Method for reinforcing high-strength protective glass

A protective glass and high-strength technology, applied in the field of glass strengthening, can solve the problems of glass strength reduction, cost increase, glass surface uniformity cannot be guaranteed, etc., and achieve the effect of property improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

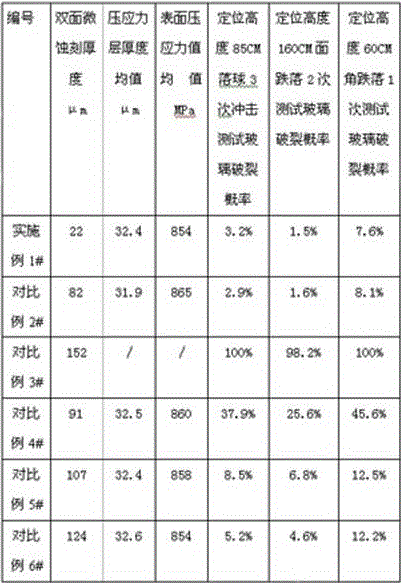

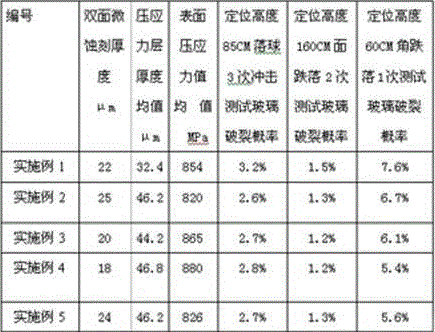

Examples

Embodiment 1

[0028] 1. The glass is edged, chamfered and punched by the engraving machine;

[0029] 2. Chemical pretreatment: Place the glass in molten potassium nitrate salt for high temperature pretreatment. The pretreatment temperature is 380°C and the chemical strengthening time is 30 minutes;

[0030] 3. Ultrasonic cleaning: use 8-10wt% lye for initial washing, and the cleaning time is 5 minutes; then use 4-6wt% lye for fine washing, and the cleaning time is 5 minutes; then rinse with pure water, and the cleaning time is 20 minutes ~ 25 minutes, pure water is 12 ~ 18 trillion; after washing with pure water, slowly dehydrate and then air dry;

[0031] 4. Micro-etching treatment: Soak the glass in the micro-etching medium or evenly spray the micro-etching medium on the glass surface. The micro-etching treatment time is 2-15 minutes. The micro-etching medium package is expressed in mass percentage, HF: 1 %, H 2 SO 4 : 3%, HNO 3 : 4%, the rest is pure water.

[0032] 5. Chemical stre...

Embodiment 2

[0034] 1. The glass is edged, chamfered and punched by the engraving machine;

[0035] 2. Chemical pretreatment: place the glass in molten potassium nitrate salt for high temperature pretreatment, the pretreatment temperature is 400°C, and the chemical strengthening time is 2 minutes;

[0036] 3. Ultrasonic cleaning: use 8-10wt% lye for initial washing, and the cleaning time is 5 minutes; then use 4-6wt% lye for fine washing, and the cleaning time is 5 minutes; then rinse with pure water, and the cleaning time is 20 minutes ~ 25 minutes, pure water is 12 ~ 18 trillion; after washing with pure water, slowly dehydrate and then air dry;

[0037] 4. Micro-etching treatment: Soak the glass in the micro-etching medium or evenly spray the micro-etching medium on the glass surface. The micro-etching treatment time is 2-15 minutes. The micro-etching medium package is expressed in mass percentage, HF: 5 %, H 2 SO 4 : 4%, the rest is pure water.

[0038] 5. Chemical strengthening tre...

Embodiment 3

[0040] 1. The glass is edged, chamfered and punched by the engraving machine;

[0041] 2. Chemical pretreatment: place the glass in molten potassium nitrate salt for high temperature pretreatment, the pretreatment temperature is 390°C, and the chemical strengthening time is 10 minutes;

[0042] 3. Ultrasonic cleaning: use 8-10wt% lye for initial washing, and the cleaning time is 5 minutes; then use 4-6wt% lye for fine washing, and the cleaning time is 5 minutes; then rinse with pure water, and the cleaning time is 20 minutes ~ 25 minutes, pure water is 12 ~ 18 trillion; after washing with pure water, slowly dehydrate and then air dry;

[0043] 4. Micro-etching treatment: Soak the glass in the micro-etching medium or evenly spray the micro-etching medium on the glass surface. The micro-etching treatment time is 2-15 minutes. The micro-etching medium package is expressed in mass percentage, HF: 3 %, H 2 SO 4 : 1%, HNO 3 : 2%, the rest is pure water.

[0044] 5. Chemical str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com