Device and method for co-production or single production of refined methanol with rough methanol

A production device and technology for crude methanol, applied in chemical instruments and methods, ether preparation, organic compound preparation, etc., can solve the problems of inflexible production plans for refined methanol and dimethyl ether products, and achieve flexible product plans and improve equipment. Utilization, strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

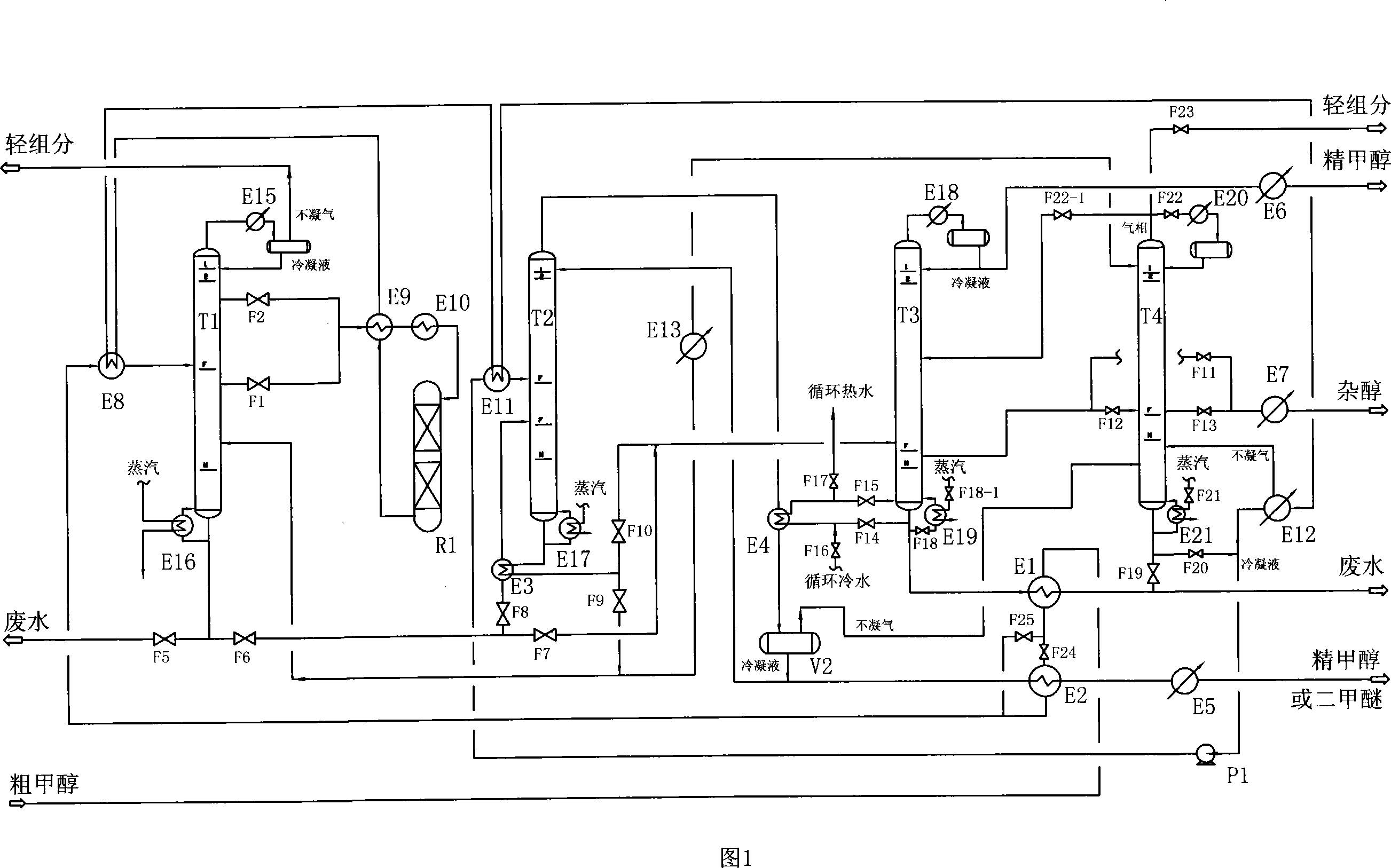

[0021] Referring to Fig. 1, it comprises a reactor R1, a tower T1, two towers T2, three towers T3 and four towers T4, said each tower has a tower top condenser and a tower still reboiler, wherein the tower top condenses The existing primary condenser or secondary condenser can be used as the condenser. To simplify the description, the structure of the primary condenser is shown in the figure. In the project, some pumps and tanks need to be added to this device, which is common knowledge in this industry, and it is omitted in this figure for the sake of simplification.

[0022] The specific connections between the reactor R1 and the four towers are as follows:

[0023] 1. The crude methanol raw material is connected to the feed port of the first tower T1 through three heat exchangers E1, E2 or E2 across the line, E8, and the heat exchangers E1 and E2 are respectively used for the crude methanol feed and the bottom of the three tower T3 The product exchanges heat with the top p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com