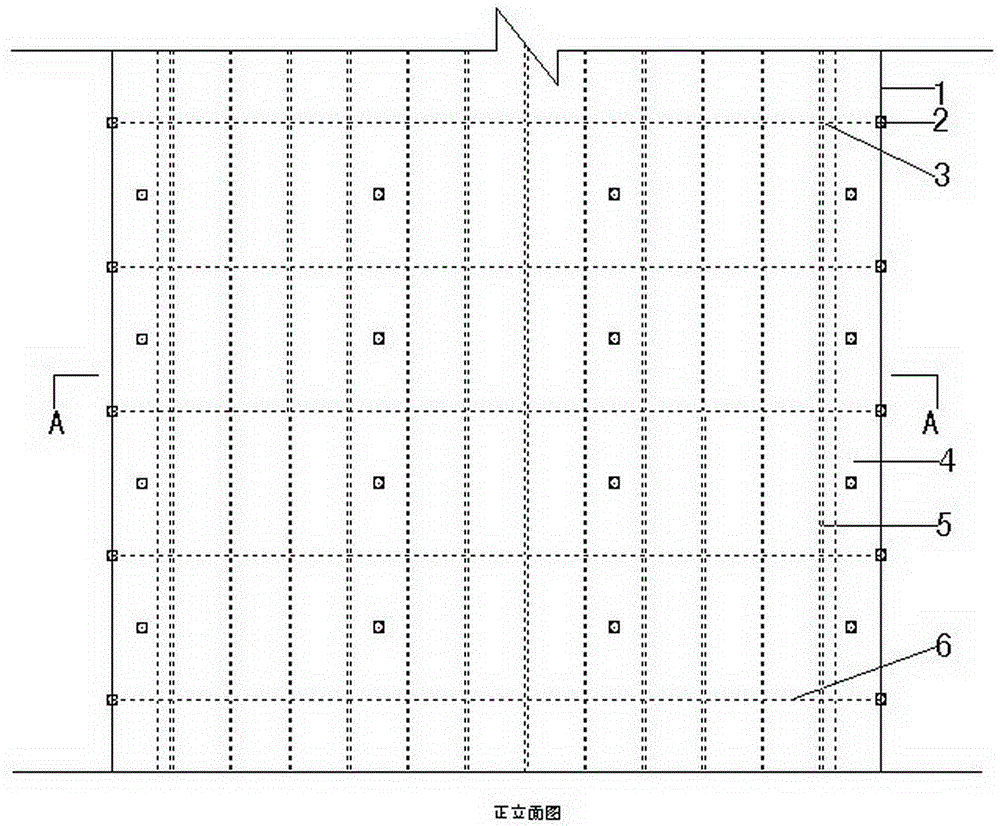

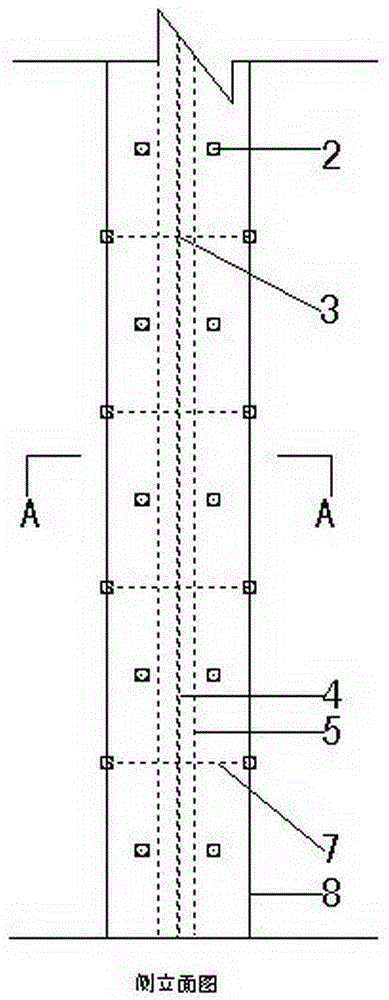

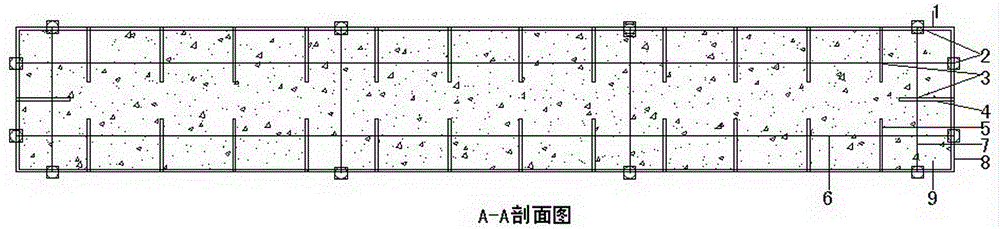

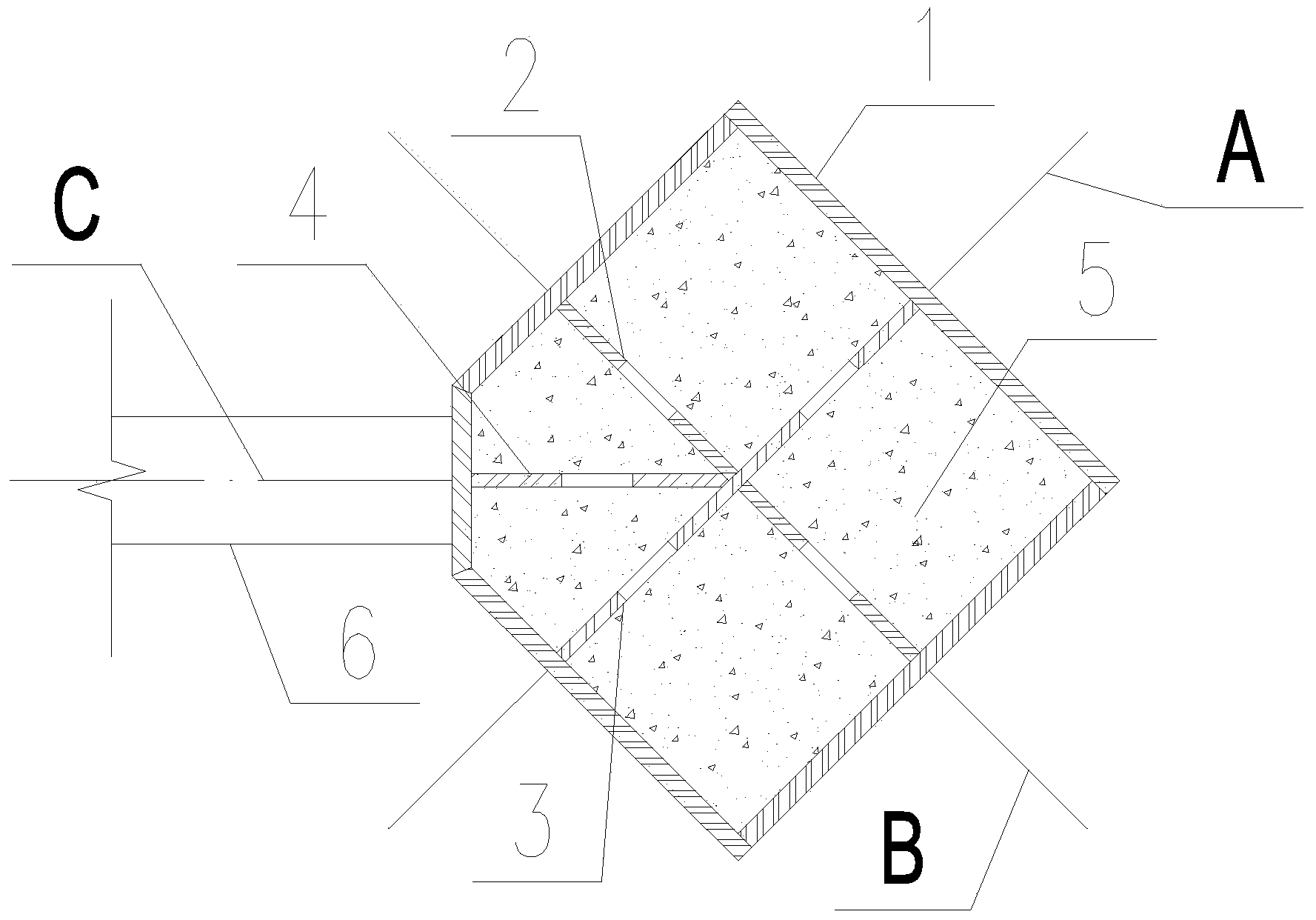

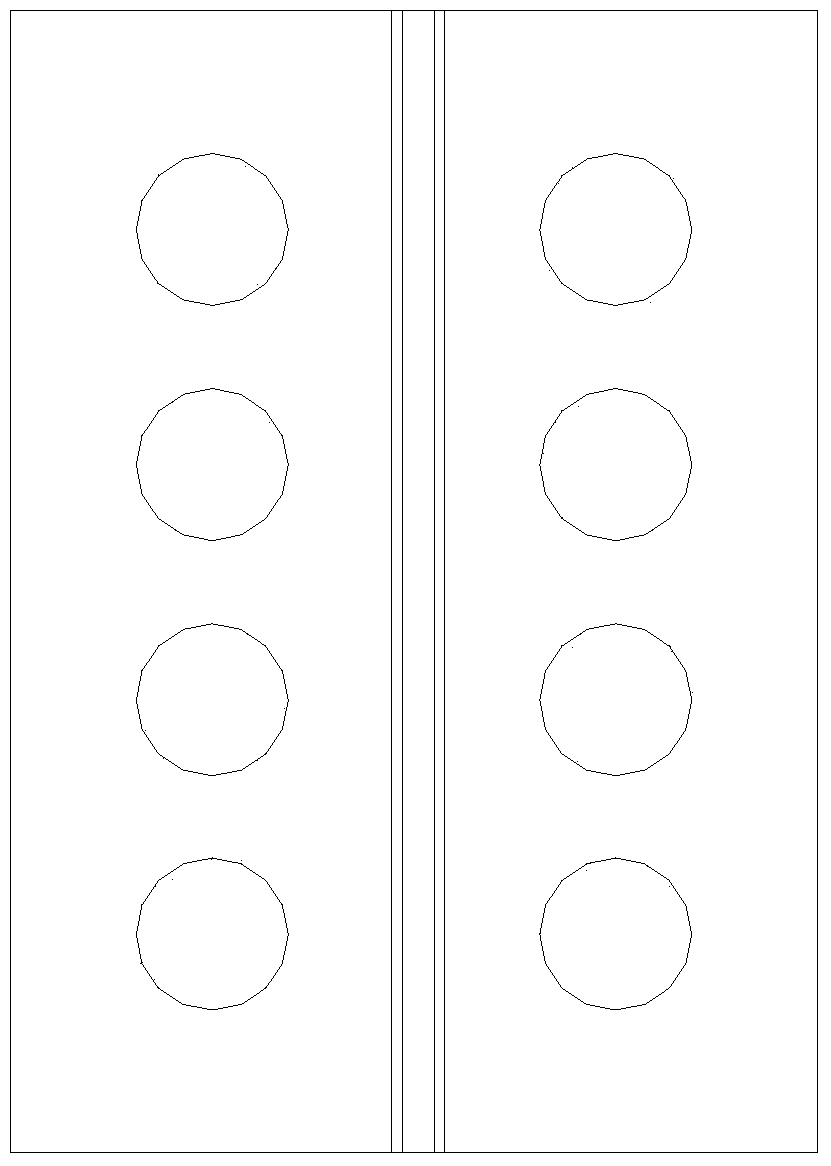

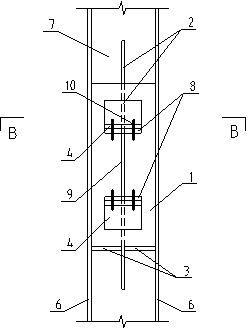

Punched rib and pull rod constraint double-layer steel plate concrete shear wall

The invention discloses a punched rib and pull rod constraint double-layer steel plate concrete shear wall. The punched rib and pull rod constraint double-layer steel plate concrete shear wall comprises two opposite wall body steel plates, connection steel plates at the two ends of a wall body, filling concrete defined by the steel plates on the four sides, punched stiffening ribs and pulling rods penetrating through the punched stiffening ribs. The punched stiffening ribs are arranged on the inner side faces of the steel plates and connected through the pulling rods penetrating through holes. The pulling rods comprise the pulling rods in the wall length direction and the pulling rods in the wall thickness direction. The pulling rods in the wall length direction penetrate through the stiffening ribs arranged in the wall length direction and the connection steel plates at the two ends. The pulling rods at the two ends of the wall body in the wall thickness direction penetrate through the stiffening ribs in the wall thickness direction and the two opposite wall body steel plates. The pulling rods at other portions in the wall thickness direction are arranged between every two adjacent stiffening ribs arranged in the wall length direction every other 2-5 stiffening ribs, and are staggered with the pulling rods in the wall thickness direction along the wall height part at proper intervals. The bearing capacity and ductility of the shear wall can be improved.

