Patents

Literature

49results about How to "Flexible product plan" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

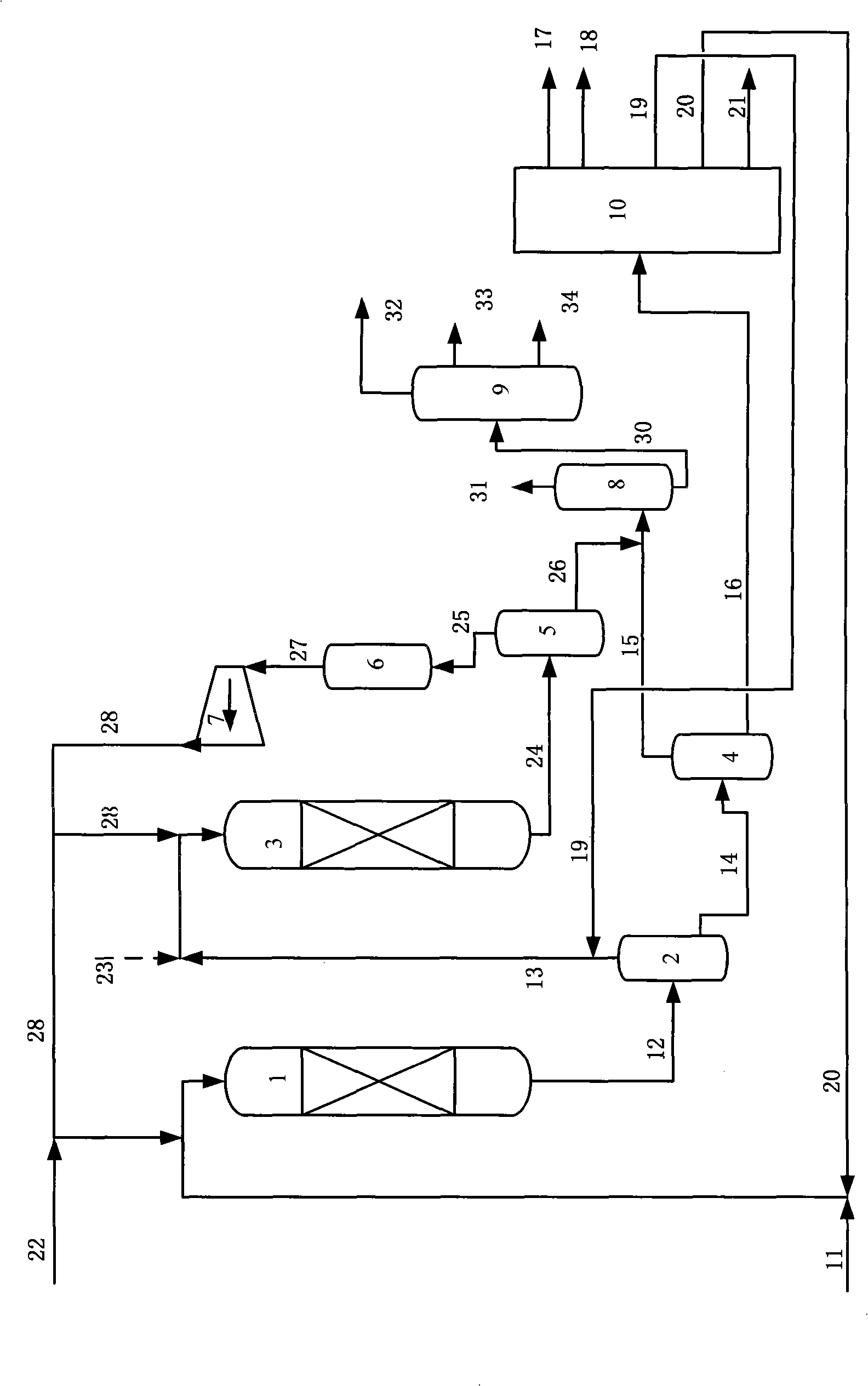

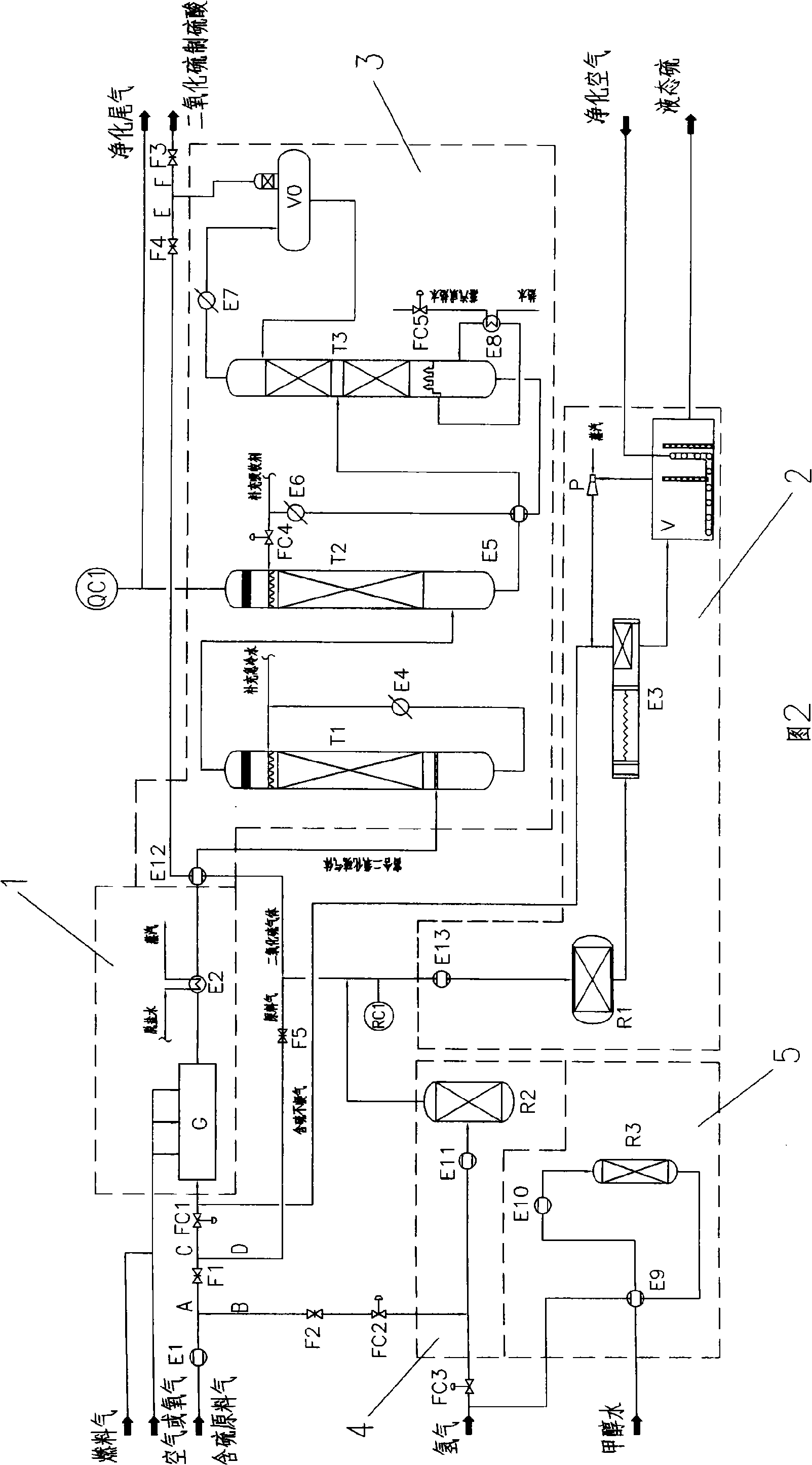

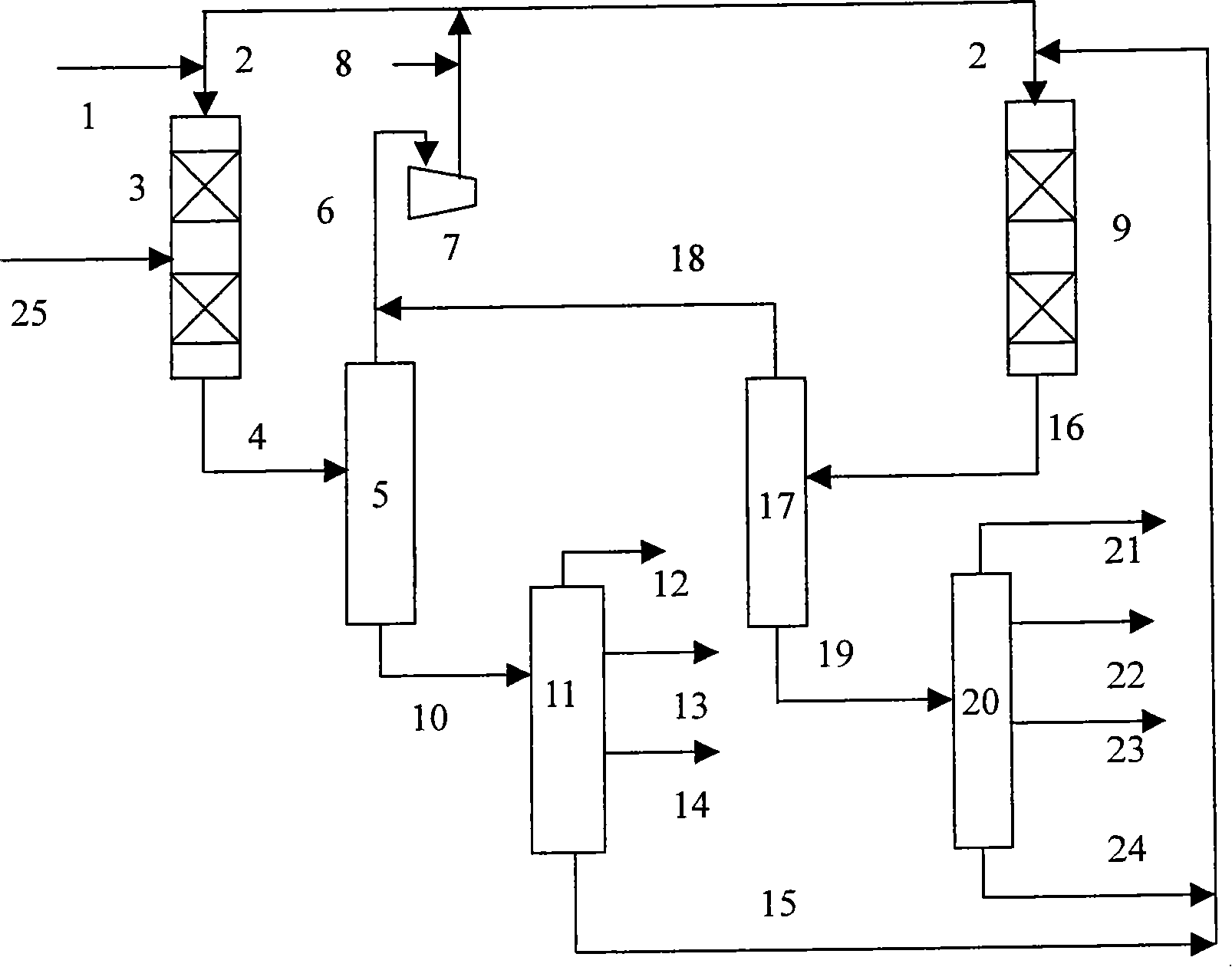

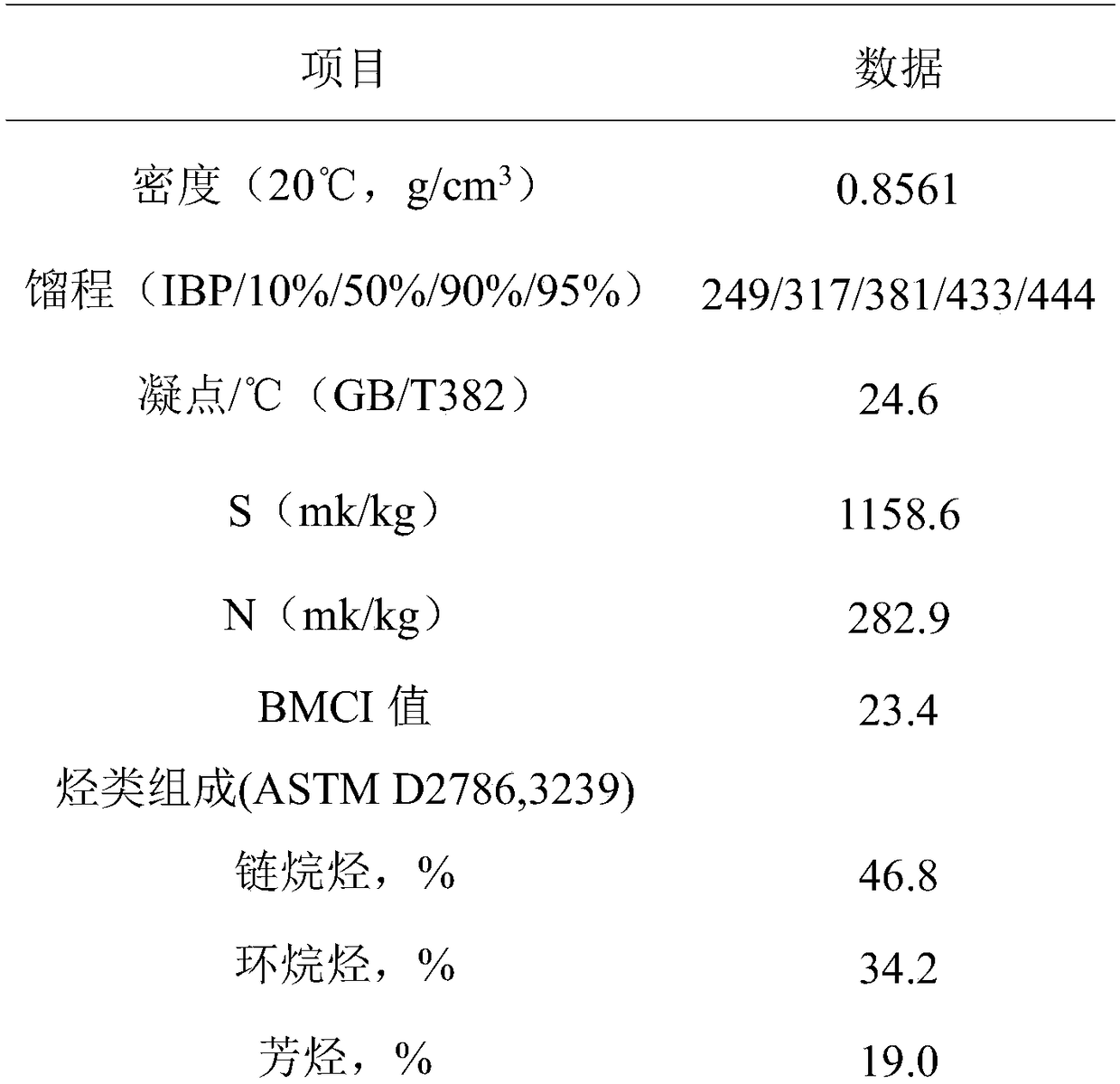

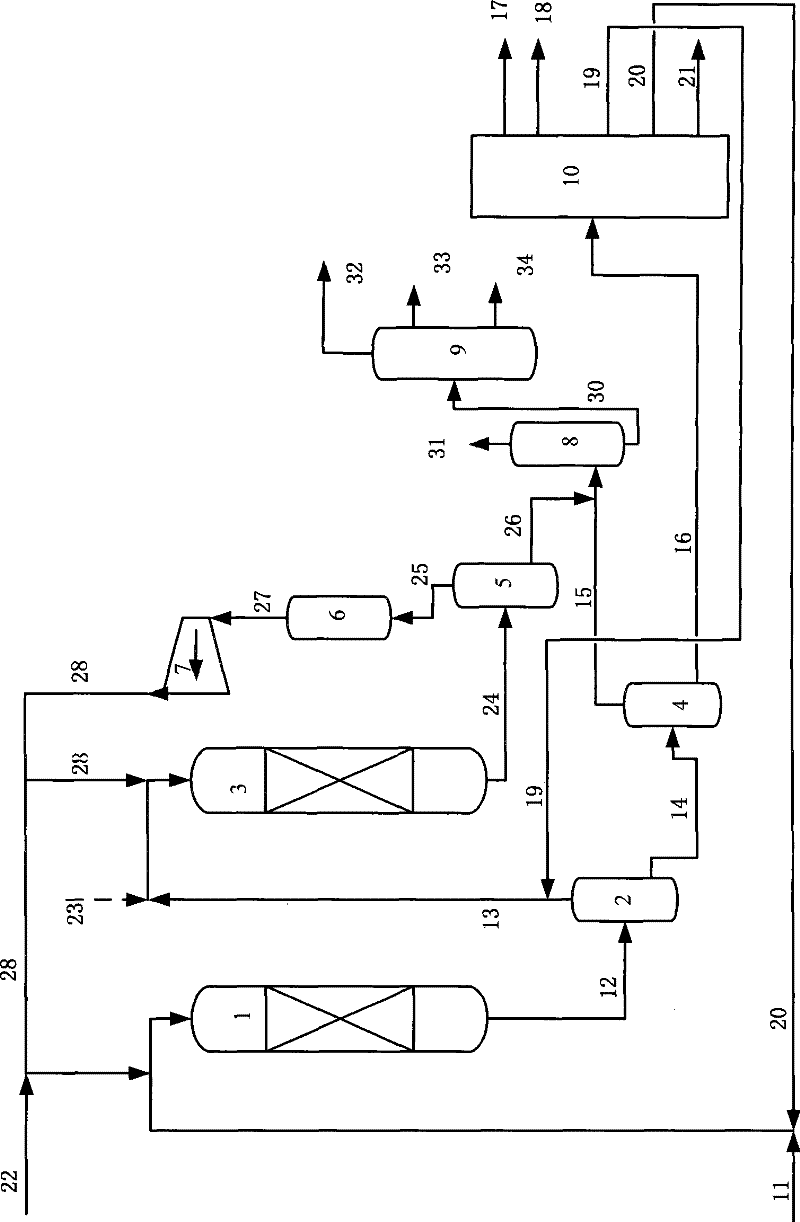

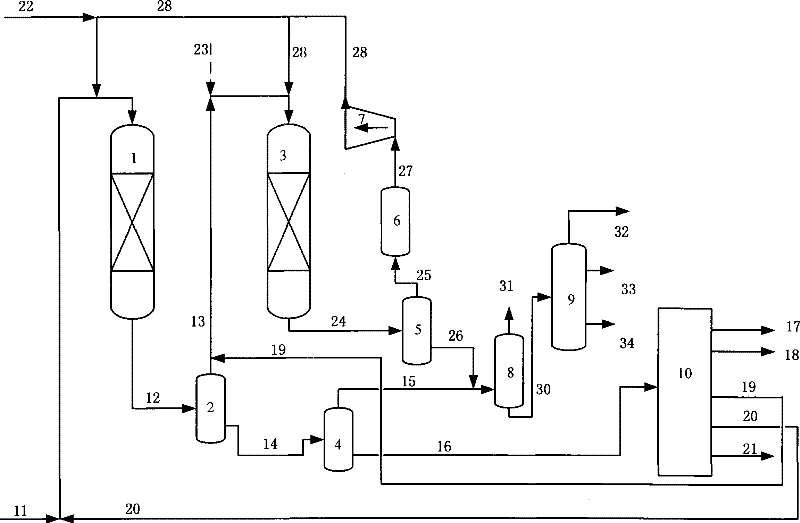

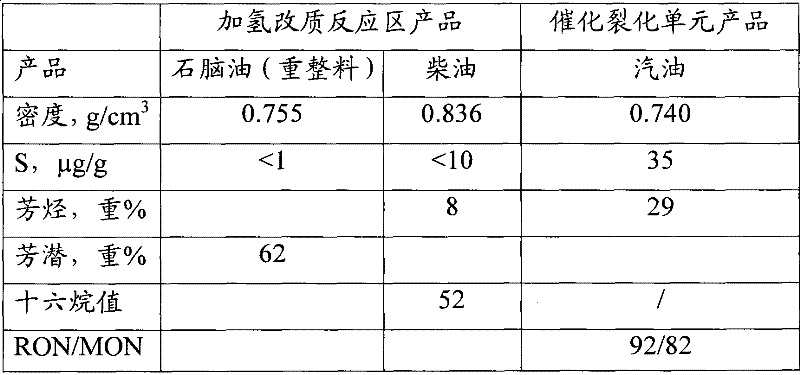

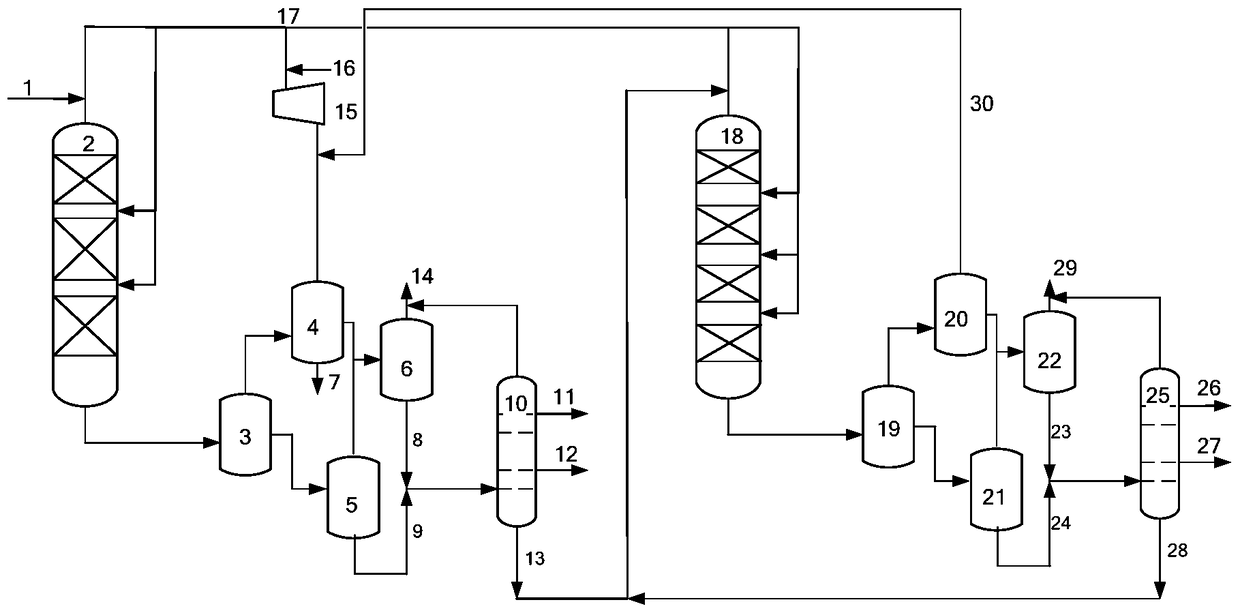

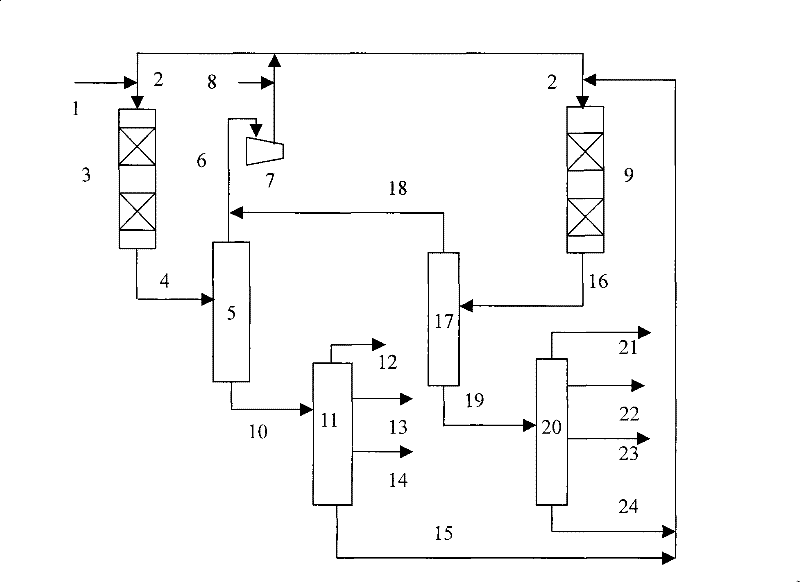

Optimized hydrogenation-catalytic cracking combination process

The invention relates to an optimized hydrogenation-catalytic cracking combination process, comprising the following steps: wax oil raw materials react in a hydrotreating reaction area; obtained hydrogenation wax oil is taken as catalytic cracking raw oil and directly enters a catalytic cracking unit without being fractionated; catalytic heavy cycle oil circulates back the hydrotreating reaction area; gas phase material flow at the top of a high-pressure hot separator, catalytic light cycle oil and optional crude diesel oil enter a hydrogenation upgrading reaction area carry out hydrogenationupgrading reaction; and reaction products thereof are fractionated to obtain hydrogenation naphtha and hydrogenation diesel. A hydrotreating unit and a hydrogenation upgrading unit shares a hydrogensystem, the device investment and operation cost are lowered, the product scheme is flexible, and high-quality low-sulphur gasoline, high-quality diesel and reforming raw materials can be produced atthe same time.

