Fiber reinforce plastic (FRP) reinforced concrete-filled steel tube combination column

A technology of concrete filled steel tubes and composite columns, applied in the field of concrete columns, can solve the problems of reduced bearing capacity, rigidity and stability of components, insufficient strength of concrete, weakened restraint capacity of core concrete, etc. Conducive to the effect of structural earthquake resistance and omitting formwork engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

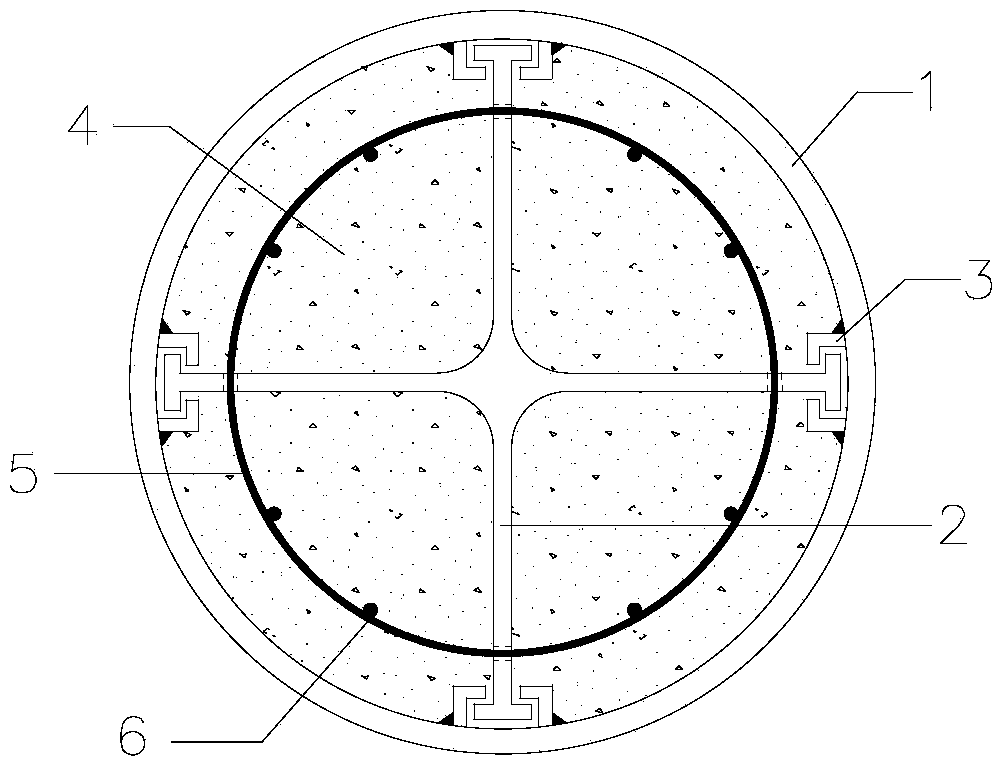

[0028] combine Figure 1~3 , including steel pipe 1, FRP stiffener 2, angle steel 3, concrete 4, stirrup 5 and longitudinal reinforcement 6.

[0029] The structure is formed by mixing concrete 4 with FRP stiffeners 2 with stirrups 5 and longitudinal steel bars 6 and steel pipes 1 . The angle steel 3 is welded to the steel pipe 1, and the welded angle steel forms a pair of two, symmetrically distributed, and the distance between them is determined according to the thickness of the FRP stiffener. For a steel pipe 1 with a larger diameter, it can be directly welded inside the steel pipe 1; for a steel pipe 1 with a small diameter, holes can be drilled at regular intervals on the pipe wall where the steel pipe 1 and the angle steel 3 are connected. The angle steel 3 and the steel pipe 1 are then connected by filling welding. The number of welding points and welding distance can be determined according to calculation. Drill holes at regular intervals along the ring direction on ...