Owner:HENAN POLYTECHNIC UNIV

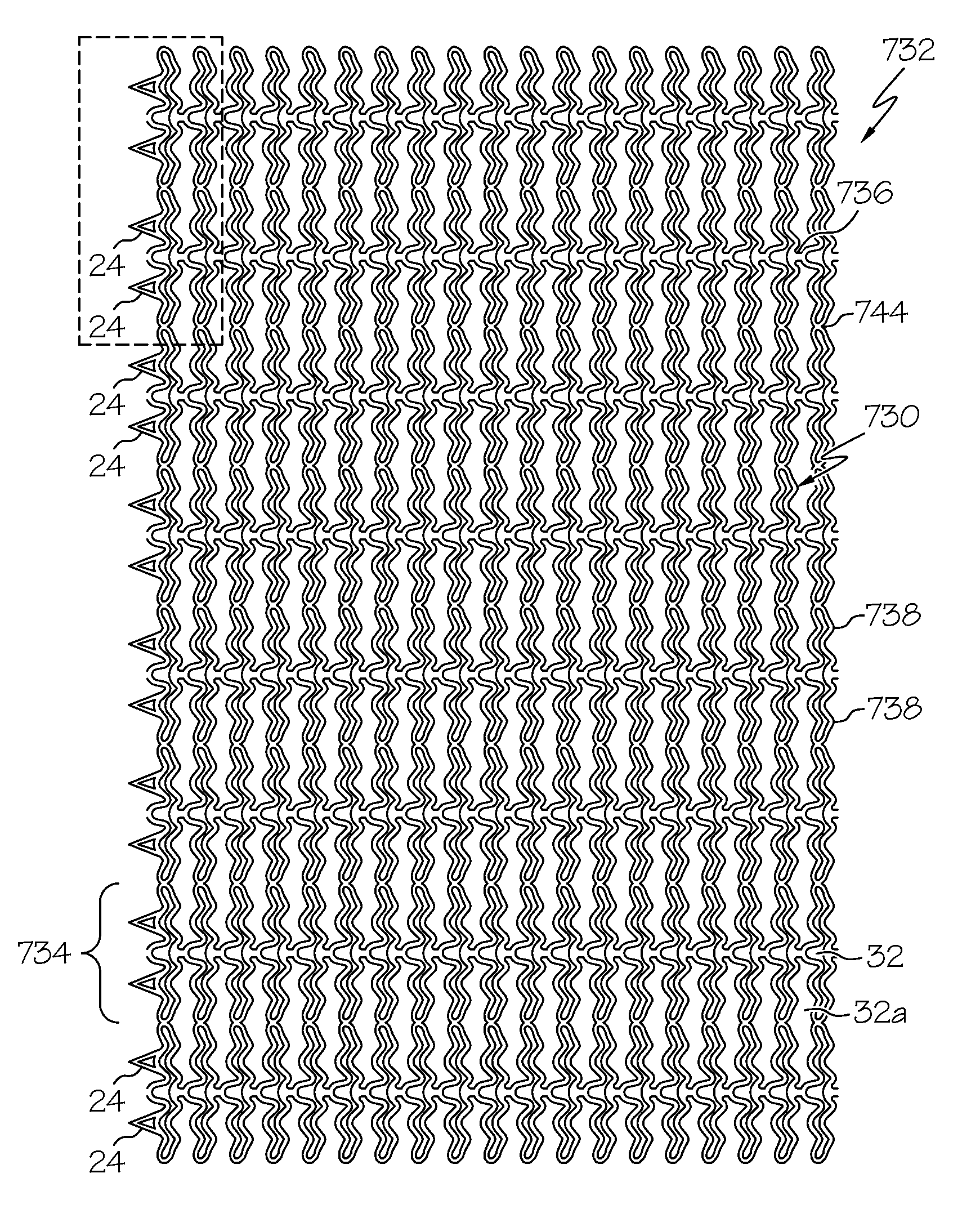

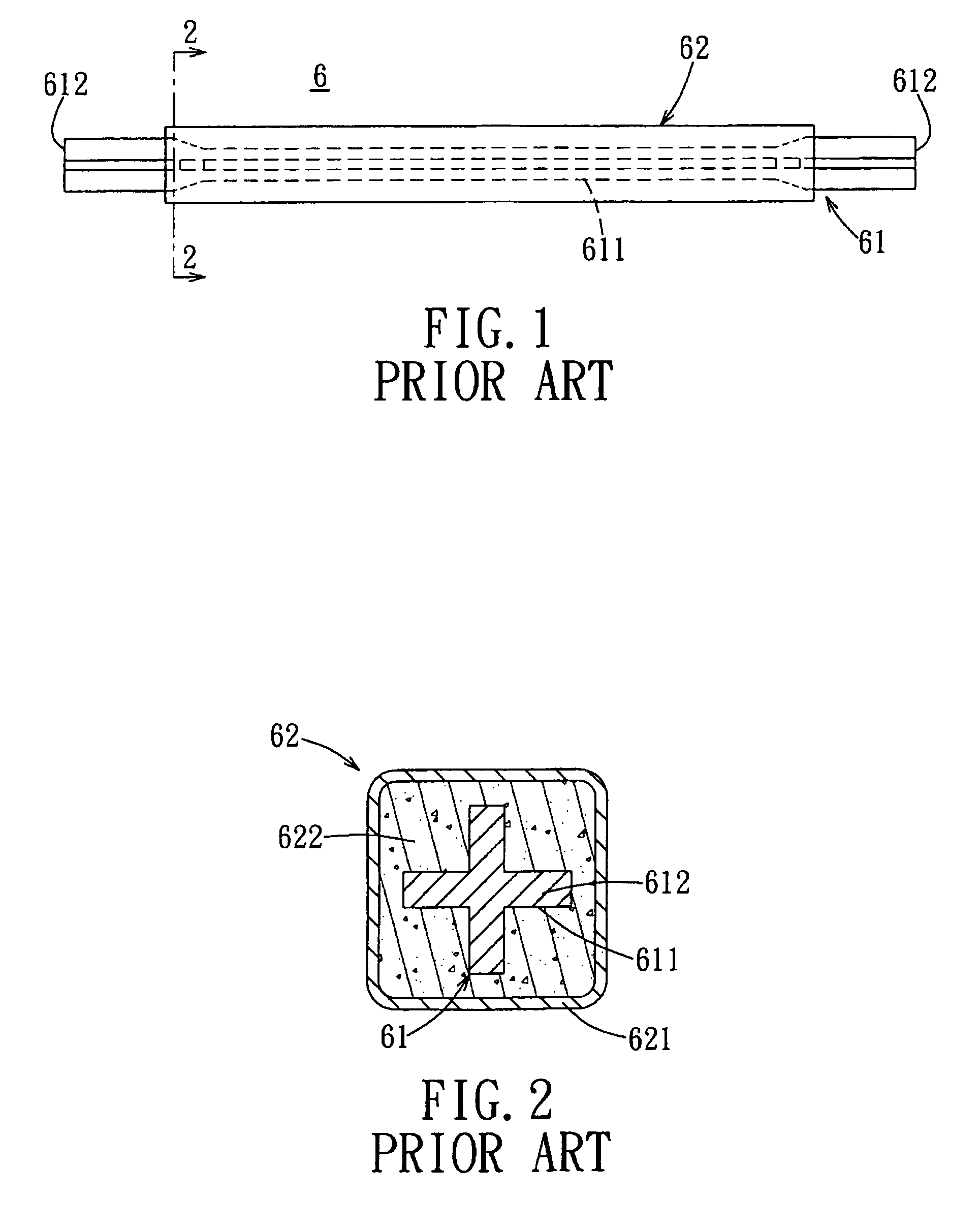

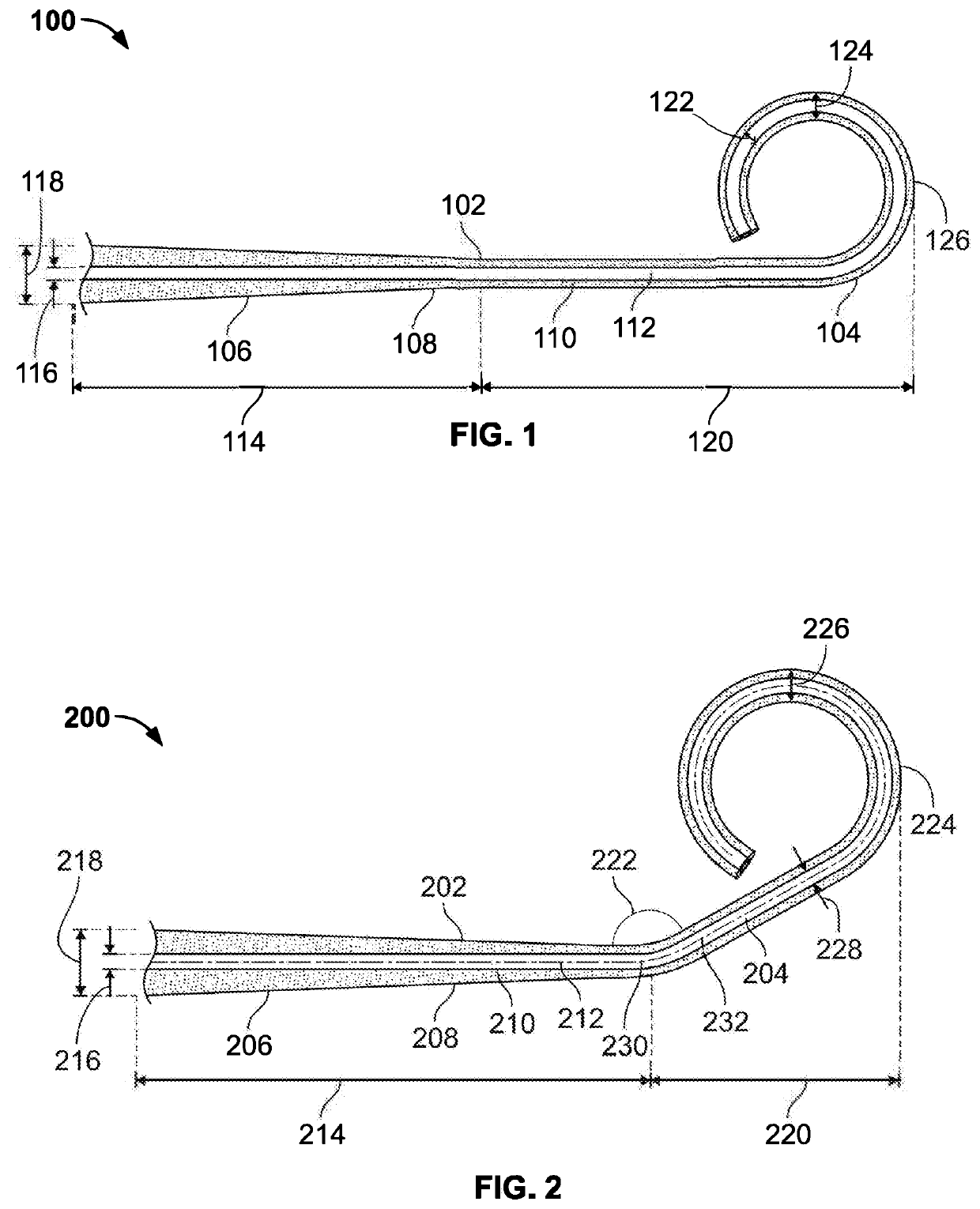

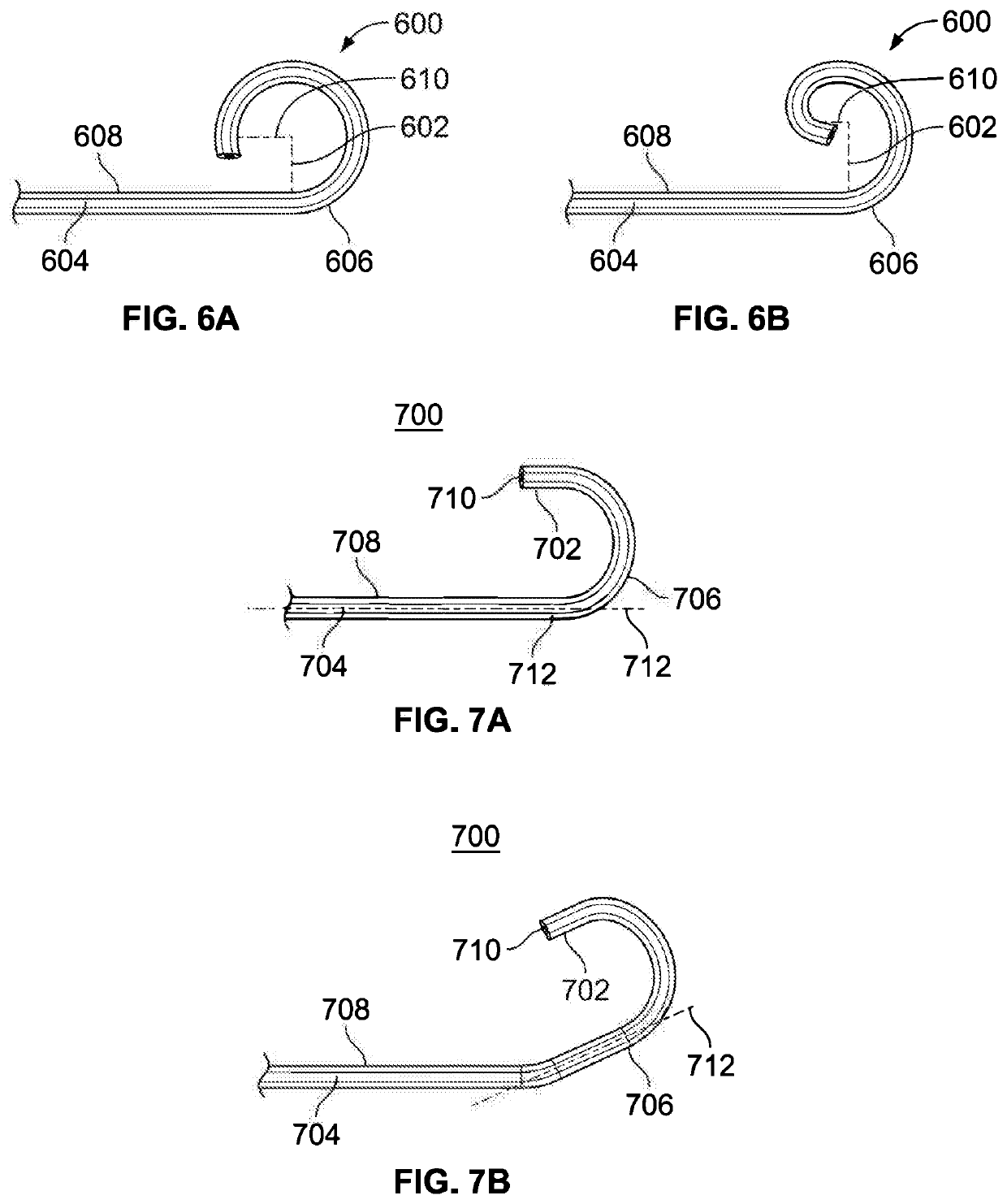

Stretchable anti-buckling coiled-sheet stent

A stent includes a coiled-up sheet having overlapping inner and outer longitudinal sections extending parallel to a longitudinal axis thereof, and defining a periphery, the coiled-up sheet being unrollable between contracted and enlarged conditions. A plurality of stretchable elements are formed in the coiled-up sheet, the stretchable elements being expandable about the periphery between an unstretched condition to facilitate placement in a delivery device in the contracted condition and a stretched condition to facilitate expansion of the coiled-up sheet to the enlarged condition upon deployment from the delivery device. Preferably, the coiled-up sheet is biased to the enlarged condition, and the stretchable elements are biased to the stretched condition. More preferably, at least one of the biases is provided by a shape memory property of the coiled-up sheet, which is activated by exposing the stent to body temperature.