Owner:CHINA PETROLEUM & CHEM CORP +1

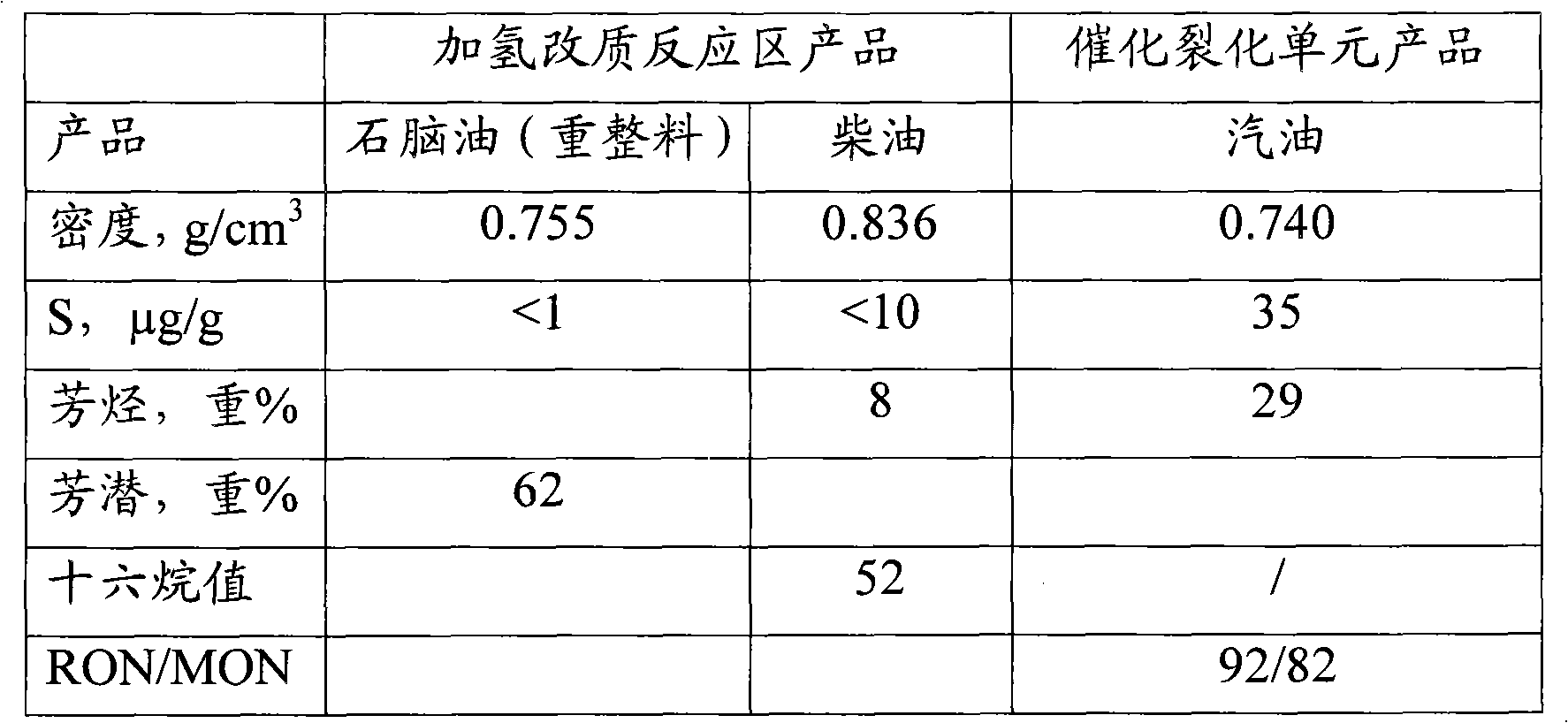

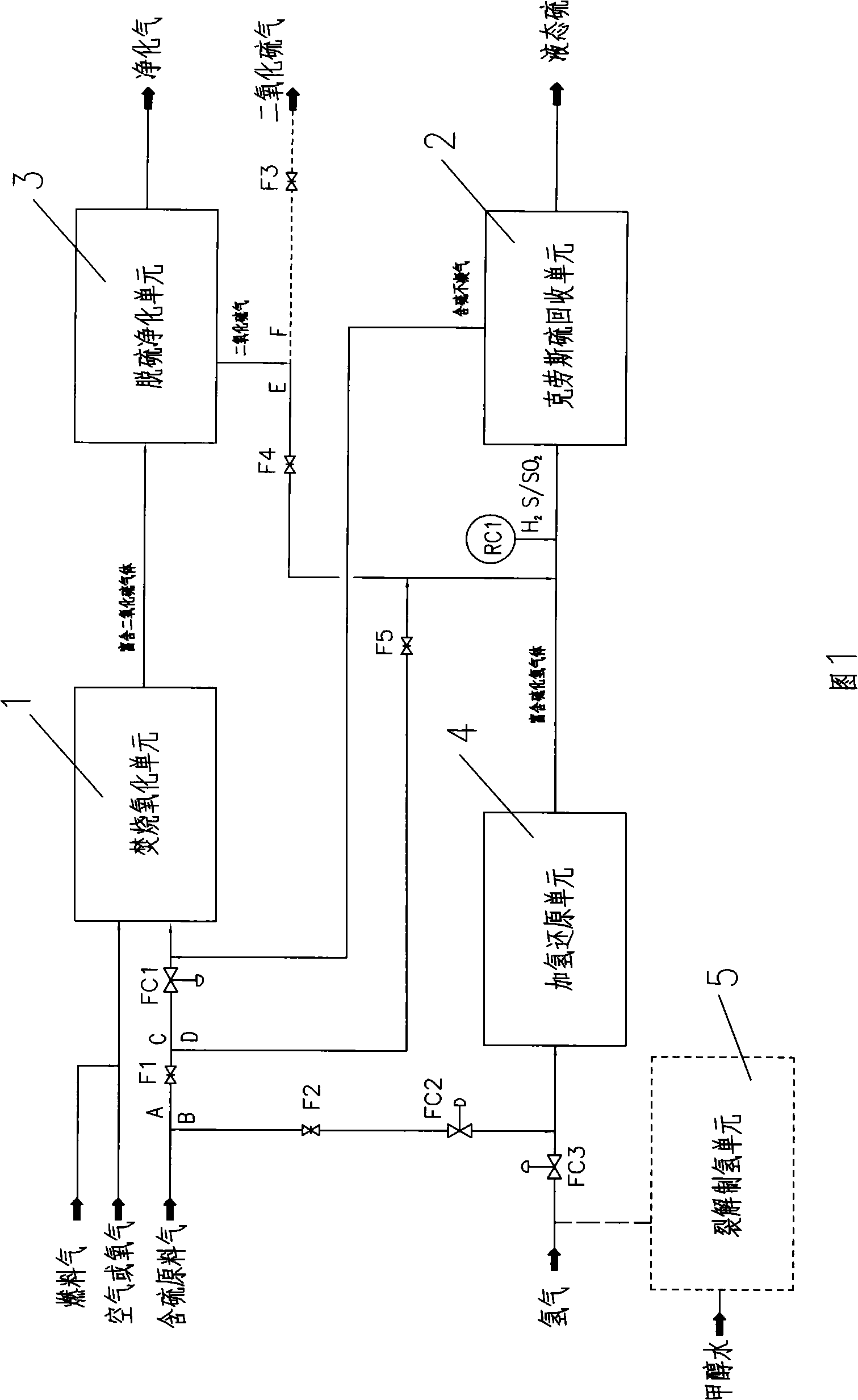

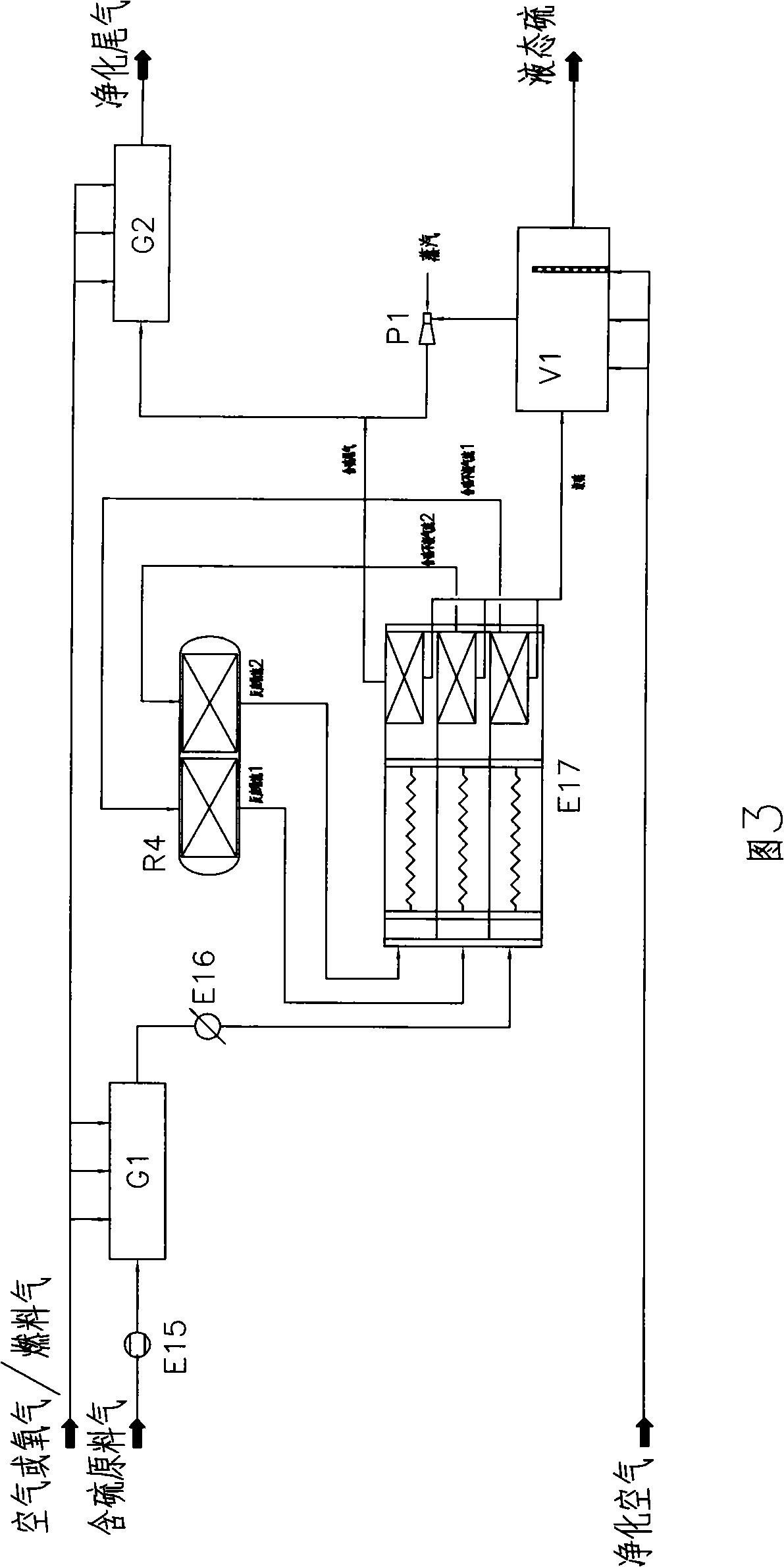

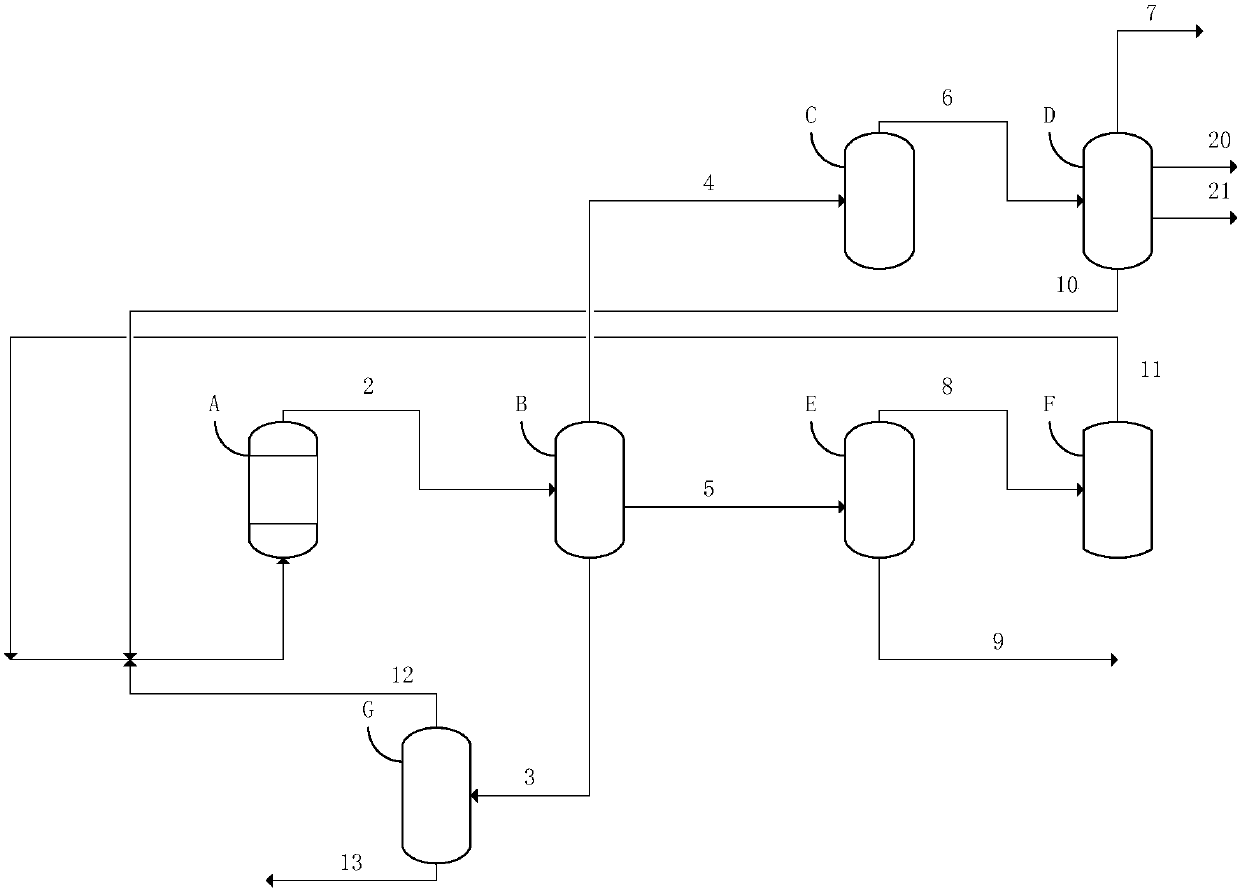

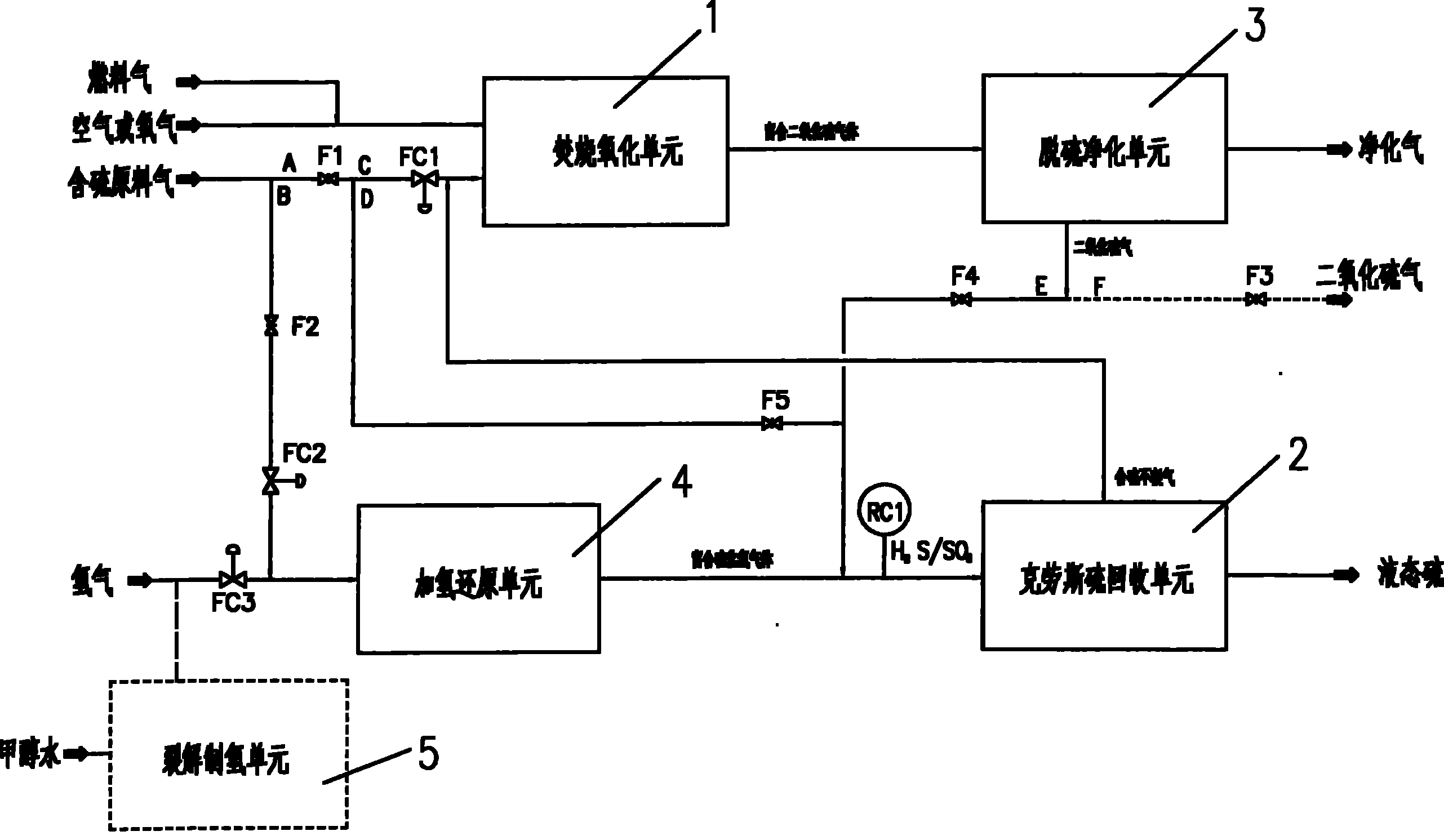

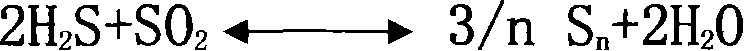

Oxidation, reduction and sulfur recovery multipurpose device

ActiveCN101289170ASulfur conversion overHigh recovery rateSulfur preparation/purificationSulfurSulfide

The invention relates to an oxidation-reduction multi-purpose device for sulfur recovery, which is applicable to desulfurization and purifying of sulfur-bearing gas produced during the production processes of oil refining, chemical engineering, coal chemical industry, thermal power plants, etc. The oxidation-reduction multi-purpose device for sulfur recovery comprises a burning oxidation unit, a desulfurization and purifying unit, a hydrogenation reduction unit and a Claus sulfur recovery unit. The invention gets rid of a demanding oxygen-limited burning section positioned in the front part in traditional Claus reaction, which is improved into peroxide burning, and does not necessary pursue sulfur conversion rate of the Claus reaction excessively, and only needs to control the SO2 conversion rate of sulfide in the peroxide burning and the circulating load of desulfurizer in the desulfurization and purifying reaction and the deficiency-degree regenerated thereby, can achieve or exceed recovery percent and SO2 emission of lower concentration than the Claus sulfur recovery device, with adjustable concentration of emission. The oxidation-reduction multi-purpose device of the invention can produce H2S through the hydrogenation reduction unit, thus having no requirement for the concentration of H2S in the sulfur-bearing gas, flexible operation and good comprehensive processing capacity.

Owner:苏州璞赛环境科技有限公司

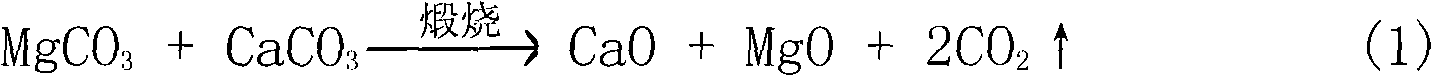

Process for removing calcium from magnesite

The invention relates to a process for removing calcium from magnesite. The process is characterized by finally reducing the content of calcium oxide below 1.5% through magnesite calcination, slaking, calcium removal, filtration, washing, drying and other treatment procedures. The process has the following beneficial effects: the magnesium hydroxide product which is obtained after removing calcium and has content of calcium oxide being lower than 1.5% can be directly applied to the fields such as flame retardants, oil additives, water treatment neutralizers and the like; other high value-added magnesium-containing materials such as industrial magnesium oxide, electrician magnesium oxide, fused magnesium oxide, light magnesium carbonate and the like can be further processed and produced; and compared with the existing processes for removing calcium from magnesite, the process has the advantages of short flow, low cost, flexible product scheme, thorough calcium removal and the like.

Owner:LIAONING XINFAZHAN REFRACTORY MATERIAL GRP

Method of producing magnesium hydroxide

ActiveCN101172627AIncrease profitReduce manufacturing costMagnesiaMagnesium hydroxideSulfatePhysical chemistry

The invention discloses a preparation method of magnesium hydroxide by using magnesium sulfate and lime milk as raw materials, and the invention has the concrete process that a magnesium sulfate solution with a certain concentration can be used to conduct the metathesis reaction with a calcium chloride solution to produce the magnesium chloride solution and calcium sulfate precipitation; the filter mass is washed and dried after the solid-liquid separation to generate calcium sulfate products; the filter liquid continues to counteract with lime milk with a certain concentration to produce the calcium chloride solution and the magnesium hydroxide precipitation; and then the filter mass is washed, dried and crashed after the solid-liquid separation to generate magnesium hydroxide products; and then the filter liquid returns to the metathesis reaction for recycling. The invention with low producing cost remarkably improves environmental and economic benefits.

