Corrugated shear panel and anchor interconnect system

a technology of corrugated shear panels and anchors, applied in the construction industry, can solve the problems of building collapse, reduced structural strength, and low structural strength of the corrugated shear panel, and achieve the effect of greater resistance to shear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

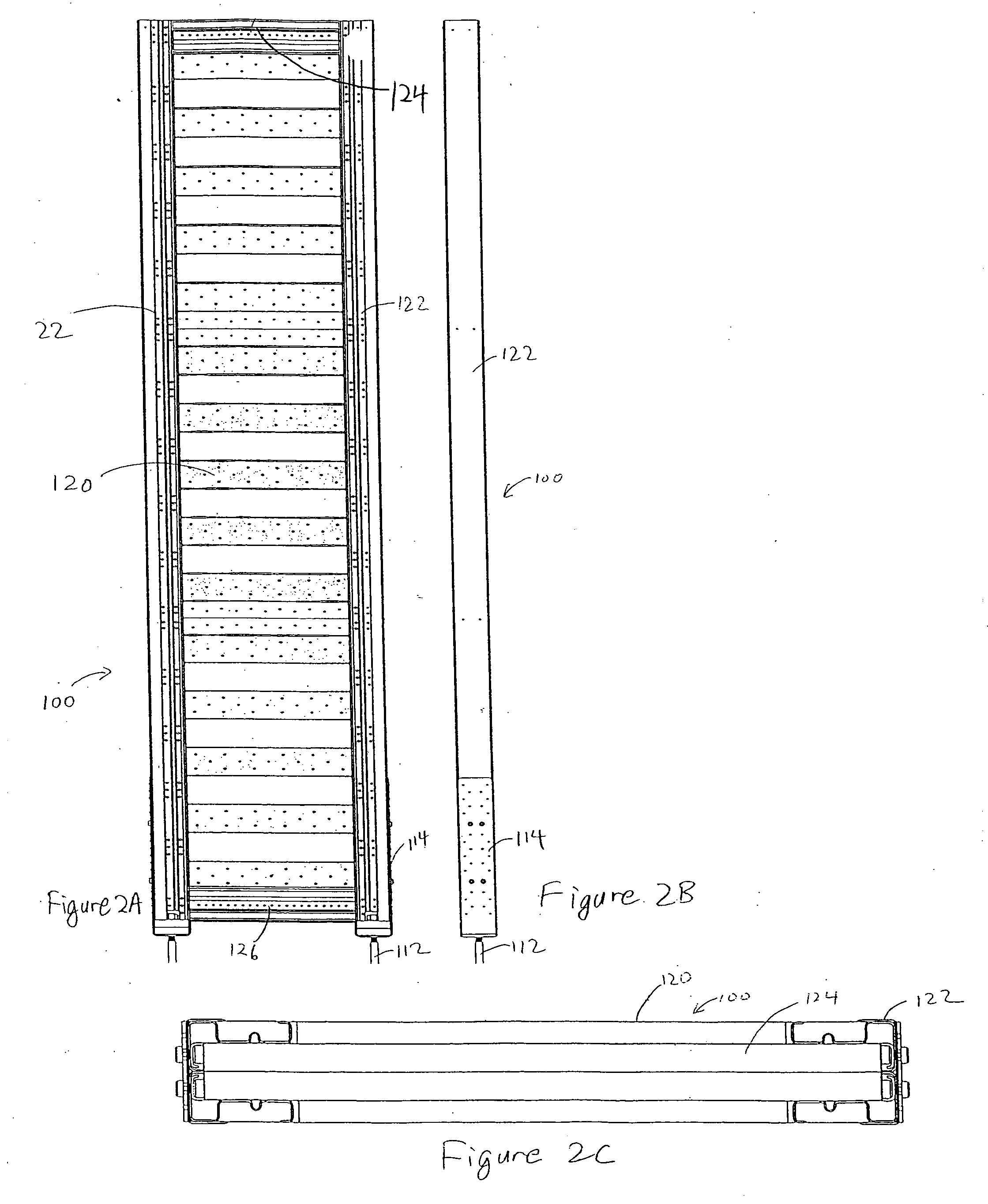

[0121] Reference will now be made to the drawings wherein like numerals refer to like parts throughout. FIGS. 1 through 6 relate to embodiments of the invention that use one design of a chord that forms various structures described below. FIGS. 7 through 12 relate to embodiments of the invention that use another design of the chord. It will be appreciated that the chords of different designs both afford advantages in a substantially similar manner that is described below.