Owner:BOSTON SCI SCIMED INC

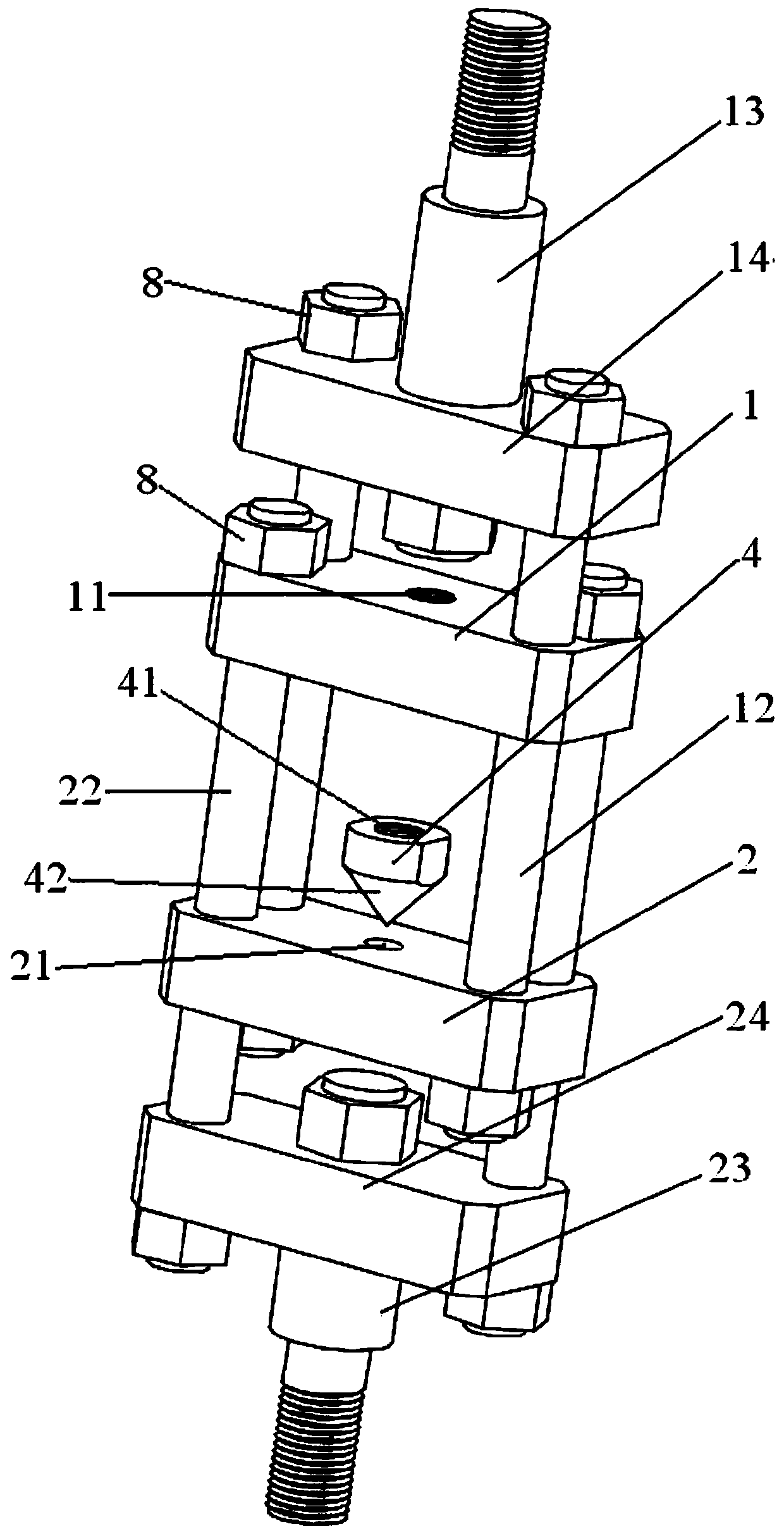

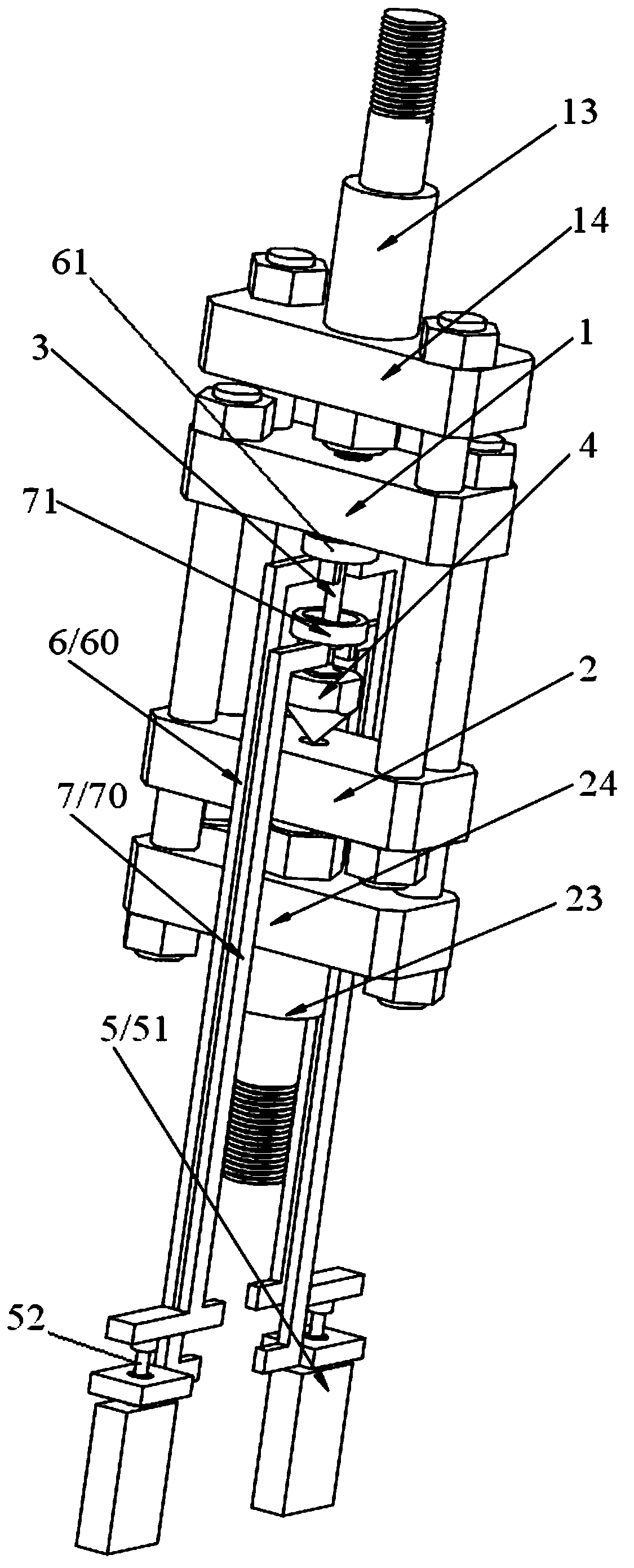

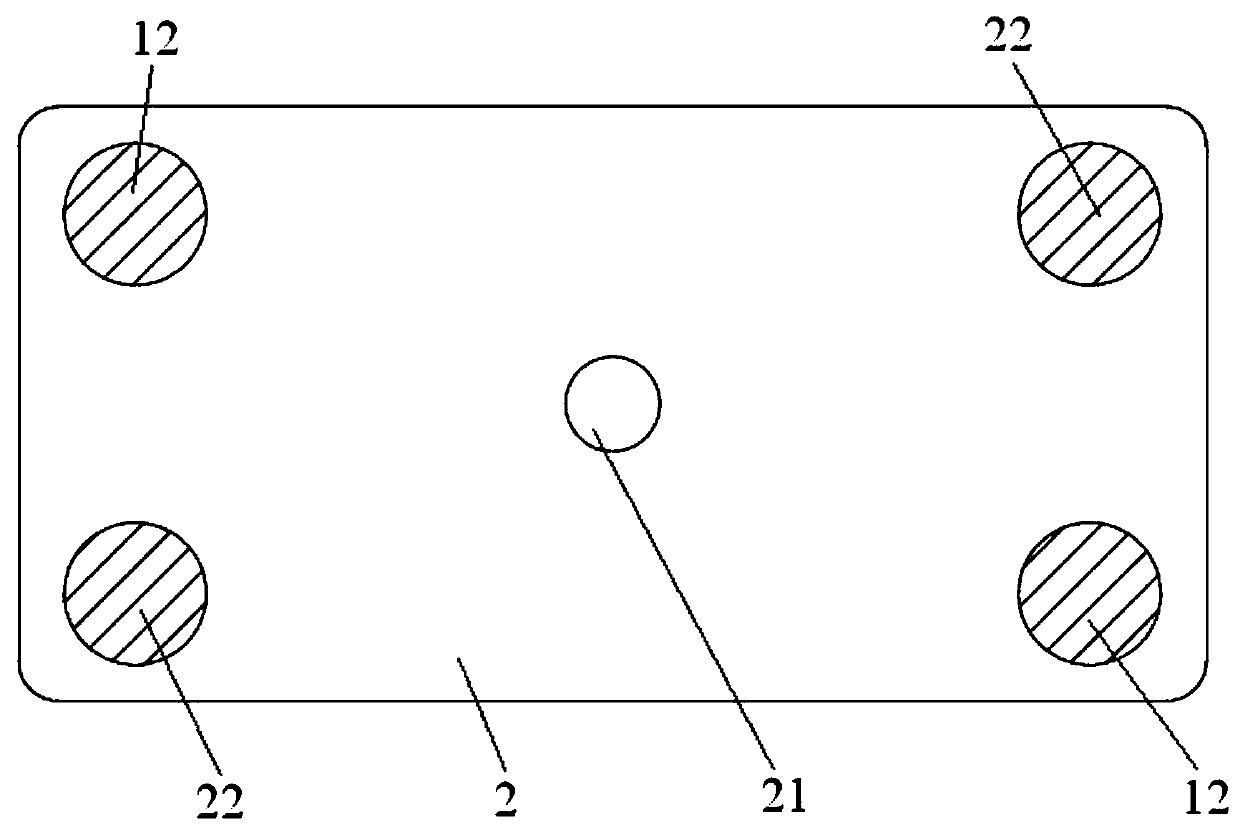

Creep compression experimental apparatus

ActiveCN109870371ANeutral goodReduce risk of damageInvestigating material ductilityNuclear energy generationUniaxial compressionTest sample

The invention provides a creep compression experimental apparatus. The creep compression experimental apparatus comprises an installation frame connected between an upper stretching rod and a lower stretching rod of a creep test machine, wherein the installation frame comprises an upper pressure block and a lower pressure block, the upper pressure block is provided with a threaded hole A, the lower pressure is provided with a conical hole coaxial with the threaded hole A, one end of a test sample is fixed in the threaded hole A, the other end is located in the conical hole by virtue of a conical head of a conical positioning device, and when the conical head is matched with the conical hole, the threaded hole A, the conical head, the conical hole and the test sample are coaxial. The auto-positioning function is realized by virtue of a conical surface contact of the conical positioning device, so that the test sample can be well centralized in the single-axis compression process, and the instability bending possibility of the test sample can be reduced. By virtue of the reversely-arranged extension rod, the rebound displacement of a precompressed sensor measuring head in the reset process is taken as the compression creep deformation of a sample, so that the occurrence of overstroke of the sensor measuring head and damage to the displacement sensor can be effectively avoided.