Owner:河北镁神科技股份有限公司

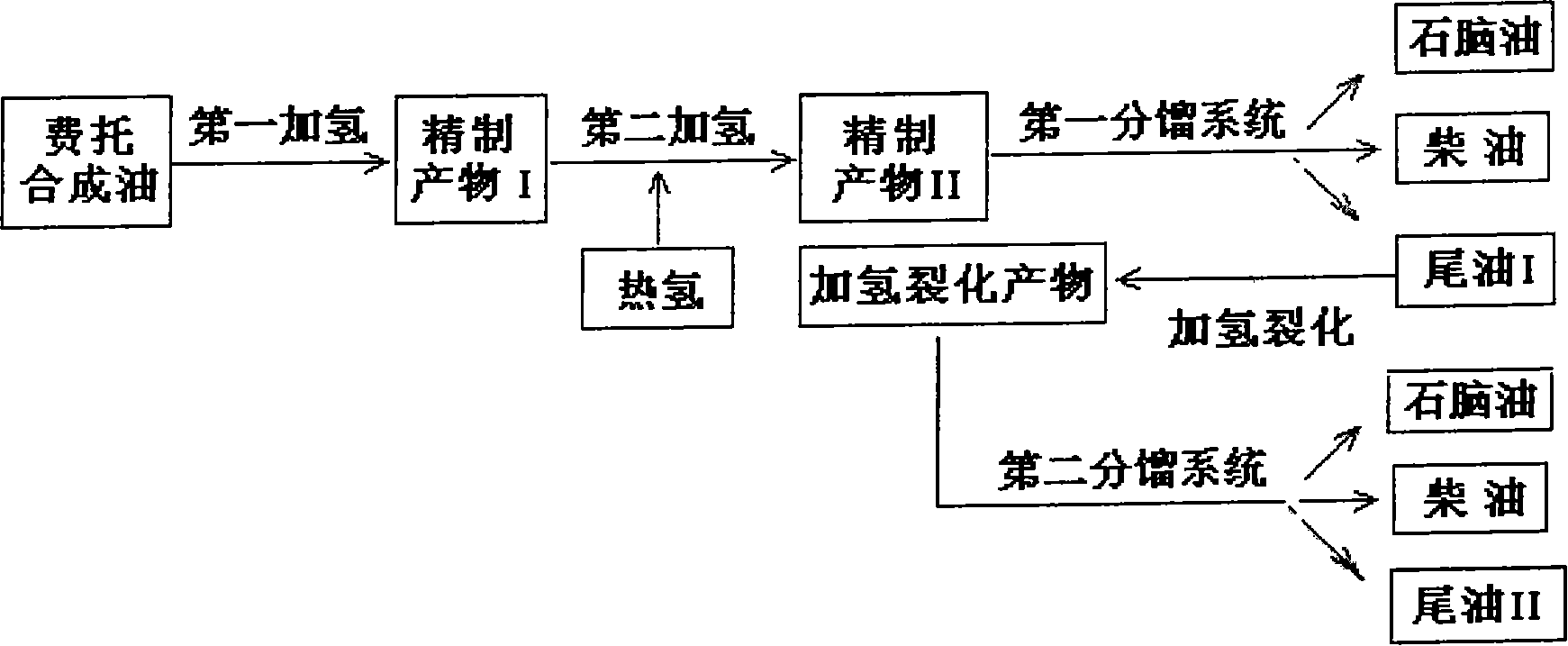

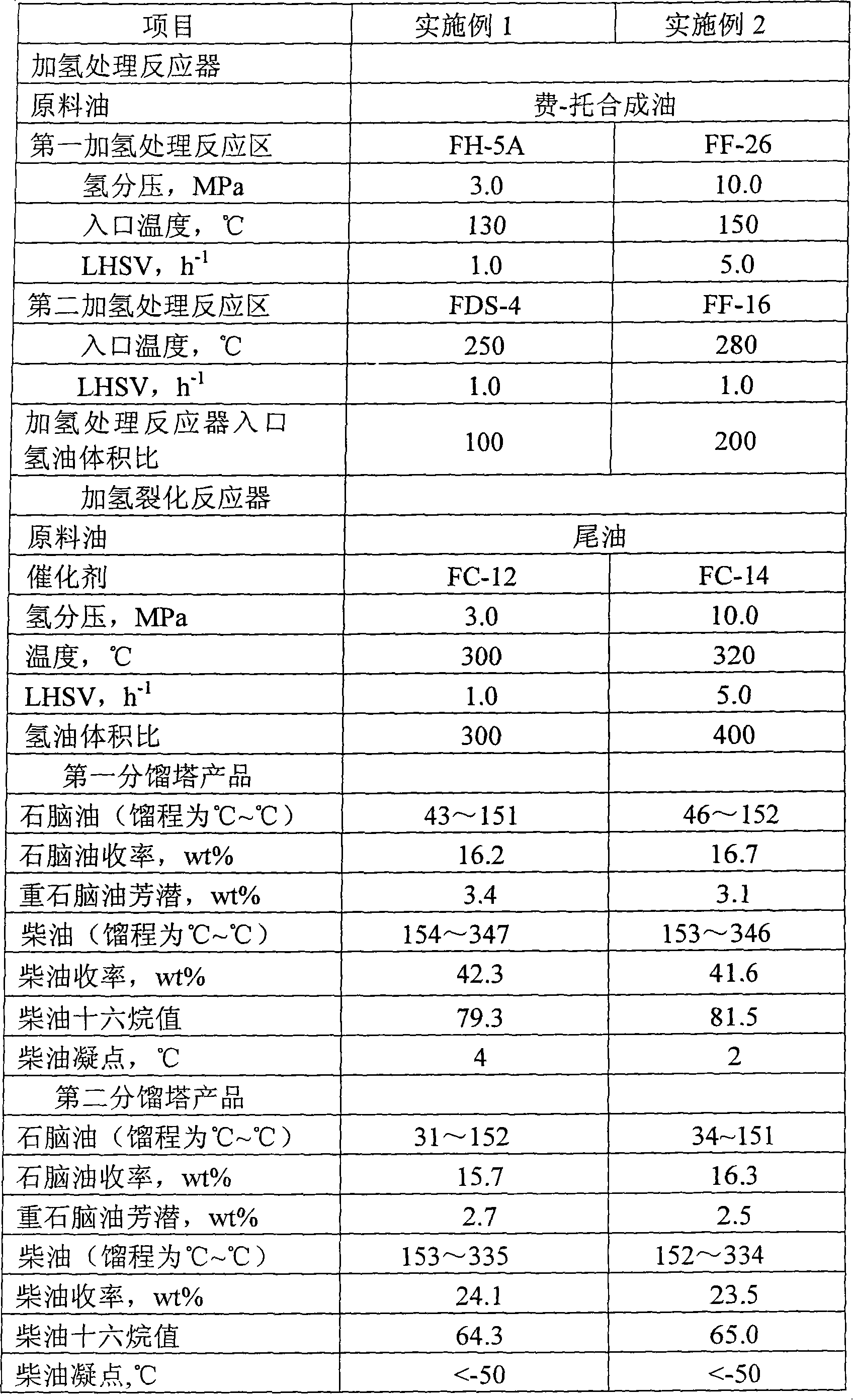

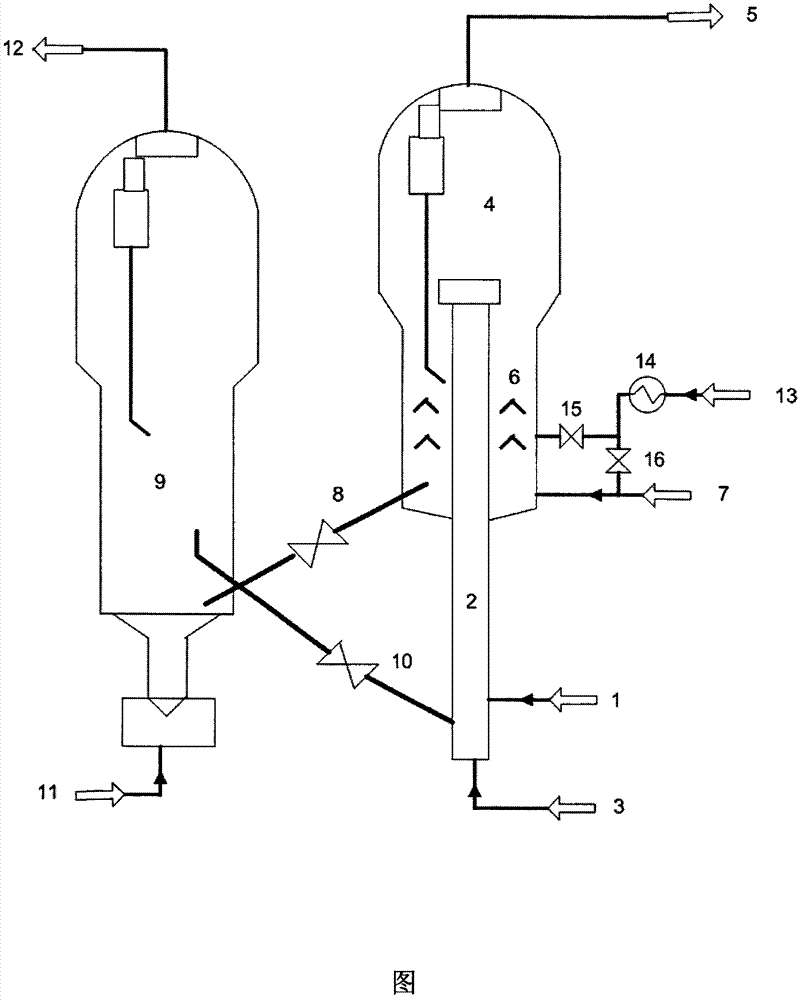

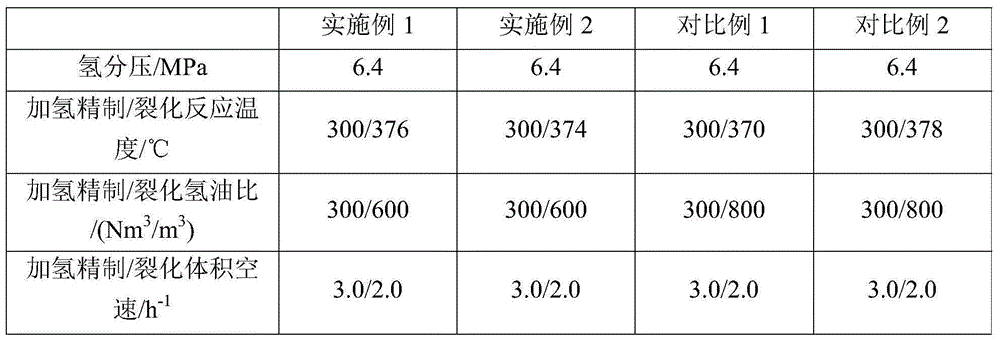

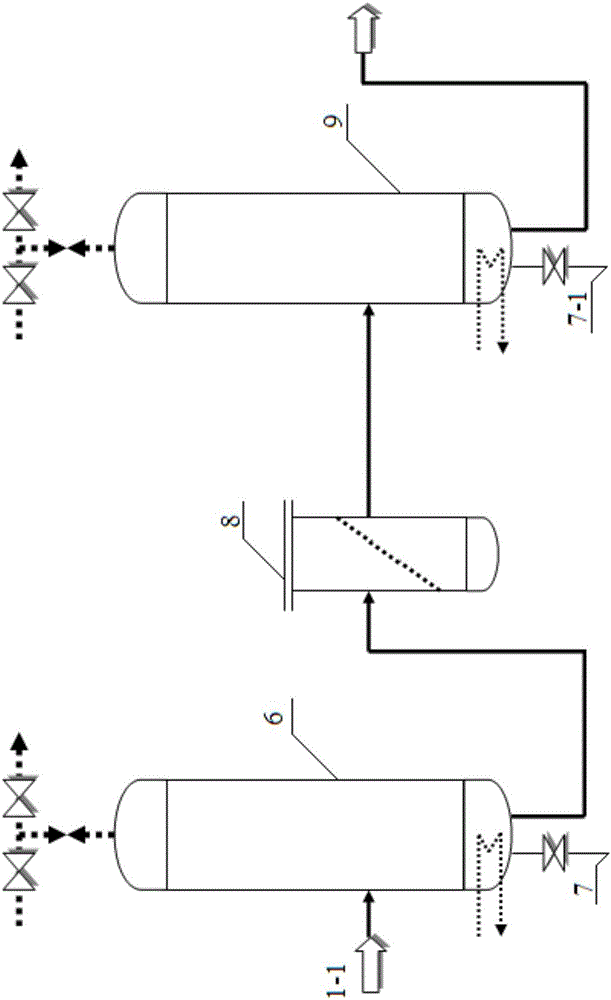

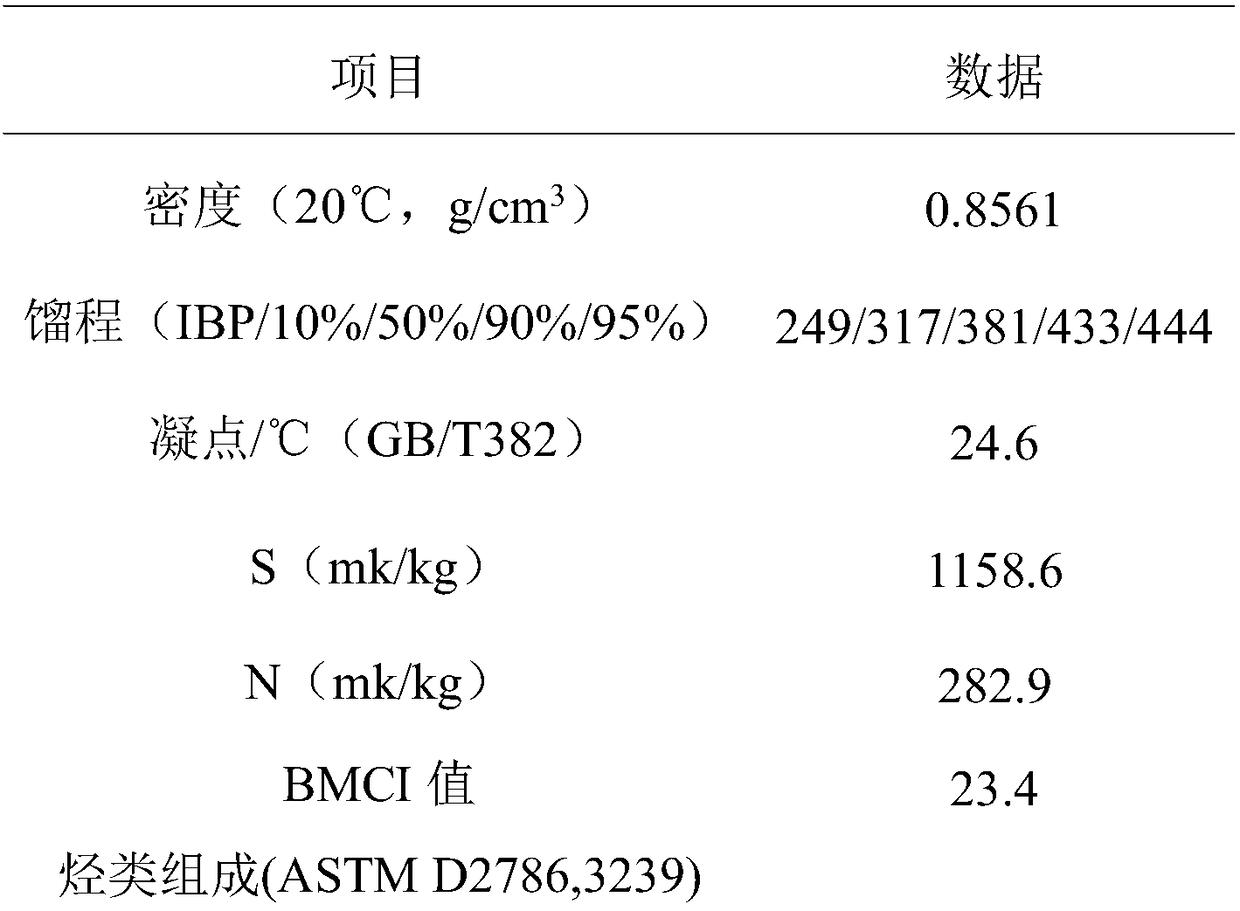

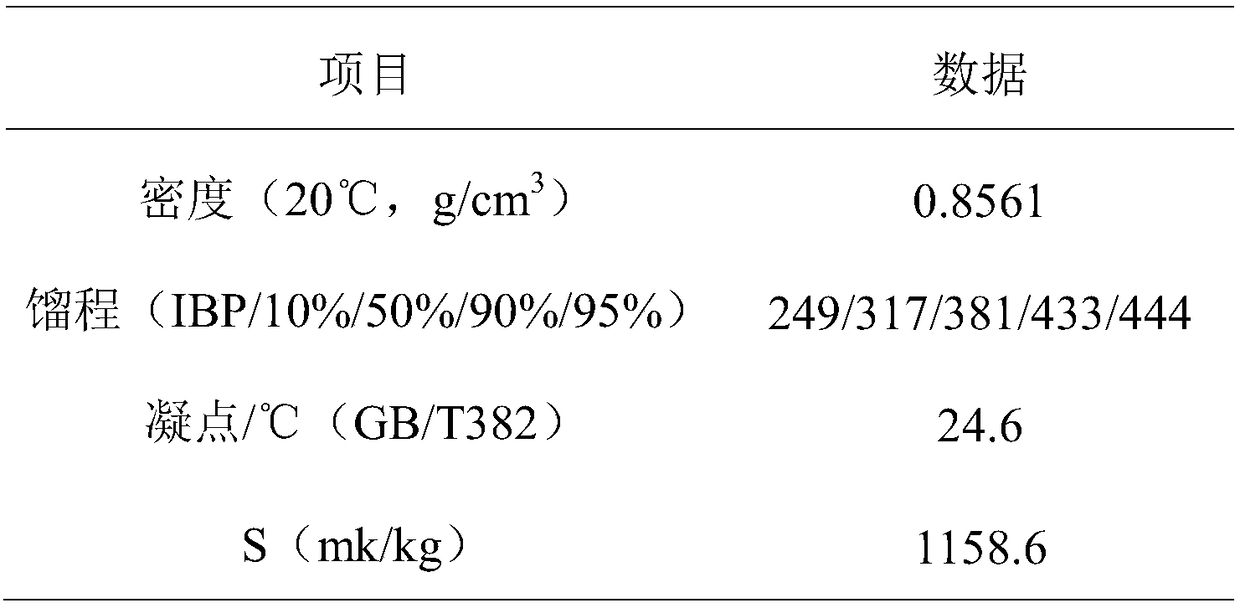

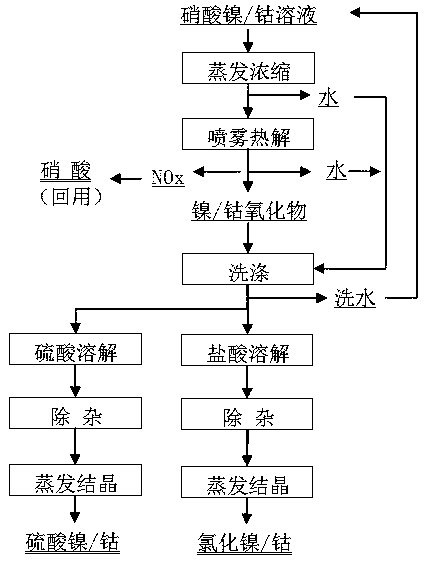

Hydrogenation processing method for f-t synthetic oil

ActiveCN101177626AEffective hydrotreatingGuaranteed long-term operationTreatment with hydrotreatment processesNaphthaHydrogen

The invention discloses a hydrogenation processing method of Fischer-Tropsch synthetic oil and the processing method is that the Fischer-Tropsch synthetic oil is subjected to hydrogenation processing in a plurality of hydrogenation processing reaction zones with different entrance temperatures. The entrance temperatures of hydrogenation processing reaction zones are raised by injecting hot hydrogen. The tail oil separated after hydrogenation processing is subjected to hydrogen cracking. Hydrogenation processing products and hydrogen cracking products enter different fractionating systems. The invention can acquire high-quality clean diesel oil with cetane value higher than 75 and low-freezing clean oil with solidifying point lower than 50 DEG C below zero, meanwhile, naphtha acquired is high-quality raw material used for producing ethylene by steam cracking.

Owner:SYNFUELS CHINA TECH CO LTD

Hydrocarbon oil catalytic cracking method

ActiveCN102816589AFlexible product planHigh yieldTreatment with plural serial stages onlyHydrocarbon from oxygen organic compoundsGlobal wind patternsEnergy recovery

A hydrocarbon oil catalytic cracking method includes: hydrocarbon oil cracking raw materials and catalyst regenerant lifted by steam and entering a riser reactor are contacted for the cracking reaction, the mixture of catalysts and cracking reaction oil gas obtained at an outlet of a riser enters a settler for separation, the separated cracking reaction oil gas ascends to enter a subsequent product separation system through an oil gas pipeline on the top of the settler, the separated carbon deposit catalysts descend to enter a steam stripping section and then enter a regenerator through a spent catalyst circulation line to react with prevailing wind to be burnt, the obtained regenerated fume enters a fume energy recovery system through a fume pipe on the top of the regenerator, and the obtained catalyst regenerant returns to the riser reactor through a regenerant circulation line and lifted by steam to react with the hydrocarbon oil cracking raw materials. The hydrocarbon oil catalytic cracking method is characterized by further including steps of preheating oxygenated compound materials to directly enter the steam stripping section, or mixing all or part of oxygenated compound materials with stripping steam to enter the steam stripping section, and contacting with the carbon deposit catalysts falling into the steam stripping section to perform an oxygenated compound conversion reaction, wherein reaction oil gas generated in the conversion reaction ascends to be mixed with the cracking reaction oil gas to enter an oil gas pipeline on the top of the settler.

