H section steel girder-column minor axis connecting top and bottom angle steel node and preparing method of H section steel girder-column minor axis connecting top and bottom angle steel node

A technology of H-shaped steel and angle steel, which is applied in the direction of construction, building structure, and building material processing, can solve the problems of analysis, design, and installation difficulties, and the limited number of nodes, so as to delay local buckling and bulging, and improve overall rigidity And the effect of high bearing capacity and high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

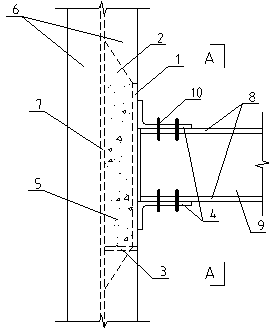

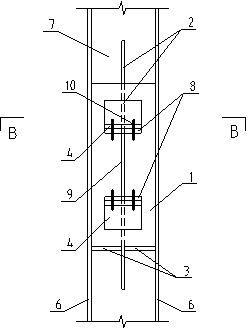

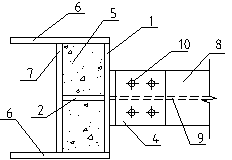

[0027] In the present invention, the H-shaped steel column is composed of a web 7 and two flanges 6 arranged at both ends of the web 7 , and the H-shaped steel beam is composed of a web 8 and two flanges 9 arranged at both ends of the web 8 . Between the two flanges 6 of the H-shaped steel column, a gusset plate 1 is welded at a position flush with the outer edge of the flange 6 . A stiffening plate 2 is welded at the vertical center line inside the gusset plate 1, and the gusset plate and the stiffening plate are perpendicular to each other. The stiffener 2 is trapezoidal, wherein the short bottom of the trapezoid is welded to the gusset plate 1 , and the long bottom is welded to the web 7 of the H-shaped steel column. The angle steel 4 is composed of two top angle steels and bottom angle steels with the same structure, the top angle steel is located at the top, and the bottom angle steel is located below. One limb of the angle steel 4 is provided with double rows of high-str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com