Owner:CENT SOUTH UNIV

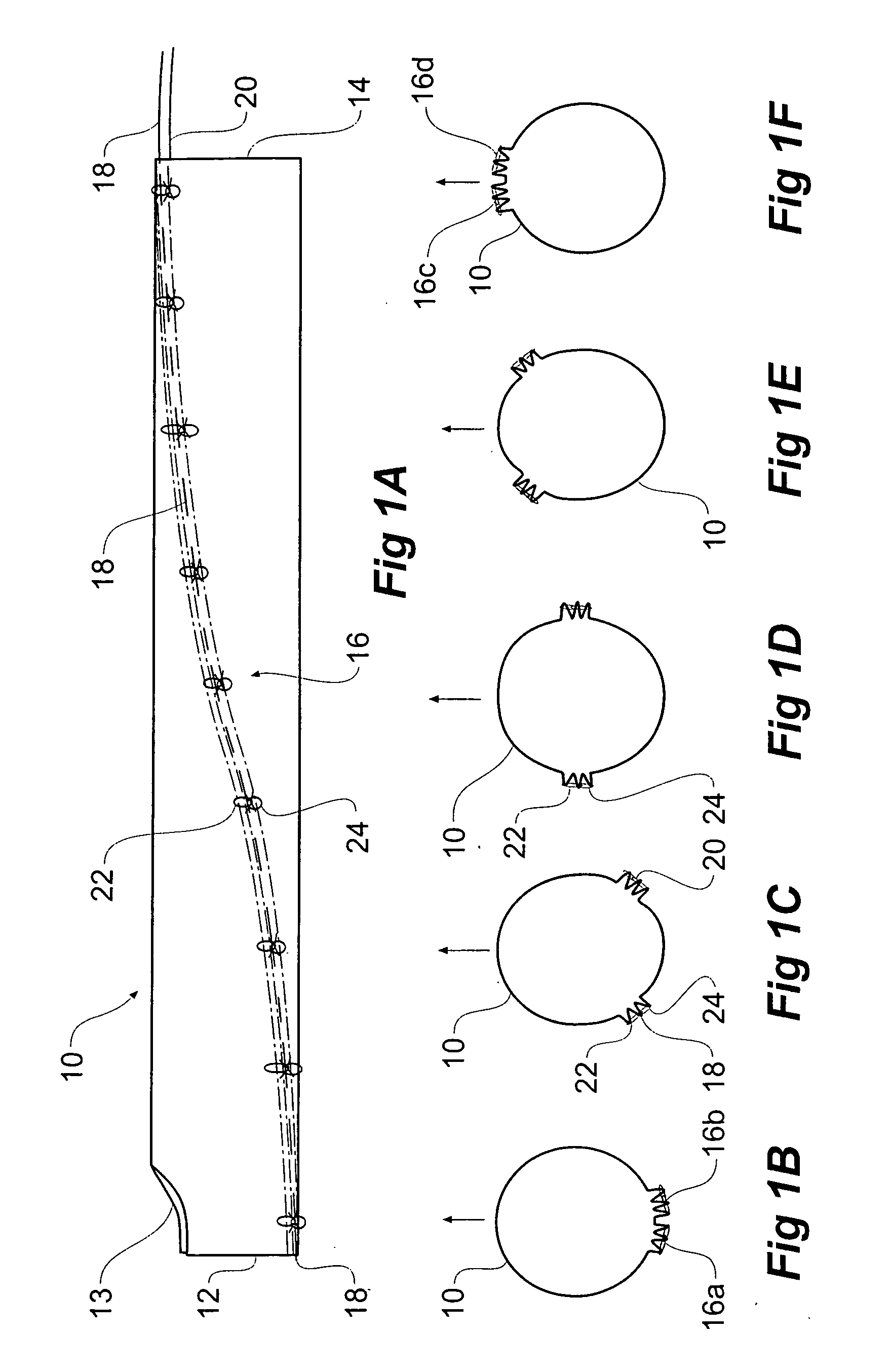

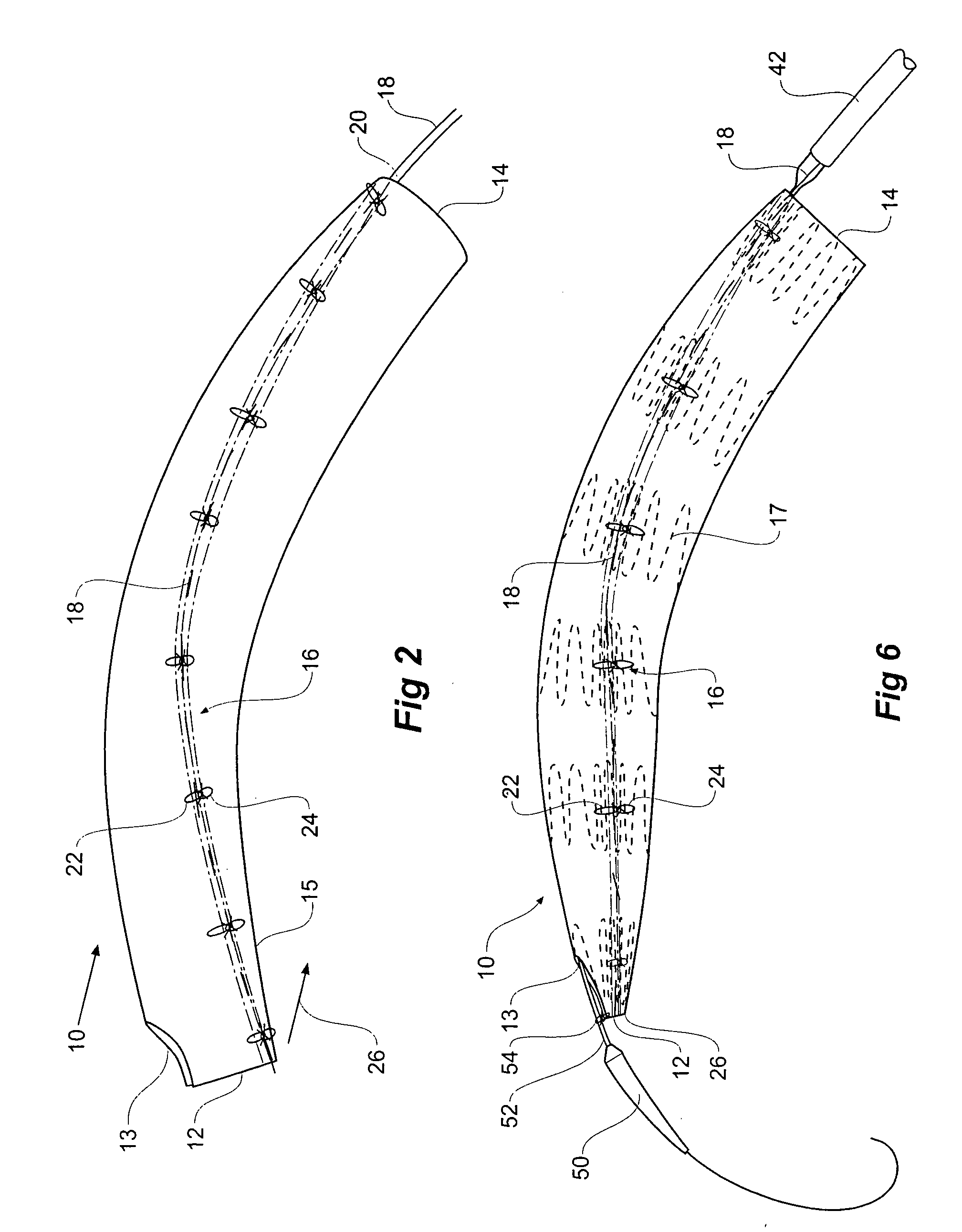

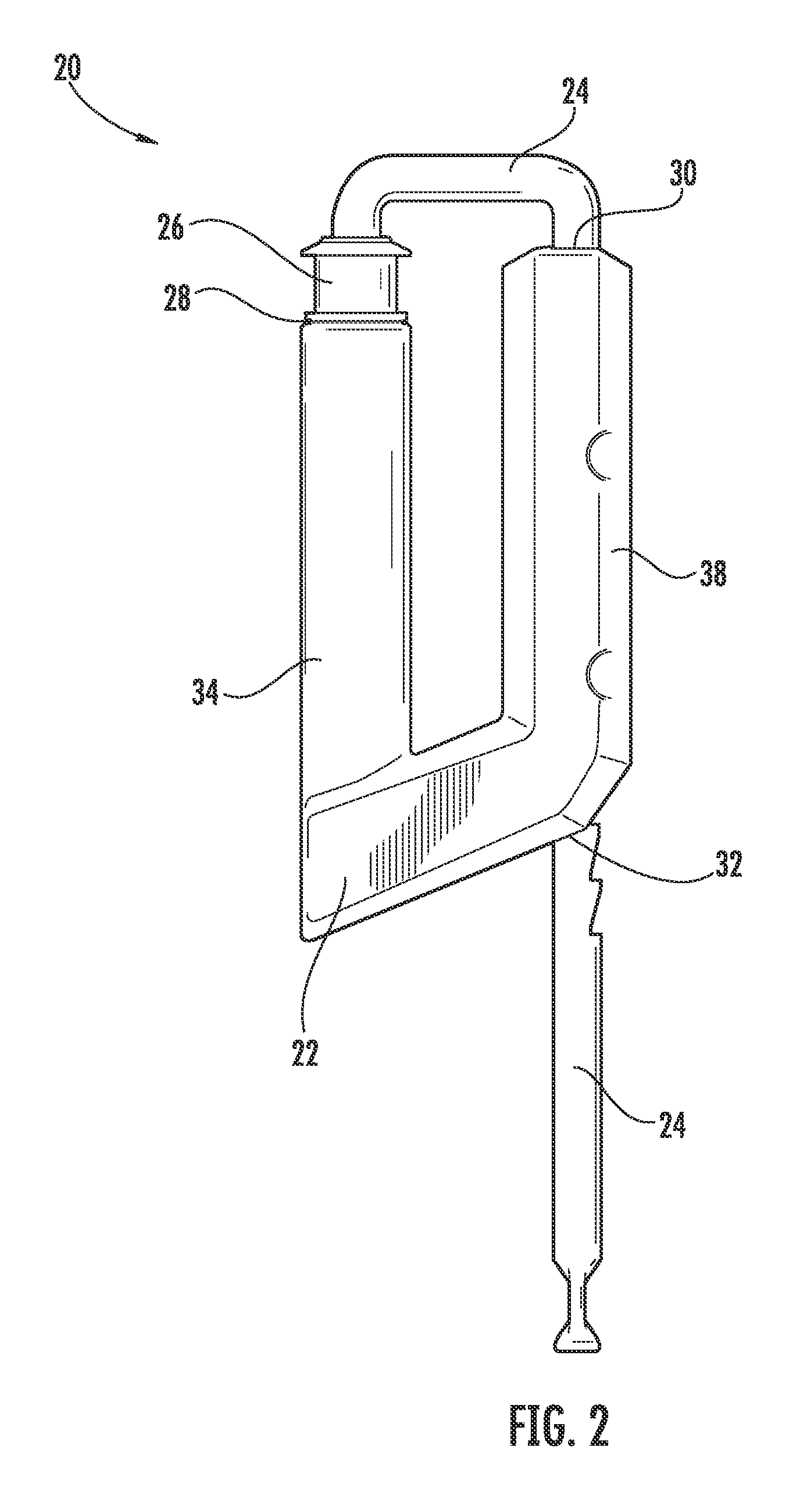

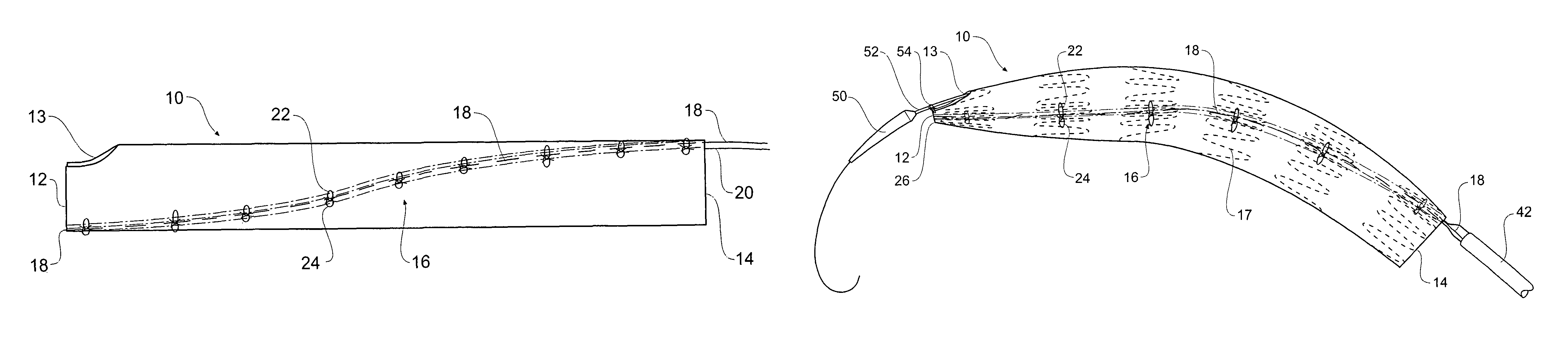

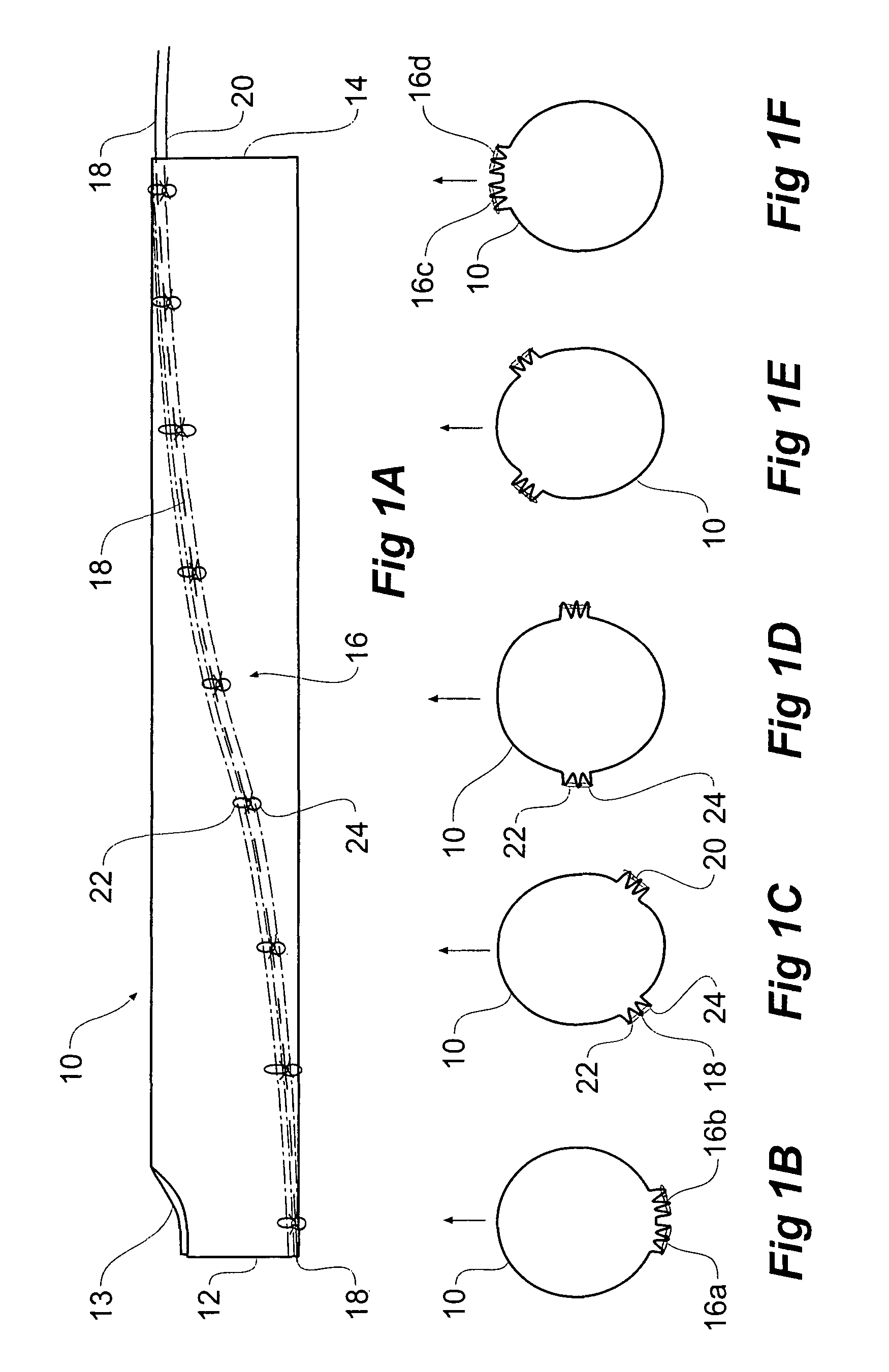

Stent grafts for the thoracic aorta

ActiveUS8377113B2Precise positioningDifficult to withdrawStentsBlood vesselsThoracic aortaInsertion stent

A method of temporarily reducing the diameter of a stent graft (10) and a stent graft with its diameter reduced. The stent graft has a tubular body and self expanding stents. The method comprising extending a release wire (18, 20) part helically along the graft material tube from substantially one side of the graft material tube at one end (14) of the graft material tube to substantially the opposite side of the graft material tube at the other end (12) of the graft material tube along the stent graft and stitching the release wire into the graft material tube, at each of a number of positions along the release wire looping flexible threads (22, 24) around the release wire and extending the flexible threads laterally around the circumference of the stent graft in each direction to a position away from the release wire, engaging the first flexible threads into the graft material or around struts of the stent, and drawing the ends of the thread together and tying ends of the thread to thereby temporarily reduce the overall diameter of the stent graft.