Owner:CHINA PETROLEUM & CHEM CORP +1

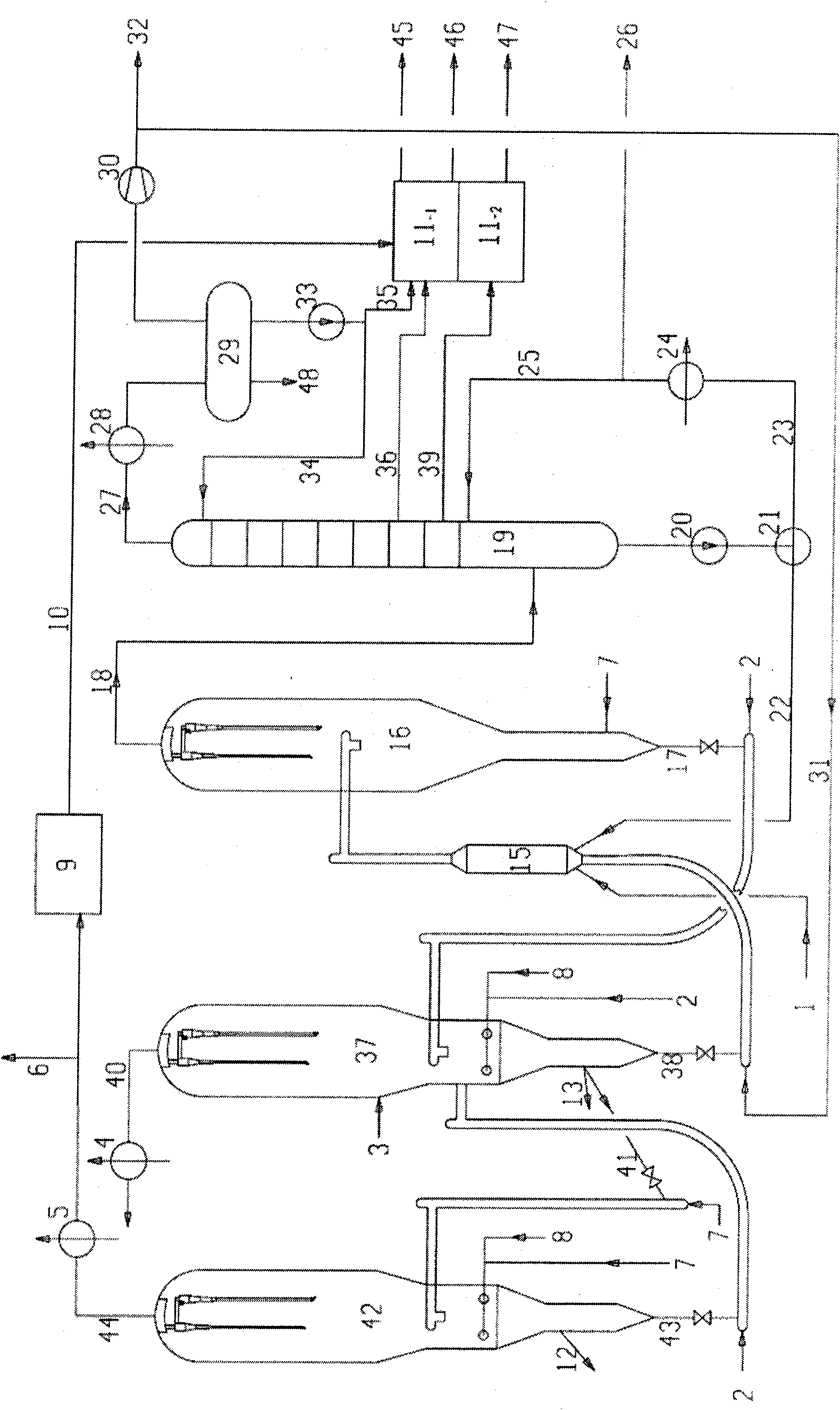

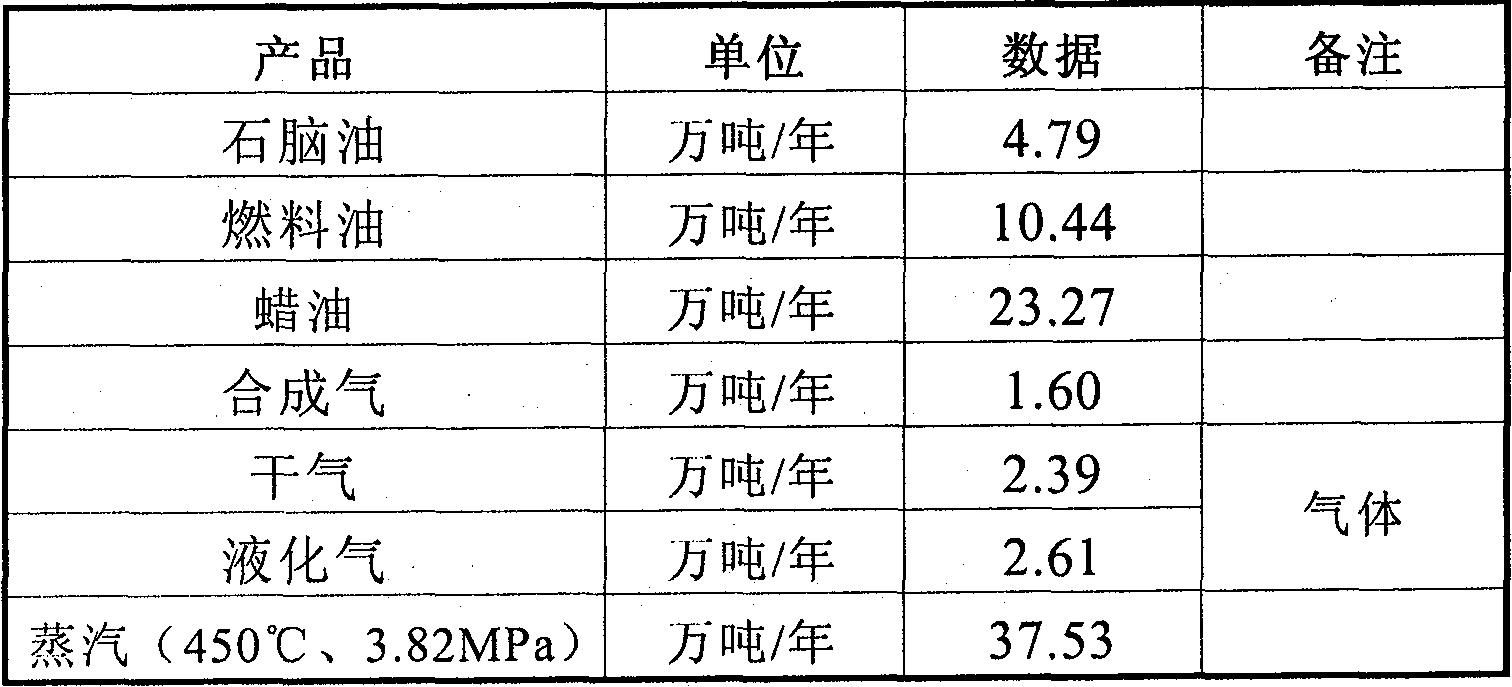

Comprehensive processing and utilizing method for heavy oil

InactiveCN102031135AAchieve rapid lysisImprove light oil yieldThermal non-catalytic crackingHydrogen separationSyngasFuel oil

The invention belongs to the field of petroleum processing and utilization, and relates to a comprehensive processing and utilizing method for heavy oil. By integrating quick cracking of the heavy oil, pre-combustion and gasification of the generated coke, recycling of non-converted heavy oil, hydrogen production by synthetic gas generated through gasification, and a hydrofining process for cracked oil products, light oil can be prepared from the heavy oil to the greatest degree, the light oil is hydrogenated to form high-quality clean oil products, and also can generate the synthetic gas through gasification, and the synthetic gas can serve as a hydrogen production raw material to provide a cheap hydrogen source for oil product hydrofining, and also can serve as fuel gas to provide clean fuel for a refinery. The invention provides a low-cost comprehensive processing and utilizing method for converting the heavy oil into clean light oil products to the greatest degree.

Owner:WISON ENG

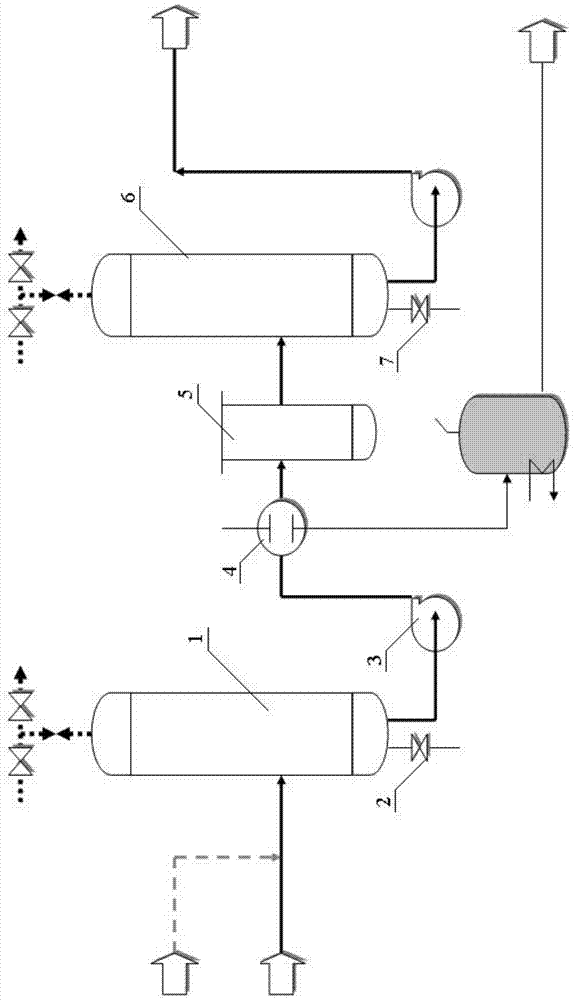

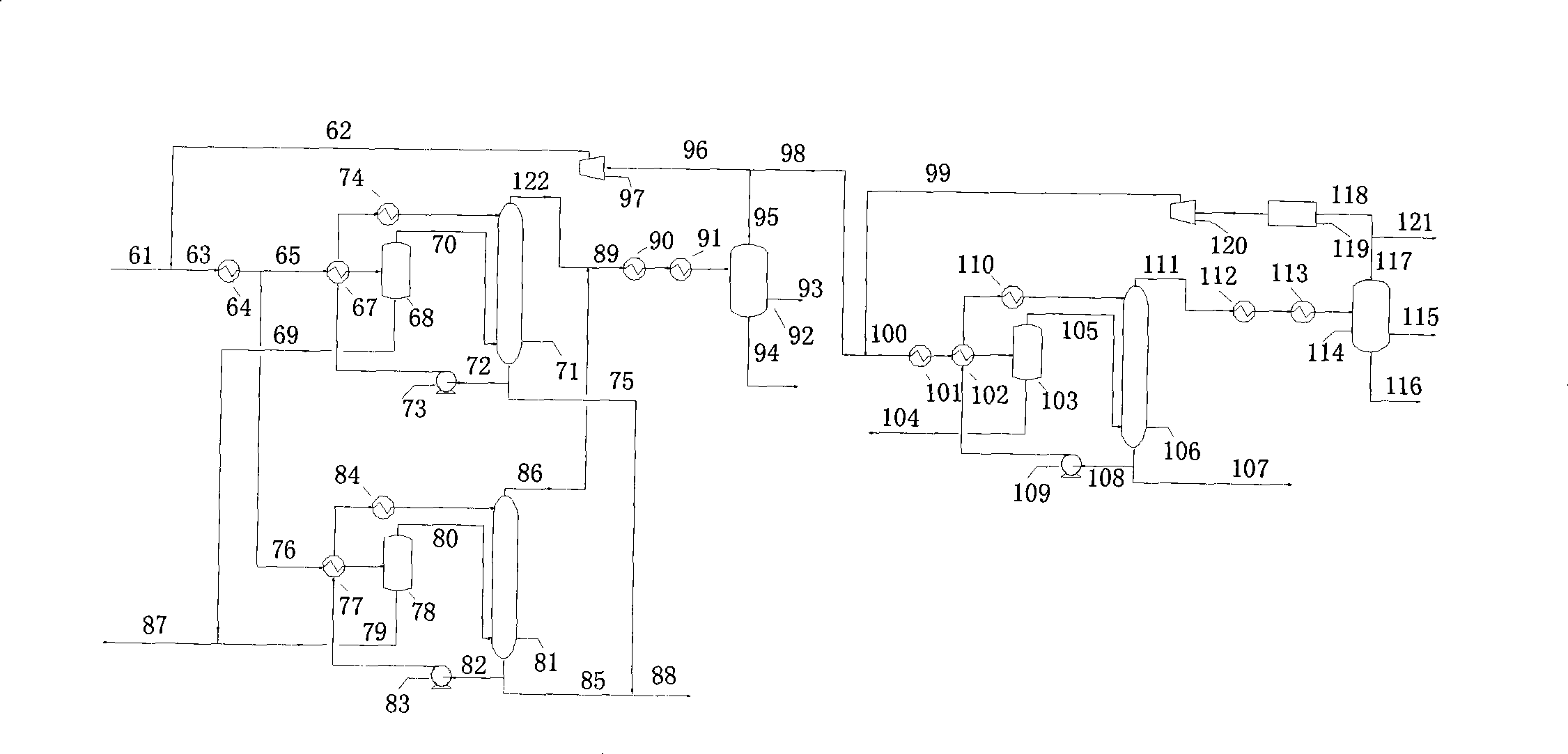

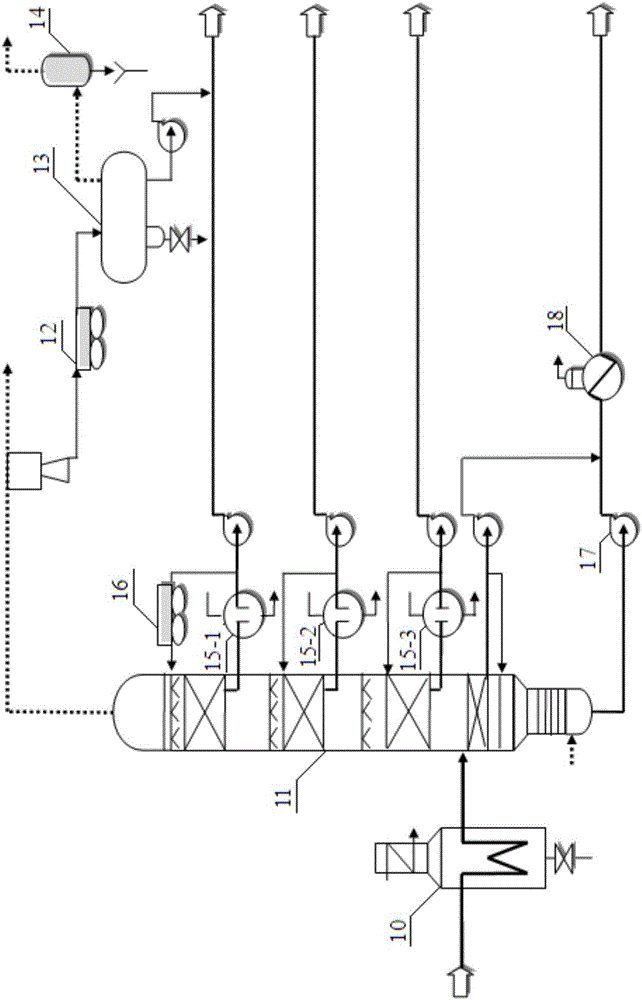

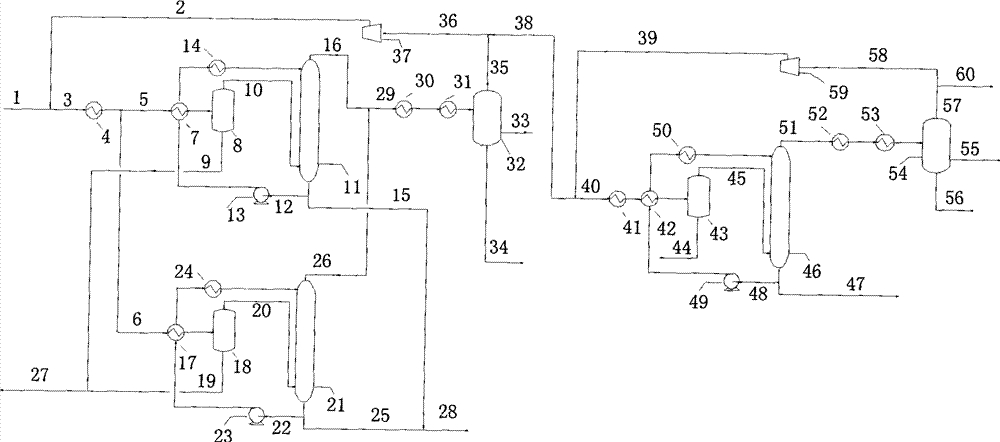

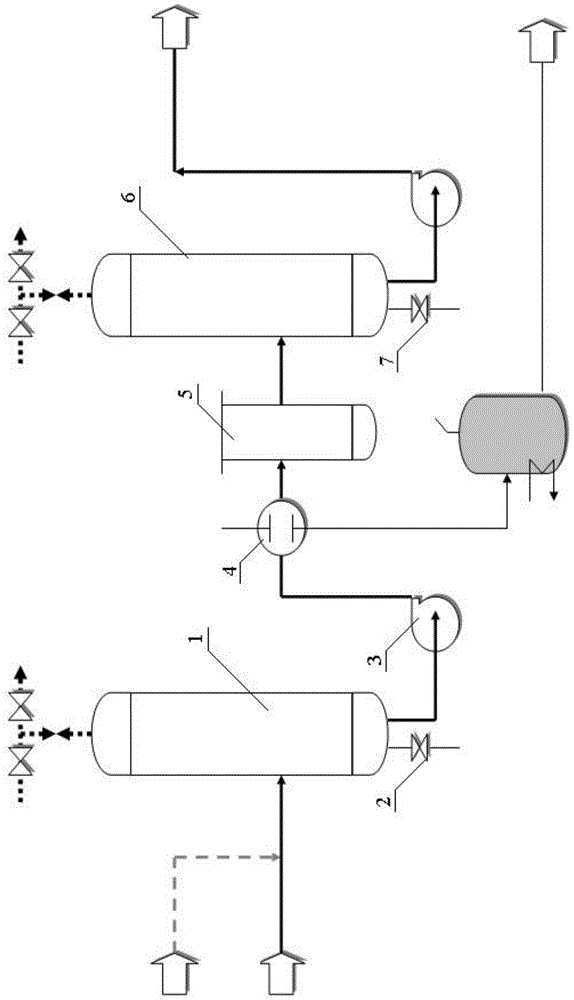

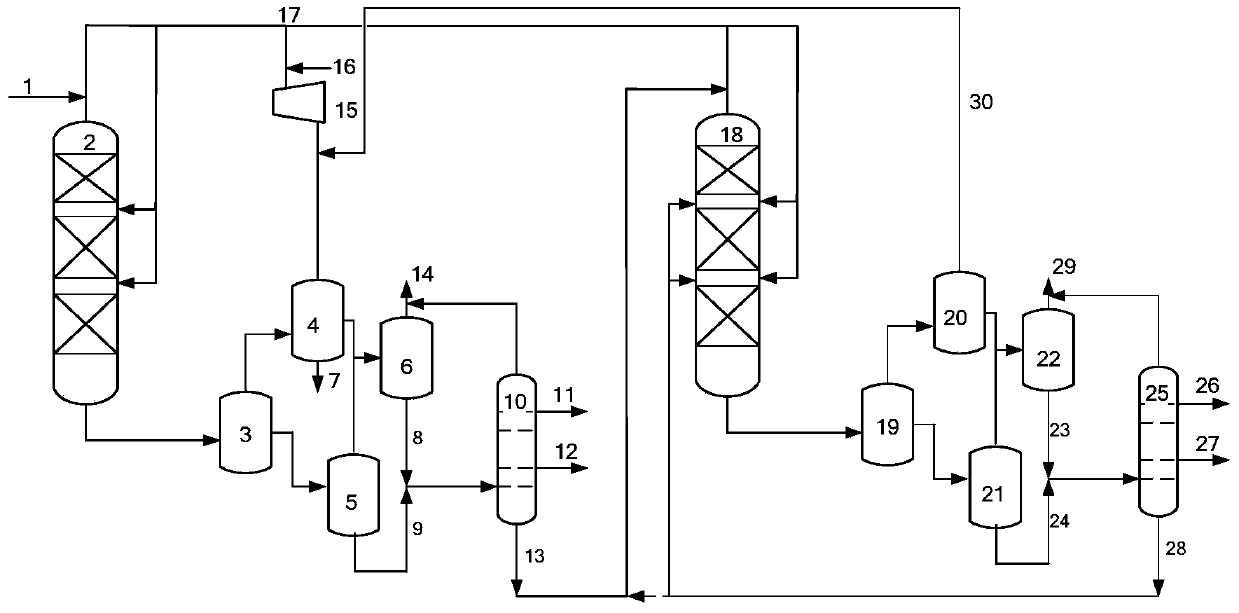

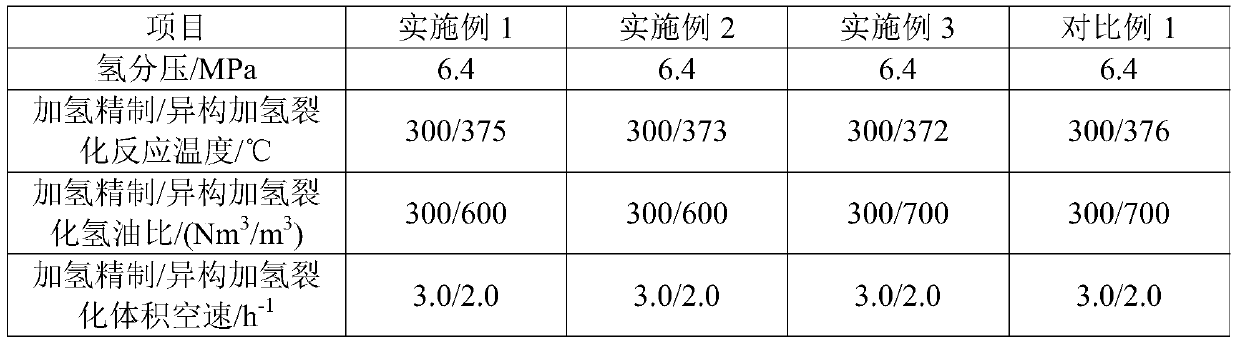

Method of producing low-sulfur low freezing point diesel by full-range shale oil

ActiveCN103497782AHigh yieldFlexible product planTreatment with hydrotreatment processesNaphthaOperational costs

The invention relates to a method of producing low-sulfur low freezing point diesel by full-range shale oil, relates to a production method of low-sulfur low freezing point diesel and solves the technical problems that the existing method of producing diesel by shale oil is complex in process and high in investment and operational cost. A material pre-fractionation unit, a reaction unit and a fraction unit are adopted in the method. The method has the advantages that finished diesel yield is high during processing of the full-range shale oil; the quality of the low-sulfur low freezing point diesel meets the national standard IV; a product scheme is flexible, the production of refined diesel and the production of the low-sulfur low freezing point diesel are both considered, and product distribution is adjusted; during the processing of the full-range shale oil, the material pre-fractionation unit is additionally provided with an absorbing column and a flash tank, lightweight shale oil is used as absorbent, LPG components in noncondensable gas can be recycled, applying a product stabilization column to the product fractionation unit to separate LPG and naphtha is avoided, and cost reduction and efficiency increasing are achieved. The invention belongs to the field of diesel production.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE

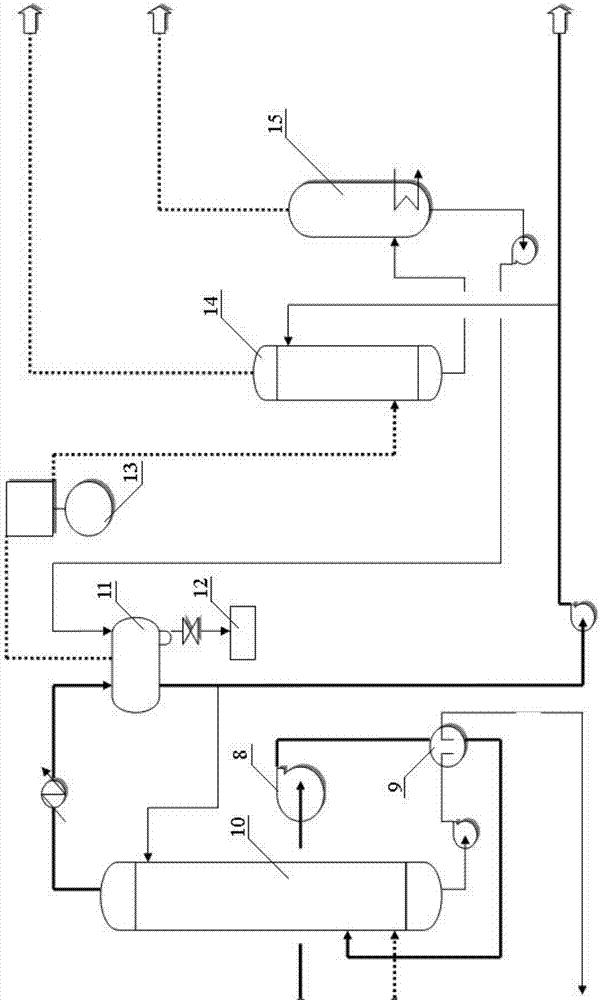

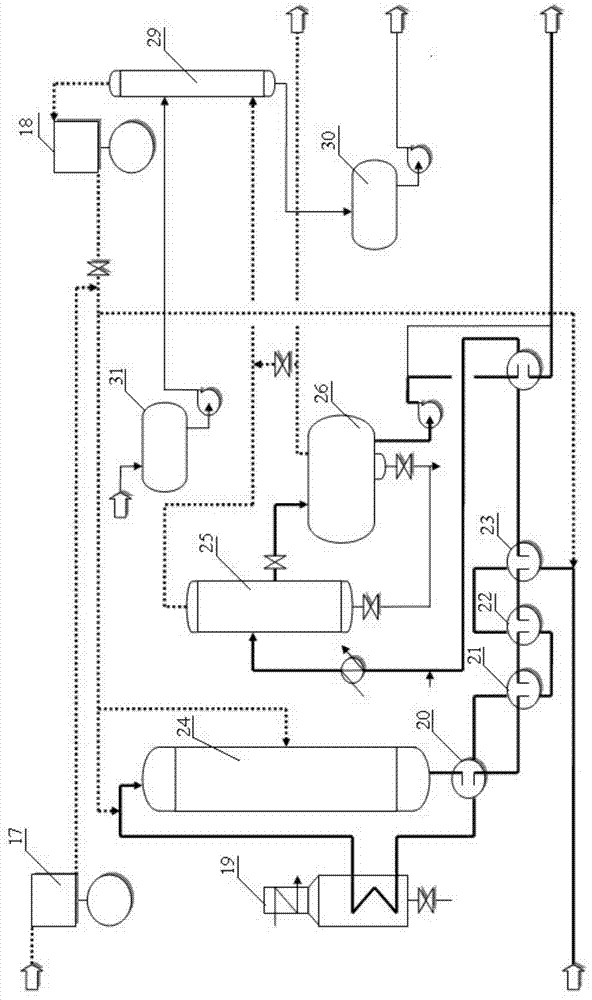

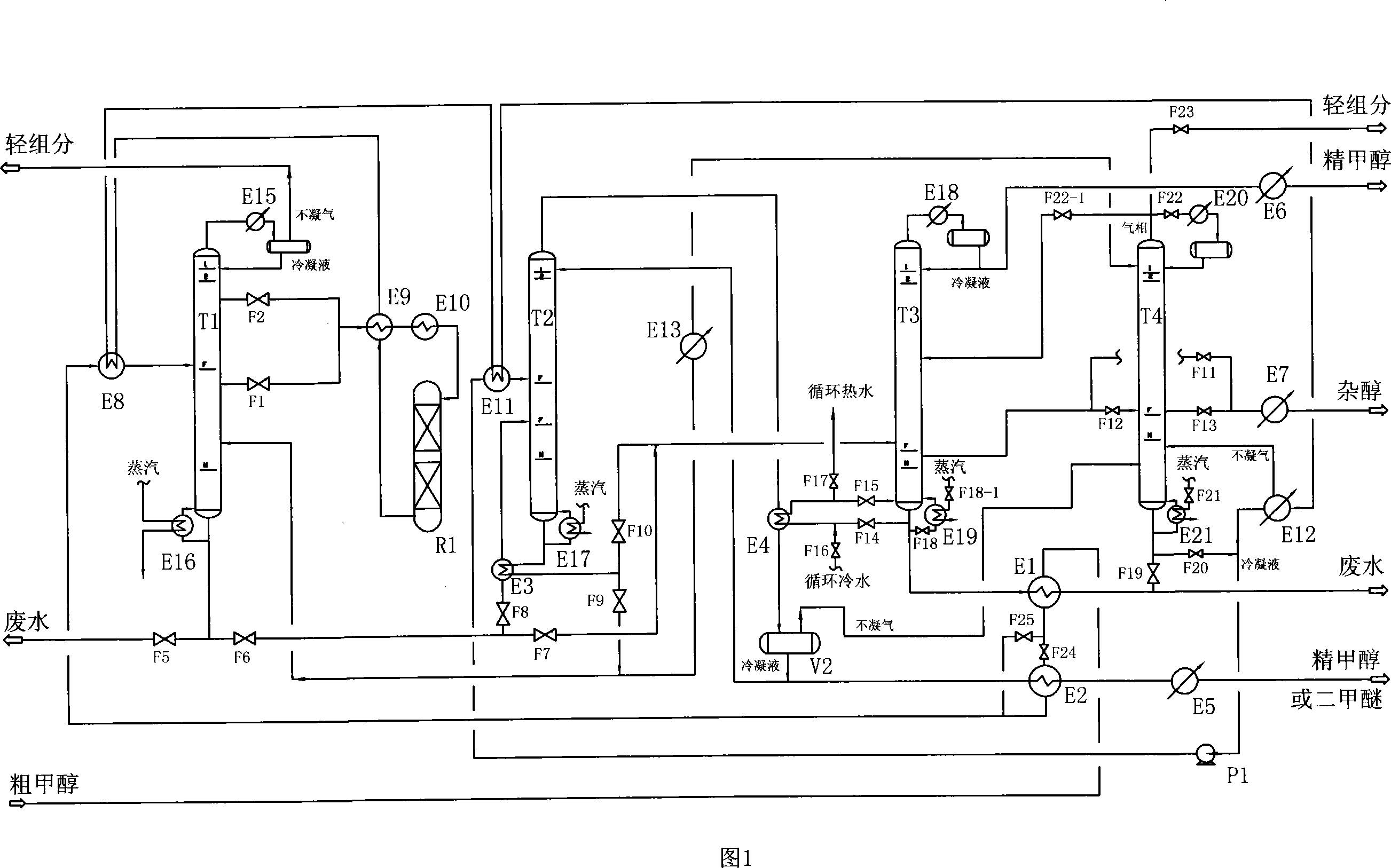

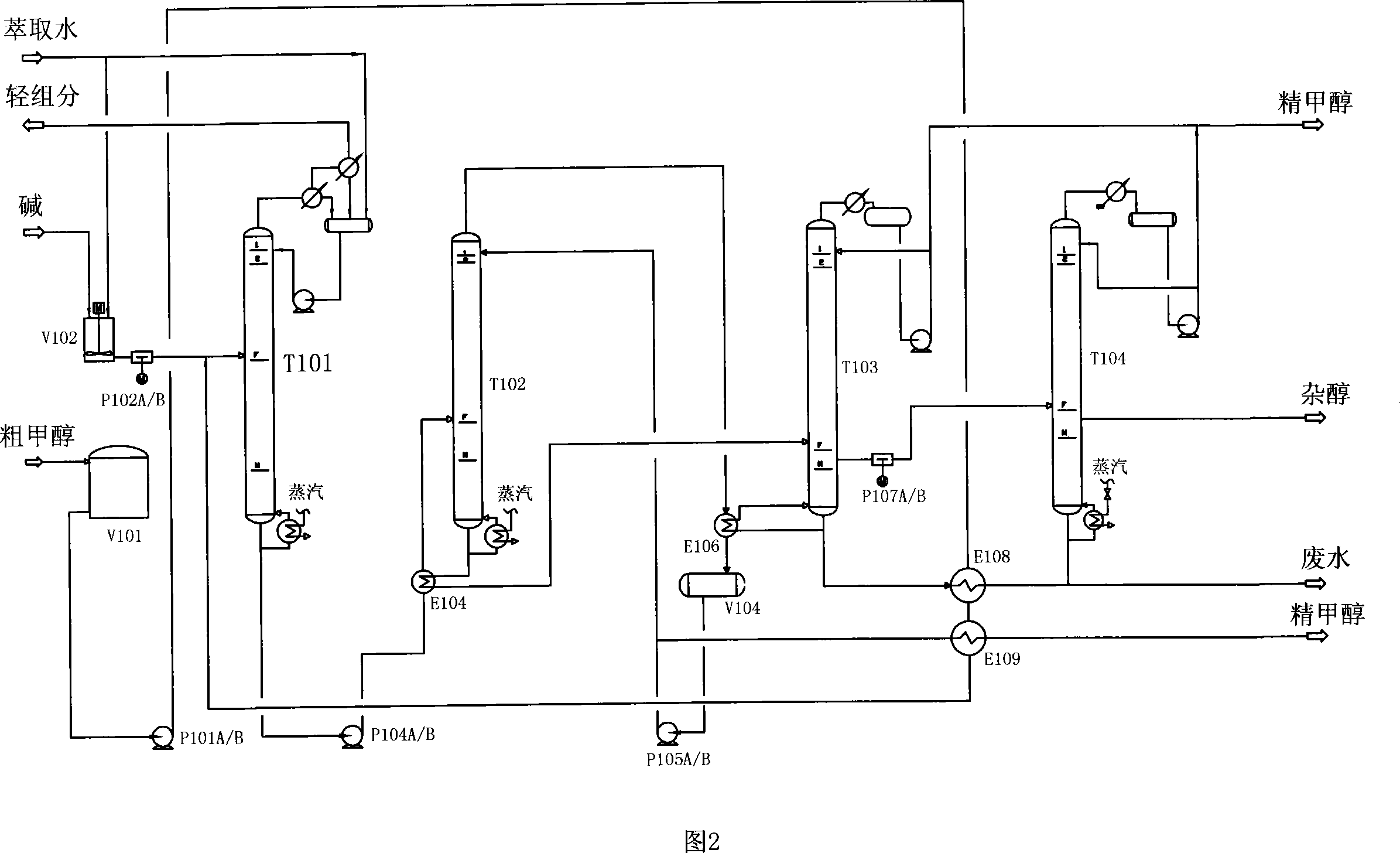

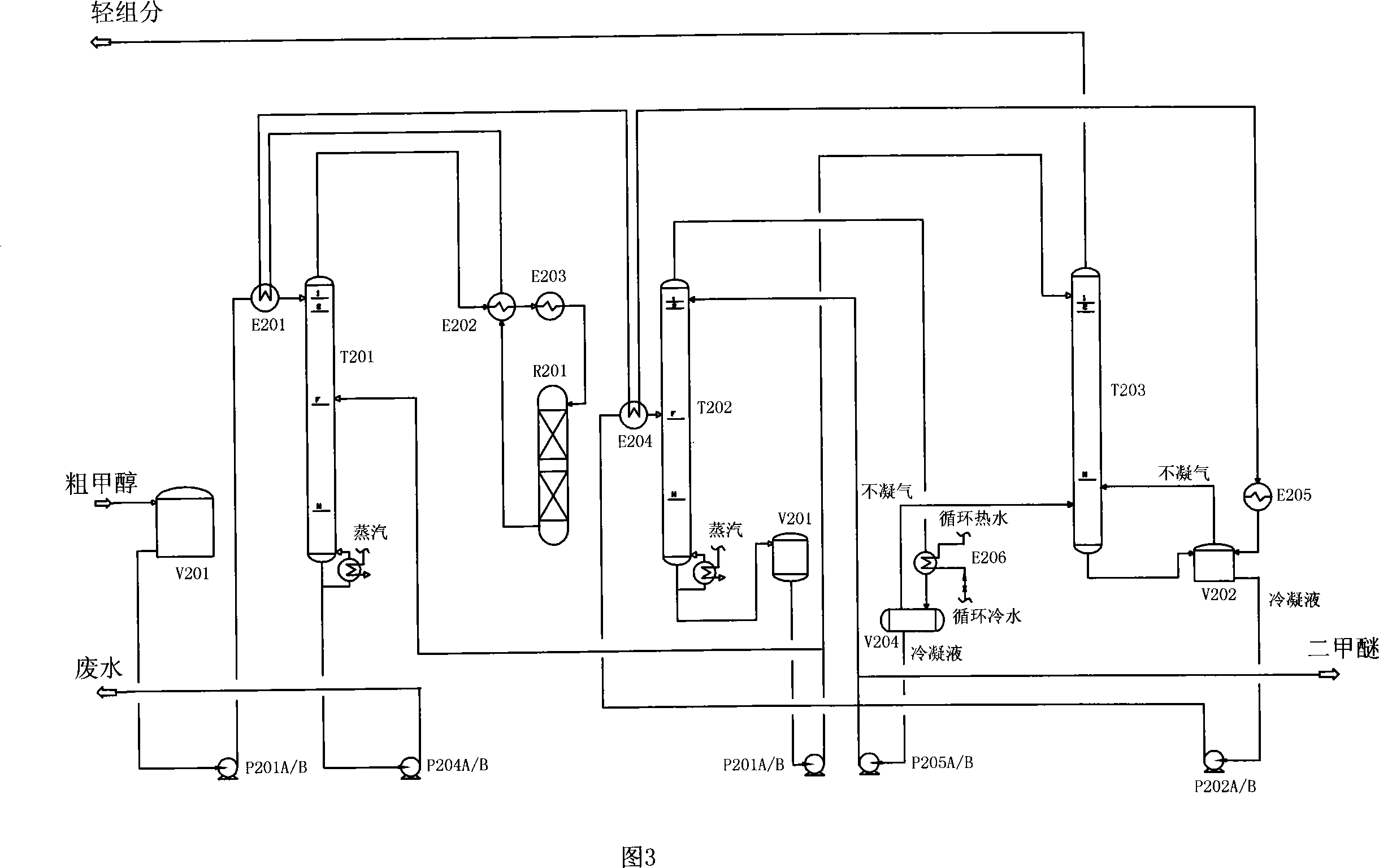

Device and method for co-production or single production of refined methanol with rough methanol

InactiveCN101172934ASave investmentSave energyOrganic compound preparationDistillation in boilers/stillsDistillationCogeneration

The invention relates to a production device and method for co-production of crude methanol or single production of refined methanol and / or dimethyl ether. It includes a reactor and four towers. The present invention organically combines the methanol rectification device and the dimethyl ether device, and all the rectification towers of dimethyl ether are shared with the methanol rectification tower, which can realize the co-production of refined methanol and dimethyl ether or the single production of refined methanol or dimethyl ether The operation of the three technical processes of methyl ether saves investment and energy, reduces production costs, makes the best use of everything, and improves the utilization rate of the device. Moreover, when co-producing or producing dimethyl ether alone, the crude methanol raw material passes through the first tower to remove light components, which reduces the load on the reactor, the reaction product is easy to separate, and the quality of the dimethyl ether product is high; The methanol vapor returns directly to the three towers without condensation, and the separation capacity of the three towers is used to obtain refined methanol, which saves investment and reduces energy consumption.

