Hydraulic prop having anchoring force energy-absorbing buffering function

A technology of hydraulic prop and fixed force, which is applied in the direction of prop/bracket, mining equipment, earthwork drilling and mining, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

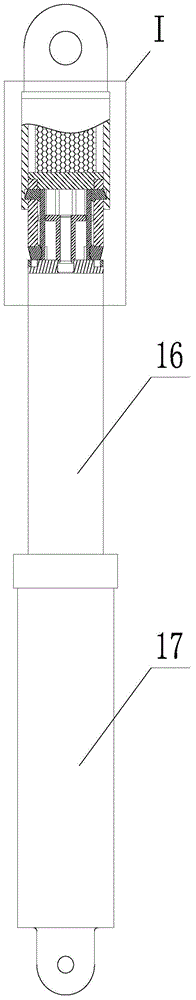

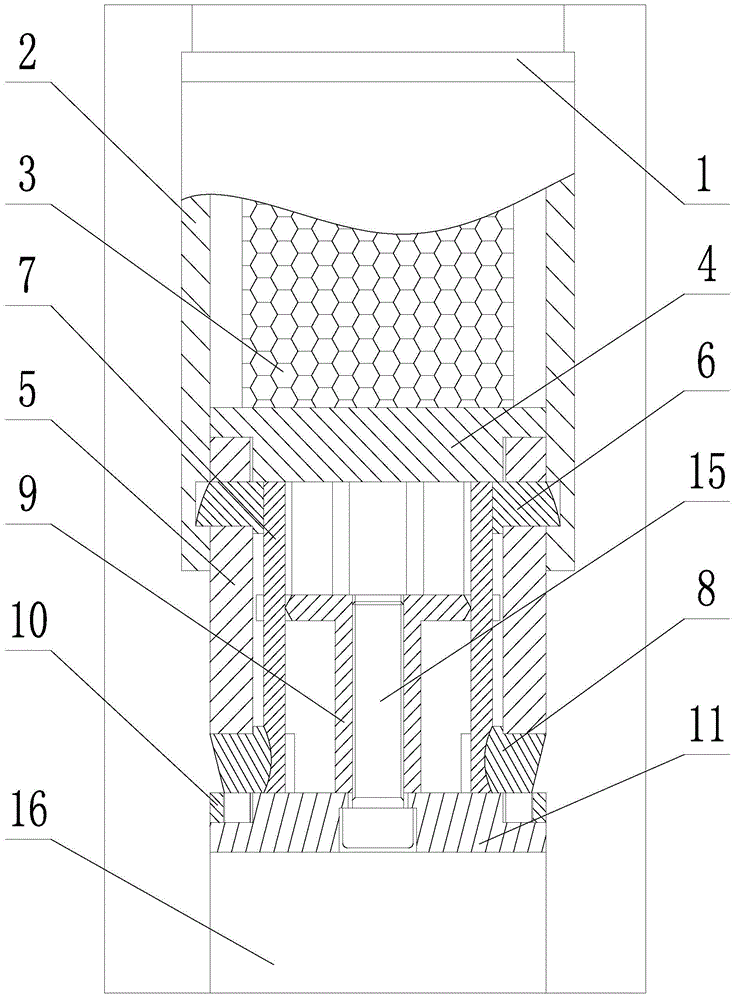

[0020] Such as Figure 1~6 As shown, a hydraulic prop with constant force energy absorbing and buffering function includes a main part of the prop, and the main part of the prop includes a live post 16, a cylinder body 17 and a safety valve, and the live post 16 is installed in the cylinder body 17, The safety valve is located outside the cylinder body 17 and communicates with the inside of the cylinder body 17; its characteristic is that a fixed-force energy-absorbing buffer mechanism is arranged at the end of the live column 16 of the main body of the column.

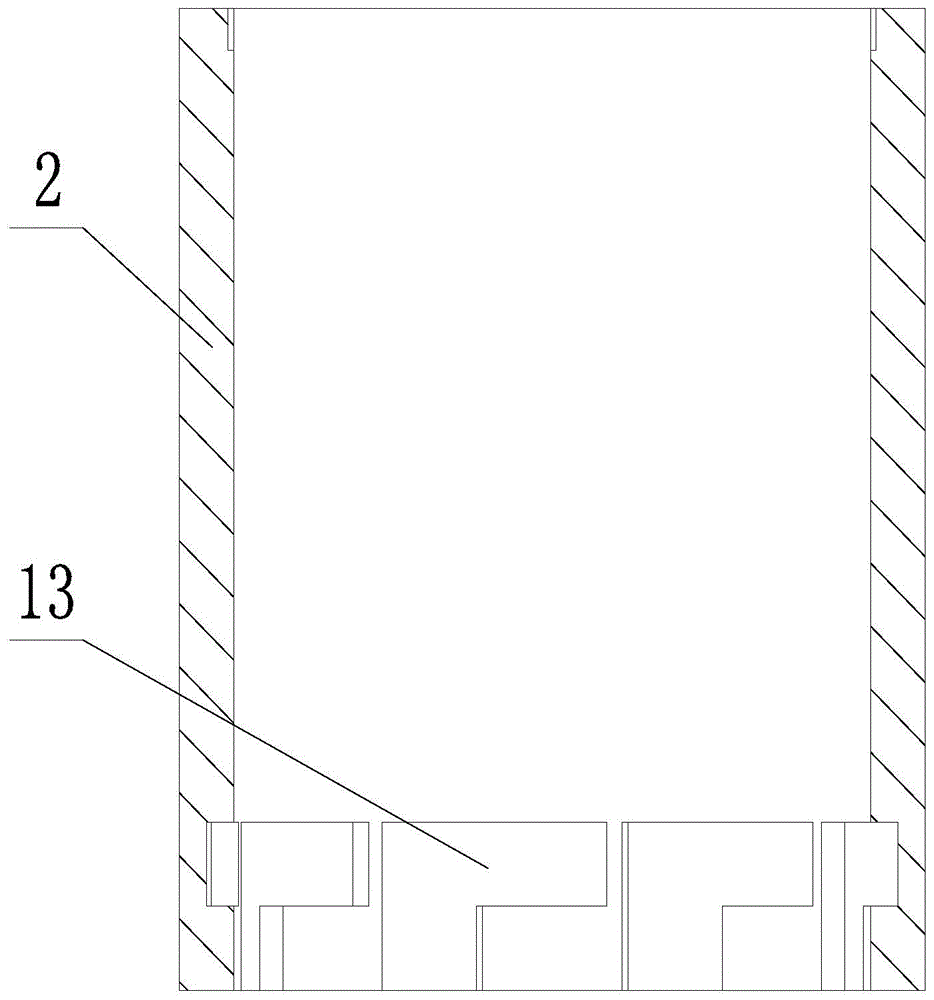

[0021] The fixed-force energy-absorbing buffer mechanism part includes an energy-absorbing section and a constant-force section, the energy-absorbing section includes a terminal 1, an outer sleeve 2, an energy-absorbing block 3 and a pressure plate 4, and the fixed-force sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com