Owner:COOK MEDICAL TECH LLC

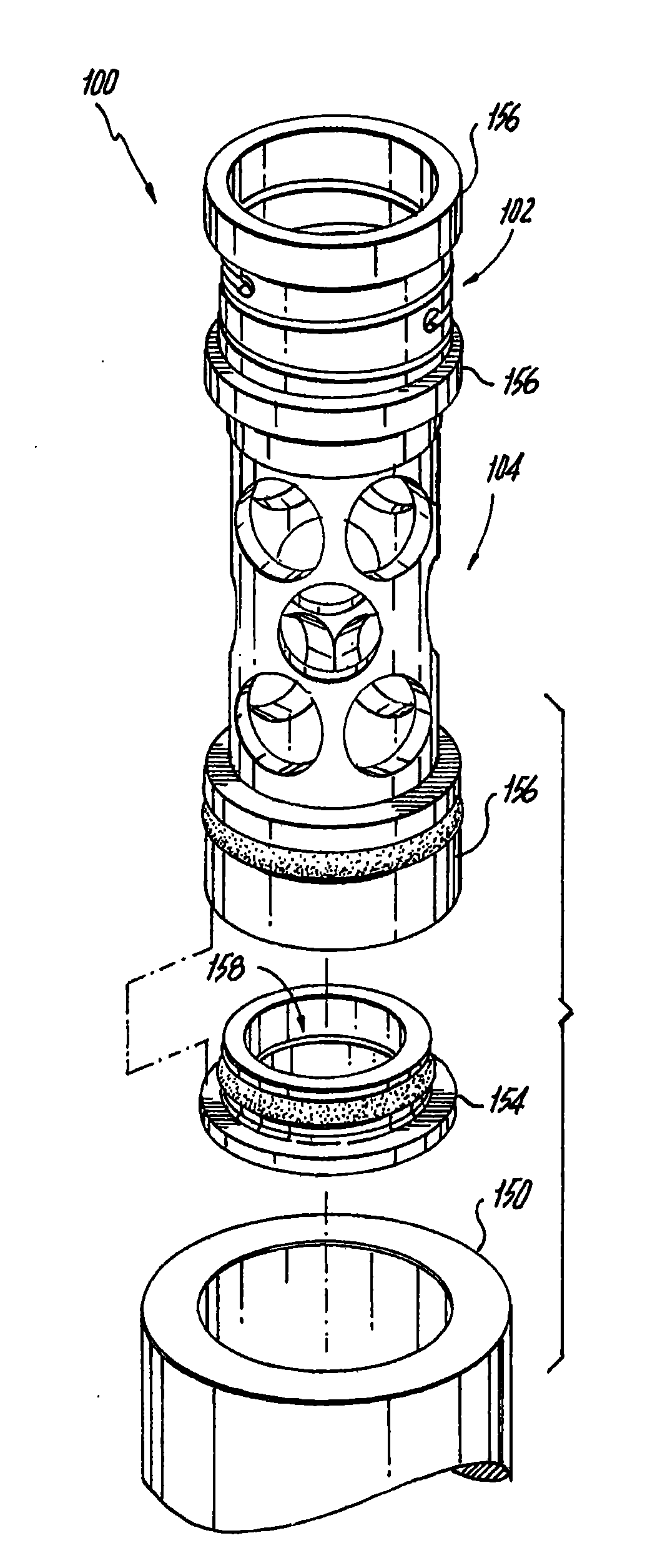

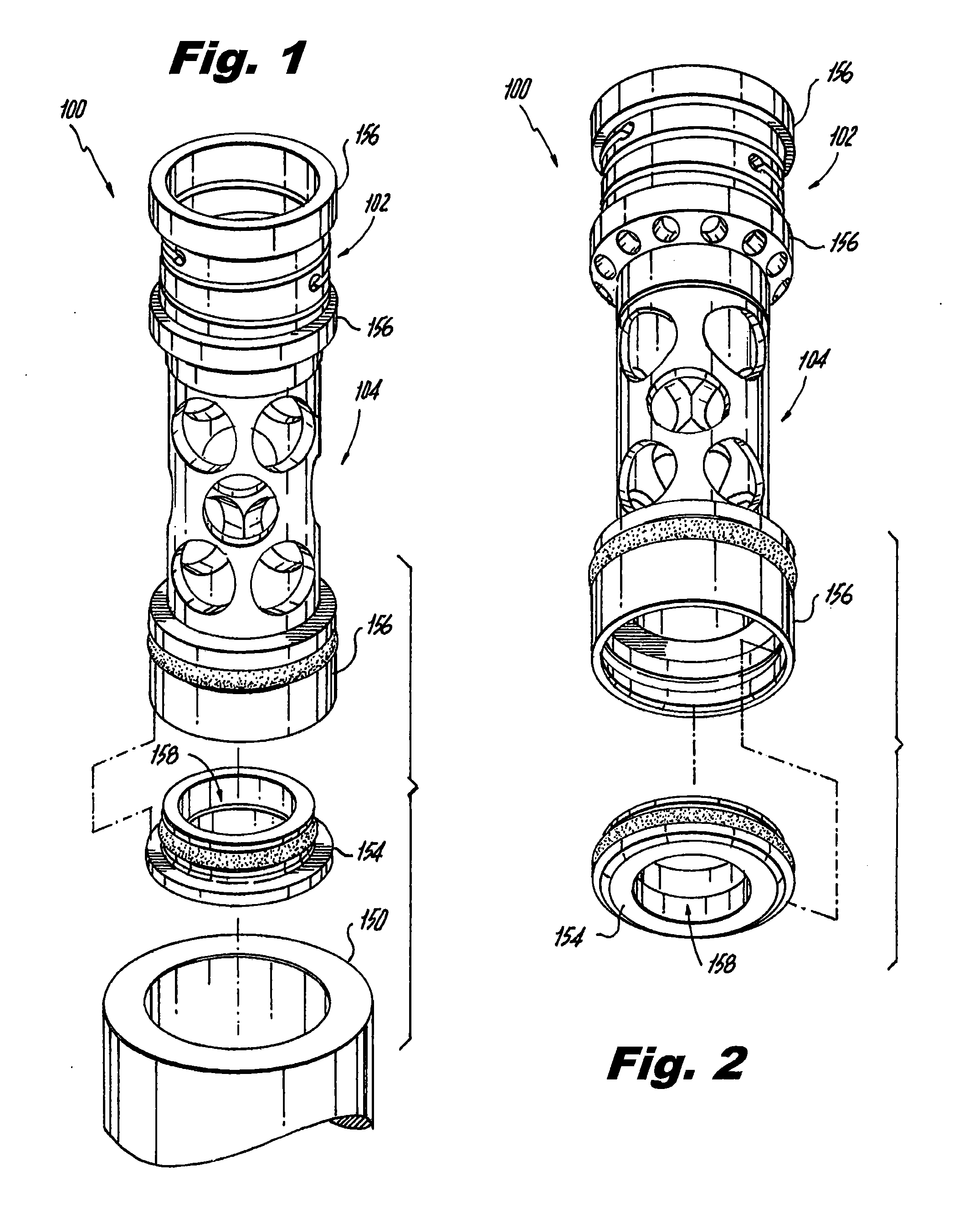

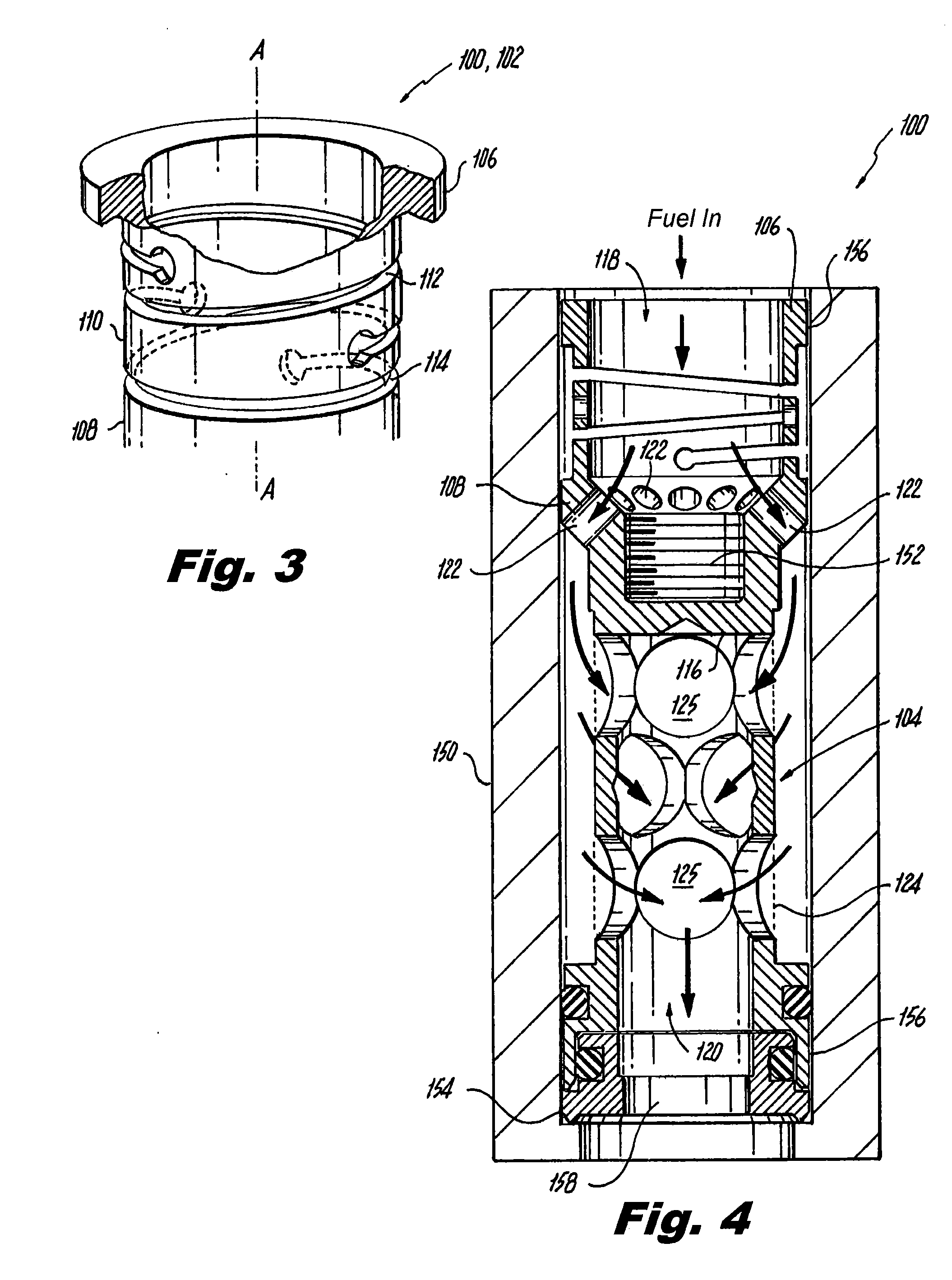

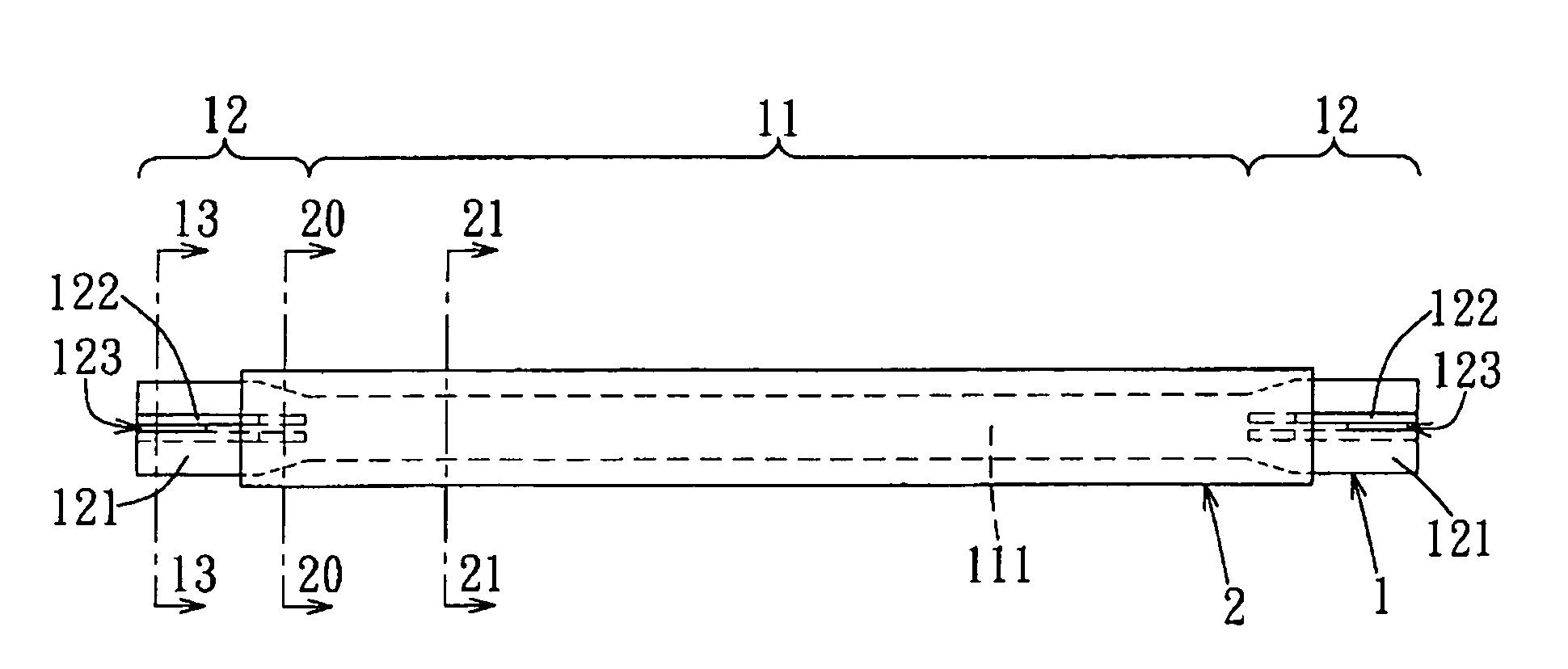

Machined springs for injector applications

ActiveUS20130126641A1Providing some stiffnessDelayed bucklingLiquid fuel feeder/distributionEngine fuctionsEngineeringThermal expansion

A machined spring for injector applications includes opposed first and second spring bases separated apart along a longitudinal axis. A spring body connects the first and second spring bases. The spring body includes a generally annular wall with a plurality of spring channels defined therethrough, such as machined channels. Exemplary applications for such machined springs include liquid strainers, valve components, and structural components for accommodating thermal expansion in injectors.