Owner:褚雅志

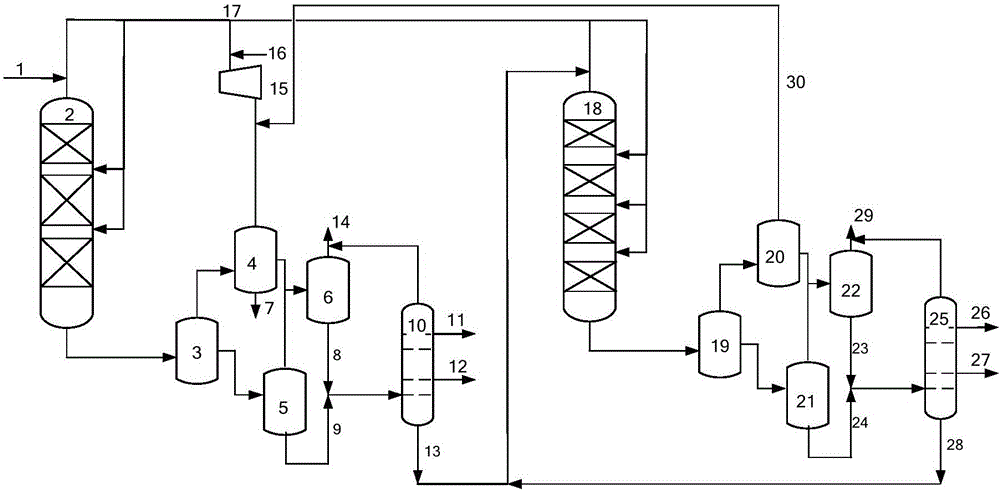

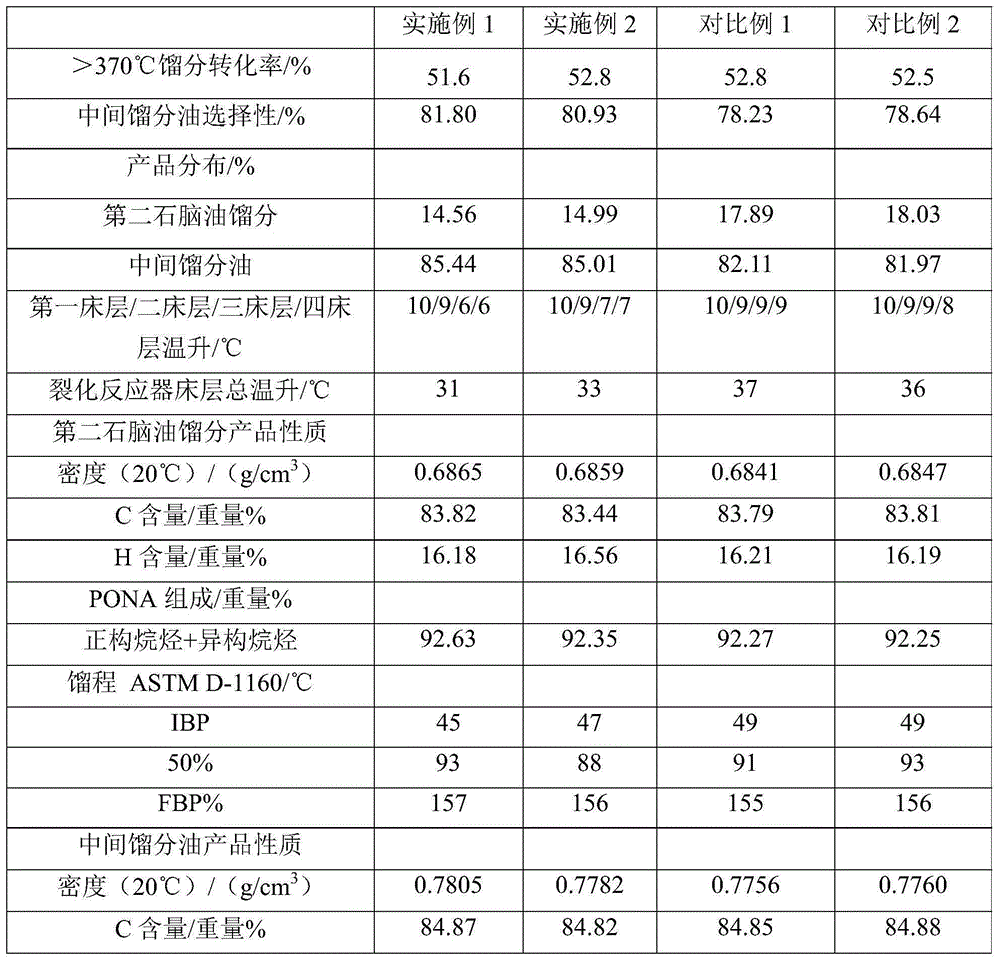

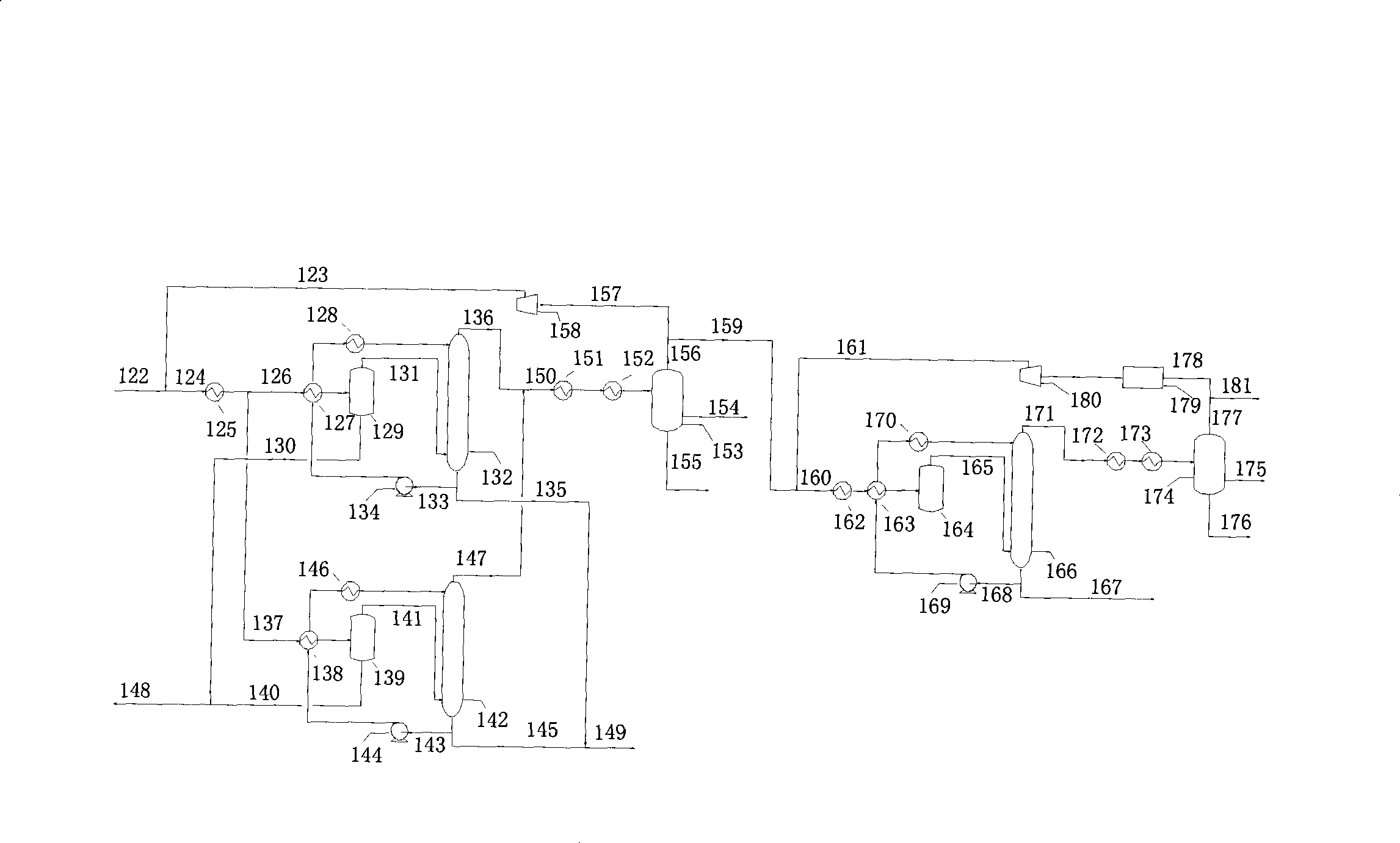

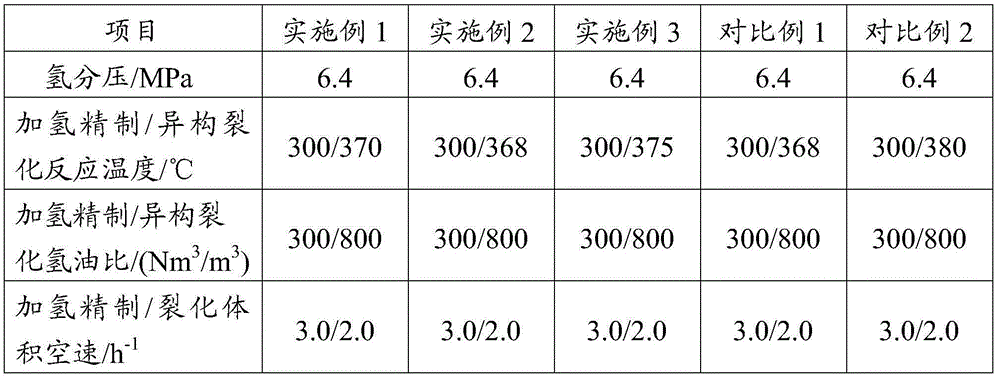

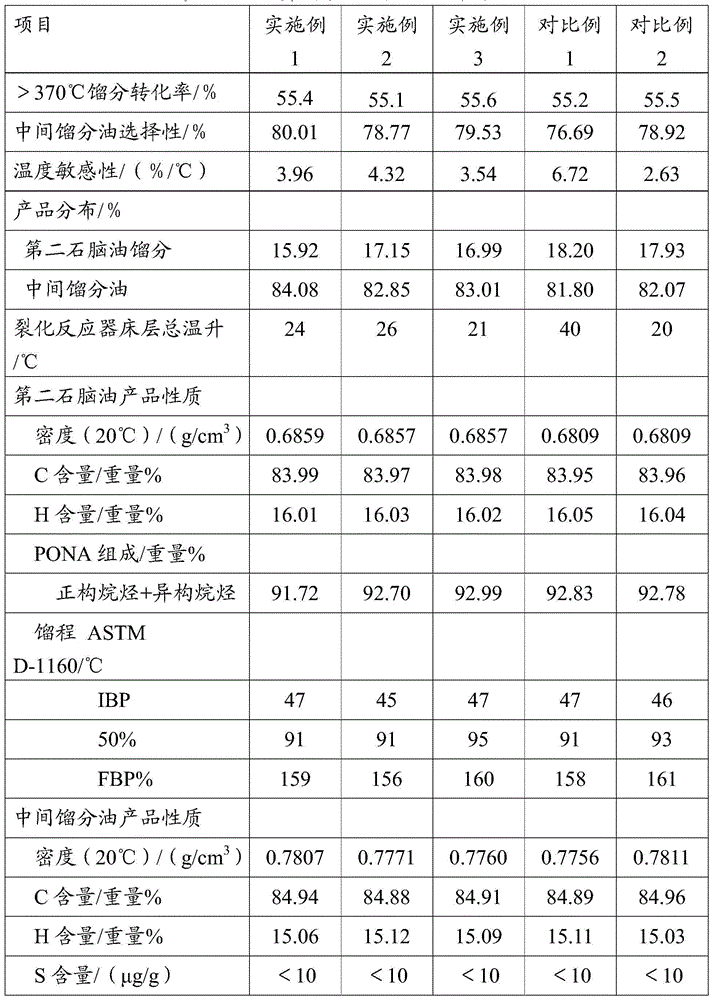

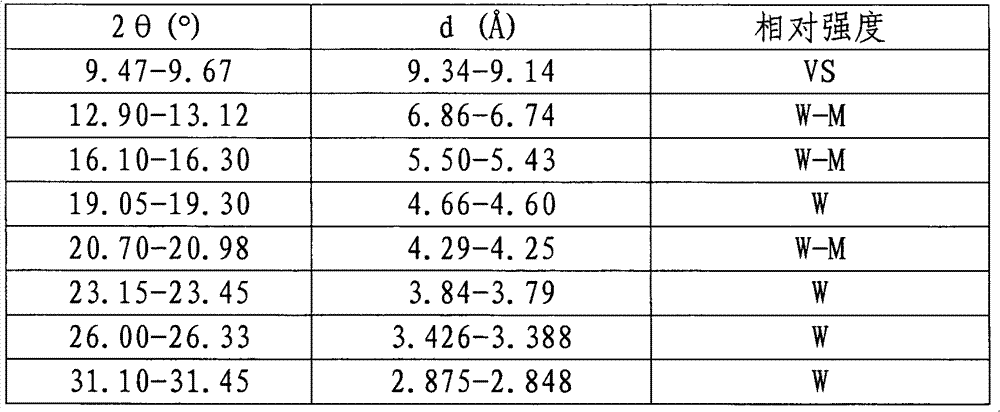

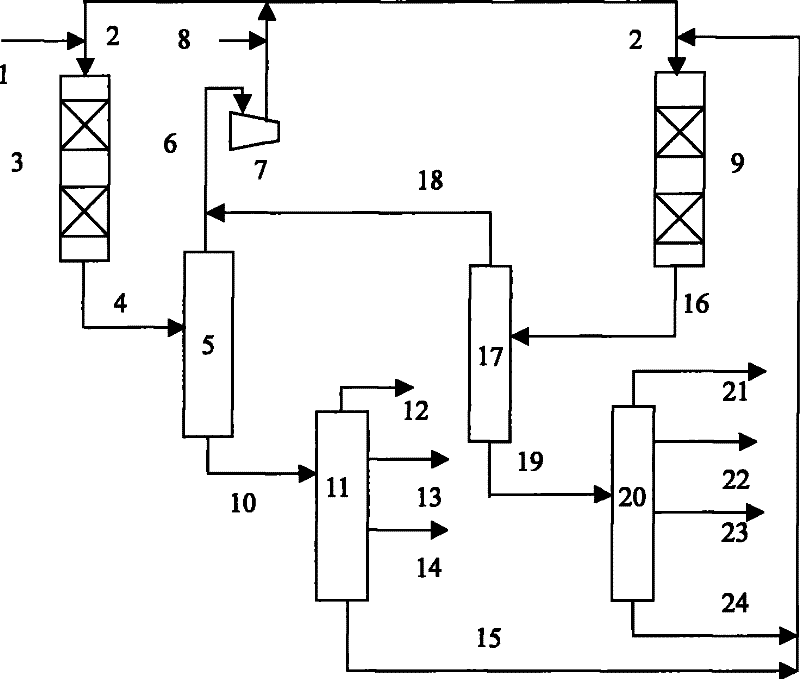

Method for producing middle distillate oil from Fischer-Tropsch synthetic oil

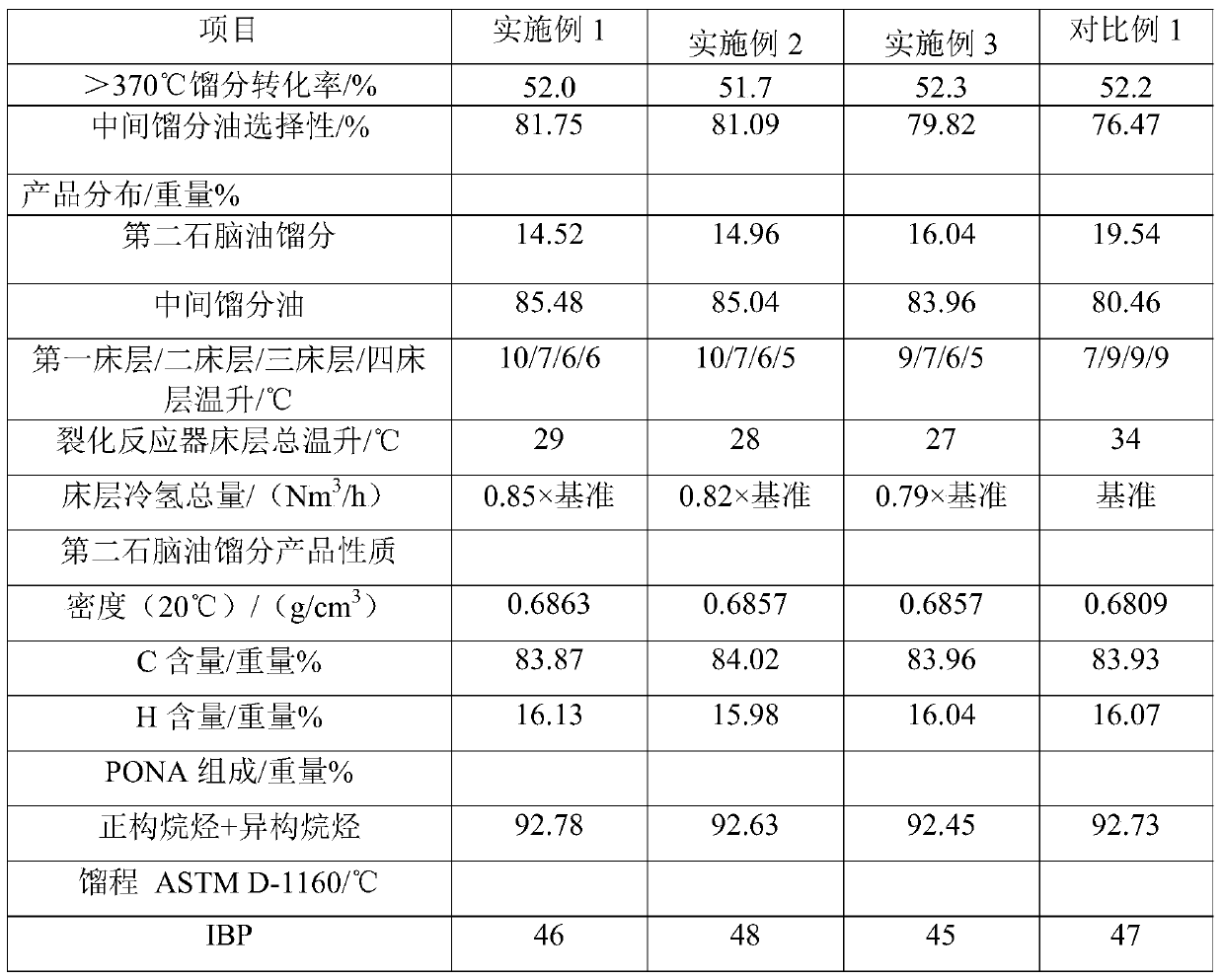

The invention relates to the field of oil refining and discloses a method for producing middle distillate oil from Fischer-Tropsch synthetic oil. The method comprises the following steps: introducing the Fischer-Tropsch synthetic oil and a hydrogen-containing stream into a hydrofining reactor for reaction; sequentially separating and fractionating hydrofining reaction effluents to obtain a first naphtha fraction, a light diesel oil fraction and a heavy oil fraction; introducing the heavy oil fraction into a heterogeneous hydrocracking reactor for reaction; then sequentially separating and fractionating heterogeneous hydrocracking reaction effluents, wherein at least two reaction regions are arranged in the heterogeneous hydrocracking reactor; cracking activities of heterogeneous hydrocracking catalysts per unit volume in two adjacent reaction regions are sequentially reduced in a flow direction of the reaction stream. With adoption of the method provided by the invention, the selectivity and yield of the middle distillate oil can be improved when the middle distillate oil is produced through hydrogenation and quality increasing of the Fischer-Tropsch synthetic oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

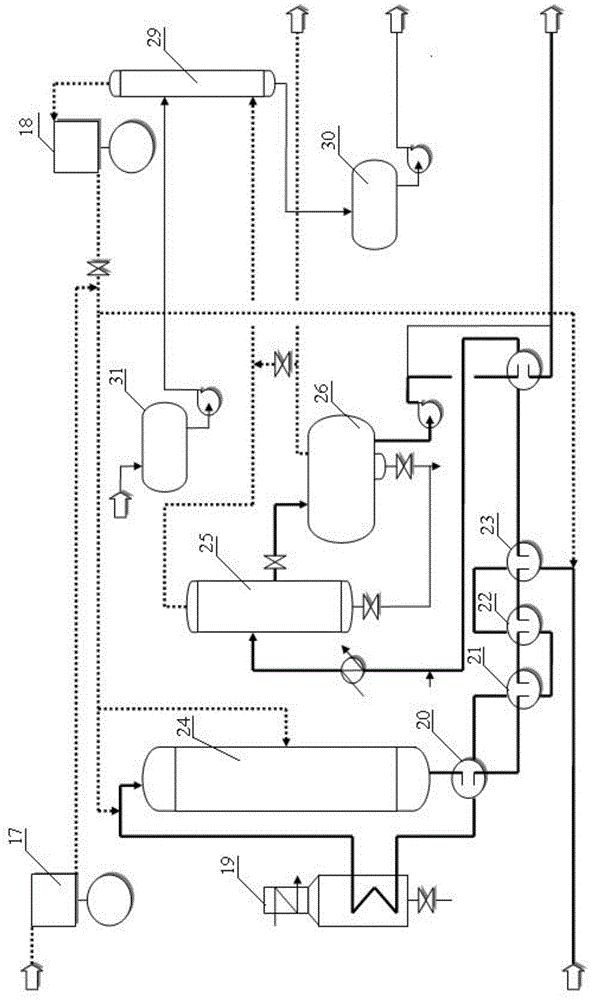

Method for preparing aromatic hydrocarbon by methyl alcohol

ActiveCN107778122AFlexible product planAvoid accumulationHydrocarbon purification/separationHydrocarbon from oxygen organic compoundsGas separationOil phase

The invention relates to a method for preparing aromatic hydrocarbon by methyl alcohol, and mainly solves the problems of ethane accumulation and low aromatic hydrocarbon yield in a system for preparing the aromatic hydrocarbon by the methyl alcohol in the prior art. The method for preparing the aromatic hydrocarbon by the methyl alcohol comprises the following steps: 1) providing methyl alcohol raw material logistics, light hydrocarbon cycle logistics, C5 cycle logistics and methyl alcohol cycle logistics; 2) after the above four types of logics are mixed, obtaining reaction feedstock; 3) sending the reaction feedstock into an aromatization reactor to be in contact with a ZSM-5 molecular sieve catalyst to obtain a reaction product; 4) cooling and separating the cooling product to obtain agaseous phase, an oil phase and an aqueous phase; 5) separating the gaseous phase into hydrogen, fuel gas, ethylene and light hydrocarbon cycle logistics through a gas separation unit; 6) separatingthe oil phase into the C5 cycle logistics and an aromatic hydrocarbon product; 7) separating the aqueous phase into the methyl alcohol cycle logistics and wastewater through a methyl alcohol recoveryunit. According to the technical scheme, the above problem is favorably solved, and the method can be used for the industrial production of the preparation of the aromatic hydrocarbon by the methyl alcohol.

Owner:CHINA PETROLEUM & CHEM CORP +1

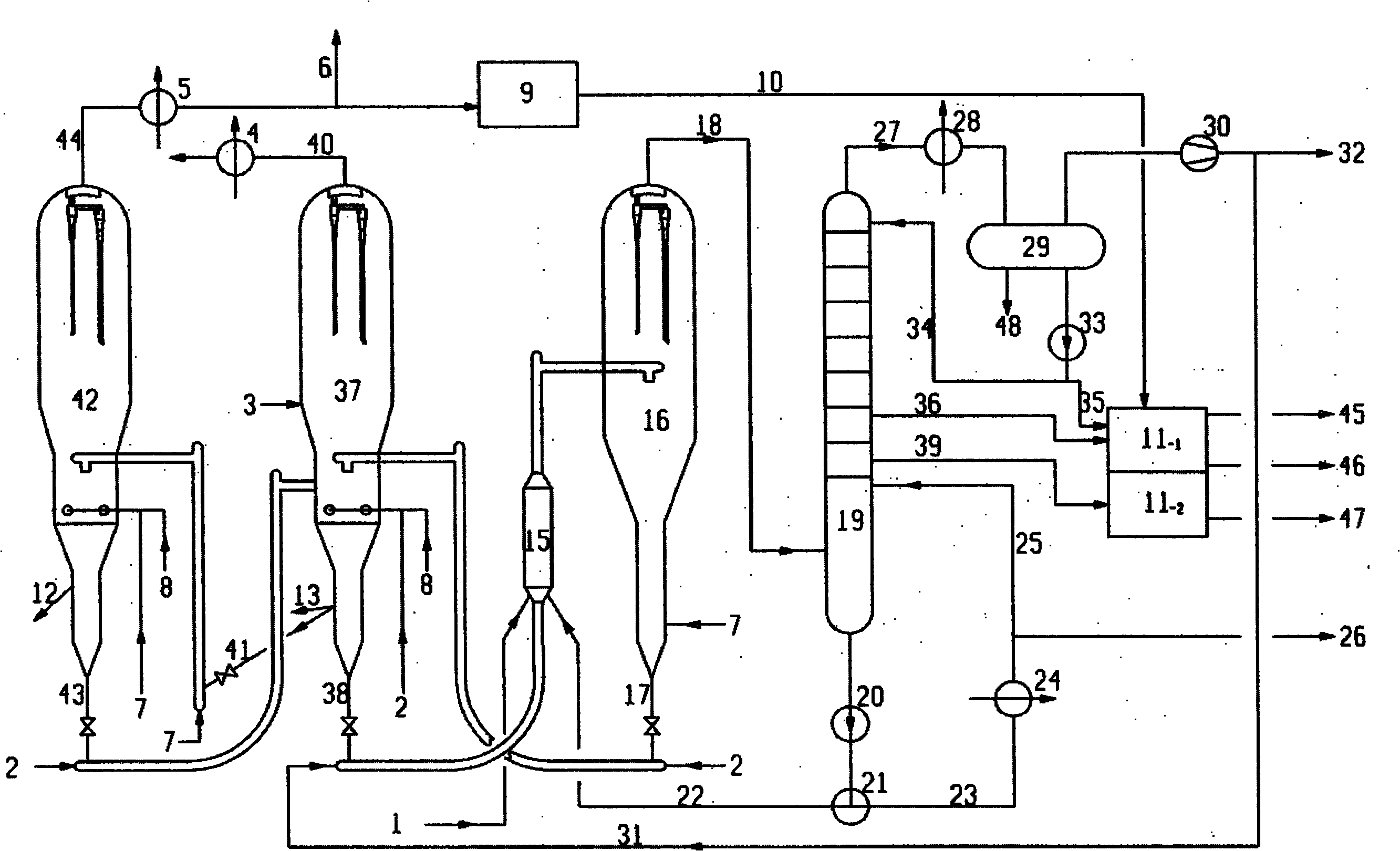

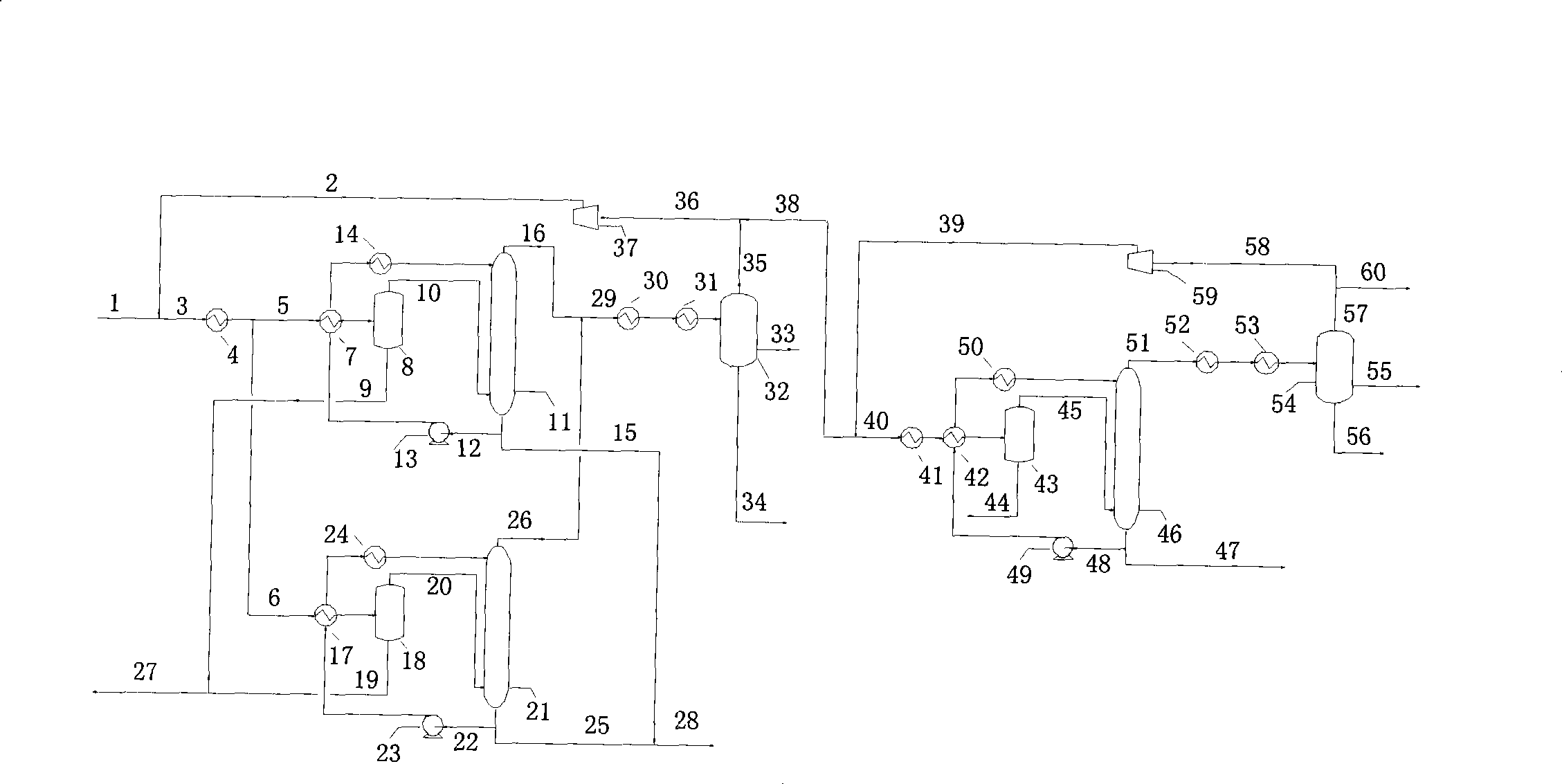

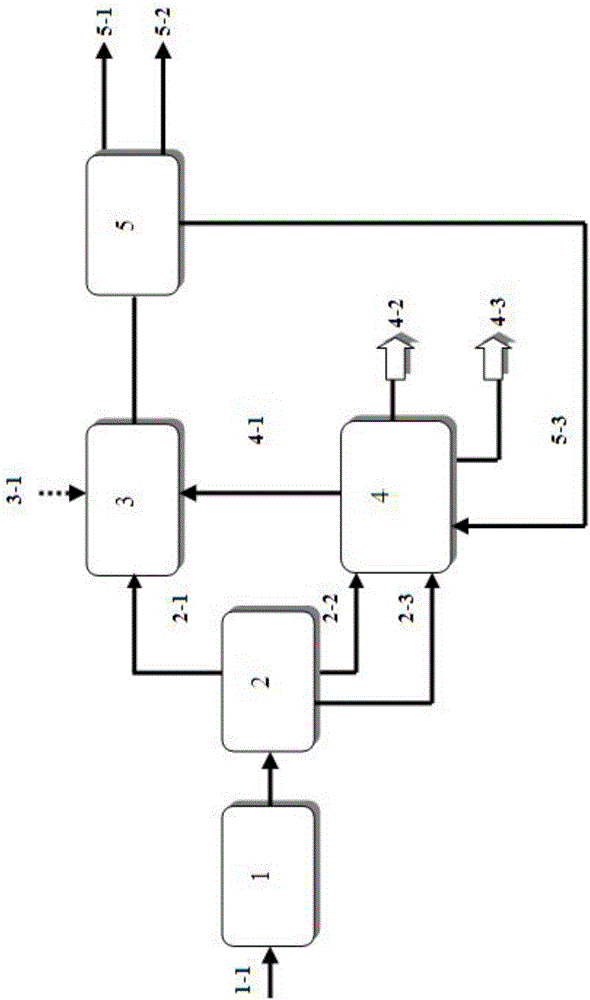

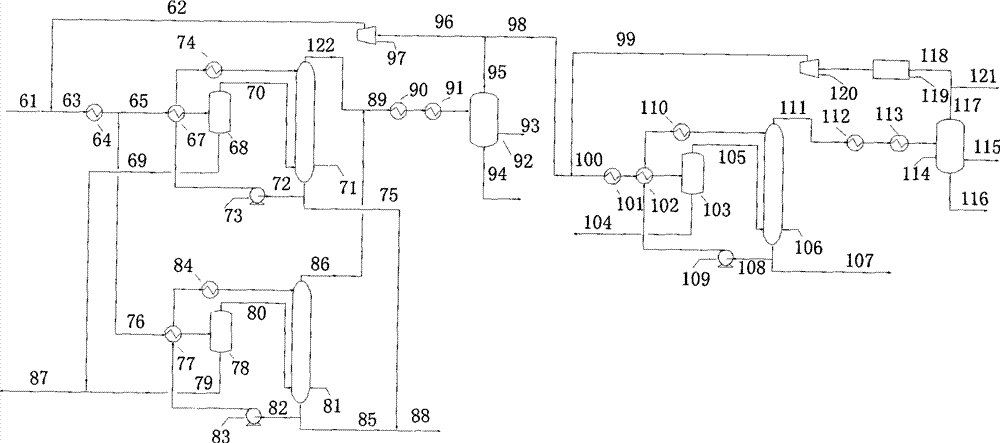

Technique for producing oil products by fischer-tropsch synthesis

ActiveCN101381616AFlexible product planReduce the numberLiquid hydrocarbon mixture recoveryExhaust gasChemistry

The invention relates to a technological method for preparing oil products by the Fischer-Tropsch synthesis. In the technological method, a FT synthesis process comprises a first-stage FT synthesis process and a second-stage FT synthesis process; in particular, the technological method comprises the following steps: (1) synthesis gases are subjected to FT synthesis reaction in a first-stage synthesis reactor; (2) a part of tail gases from the first-stage synthesis reactor are circularly returned to an entrance of the first-stage synthesis reactor, and another part of the tail gases enter a second-stage synthesis reactor for the further FT synthesis reaction; (3) a part of tail gases from the second-stage synthesis reactor are circularly returned to an entrance of the second-stage synthesis reactor, and another part of the tail gases are used for reclaiming low-carbon hydrocarbons and hydrogen gases and then are used as fuel gases; and (4) by utilizing the recovered hydrogen gases, the hydrocarbon products in the first-stage synthesis reactor and the second-stage synthesis reactor and the hydrocarbon products which are obtained by separating and recovering the tail gases are subjected to hydrogenation and purification and then are fractionated to generate various oil products. Compared with prior art, the technological method has the characteristics of economy, flexibility, low cost and the like.

