Connecting joint of fabricated concrete composite wall with built-in thermal insulation layer and light steel frame

A technology for connecting joints and concrete, applied in insulation, walls, protective buildings/shelters, etc., to achieve the effects of reducing steel corrosion, increasing gravity load, reducing design strength and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

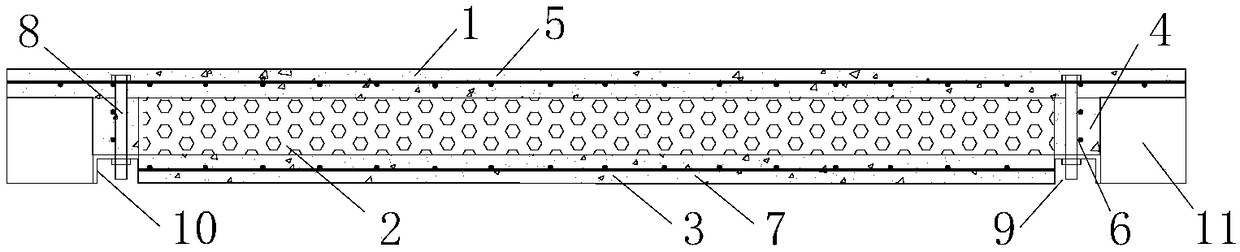

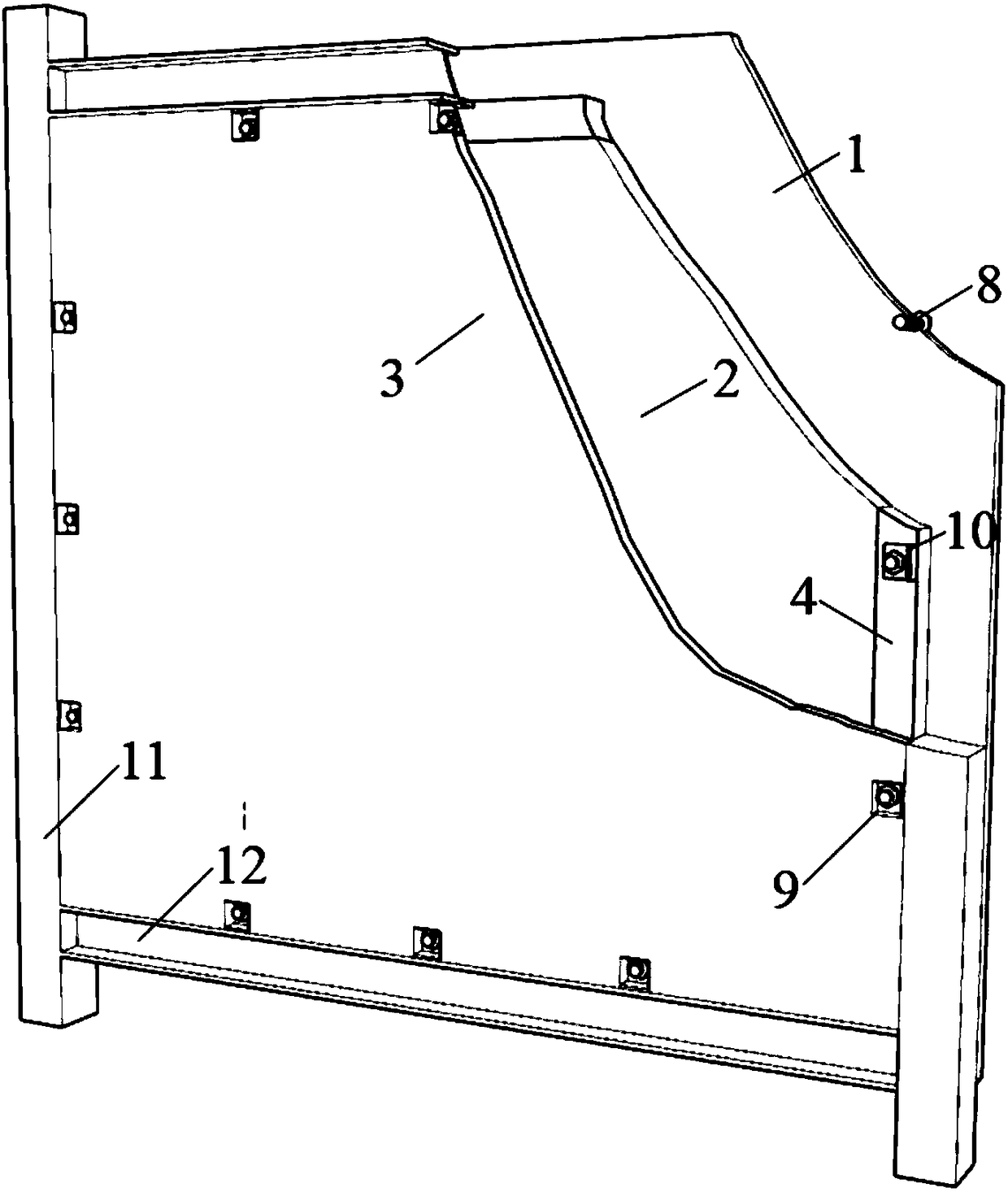

[0032] The prefabricated built-in insulation layer concrete composite wall-light steel frame connection node in the invention, combined with the attached Figure 3-6 The preparation method of the present invention is set forth as follows:

[0033] The first step: According to the size of the wall panel, make the formwork required for pouring the wall panel components, lay the outer page orthogonal reinforcement mesh in the formwork, the outer page orthogonal reinforcement mesh is placed in the middle of the outer page foamed concrete, and at the position of the concrete frame Internally locate and fix frame reinforcement mesh and embedded bolts.

[0034] Step 2: Configure the concrete on the inner and outer pages of the wall panel and the concrete on the concrete frame.

[0035] Step 3: Pour the configured outer page concrete, vibrate it compactly and plaster the plane layer according to the thickness of the outer page concrete, lay the built-in insulation layer on the outer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com