Preparation method of high-purity boehmite

A pseudo-boehmite, high-purity technology, applied in the field of metal-organic compound synthesis, can solve the problem that the crystal phase purity of pseudo-boehmite is only 97%, the price is expensive, and the production cost of high-purity pseudo-boehmite increases, etc. problems, to achieve the effect of saving equipment investment, easy filtration, and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

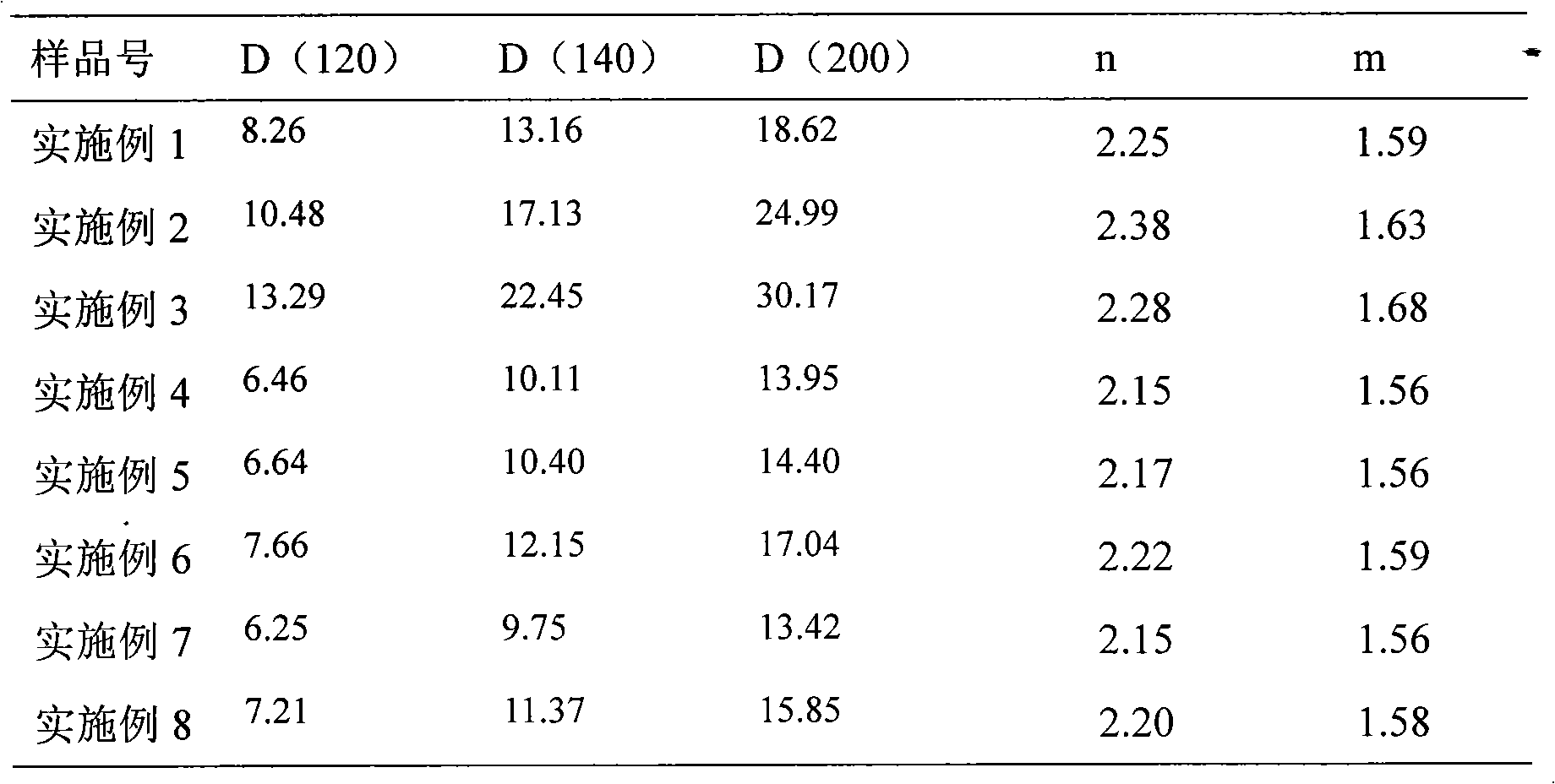

Embodiment 1

[0015] Put 27g of aluminum ingots, 1.33g of anhydrous aluminum trichloride and 50g of n-butanol (water content less than 0.2%) in a 1L four-necked flask with a condenser, and after reflux for 1 hour, add 260g of n-octanol and 24g of n-butanol Mix alcohol with alcohol, reflux for 1h, and filter while hot. Put the filtrate into a 2L four-neck flask with a reflux condenser and a water separator. After the temperature reaches 80°C, add 400g of deionized water at a temperature of 80°C, hydrolyze for 4 hours, separate the alcohol, and then add 500g of deionized water. Raise the temperature to 95°C, reflux and age for 14 hours, distill off the remaining alcohol and part of the water, and dry at 120°C for 6 hours to obtain 60g of white pseudo-boehmite. After XRD, differential thermal and ICP-MS analysis, it is proved that it is a high-purity pseudo-boehmite with a crystal phase purity of 100% and an impurity content of less than 0.01%. The calculated n and m values are listed in Tab...

Embodiment 2

[0017] Put 27g of aluminum ingot, 1.33g of anhydrous aluminum trichloride and 50g of n-butanol (water content is less than 0.2%) in the 1L four-neck flask with condenser tube, after reflux reaction for 0.5h, add 234g of n-octanol and 24g of n-butanol Butanol mixed with alcohol, refluxed for 1h, the following operations were the same as in Example 1.

Embodiment 3

[0019] Put 27g of aluminum wire, 1.33g of anhydrous aluminum trichloride and 50g of n-butanol in a 2L four-neck flask, and after reacting for 0.5h, add 260g of n-octanol and 24g of n-butanol mixed alcohol, and reflux for 2h. The following operations are the same as in the example 1. The hydrolysis temperature is 80°C for 4 hours, the aging temperature is 100°C for 12 hours, and the drying temperature is 120°C for 6 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com