Owner:COLLINS ENGINE NOZZLES INC

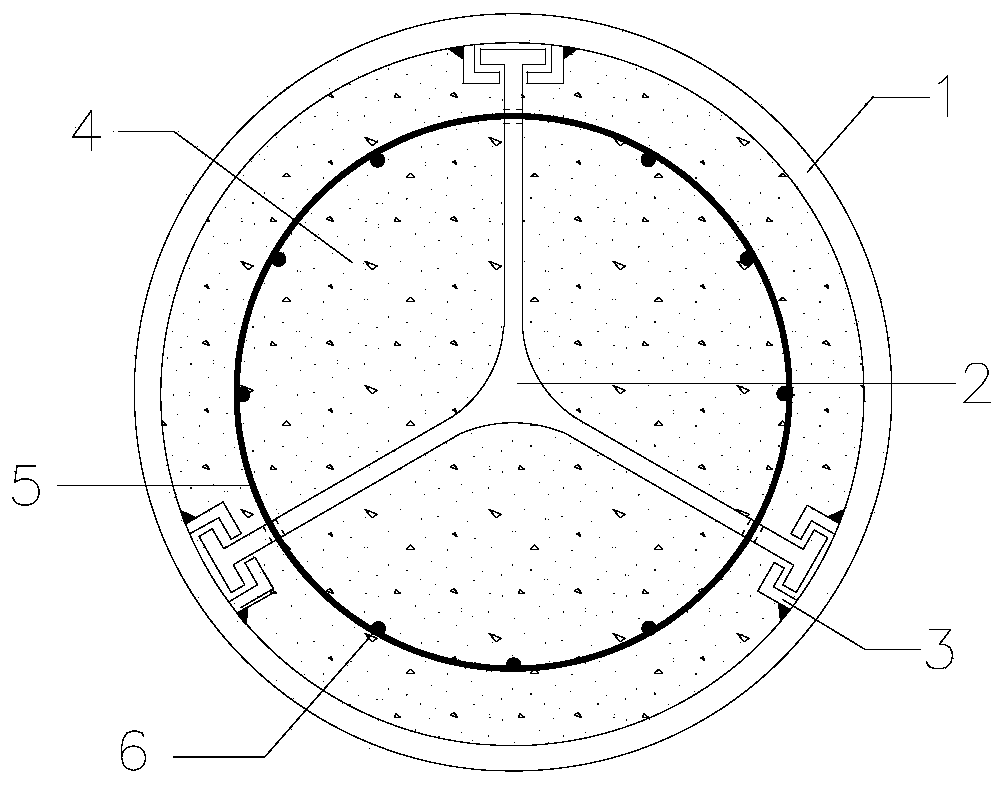

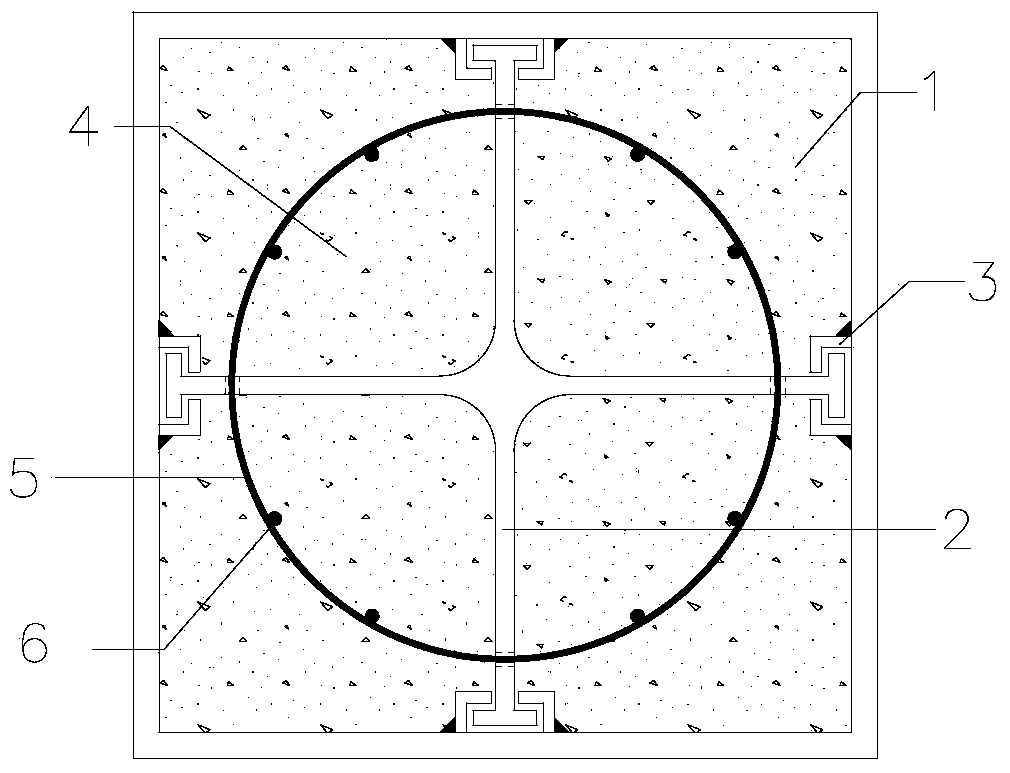

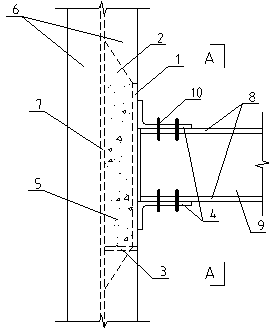

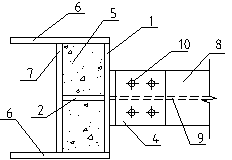

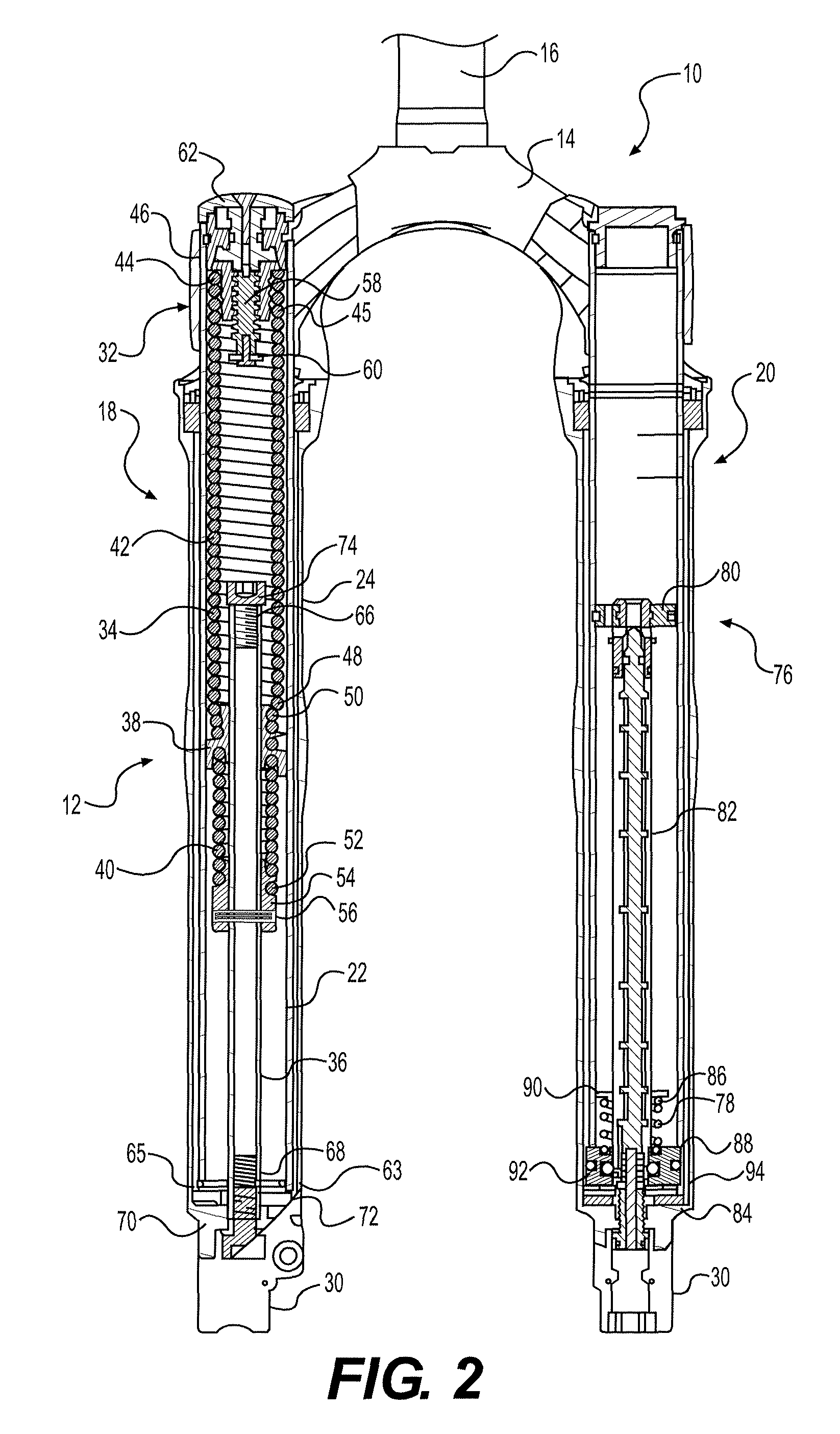

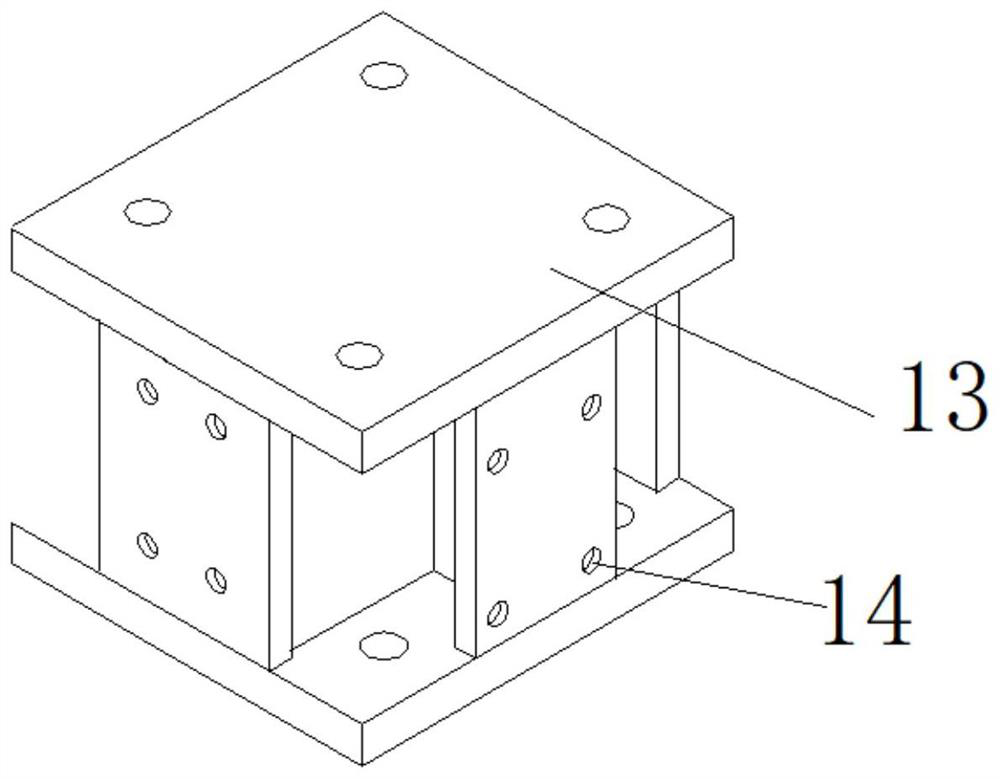

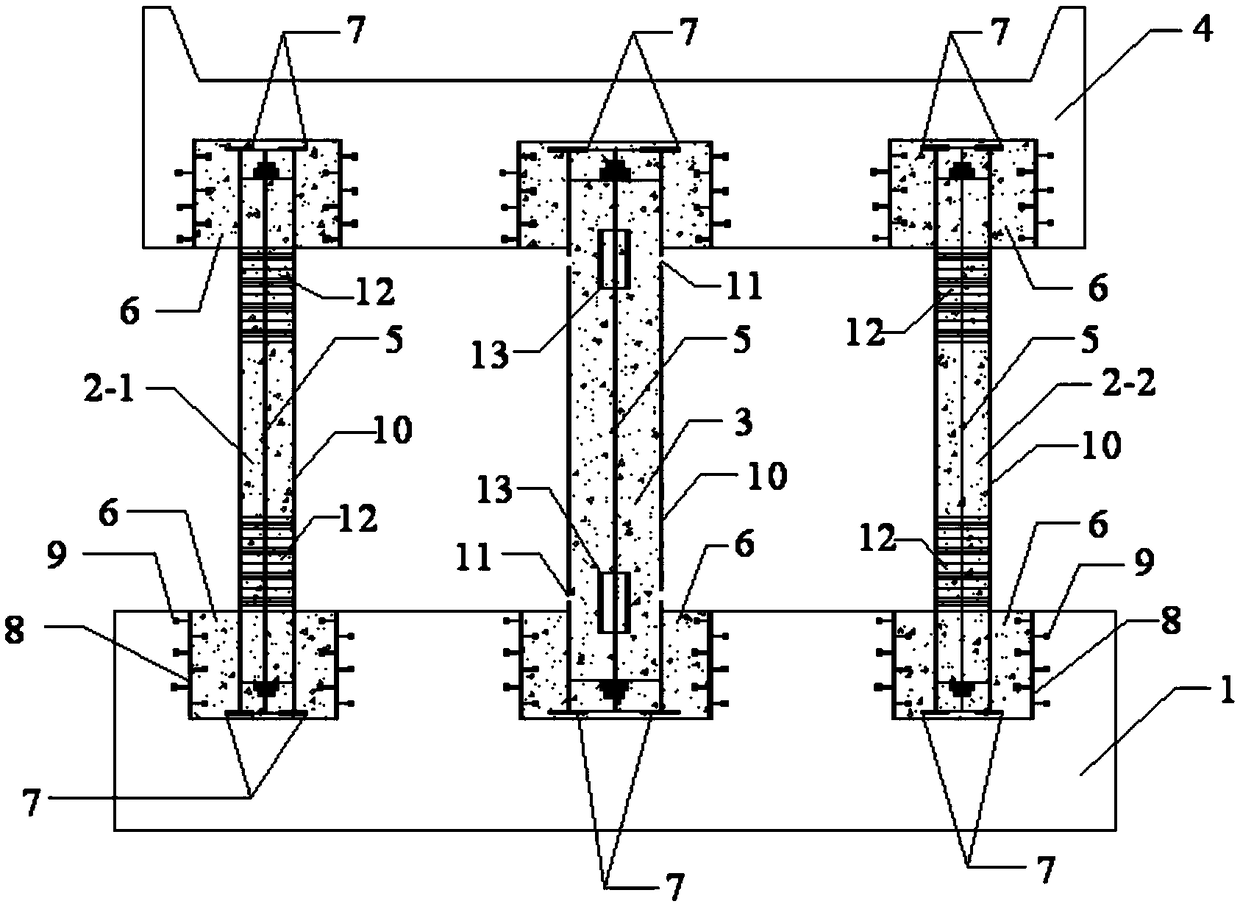

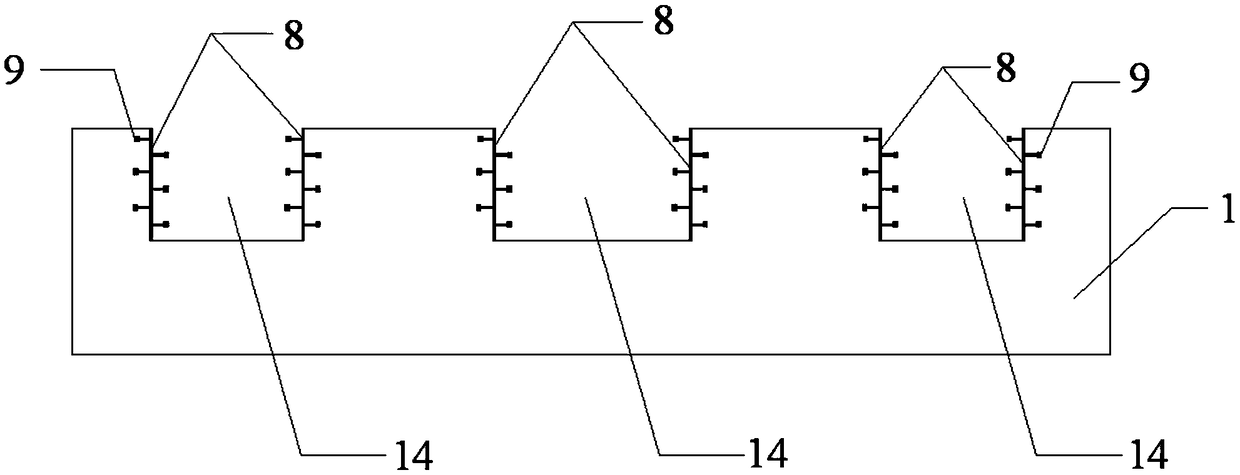

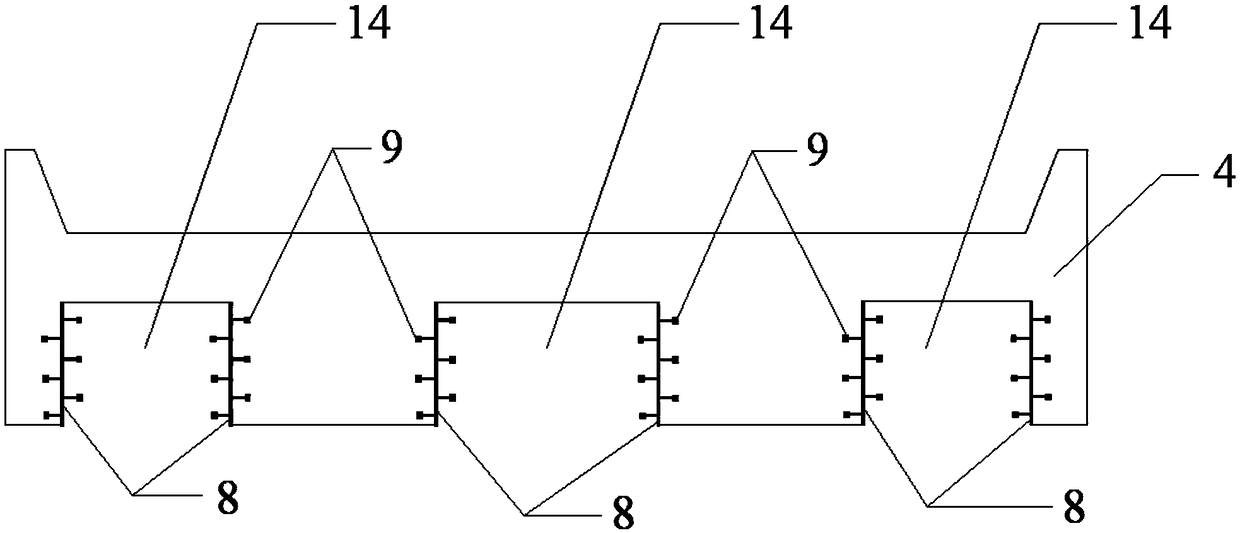

Multi-cavity concrete filled steel tubular column with perforated inner diaphragms and implementation method of column

InactiveCN103711256AIncrease binding forceImprove initial lateral stiffnessStrutsBuilding material handlingShearing deformationSeismic energy

The invention relates to a multi-cavity concrete filled steel tubular column with perforated inner diaphragms and an implementation method of the column. The multi-cavity concrete filled steel tubular column comprises a polygonal steel pipe, an overall perforated inner diaphragm, a perforated inner diaphragm, a rib plate and concrete. The overall perforated inner diaphragm and the perforated inner diaphragm are arranged inside the polygonal concrete filled steel tubular column, and a large cavity is divided into a few of small cavities, so that the constraint capability on core concrete is improved; the concrete is communicated into a whole through holes of the inner diaphragms, so that the compactibility of the concrete is improved, the bearing capacity and the anti-seismic property are improved, seismic energy is consumed by shearing deformation of the inner diaphragm and the concrete in the holes under reciprocating action of the earthquake, and a steel plate is omitted by perforation of the inner diaphragms, so that construction cost is reduced.

Owner:BEIJING UNIV OF TECH

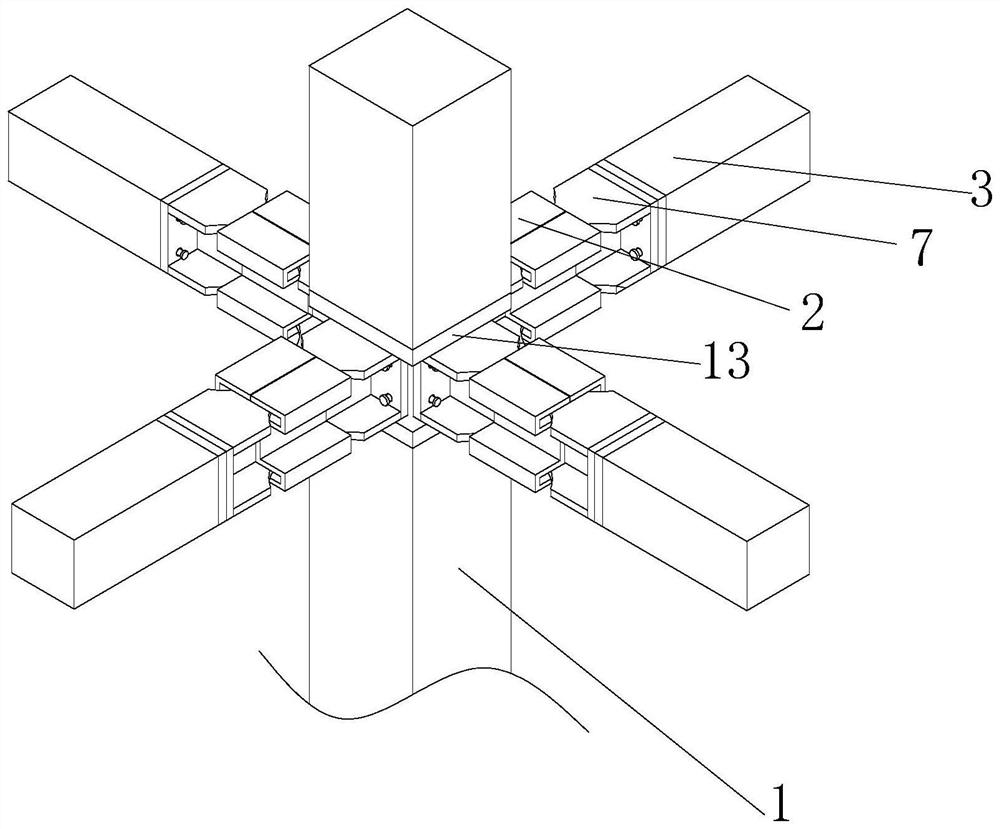

H section steel girder-column minor axis connecting top and bottom angle steel node and preparing method of H section steel girder-column minor axis connecting top and bottom angle steel node

