Oxidation, reduction and sulfur recovery multipurpose device

A technology for sulfur recovery and sulfur dioxide, applied in the preparation/purification of sulfur, etc., can solve the problems of increasing the technological process, increasing the difficulty of system control, and unsatisfactory sulfur conversion rate, and achieving the effect of simple sulfur conversion rate and easy sulfur conversion rate.

Active Publication Date: 2010-08-25

苏州璞赛环境科技有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The main problems in the traditional Claus sulfur recovery process are: the conversion rate of sulfur is not ideal; there is sulfur dioxide in the tail gas; 2 S / SO 2 =2 The control accuracy is difficult to grasp, which will increase the difficulty of system control

This process cannot be said to be an effective method when the hydrogen source is sufficient, but it sends all the tail gas to the hydrogenation reactor, which has a large load, high investment, and more importantly, it is not nearly reasonable from the process route. , that is, in the process route of sulfur-containing gas→oxygen-limited combustion→Claus reaction→hydrogenation reduction→absorption regeneration→incineration and venting, secondary combustion is carried out, and because there is H in the tail gas produced by Claus reaction 2 S, and SO 2 , it is difficult to absorb both H 2 S absorbs SO 2 , so the SO in the exhaust gas should be 2 Hydrogenation reduction to H 2 S, reabsorbed and desorbed H 2 After S, return to the combustion furnace G1 for another sulfur recovery. Therefore, its hydrogenation reduction is an unnecessary process, which makes the process complicated, and the total investment and operating costs of the device are high.

To sum up, the existing Claus-type (including super and super-excellent and tail gas treatment) sulfur recovery devices are to increase the process flow and increase the operating cost to obtain a higher sulfur recovery rate and exhaust emission standards.

Moreover, they do not consider the comprehensive performance of the device, and basically only deal with the sulfur-containing feed gas rich in hydrogen sulfide. If the hydrogen sulfide concentration in the feed gas is less than 20% of the unit volume, it is difficult to limit oxygen combustion, resulting in Claus reaction not working