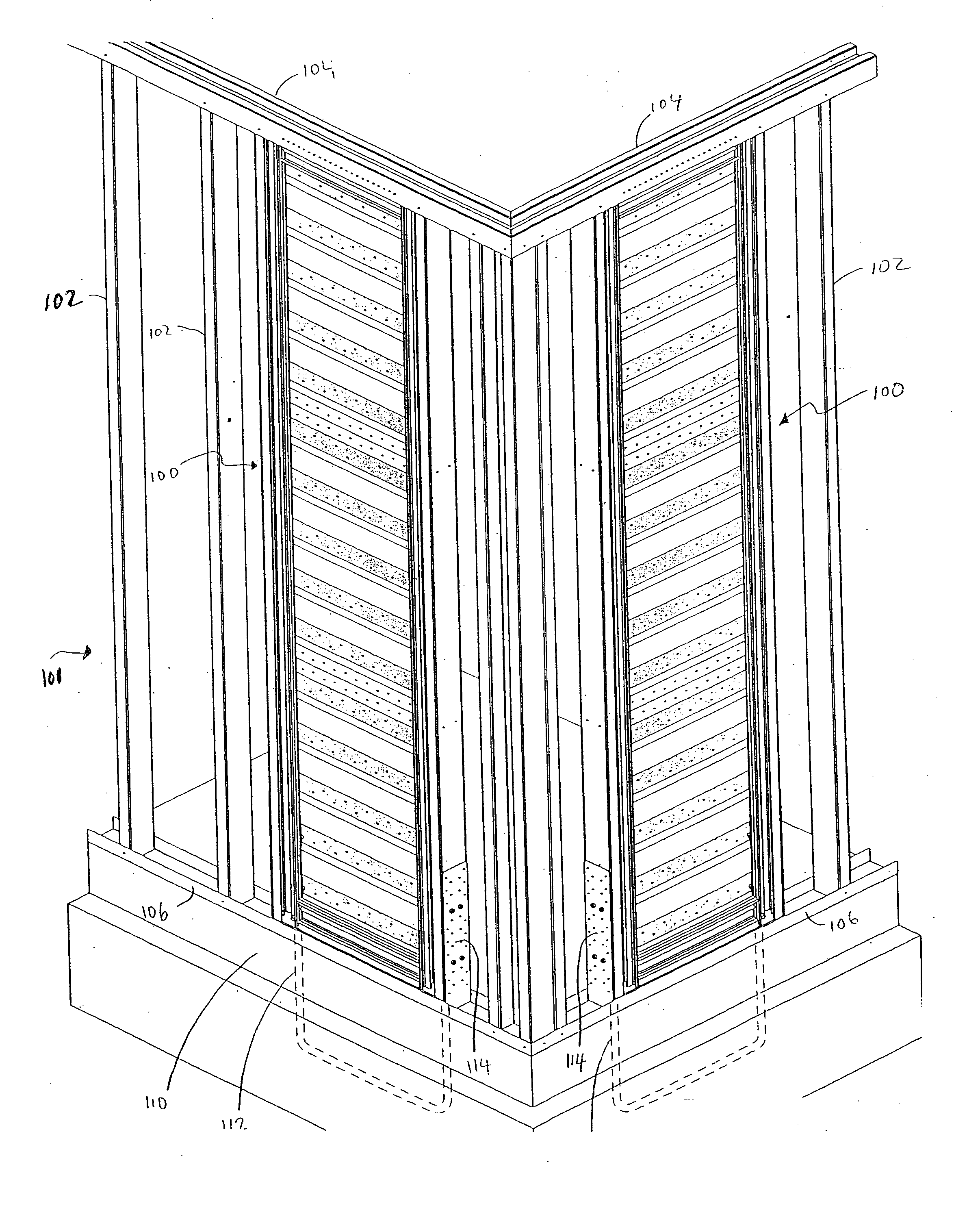

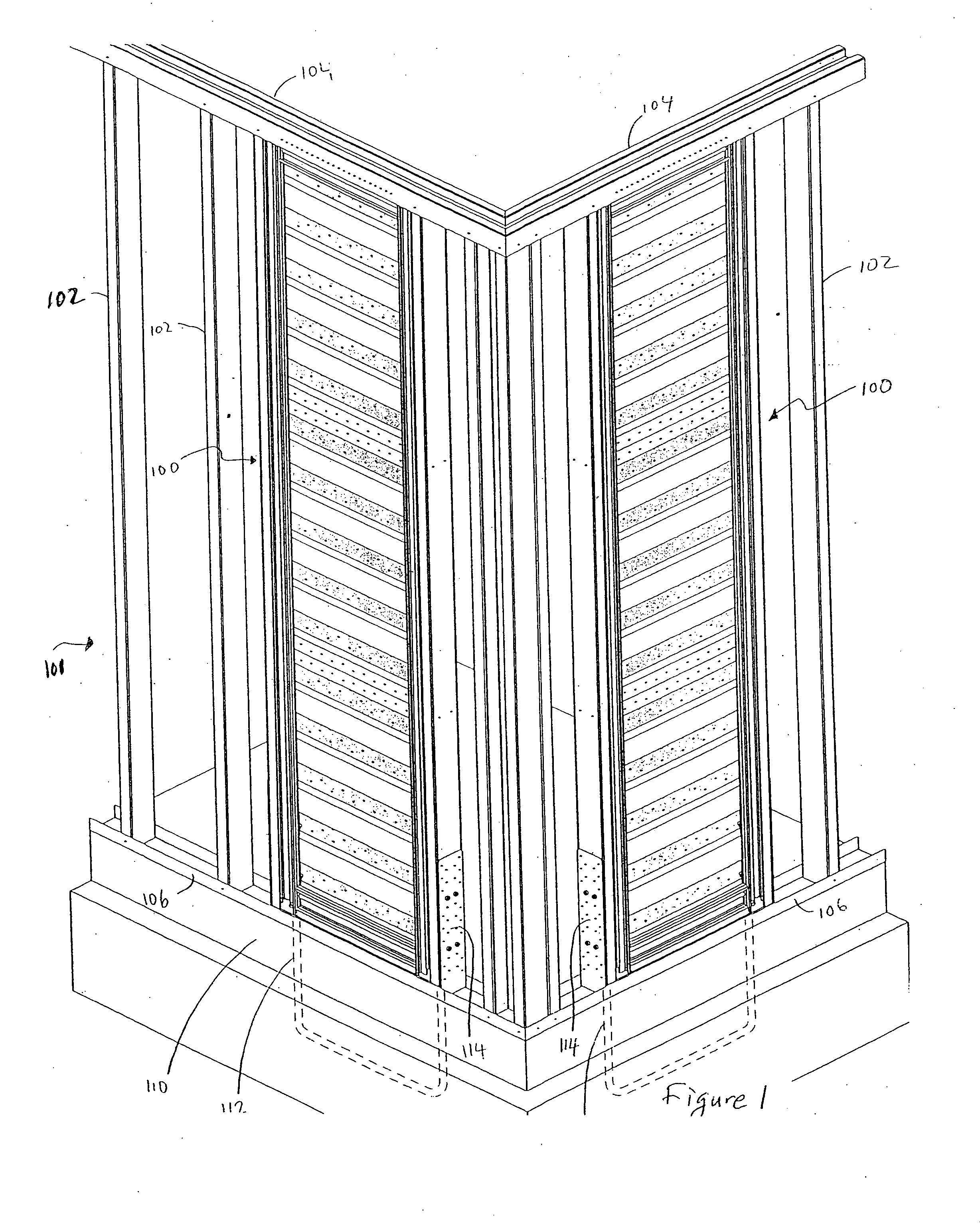

[0122]FIG. 1 is a perspective view of two adjoining wall frames 101 joined at a corner. The wall frame 101 comprises a plurality of vertical chords 102 that are secured at the top by a horizontal chord comprising an M-track 104, and at the bottom by a bottom track 106. In this embodiment, the chords 102, 104 are steel; however, a person of ordinary skill in the art will appreciate that they can be made of a number of different materials, including wood, without departing from the spirit of the invention. The wall f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com