ActiveCN104213645AIncrease stiffnessImprove bearing capacityBuilding material handlingSteel columnsMinor axis

The invention discloses an H section steel girder-column minor axis connecting top and bottom angle steel node and a preparing method of the H section steel girder-column minor axis connecting top and bottom angle steel node, wherein the H section steel girder-column minor axis connecting top and bottom angle steel node is characterized in that a T-shaped combined body is welded on an H section steel column, angle steel is symmetrically arranged on the T-shaped combined body, the angle steel is fixedly connected with the H section steel column, a supporting plate is welded at the bottom of the T-shaped combined body, and two spaces defined by the H section steel column, the T-shaped combined body and the supporting plate are filled with concrete fillers. The preparing method comprises the following steps that a node plate and a stiffening plate are welded into the T-shaped combined body; two sections of angle steel are welded at the outer side of the node plate; the T-shaped combined body and the supporting plate are welded on the H section steel column; the angle steel and the H section steel column are connected by high-strength bolts; a rectangular region of a node area is poured with concrete. The H section steel girder-column minor axis connecting top and bottom angle steel node and the preparing method have the advantages that the respective advantages of steel and concrete are fully utilized, the anti-seismic performance is good, the bearing capability is great, and the construction is simple and convenient.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Buckling restrained brace

ActiveUS8424252B2Firmly connectedBuckling of the axial member can be reducedProtective buildings/sheltersBuilding reinforcementsBuckling-restrained braceCoupling

