A method for producing middle distillates from Fischer-Tropsch synthetic oil

A technology for Fischer-Tropsch synthetic oil and middle distillate oil, which is applied in the field of oil refining, can solve the problems of low yield and low selectivity of middle distillate oil, etc., so as to improve the selectivity and yield, save investment costs, and have flexible product solutions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] The present embodiment is used to illustrate the method for producing middle distillates from Fischer-Tropsch synthetic oil of the present invention, specifically as follows:

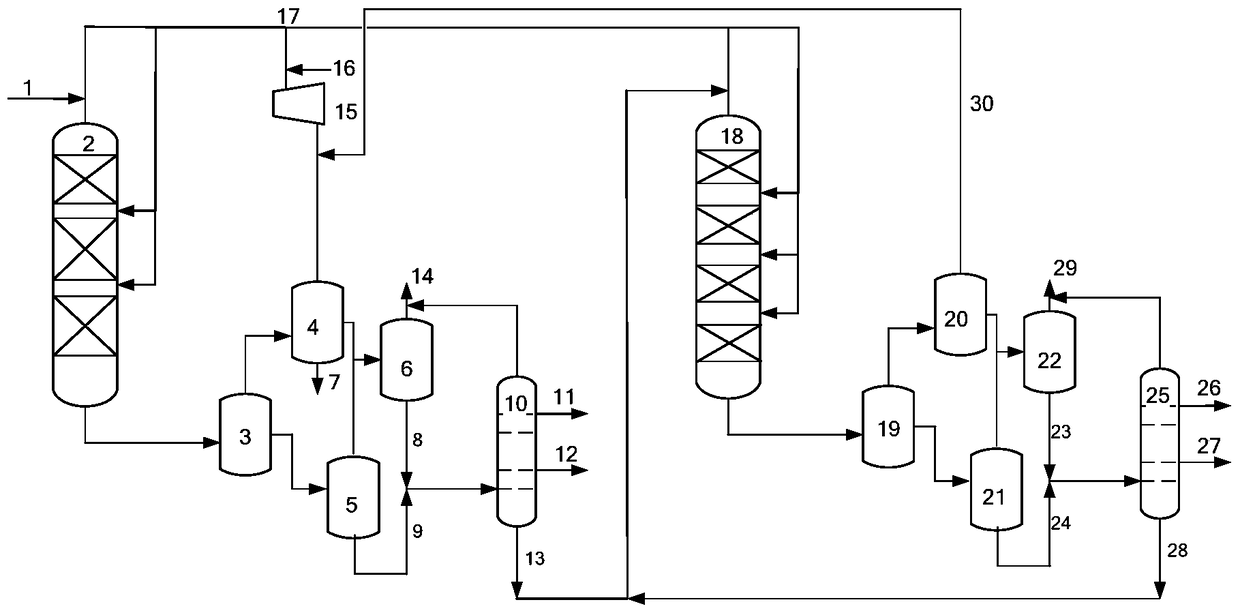

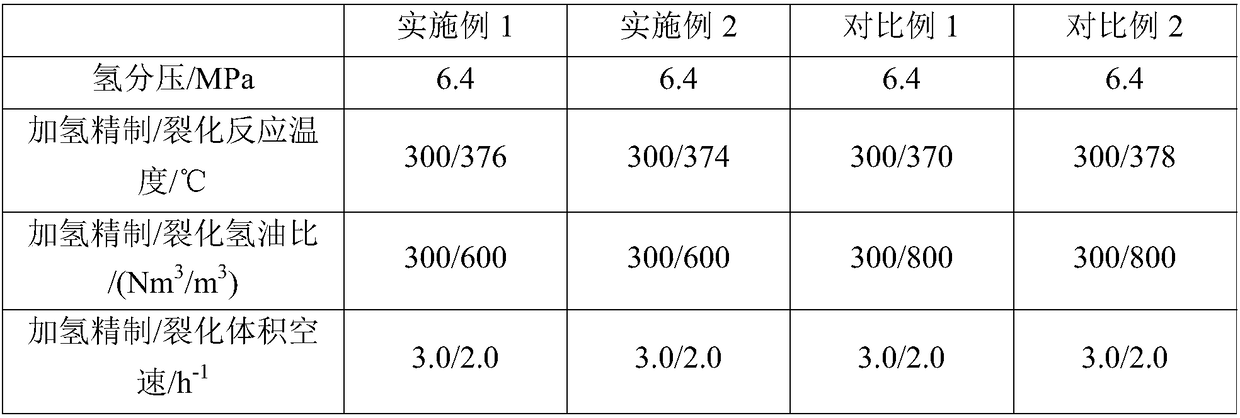

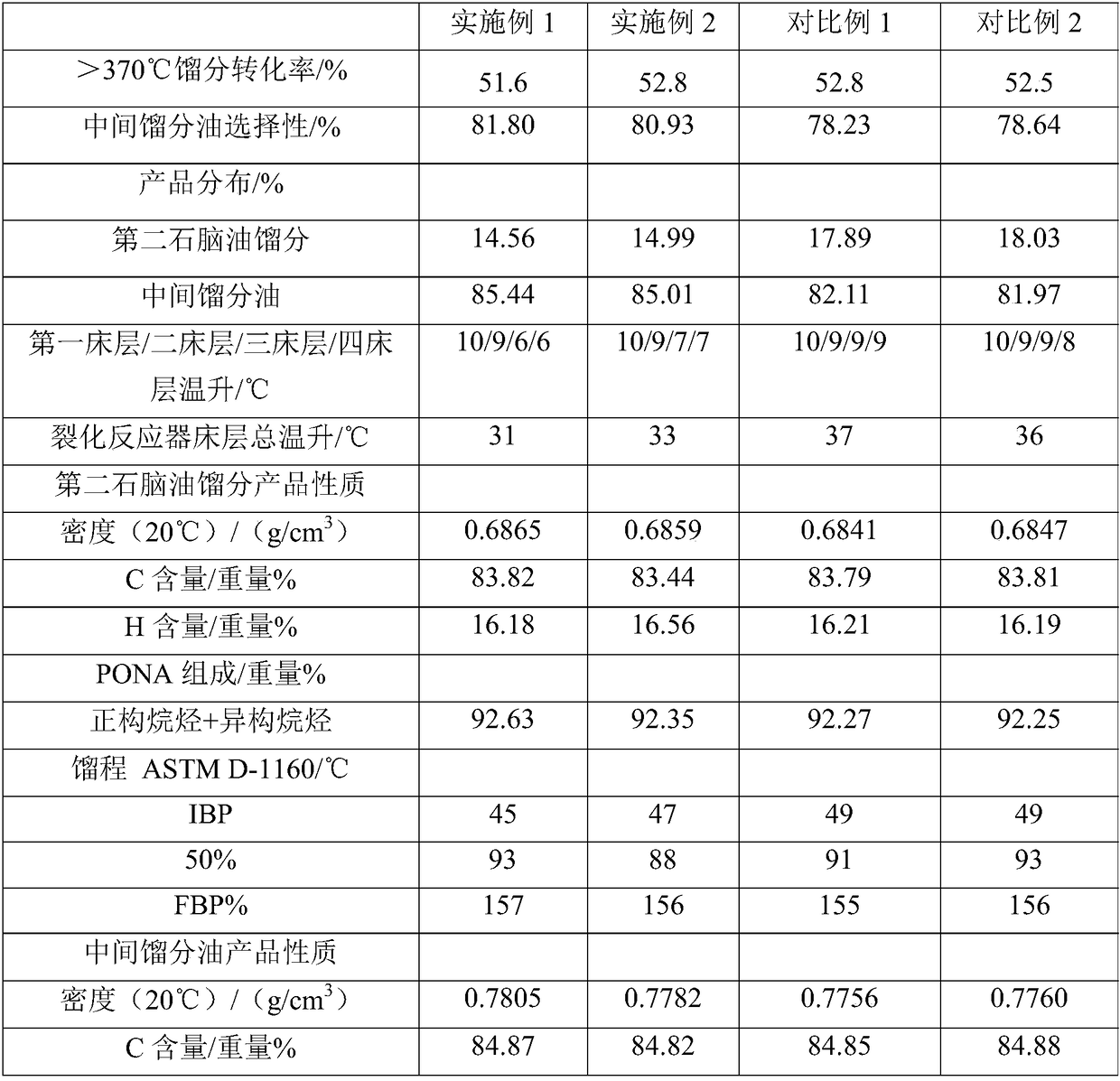

[0077] The Fischer-Tropsch synthetic oil raw material enters the hydrofinishing reactor, and successively contacts and reacts with the hydrogenation protection catalyst and the hydrofinishing catalyst, and the hydrofinishing reaction effluent enters the separation and fractionation system for separation and fractionation to obtain the first naphtha fraction, light Diesel fractions and heavy oil fractions. Wherein the heavy oil fraction enters the heterogeneous hydrocracking reactor provided with the upper reaction zone and the lower reaction zone, and according to the flow direction of the reactant flow, the heavy oil fraction is respectively in the upper reaction zone and the lower reaction zone with the isomerization hydrocracking catalyst RCF -1 contacting and reacting with isomeric hydrocrack...

Embodiment 2

[0081] The present embodiment is used to illustrate the method for producing middle distillates from Fischer-Tropsch synthetic oil of the present invention, specifically as follows:

[0082] The Fischer-Tropsch synthetic oil raw material enters the hydrofinishing reactor, and successively contacts and reacts with the hydrogenation protection catalyst and the hydrofinishing catalyst, and the hydrofinishing reaction effluent enters the separation and fractionation system for separation and fractionation to obtain the first naphtha fraction, light Diesel fractions and heavy oil fractions. Wherein the heavy oil fraction enters the heterogeneous hydrocracking reactor provided with the upper reaction zone and the lower reaction zone, and according to the flow direction of the reactant flow, the heavy oil fraction is respectively in the upper reaction zone and the lower reaction zone with the isomerization hydrocracking catalyst RCF -1 contact with the heterogeneous hydrocracking cat...

Embodiment 3

[0099] Present embodiment adopts the method similar to embodiment 1 to carry out, and difference is:

[0100] In this embodiment, based on the total weight of the tail oil fraction in the isomerization hydrocracking reaction effluent, the tail oil fraction recycled back to the inlet of the isomerization hydrocracking reactor is 40% by weight. All the other are the same as in Example 1. See Table 4 and Table 5 for specific reaction conditions, reaction performance and product properties after isomerization hydrocracking reaction.

[0101] It can be seen from Table 5 that the selectivity of the middle distillate in this example is 81.36%, and the bed temperature rise of the cracking reactor is 33°C.

[0102] It can be seen from Table 5 that the cetane number of the middle distillate oil is 79, and the sulfur and nitrogen contents are very low, so it can be used as a blending component of high cetane number diesel oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com