Owner:YANKUANG ENERGY R&D CO LTD

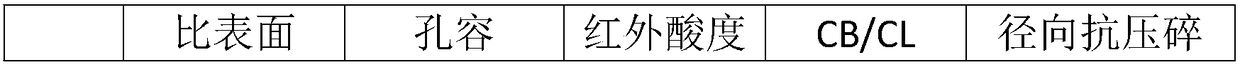

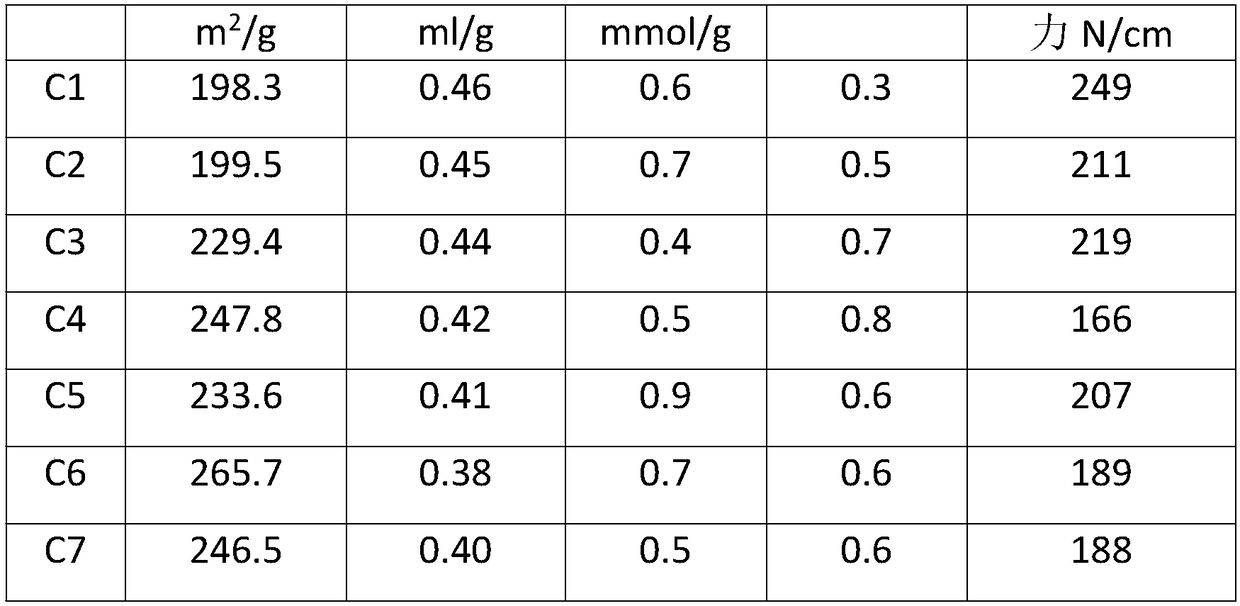

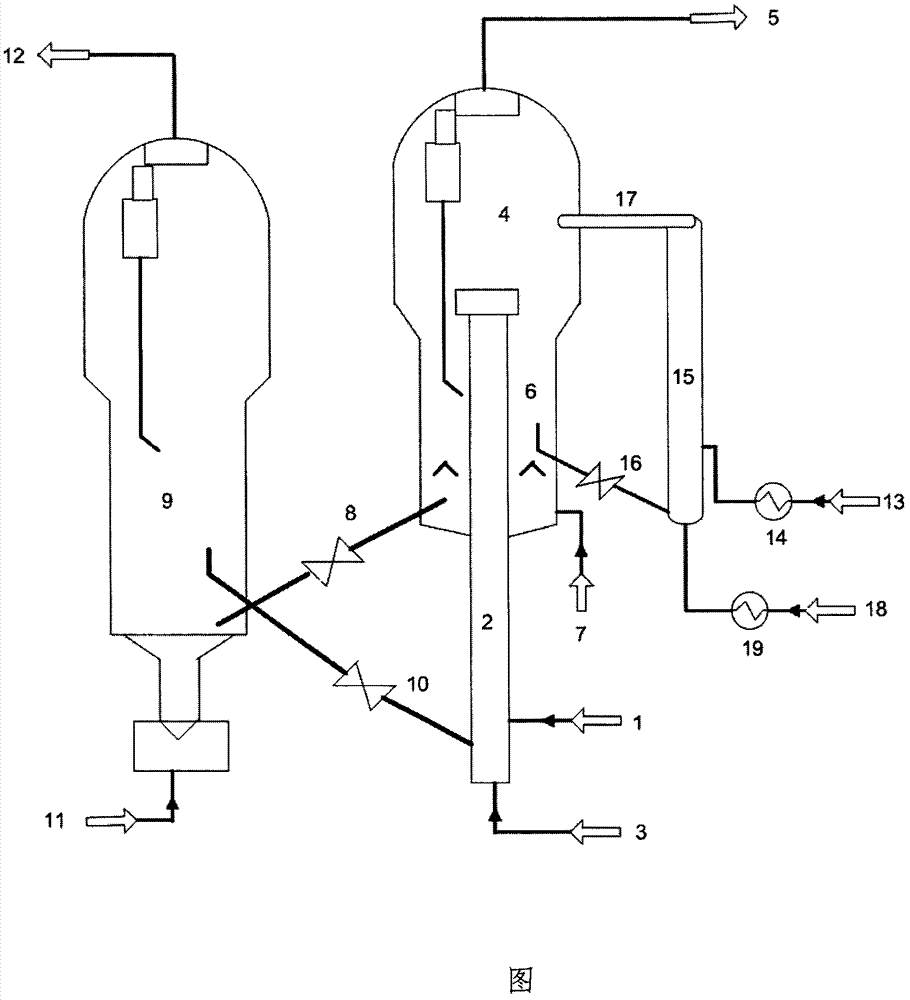

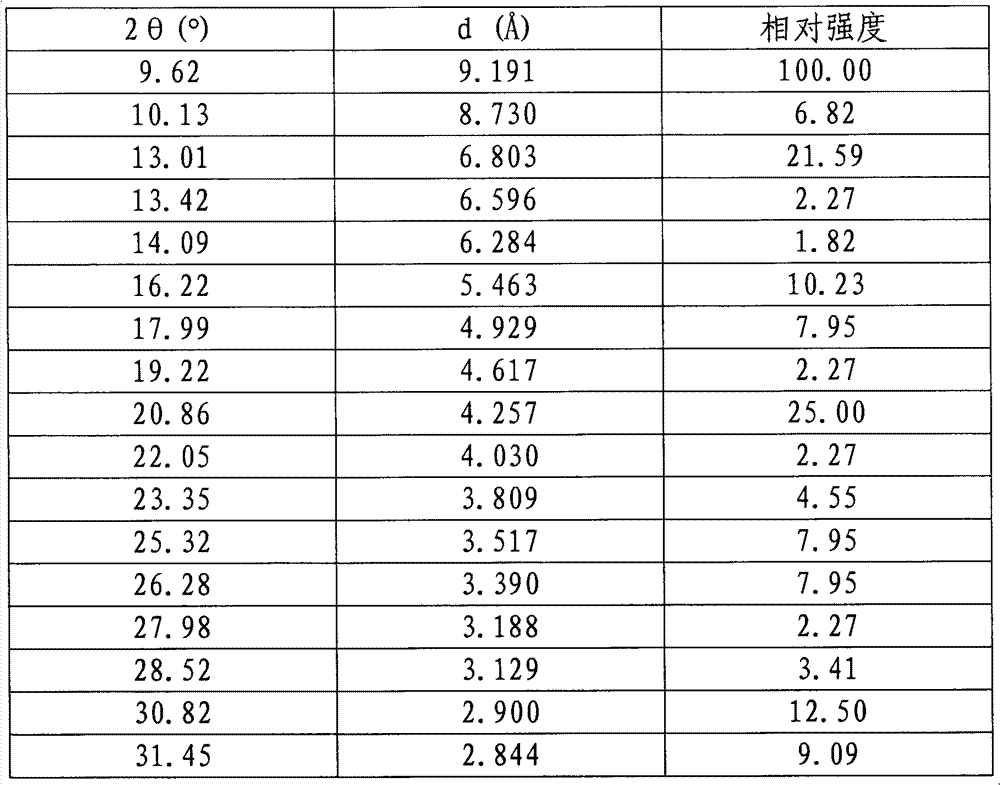

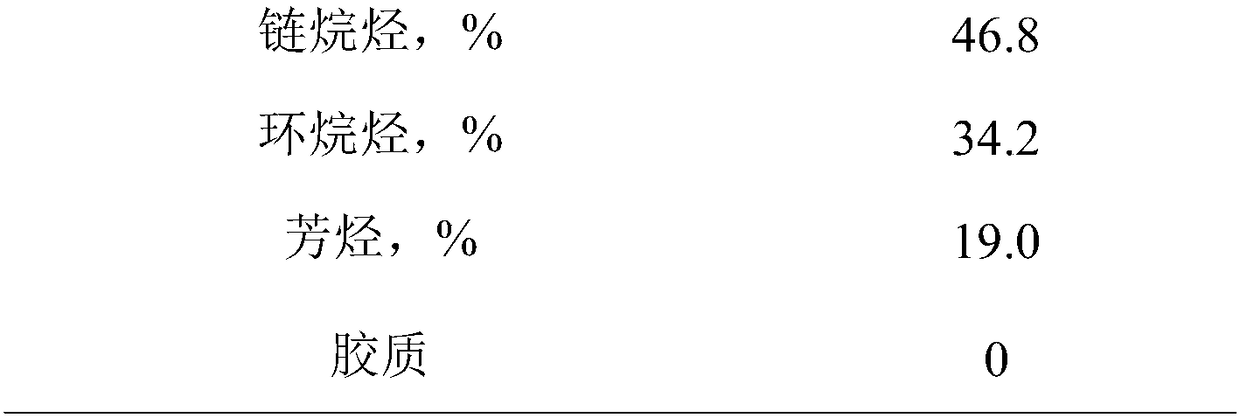

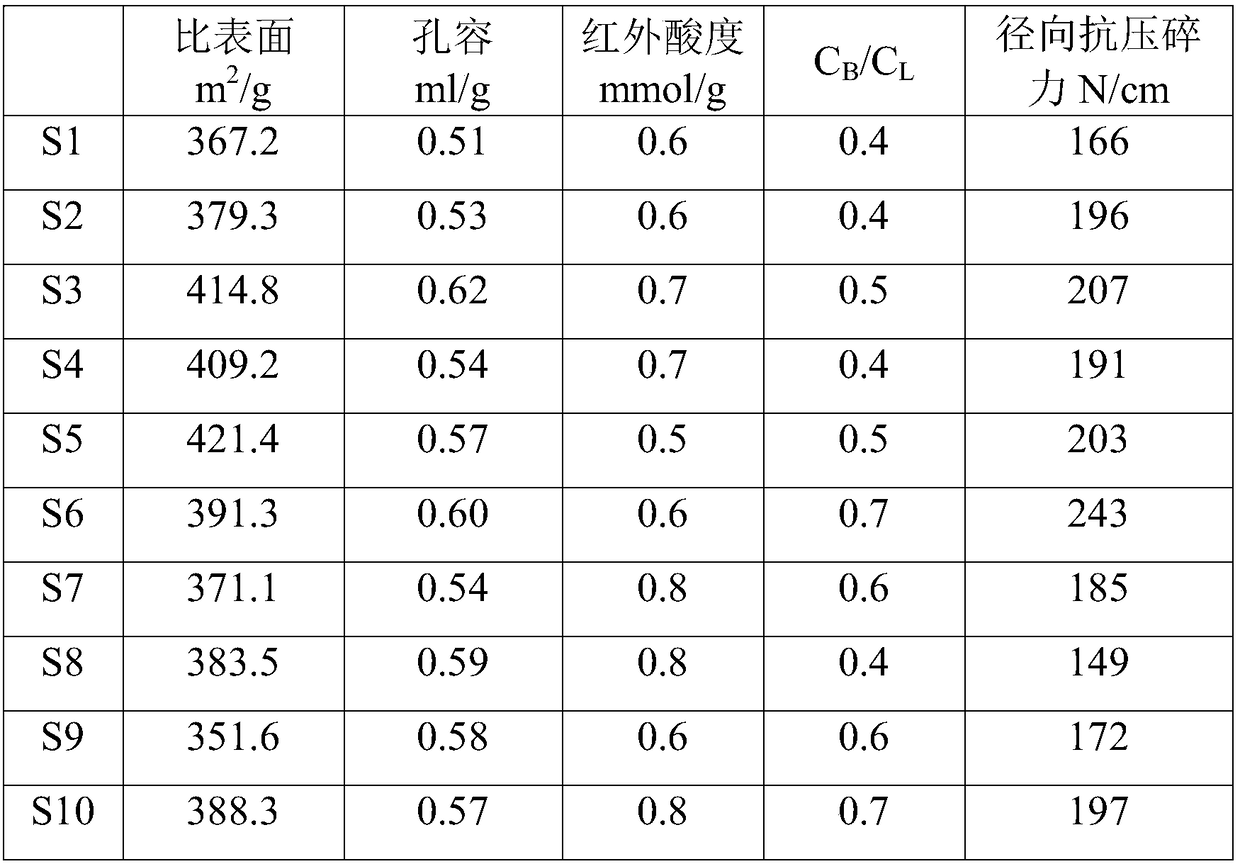

Hydrogenation catalyst and preparation method thereof

InactiveCN108262065AFlexible product planAdjustable process conditionsMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveTungsten

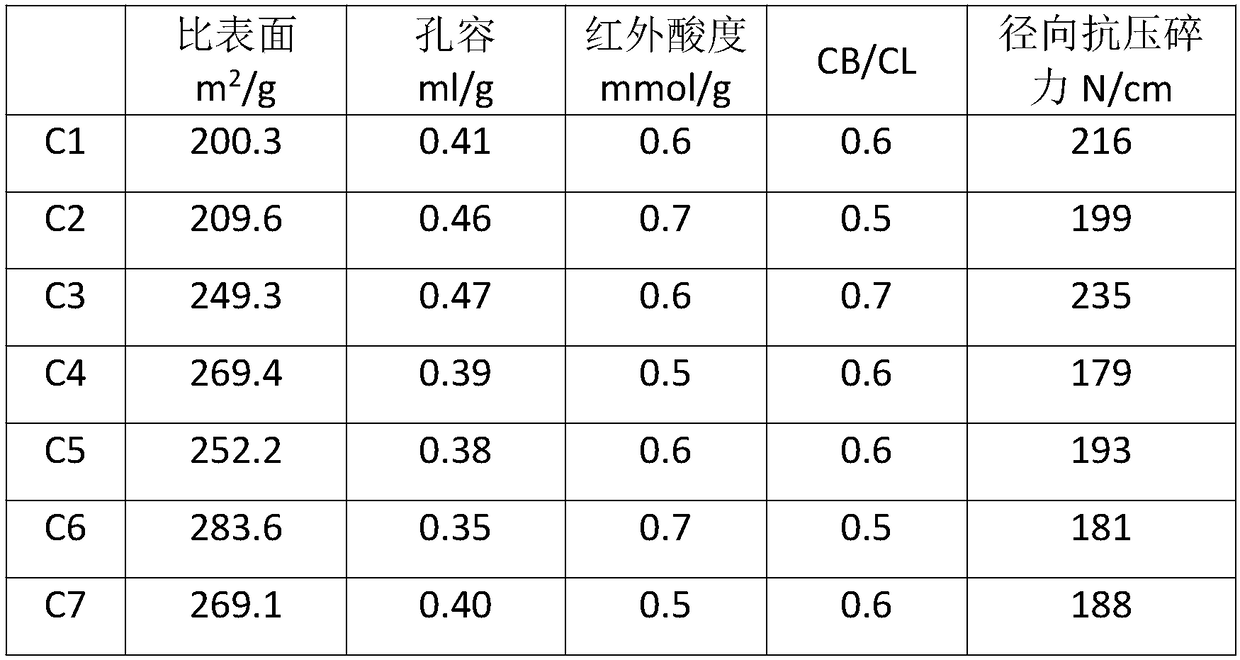

The invention relates to a hydrogenation catalyst and a preparation method thereof. The hydrogenation catalyst comprises a reactive metal and a carrier, the reactive metal comprises a VIB-group metaland a VIII-group metal, the VIB-group metal is molybdenum and / or tungsten, the VIII-group metal is cobalt and / or nickel, the carrier comprises a solid acid component and an unformed heat-resistant oxide, the solid acid component is a mixture of an MCM-22 molecular sieve and a Beta molecular sieve, the specific surface area of the hydrogenation catalyst is 200-320m<2> / g, total pore volume is 0.30-0.50ml / g, infrared acid amount is 0.50-1.0mmol / g, the ratio of acid B to acid L is 0.2-1.0, and radial crushing strength is larger than 150N / cm. The hydrogenation catalyst is used for processes such ashydrocracking, hydro-upgrading and hydroisomerization.

Owner:PETROCHINA CO LTD

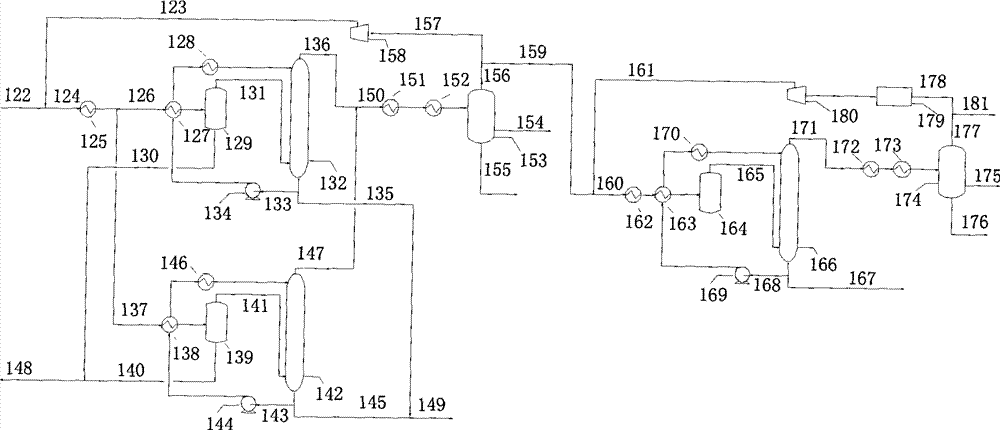

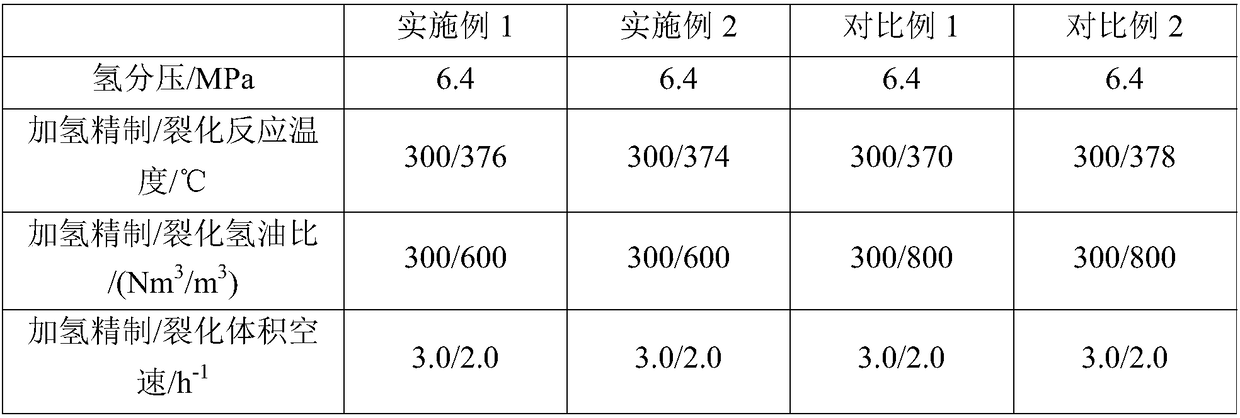

Method for producing middle distillate oil through hydrogenation of Fischer-Tropsch synthesis oil

ActiveCN106398762ADifferent performanceFlexible product planTreatment with hydrotreatment processesHydrogenNaphtha

The invention relates to a method for producing middle distillate oil through hydrogenation of Fischer-Tropsch synthesis oil. According to the method, the whole distillate of Fischer-Tropsch synthesis oil and hydrogen gas are mixed, the obtained mixture enters a hydrorefining reactor and is subjected to a contact reaction with a hydrorefining catalyst, the obtained hydrorefining reaction effluent is sequentially subjected to separation and fractionation to obtain a first naphtha distillate, a light diesel oil distillate and a heavy oil distillate, the heavy oil distillate is mixed with at least a distillate oil and hydrogen gas, the obtained mixed material enters a hydroisomerization cracking reactor and is subjected to a contact reaction with a hydroisomerization cracking catalyst, and the obtained hydroisomerization cracking reaction effluent is sequentially subjected to separation and fractionation to obtain a second naphtha distillate, a middle distillate oil and a tail oil distillate. With the method of the present invention, the selectivity and the yield of the middle distillate oil are easily improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing low-carbon olefin through petroleum hydrocarbon oil catalytic cracking

ActiveCN102816590AFlexible product planHigh yieldTreatment with plural serial stages onlyHydrocarbon from oxygen organic compoundsFluidized bedCarbon deposit

Provided is a method for producing low-carbon olefin through petroleum hydrocarbon oil catalytic cracking. A petroleum hydrocarbon raw material and a catalyst regenerating agent which enters a lift pipe reactor and is used for steam lifting are contacted and perform cracking reaction under the condition of the cracking reaction. The method is characterized by further comprising the step of introducing 10-50 weight% of carbon deposit catalyst into a fluidized bed reactor to be contacted with and react with an oxygen-containing compound raw material, wherein the feeding of the oxygen-containing compound raw material includes two portions, one feeding portion containing ethanol and / or diethyl ether enters from the bottom of the fluidized bed reactor after subjected to heat exchange, the other feeding portion with no ethanol and / or diethyl ether enters from the middle-lower portion of the reactor after subjected to heat exchange and temperature rise, and a mixture of a reaction oil-gas product and the catalyst returns to a precipitator through a conveying line at the top of the fluidized bed reactor to be mixed with cracking reaction oil and gas and the carbon deposit catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

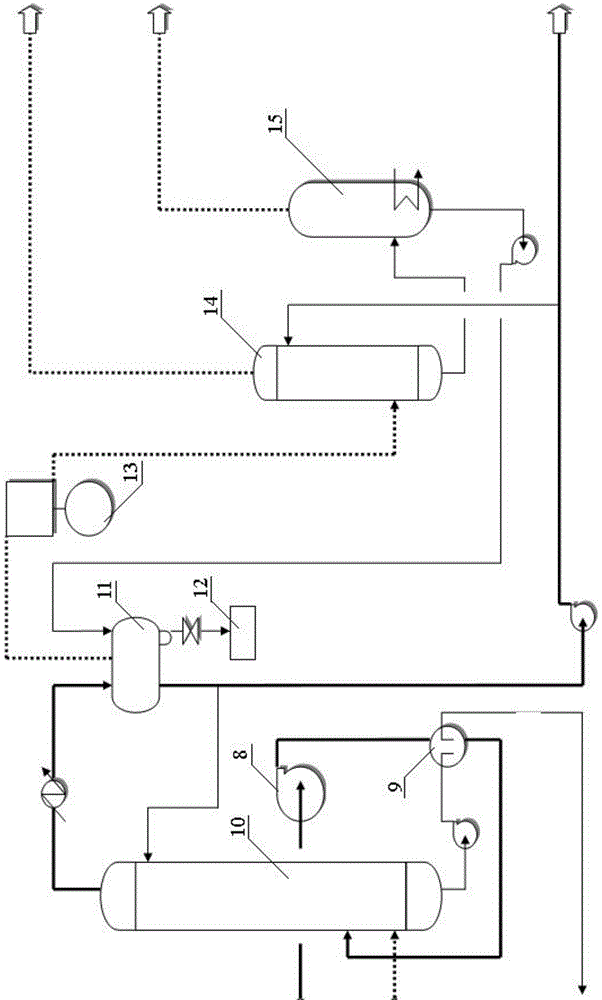

Deep processing method for shale oil

ActiveCN106221797AImprove utilization efficiencyImprove the level of deep processingTreatment with hydrotreatment processesHydrocarbon oils treatment productsDistillationCombined method

The invention relates to a shale oil deep processing combined process, in particular to a deep processing method for shale oil. The deep processing method aims at solving the technical problems that an existing method shale oil deep processing process is complex in technological process, low in light oil product yield and insufficient in processing depth. A raw material pretreatment unit, a reduced pressure distillation unit, a hydrofining unit, a delay coking unit and a product fractionation unit are involved in the shale oil deep processing combined method. The method that coked distillate returns to a hydrofining device for redistillation is adopted, and the raw material conversion rate and the yield of a diesel oil product are increased. Vacuum distillate, vacuum residuum and hydrogenated tail oil are mixed to serve as feed of a delayed coker, the yield of coking gas and coke is reduced, and the yield of coker diesel is increased.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE

Technique for producing oil products by fischer-tropsch synthesis

ActiveCN101381616BFlexible product planReduce the numberLiquid hydrocarbon mixture recoveryHydrogenFuel gas

The invention relates to a technological method for preparing oil products by the Fischer-Tropsch synthesis. In the technological method, a FT synthesis process comprises a first-stage FT synthesis process and a second-stage FT synthesis process; in particular, the technological method comprises the following steps: (1) synthesis gases are subjected to FT synthesis reaction in a first-stage synthesis reactor; (2) a part of tail gases from the first-stage synthesis reactor are circularly returned to an entrance of the first-stage synthesis reactor, and another part of the tail gases enter a second-stage synthesis reactor for the further FT synthesis reaction; (3) a part of tail gases from the second-stage synthesis reactor are circularly returned to an entrance of the second-stage synthesis reactor, and another part of the tail gases are used for reclaiming low-carbon hydrocarbons and hydrogen gases and then are used as fuel gases; and (4) by utilizing the recovered hydrogen gases, thehydrocarbon products in the first-stage synthesis reactor and the second-stage synthesis reactor and the hydrocarbon products which are obtained by separating and recovering the tail gases are subjected to hydrogenation and purification and then are fractionated to generate various oil products. Compared with prior art, the technological method has the characteristics of economy, flexibility, lowcost and the like.