Owner:NAT APPLIED RES LAB

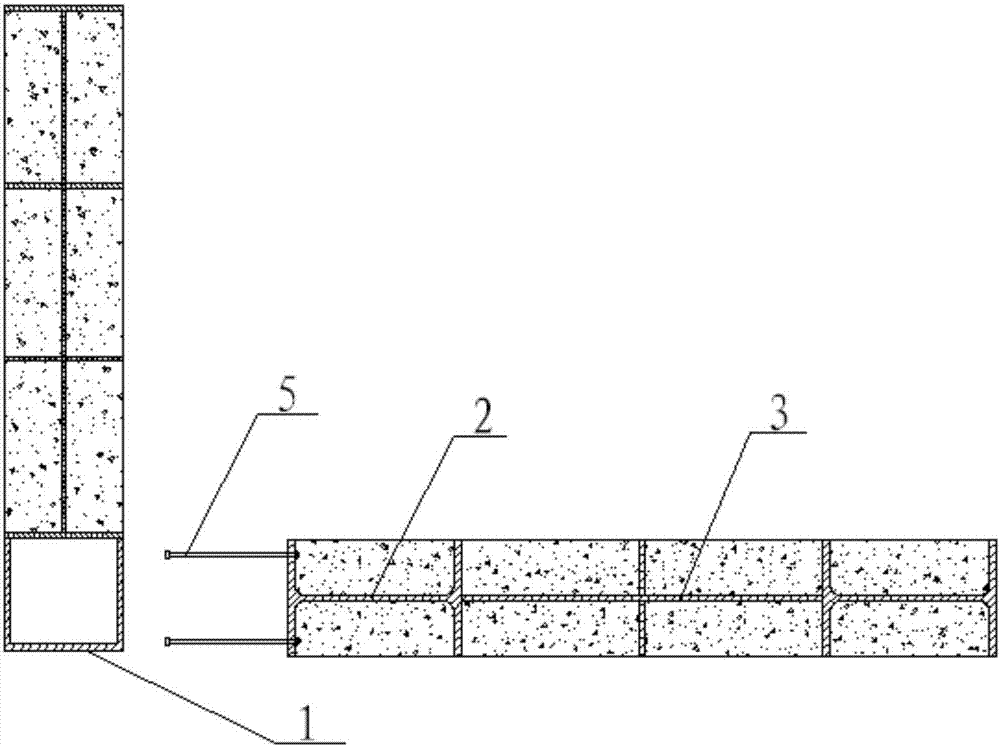

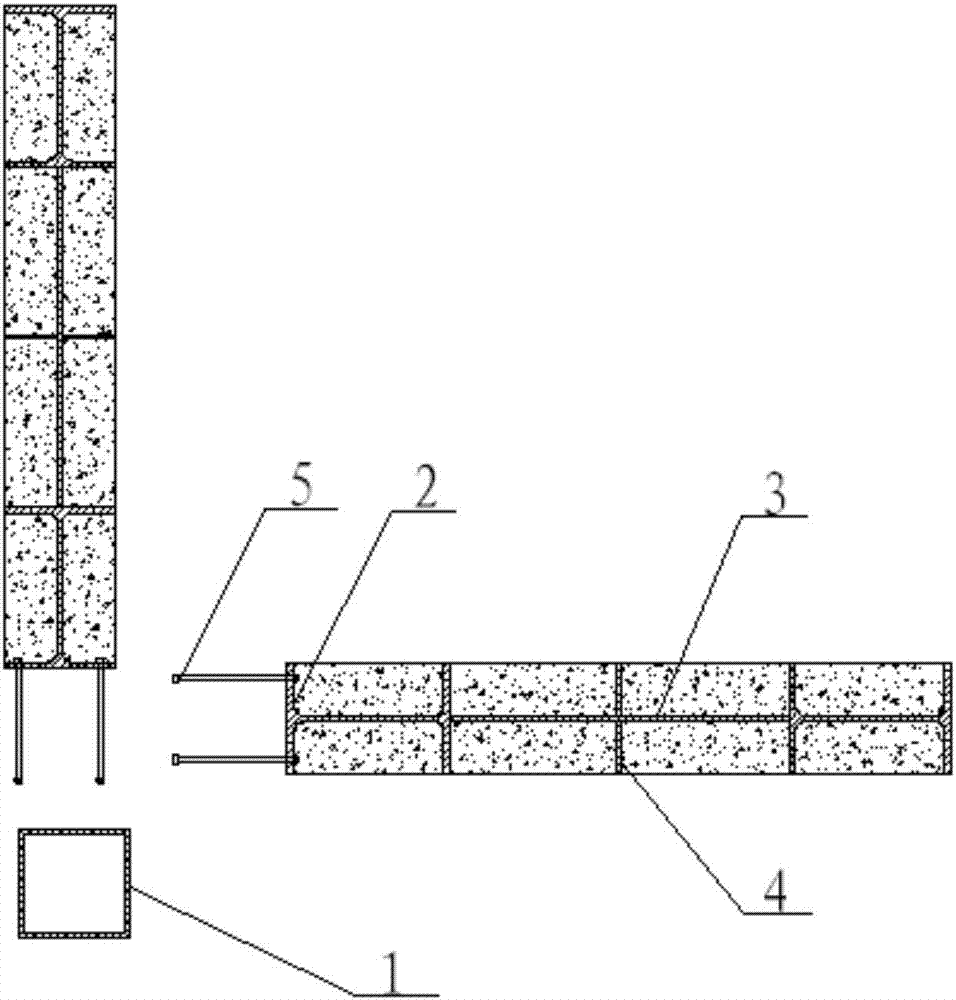

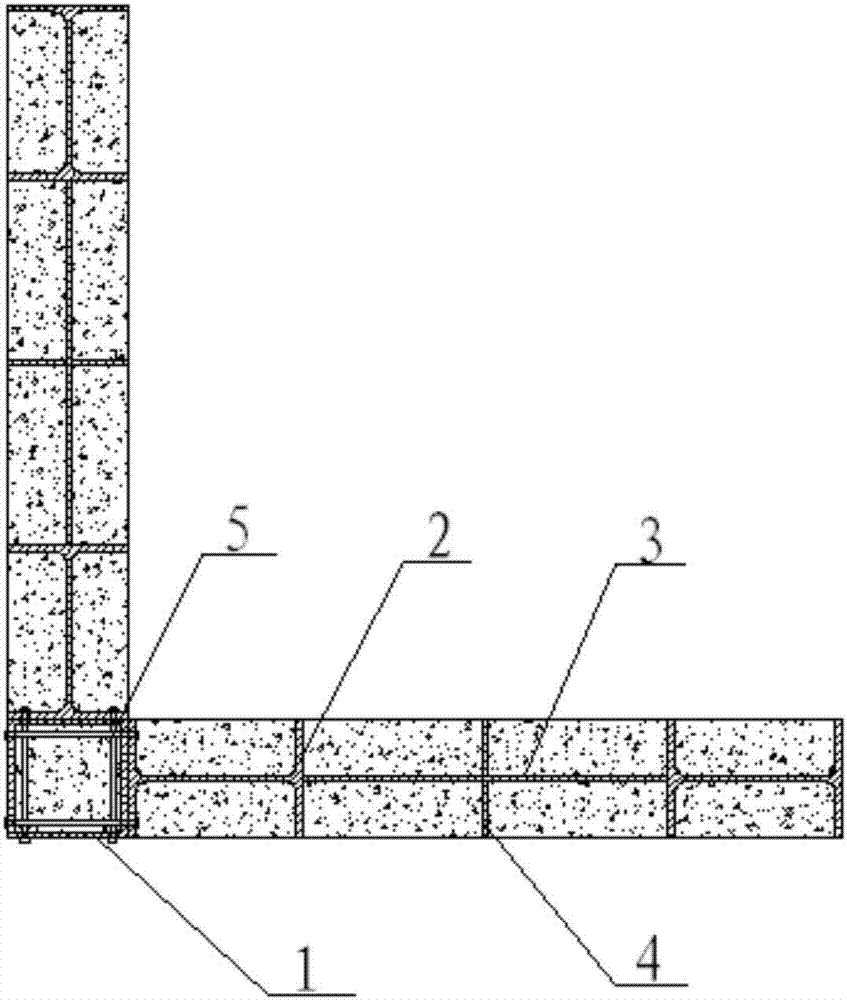

Outer corner structure of composite wall

PendingCN107190886ADelayed bucklingImprove bearing capacityWallsEngineeringUltimate tensile strength

The invention relates to the field of buildings, in particular to an outer corner structure of a composite wall. The outer corner structure of the composite wall comprises a shear wall and a connecting square tube. The shear wall comprises H-shaped steel, a middle horizontal plate and middle vertical plates. The middle vertical plates are vertically welded to the upper side surface and the lower side surface of the middle horizontal plate. The H-shaped steel is welded to the left side and the right side of the middle horizontal plate, and the edge sides of the H-shaped steel are perpendicular to the middle horizontal plates, that is to say, the middle vertical plates are parallel to the edge sides of the H-shaped steel. The shear wall is fixed on the two adjacent side surfaces of the connecting square tube to form the outer corner structure through split screw rods. The vertically adjacent split screw rods are arranged in a crossing mode. According to the outer corner structure of the composite wall, after adopting the above scheme, the outer corner structure of the composite wall has the characteristics of being flexible in layout and high in construction speed, and the whole strength of outer corners of the composite wall is ensured.

Owner:ZHEJIANG GREEN BUILDING INTEGRATION TECH CO LTD

Half-through bracket haunching type multibarrel tube-confined concrete column-steel beam node

InactiveCN105507426AIncrease stiffnessHigh strengthBridge structural detailsBuilding constructionsBridge engineeringUltimate tensile strength

The invention discloses a half-through bracket haunching type multibarrel tube-confined concrete column-steel beam node, relates to a node connecting form of a multibarrel tube-confined concrete column and a steel beam, and belongs to the technical field of constructional engineering and bridge engineering. The node comprises the multibarrel tube-confined concrete column, the steel beam and a force-transmission component. The multibarrel tube-confined concrete column comprises an inner steel pipe, an outer steel pipe and poured concrete. The steel beam comprises upper and lower flanges and a web. The force-transmission component comprises a steel bracket and an oblique haunching plate. The steel bracket comprises upper and lower flanges and a web. One end of the steel bracket penetrates the outer steel pipe to be welded to the wall of the inner steel pipe, and the other end of the steel bracket is in bolt-weld connection with the steel beam. Meanwhile, the oblique haunching plate is welded between the steel beam and the multibarrel tube-confined concrete column. The half-through bracket haunching type multibarrel tube-confined concrete column-steel beam node is simple in structure, convenient in construction, high in rigidity and strength, good in anti-seismic property, clear in force transmission path, and the like. By the node, effective force transmission between the multibarrel tube-confined concrete column and the steel beam can be achieved.

Owner:HEBEI UNIV OF TECH

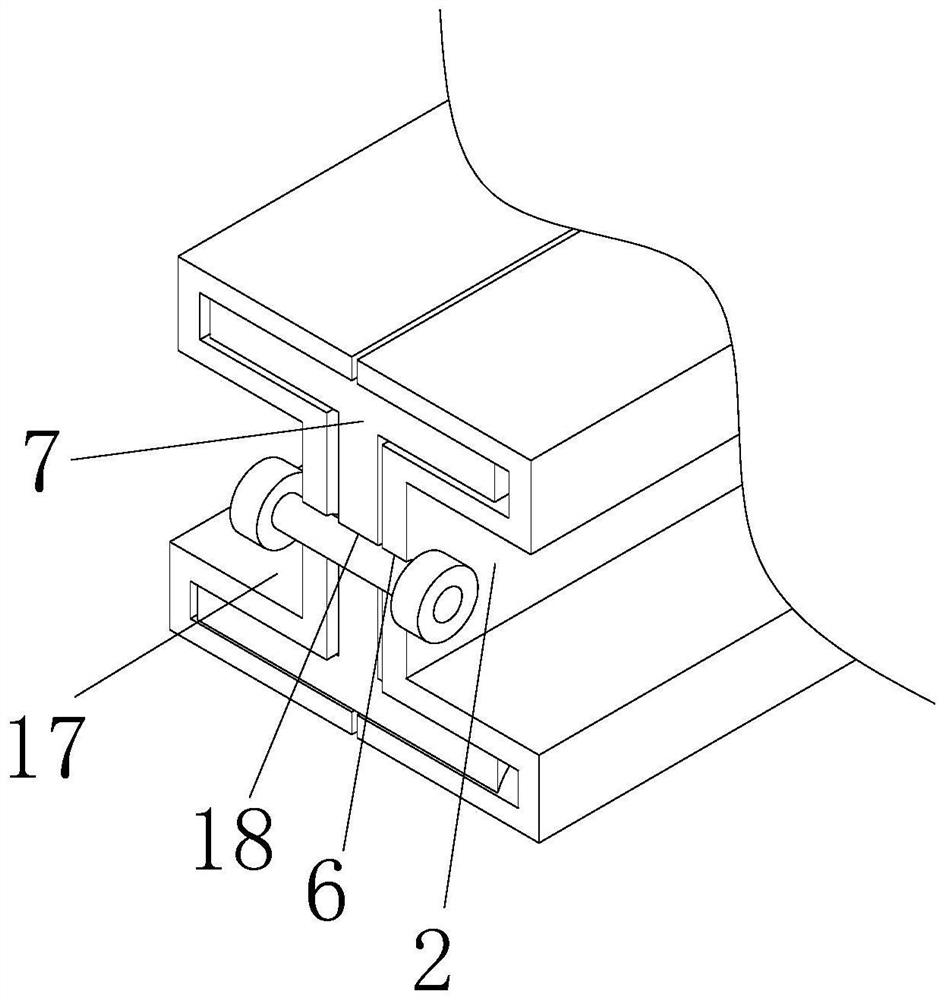

Spring suspension for a handlebar-steered vehicle

ActiveUS8496094B2Reduce weightControl displacementWheel based transmissionFrictional rollers based transmissionCoil springEngineering

A coil spring suspension designed for a handlebar-steered vehicle. The coil spring suspension generally includes a first tube, a coil spring, a shaft and a guide. A first end of the coil spring is disposed within the first tube and fixedly supported proximate a first end of the first tube. The coil spring extends beyond a second end of the first tube. The shaft fixedly supports a second end of the coil spring. The shaft and the first tube are slidably displaced relative to each other upon suspension loading to lengthwise compress the coil spring. The guide is disposed within the first tube and connected to the coil spring between the first and second ends of the coil spring. The guide is displaced with the coil spring under suspension loading and limiting lateral displacement of the coil spring.

Owner:SRAM CORPORATION

Concrete-filled steel tube beam column connecting joint capable of being replaced after earthquake

ActiveCN113323488AEasy to replaceExtended service lifeProtective buildings/sheltersShock proofingConcrete beamsClassical mechanics

The invention relates to a concrete-filled steel tube beam column connecting joint capable of being replaced after an earthquake. The concrete-filled steel tube beam column connecting joint comprises a prefabricated joint frame with threaded holes formed in the upper side, the lower side and the peripheral end face, the upper side and the lower side of the prefabricated joint frame are connected with an upper steel tube concrete column and a lower steel tube concrete column through bolts, the periphery of the prefabricated joint frame is connected with steel beams through bolts, the vertical section of the steel beams is I-shaped, arc-shaped stress grooves are formed in the front side and the rear side of a steel beam flange plate, the end, away from the prefabricated joint frame, of the steel beam is connected with a steel tube concrete beam through bolts, the surface of the steel beam is slidably connected with a first arch-shaped connecting piece and a second arch-shaped connecting piece which are spliced with each other, the first arch-shaped connecting piece, the second arch-shaped connecting piece and the steel beam are fixedly connected through fasteners, the dog-bone type steel beam can be prevented from buckling through the arch-shaped connecting pieces, the strength of the steel beam is enhanced to a certain degree, the energy dissipation capacity is enhanced, the ductility is improved, meanwhile, the steel beam is protected to a certain degree, and the service life of the steel beam is prolonged to a certain degree.

Owner:CHONGQING UNIV

Multi-pier system high in durability and resistant to earthquake collapsing and construction method

ActiveCN108867342AImprove collapse resistanceExtend the natural vibration periodBridge structural detailsBridge erection/assemblyBridge engineeringAxial force

The invention discloses a multi-pier system high in durability and resistant to earthquake collapsing and a construction method, and belongs to the field of bridge engineering. The system is mainly composed of a bearing platform, a middle pier, side piers, a prefabricated cover beam and others. All the piers are made from stainless steel tube concrete and prefabricated in a factory, anti-pull rings are arranged at the two ends of steel tubes, and non-bonding prestressed tendons are arranged in the middles of sections. The dimension of the section of the middle pier is larger than that of the side piers on the left side and the right side, and the steel tubes at the boundary positions of the middle pier, the bearing platform and the cover beam are annularly cut off after construction is completed. CFRP is wound around the upper ends and the lower ends of the side piers. According to the structural system, construction advantages of prefabricated structures are utilized, and the risk ofdurability is low in a normal using state. Under a strong earthquake, the middle pier is converted into a rocking-self returning system to prolong a structural natural vibration period without damageto the middle pier; axial bearing capacity of the multi-pier system is provided. Under the strong earthquake, the side piers are similar to steel tube concrete, can provide lateral strength, rigidityand energy consumption capacity, but bear small axial force, and will not collapse and get damaged.

Owner:INST OF DISASTER PREVENTION

Bedding box for use with compact excavator

InactiveUS8789722B2Easy to transportImprove rigidityPipe supportsPipe laying and repairTerrainGusset plate

Owner:REUTHE JAMES T

Variable-stiffness distal extension for a blood pump system

PendingUS20200330664A1Reduce the potential for damageImpact performanceGuide wiresBlood pumpsMedicineBlood pump

Systems and methods for providing a blood pump system having a variable stiffness distal extension are disclosed. A variable stiffness distal extension may have at least one section of continuously varying stiffness, resulting in a stiffness profile that decreases in a distal direction along a length of the distal extension. The varying stiffness may be accomplished by varying one or more radial dimensions of the extension. For example, in some implementations, an outer diameter of a distal extension may decrease along at least a portion of a distal extension. The distal extension may include a lumen configured to receive a longitudinally extending element.

Owner:ABIOMED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com