Outer corner structure of composite wall

A technology of combining walls and corners, applied in the direction of walls, building components, building structures, etc., can solve problems such as imperfect structural details, and achieve the effect of improving stiffness, improving connection performance, and ensuring performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

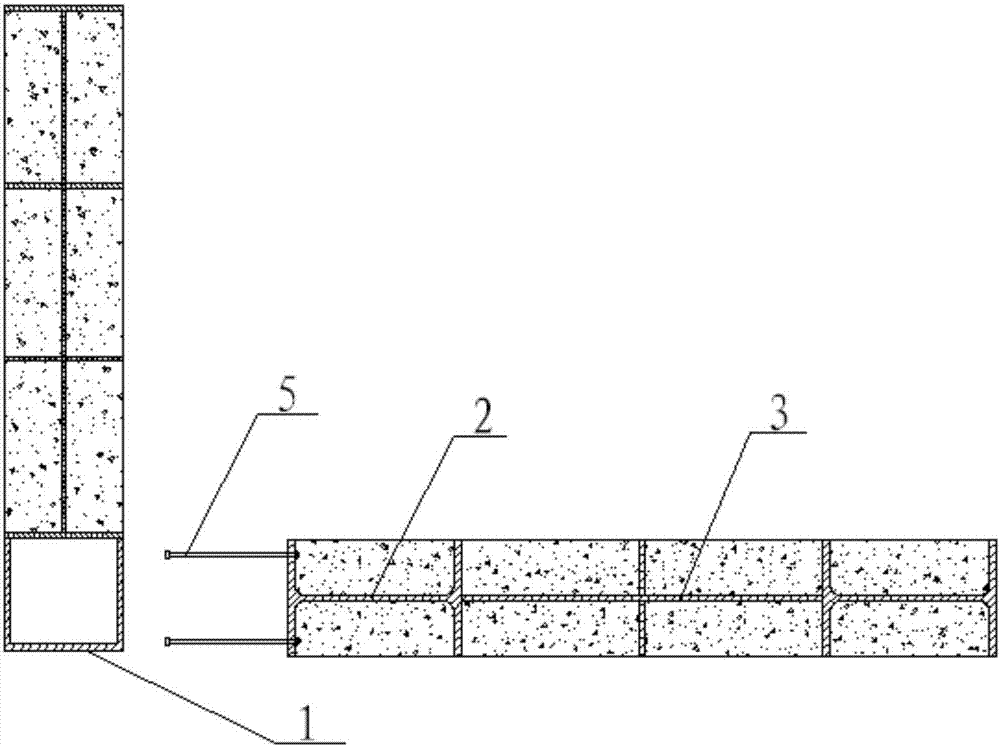

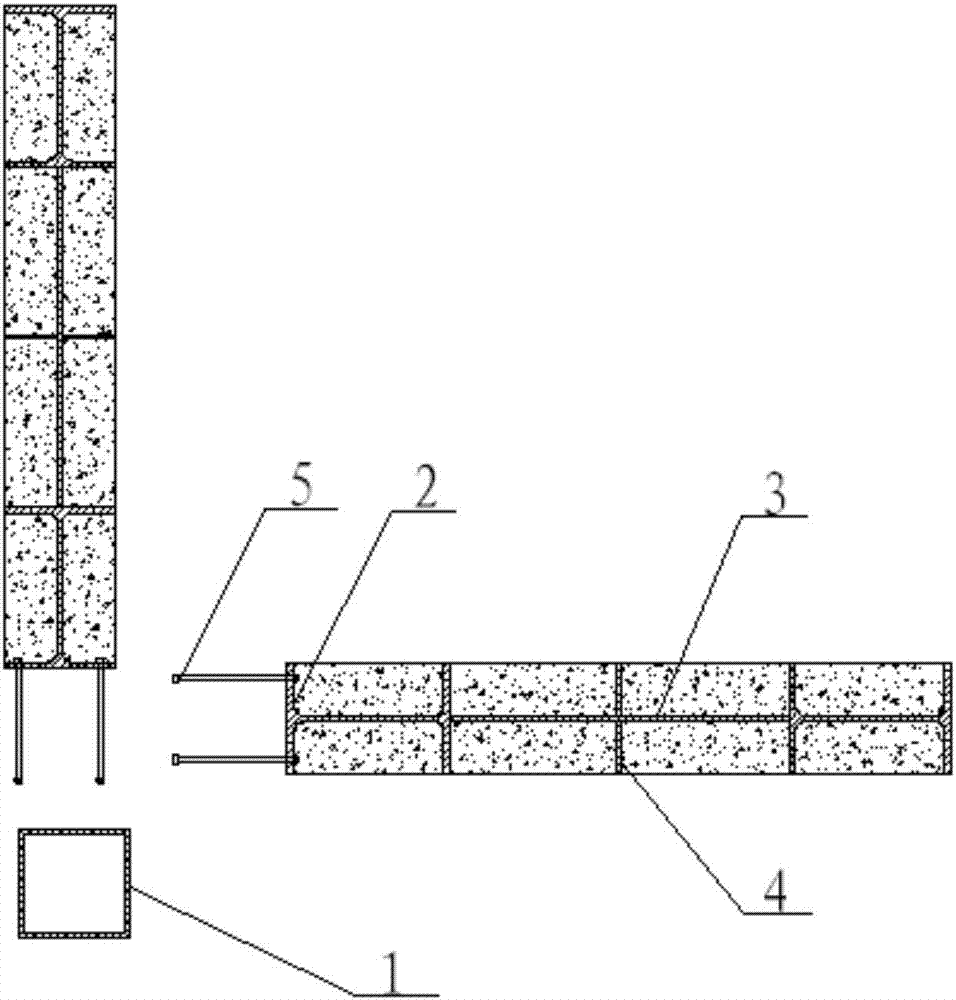

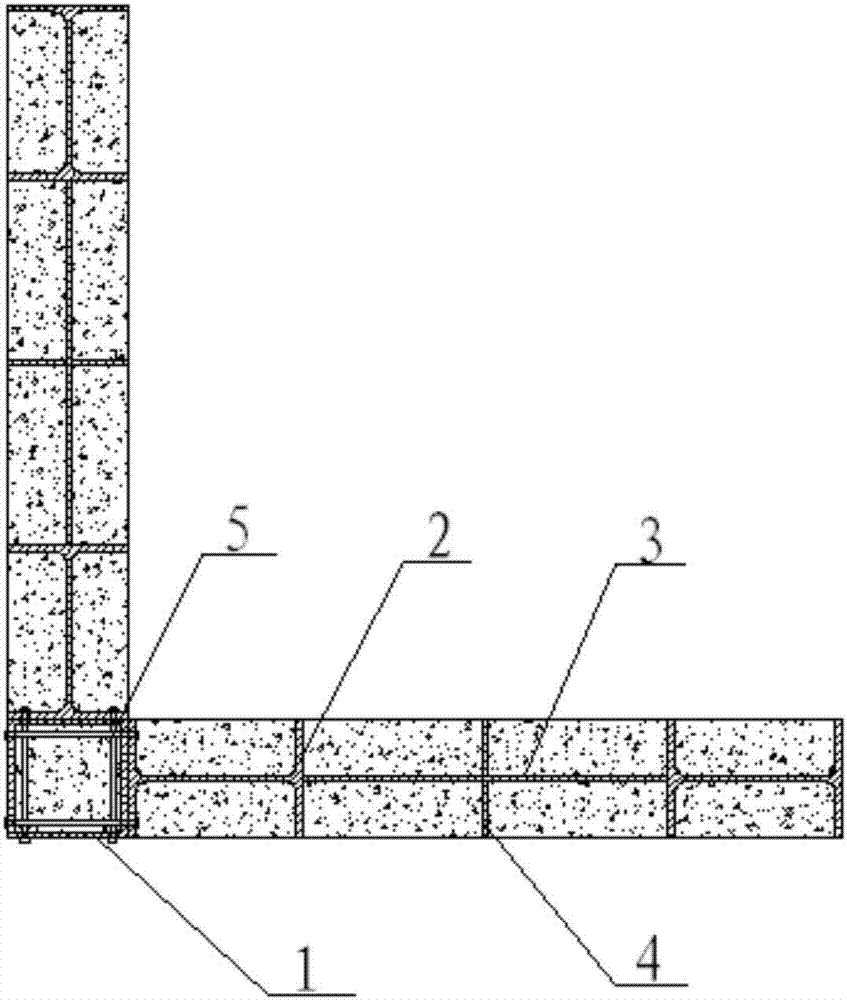

[0020] As shown in the figure, a composite wall corner structure includes a shear wall and connecting square pipe 1. The shear wall includes H-shaped steel 2, a middle horizontal plate 3, and a middle vertical plate 4. The middle vertical plate 4 is vertically welded to the middle horizontal plate. 3 On the upper and lower sides, the H-shaped steel 2 is welded on the left and right sides of the middle horizontal plate 3, and the side of the H-shaped steel 2 is perpendicular to the middle horizontal plate 3, that is, the middle vertical plate 4 is parallel to the side of the H-shaped steel 2. The figure only shows the situation of one row of middle vertical plates 4, but in fact, several rows of middle vertical plates 4 can be arranged between two H-shaped steels 2, and the H-shaped steels 2 can also be welded by the middle horizontal plates 3 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com