Owner:YANKUANG ENERGY R&D CO LTD

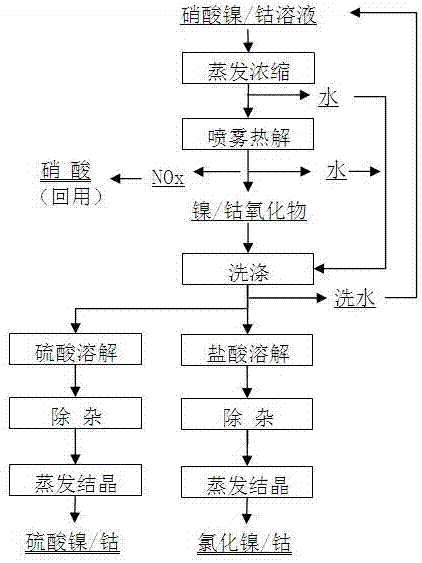

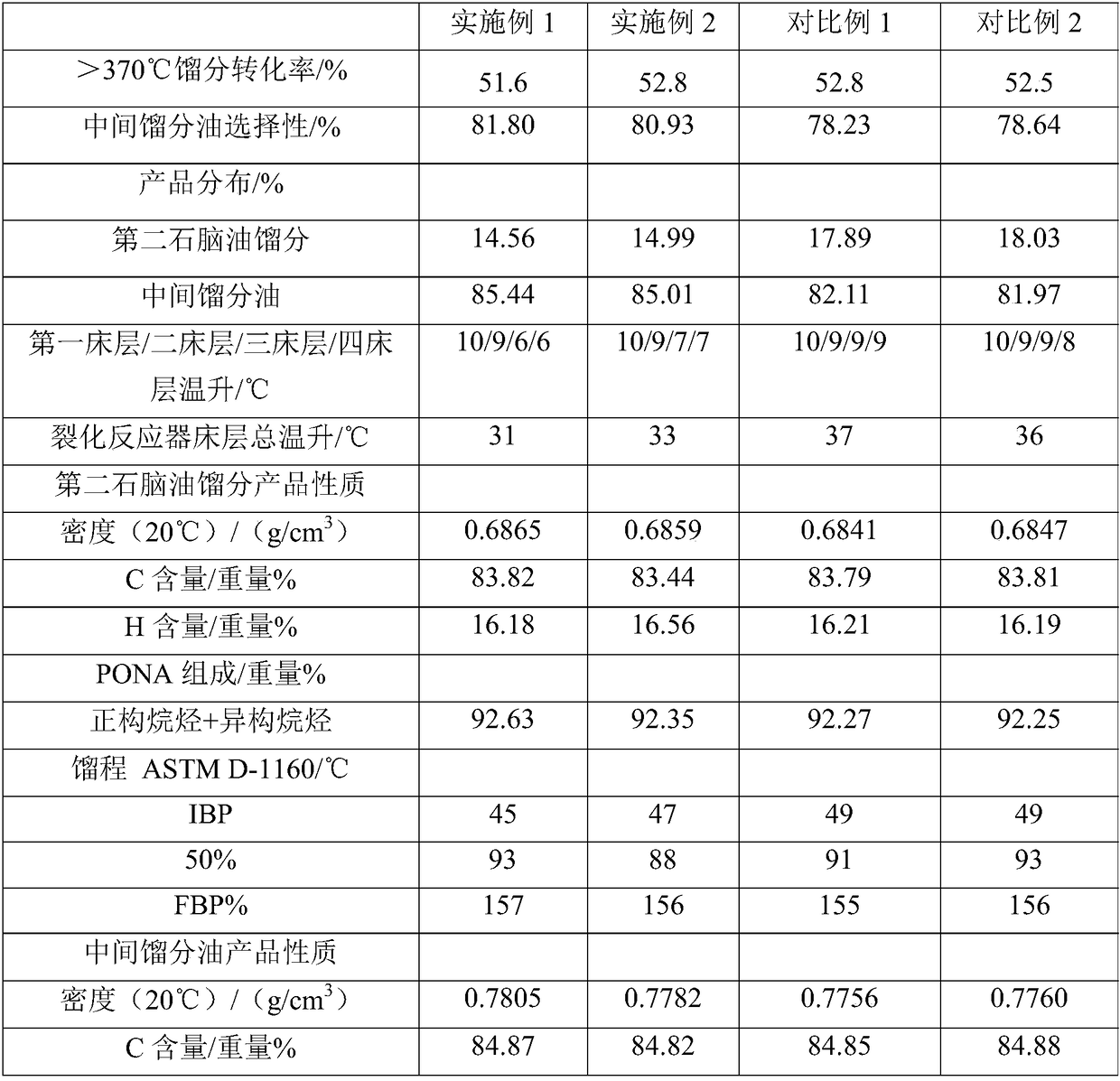

Method for transformation and nitric acid reuse of nickel nitrate/cobalt nitrate solution system

ActiveCN107385210ALow running costLess investmentProcess efficiency improvementSystem transformationImpurity

The invention discloses a method for transformation and nitric acid reuse of a nickel nitrate / cobalt nitrate solution system. The nickel nitrate / cobalt nitrate solution system can be transformed into a sulfate and chlorate system at the low temperature; the requirements for producing various products such as nickel sulfate / cobalt sulfate, nickel chloride / cobalt chloride, and electrodeposited nickel / electrodeposited cobalt can be met; nitric acid regeneration and reuse and water cyclic utilization are achieved while system transformation is achieved; in the whole process, no impurity is introduced, and no waste water or waste residue is generated; clean and pollution-free effects are achieved; the method is easy to implement compared with a traditional extraction process; the investment is small, energy saving and environmental friendliness are achieved, and the operation cost is low; the method can be applied to production of various salts or metals; the product scheme is flexible, different market requirements can be met, and the method conforms to the environment-friendly development concept; and the method is a novel efficient and clean metallurgy technology and has good economic benefits and resource environment benefits.

Owner:JINCHUAN GROUP LIMITED

Hydrogenation catalyst and preparation method thereof

InactiveCN108262067AFlexible productionFlexible product planMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveSolid acid

The invention relates to a hydrogenation catalyst and a preparation method thereof. The hydrogenation catalyst comprises a reactive metal and a carrier, the reactive metal comprises a VIB-group metaland a VIII-group metal, the VIB-group metal is molybdenum and / or tungsten, the VIII-group metal is cobalt and / or nickel, the carrier comprises a solid acid component and an unformed heat-resistant oxide, the solid acid component is a mixture of an MCM-22 molecular sieve and a Y molecular sieve, the specific surface of the hydrogenation catalyst is 200-320m<2> / g, total pore volume is 0.30-0.50ml / g,infrared acid amount is 0.50-1.0mmol / g, the ratio of acid B to acid L is 0.2-1.0, and radial crushing strength is larger than 150N / cm. The hydrogenation catalyst is applied to processes such as hydrocracking, hydro-upgrading and hydroisomerization.

Owner:PETROCHINA CO LTD

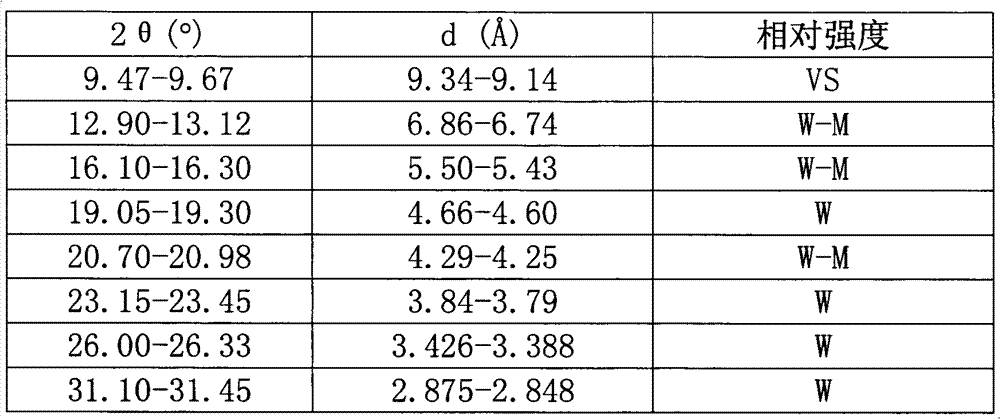

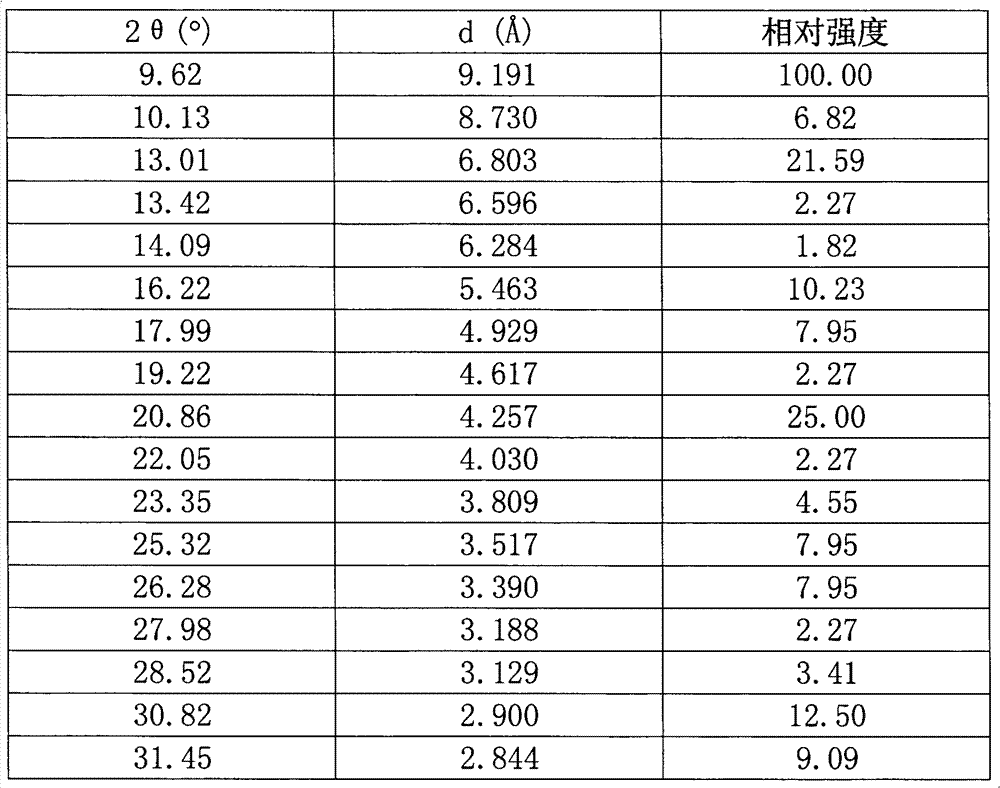

Hydrogenation catalyst support and preparation method thereof

InactiveCN108262066AFlexible productionFlexible product planMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveSilicon

The invention relates to a hydrogenation catalyst support, comprising a solid acid component and an amorphous heat-resistant oxide; the hydrogenation catalyst support has specific surface area of 220-430 m<2> / g, total pore volume of 0.35-0.70 ml / g, infrared acid quantity of 0.50-1.0 mmol / g, the ratio of acid B to acid L being 0.2-1.0 and radial crushing strength of greater than 130 N / cm; based onthe total weight of the support, the solid acid component accounts for 10-80%, and the amorphous heat-resistant oxide accounts for 20-90%, wherein the solid acid component is MCM-22 molecular sieve having silicon-aluminum ratio of 10-50, specific surface area of 400-700 m<2> / g, and pore volume of 0.35-0.75 ml / g. In addition, a preparation method of the hydrogenation catalyst support is also disclosed; the hydrogenation catalyst support is widely applicable to hydrogenation cracking, hydrogenation upgrading, hydroisomerization and other processes.

Owner:PETROCHINA CO LTD

Optimized hydrogenation-catalytic cracking combination process

The invention relates to an optimized hydrogenation-catalytic cracking combination process, comprising the following steps: wax oil raw materials react in a hydrotreating reaction area; obtained hydrogenation wax oil is taken as catalytic cracking raw oil and directly enters a catalytic cracking unit without being fractionated; catalytic heavy cycle oil circulates back the hydrotreating reaction area; gas phase material flow at the top of a high-pressure hot separator, catalytic light cycle oil and optional crude diesel oil enter a hydrogenation upgrading reaction area carry out hydrogenationupgrading reaction; and reaction products thereof are fractionated to obtain hydrogenation naphtha and hydrogenation diesel. A hydrotreating unit and a hydrogenation upgrading unit shares a hydrogensystem, the device investment and operation cost are lowered, the product scheme is flexible, and high-quality low-sulphur gasoline, high-quality diesel and reforming raw materials can be produced at the same time.

Owner:CHINA PETROLEUM & CHEM CORP +1

Dolomite wet process comprehensive utilization technique

InactiveCN101157464BEfficient separationReduce consumptionMagnesium chloridesCalcium/strontium/barium sulfatesSulfateResource consumption

The invention discloses a process of wet comprehensive utilization of dolomite, more specifically relates to a process for wet treatment of the dolomite to produce calcium and magnesium products, namely, the dolomite or incinerated dolomite powder is directly leached with sulfate acid to separate the calcium and the magnesium in the dolomite. The calcium precipitates in the form of calcium sulfateand the magnesium enters a solution in the form of magnesium sulfate; then magnesium hydroxide and calcium sulfate products are prepared from the magnesium solution after metathetical reaction and neutralization reaction. The intermediate product, calcium chloride, of the invention can be recycled, so the process is basically free of three-waste discharge and has notable environmental benefit; the invention, besides, significantly lowers the resource consumption and has obvious economic benefit.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Oxidation, reduction and sulfur recovery multipurpose device

ActiveCN101289170BOver recoveryHigh recovery rateSulfur preparation/purificationSulfurPhysical chemistry

The invention relates to an oxidation-reduction multi-purpose device for sulfur recovery, which is applicable to desulfurization and purifying of sulfur-bearing gas produced during the production processes of oil refining, chemical engineering, coal chemical industry, thermal power plants, etc. The oxidation-reduction multi-purpose device for sulfur recovery comprises a burning oxidation unit, a desulfurization and purifying unit, a hydrogenation reduction unit and a Claus sulfur recovery unit. The invention gets rid of a demanding oxygen-limited burning section positioned in the front part in traditional Claus reaction, which is improved into peroxide burning, and does not pursue sulfur conversion rate of the Claus reaction excessively, and only needs to control the SO2 conversion rate of sulfide in the peroxide burning and the circulating load of desulfurizer in the desulfurization and purifying reaction and the deficiency-degree regenerated thereby, can achieve or exceed recovery percent and SO2 emission of lower concentration than the Claus sulfur recovery device, with adjustable concentration of emission. The oxidation-reduction multi-purpose device of the invention can produce H2S by the hydrogenation reduction unit, thus having no requirement for the concentration of H2S in the sulfur-bearing gas, flexible operation and good comprehensive processing capacity.

Owner:苏州璞赛环境科技有限公司

Comprehensive utilization process for magnesium sulfate

InactiveCN102390848BEasy to separatePrecipitation particle size is largeCalcium/strontium/barium sulfatesLiquid-liquid reaction processesSulfateCalcium magnesium

The invention discloses a comprehensive utilization process for magnesium sulfate. The process specifically comprises the following steps of: reacting magnesium sulfate solution with lime milk under certain conditions to generate magnesium hydroxide and calcium sulfate mixture precipitate; growing magnesium hydroxide grains by controlling reactive crystallization conditions; adjusting pH value ofmixture suspension, and adding an inhibitor and a collector to perform flotation separation; and filtering and drying the magnesium hydroxide suspension and calcium sulfate suspension which are subjected to the flotation separation to obtain a magnesium hydroxide product and a calcium sulfate product respectively. The process has the advantages of environmental friendliness, simple process, shortflow, low production cost, complete calcium-magnesium separation, high product purity, wide application range, flexible and adjustable product scheme and the like.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method of producing low-sulfur low freezing point diesel by full-range shale oil

ActiveCN103497782BHigh yieldFlexible product planTreatment with hydrotreatment processesNaphthaOperational costs

The invention relates to a method of producing low-sulfur low freezing point diesel by full-range shale oil, relates to a production method of low-sulfur low freezing point diesel and solves the technical problems that the existing method of producing diesel by shale oil is complex in process and high in investment and operational cost. A material pre-fractionation unit, a reaction unit and a fraction unit are adopted in the method. The method has the advantages that finished diesel yield is high during processing of the full-range shale oil; the quality of the low-sulfur low freezing point diesel meets the national standard IV; a product scheme is flexible, the production of refined diesel and the production of the low-sulfur low freezing point diesel are both considered, and product distribution is adjusted; during the processing of the full-range shale oil, the material pre-fractionation unit is additionally provided with an absorbing column and a flash tank, lightweight shale oil is used as absorbent, LPG components in noncondensable gas can be recycled, applying a product stabilization column to the product fractionation unit to separate LPG and naphtha is avoided, and cost reduction and efficiency increasing are achieved. The invention belongs to the field of diesel production.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE

A method for producing middle distillates from Fischer-Tropsch synthetic oil

ActiveCN106350110BDifferent performanceFlexible product planTreatment with hydrotreatment processesHydrogenNaphtha

Owner:CHINA PETROLEUM & CHEM CORP +1

Method of producing magnesium hydroxide

ActiveCN101172627BIncrease profitReduce manufacturing costMagnesiaMagnesium hydroxideSulfatePhysical chemistry

The invention discloses a preparation method of magnesium hydroxide by using magnesium sulfate and lime milk as raw materials, and the invention has the concrete process that a magnesium sulfate solution with a certain concentration can be used to conduct the metathesis reaction with a calcium chloride solution to produce the magnesium chloride solution and calcium sulfate precipitation; the filter mass is washed and dried after the solid-liquid separation to generate calcium sulfate products; the filter liquid continues to counteract with lime milk with a certain concentration to produce thecalcium chloride solution and the magnesium hydroxide precipitation; and then the filter mass is washed, dried and crashed after the solid-liquid separation to generate magnesium hydroxide products; and then the filter liquid returns to the metathesis reaction for recycling. The invention with low producing cost remarkably improves environmental and economic benefits.

Owner:河北镁神科技股份有限公司

A method for nickel nitrate/cobalt solution system transformation and nitric acid reuse

ActiveCN107385210BLow running costLess investmentProcess efficiency improvementSystem transformationImpurity

The invention discloses a method for transformation and nitric acid reuse of a nickel nitrate / cobalt nitrate solution system. The nickel nitrate / cobalt nitrate solution system can be transformed into a sulfate and chlorate system at the low temperature; the requirements for producing various products such as nickel sulfate / cobalt sulfate, nickel chloride / cobalt chloride, and electrodeposited nickel / electrodeposited cobalt can be met; nitric acid regeneration and reuse and water cyclic utilization are achieved while system transformation is achieved; in the whole process, no impurity is introduced, and no waste water or waste residue is generated; clean and pollution-free effects are achieved; the method is easy to implement compared with a traditional extraction process; the investment is small, energy saving and environmental friendliness are achieved, and the operation cost is low; the method can be applied to production of various salts or metals; the product scheme is flexible, different market requirements can be met, and the method conforms to the environment-friendly development concept; and the method is a novel efficient and clean metallurgy technology and has good economic benefits and resource environment benefits.

Owner:JINCHUAN GROUP LIMITED

Hydrotreating Process of Fischer-Tropsch Synthetic Oil

ActiveCN101177625BEffective hydrotreatingGuaranteed long-term operationTreatment with hydrotreatment processesLiquid productNaphtha

Owner:SYNFUELS CHINA TECH CO LTD

A method for Fischer-Tropsch synthetic oil hydrogenation upgrading

ActiveCN107033954BDifferent performanceFlexible product planTreatment with hydrotreatment processesHydrogenDiesel fuel

The invention relates to the field of oil refining and discloses a hydrogenation quality improving method of Fischer-Tropsch synthetic oil. The method comprises the steps as follows: Fischer-Tropsch synthetic oil and a hydrogen-containing substance flow are introduced into a hydrorefining reactor to react, then a hydrorefinng reaction effluent is separated, and a heavy oil fraction is obtained; the heavy oil fraction is introduced into an isometic hydrocracking reactor to react, an isometric hydrocracking reaction effluent is separated, and a tail oil fraction is obtained, wherein at least two catalyst bed layers are contained in the isometic hydrocracking reactor, and at least part of tail oil fraction is circulated back between the catalyst bed layers of the isometic hydrocracking reactor. With the adoption of the hydrogenation quality improving method of Fischer-Tropsch synthetic oil, the selectivity of intermediate fraction oil can be improved, and higher diesel oil yield can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com