High-strength building waste regeneration concrete composite beam and construction method thereof

A technology of recycled concrete and construction waste, applied in the direction of buildings, building components, building structures, etc., can solve the problems of occupation, serious environmental and social problems, increase the production cost of building products, etc., to ensure the strength, simplify the construction process and construction Difficulty, manpower saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. According to the design requirements, construct on the wall columns, and reserve construction joints, which are the same as the top elevation of the prefabricated beams.

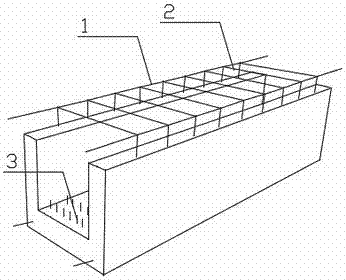

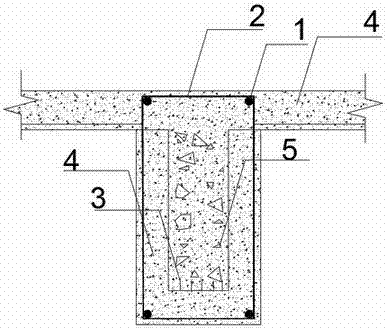

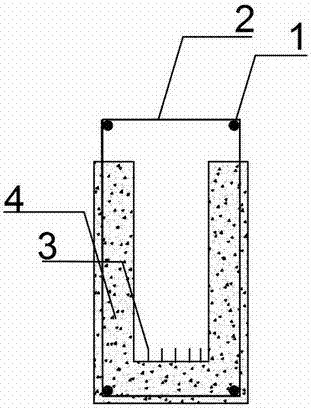

[0024] 2. In the production factory, use tools such as rubber core molds to complete a number of longitudinal bars set on the length of the high-strength construction waste recycled concrete composite beam 1, a number of closed stirrups vertically set along the long direction of the concave groove 2, and steel nails on the bottom plate The blanking of the 3rd and other parts, the longitudinal reinforcement 1 and the stirrup 2 are welded vertically to each other and the recycled aggregate concrete 4 is poured to make a high-strength recycled aggregate concrete prefabricated concave groove, and the hoisting hook is pre-buried in advance. The inner diameter d of the empty groove of the high-strength recycled aggregate concrete prefabricated concave groove is greater than 50cm.

[0025] 3. After the hi...

Embodiment 2

[0029] 1. According to the design requirements, construct on the wall columns, and reserve construction joints, which are the same as the top elevation of the prefabricated beams.

[0030] 2. In the production factory, use tools such as rubber core molds to complete a number of longitudinal bars set on the length of the high-strength construction waste recycled concrete composite beam 1, a number of closed stirrups vertically set along the long direction of the concave groove 2, and steel nails on the bottom plate The blanking of the 3rd and other parts, the longitudinal reinforcement 1 and the stirrup 2 are welded vertically to each other and the recycled aggregate concrete 4 is poured to make a high-strength recycled aggregate concrete prefabricated concave groove, and the hoisting hook is pre-buried in advance. The inner diameter d of the empty groove of the high-strength recycled aggregate concrete prefabricated concave groove is greater than 50cm.

[0031] 3. After the hi...

Embodiment 3

[0035] 1. According to the design requirements, construct on the wall columns, and reserve construction joints, which are the same as the top elevation of the prefabricated beams.

[0036] 2. In the production factory, use tools such as rubber core molds to complete several longitudinal reinforcements set on the length of the high-strength construction waste recycled concrete composite beam 1, several closed stirrups vertically arranged along the long direction of the concave groove 2, steel nails on the bottom plate The blanking of parts such as 3, the vertical welding between longitudinal bars and stirrups and the pouring of recycled aggregate concrete 4 are made into prefabricated concave grooves of high-strength recycled aggregate concrete, and the hoisting hooks are pre-buried in advance. The inner diameter d of the empty groove of the high-strength recycled aggregate concrete prefabricated concave groove is greater than 50cm.

[0037]3. After the high-strength recycled a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com