Embodiment 2

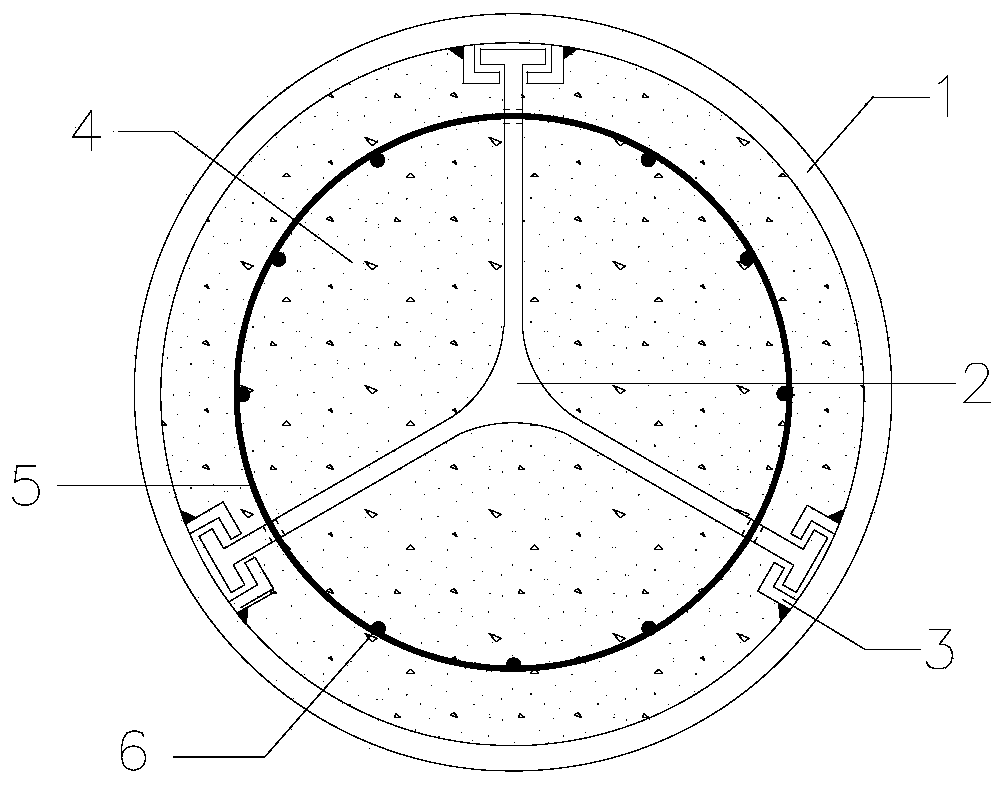

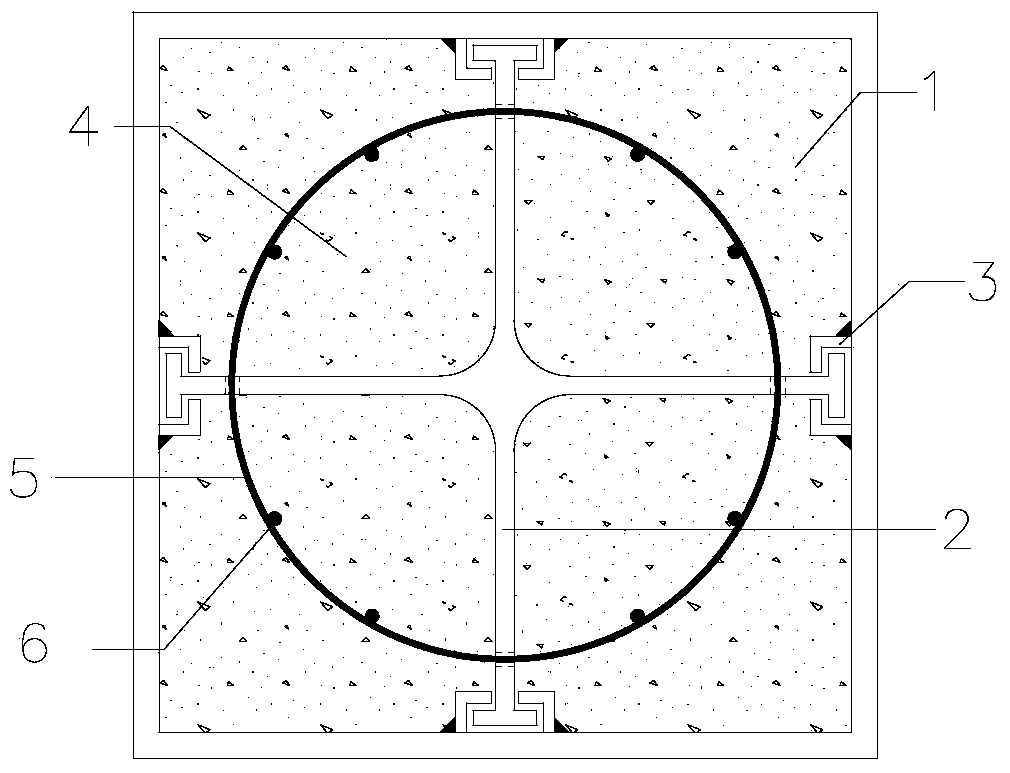

[0031] combine Figure 1~3 , including steel pipe 1, FRP stiffener 2, angle steel 3, concrete 4, stirrup 5 and longitudinal reinforcement 6.

[0032] The structure is formed by mixing concrete 4 with FRP stiffeners 2 with stirrups 5 and longitudinal steel bars 6 and steel pipes 1 . For the welding of angle steel 3 and steel pipe 1, half steel pipes can be used, and the angle steel 3 is welded at the designated position respectively, and then the half steel pipes are spliced and welded together, such as Figure 4 , 5 . For square steel pipes, rectangular steel pipes, etc., the angle steel 3 can be welded at the corresponding positions first, and then the steel plates are welded together to form square steel pipes, rectangular steel pipes such as Figure 6 . For the welding of the angle steel 3 and the steel pipe 1, the welded angle steel forms a pair in pairs and is symmetrically distributed, and the distance between them is determined according to the thickness of the FR...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com