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

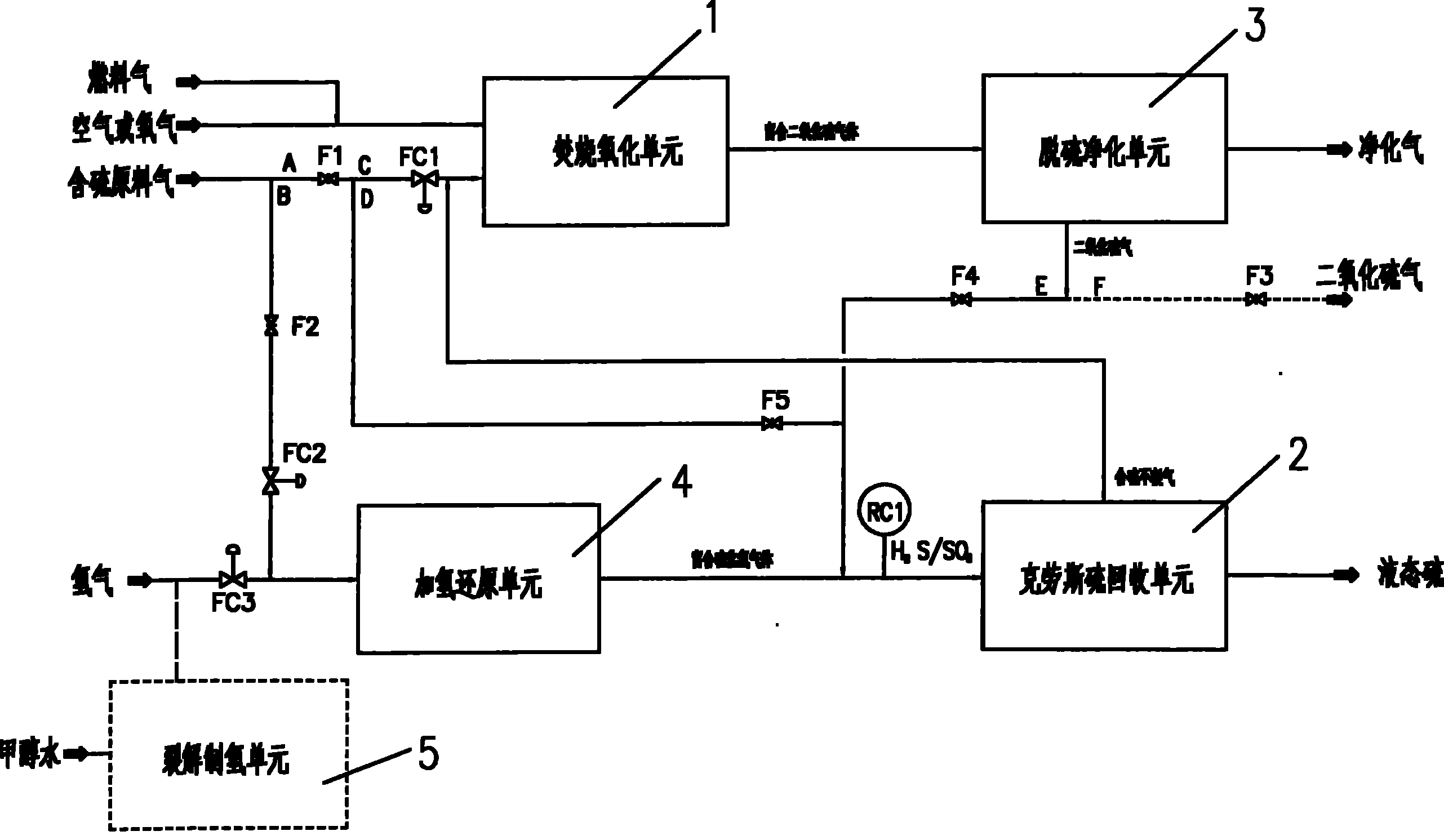

The invention relates to an oxidation-reduction multi-purpose device for sulfur recovery, which is applicable to desulfurization and purifying of sulfur-bearing gas produced during the production processes of oil refining, chemical engineering, coal chemical industry, thermal power plants, etc. The oxidation-reduction multi-purpose device for sulfur recovery comprises a burning oxidation unit, a desulfurization and purifying unit, a hydrogenation reduction unit and a Claus sulfur recovery unit. The invention gets rid of a demanding oxygen-limited burning section positioned in the front part in traditional Claus reaction, which is improved into peroxide burning, and does not pursue sulfur conversion rate of the Claus reaction excessively, and only needs to control the SO2 conversion rate of sulfide in the peroxide burning and the circulating load of desulfurizer in the desulfurization and purifying reaction and the deficiency-degree regenerated thereby, can achieve or exceed recovery percent and SO2 emission of lower concentration than the Claus sulfur recovery device, with adjustable concentration of emission. The oxidation-reduction multi-purpose device of the invention can produce H2S by the hydrogenation reduction unit, thus having no requirement for the concentration of H2S in the sulfur-bearing gas, flexible operation and good comprehensive processing capacity.

Description

technical field The invention relates to a device for recovering sulfur from sulfur-containing gas produced in the production process of oil refining, chemical industry, coal chemical industry or thermal power plant. Specifically, it is a multi-purpose device for redox sulfur recovery. Background technique At present, the well-known sulfur recovery unit abroad is the Claus (CLAUS) reaction sulfur recovery unit. Referring to Fig. 3, it mainly includes a combustion furnace G1, a secondary Claus reactor R4, a tertiary sulfur cooler E17, a liquid sulfur pool V1 and a tail gas incinerator G2. The process is: the sulfur-containing raw material gas (which is rich in hydrogen sulfide) is preheated by the preheater E15 and enters the combustion furnace G1 with oxygen or air and fuel gas for oxygen-limited incomplete combustion. The combustion reaction formula is as follows: h 2 S+3 / 2O 2 → SO 2 +H 2 o By controlling the amount of oxygen or air entering during combustion, the r...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C01B17/04

Inventor 王胜利褚雅安

Owner 苏州璞赛环境科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com