Method for transformation and nitric acid reuse of nickel nitrate/cobalt nitrate solution system

A technology of cobalt solution and nickel nitrate, applied in the direction of improving process efficiency, etc., can solve the problems of non-recyclable nitric acid, high production cost, and generation of waste residue and wastewater, and achieve the effects of flexible product solutions, small investment, and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

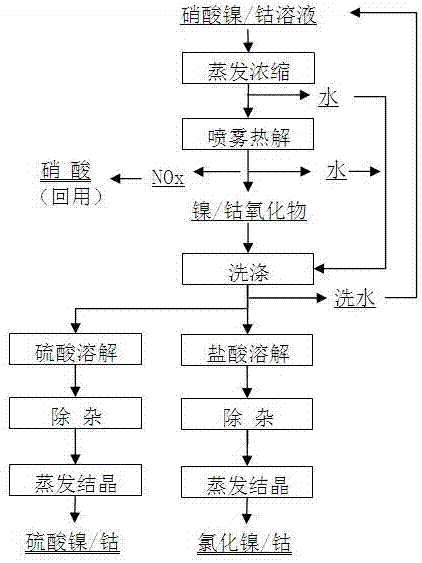

Image

Examples

Embodiment 1

[0020] A nickel / cobalt nitrate solution: Ni 120g / L, Co 0.3g / L, Cu 0.5g / L, Zn 0.3g / L, Fe 0.01g / L. This nickel nitrate / cobalt solution is carried out system conversion and nitric acid recycling, specifically comprises the following steps:

[0021] a. An energy-saving and high-efficiency evaporator is used to evaporate and concentrate the nickel nitrate / cobalt solution, and the water vapor generated during the evaporation process is condensed into water for reuse.

[0022] b. The concentrated nickel / cobalt nitrate solution is subjected to spray pyrolysis at a temperature of 200°C to obtain nickel / cobalt oxide powder, which contains Ni 71.51%, NO 3 - 2.1%, the water vapor generated during the pyrolysis process is condensed into water for reuse, and nitrogen oxides are made into nitric acid for reuse.

[0023] c. Wash the nickel / cobalt oxide powder with water, control the liquid-solid ratio to 1:1, wash the temperature at 20°C, perform two-stage countercurrent washing, and retur...

Embodiment 2

[0028] A nickel / cobalt nitrate solution: Ni 80g / L, Co 1.8g / L, Cu 0.02g / L, Zn 0.3g / L, Fe 0.01g / L. This nickel nitrate / cobalt solution is carried out system conversion and nitric acid recycling, specifically comprises the following steps:

[0029] a. An energy-saving and high-efficiency evaporator is used to evaporate and concentrate the nickel nitrate / cobalt solution, and the water vapor generated during the evaporation process is condensed into water for reuse.

[0030] b. The concentrated nickel / cobalt nitrate solution is subjected to spray pyrolysis at a temperature of 500°C to obtain nickel / cobalt oxide powder, which contains Ni 66.32%, NO 3 - 3.2%, the water vapor generated during the pyrolysis process is condensed into water for reuse, and nitrogen oxides are made into nitric acid for reuse.

[0031] c. Wash the nickel / cobalt oxide powder with water, control the liquid-solid ratio to 5:1, wash the temperature at 80°C, perform two-stage countercurrent washing, return th...

Embodiment 3

[0036] A nickel nitrate / cobalt solution: Co 50g / L, Ni 3g / L, Cu 0.01g / L, Zn 0.25g / L, Fe 0.01g / L. This nickel nitrate / cobalt solution is carried out system conversion and nitric acid recycling, specifically comprises the following steps:

[0037] a. An energy-saving and high-efficiency evaporator is used to evaporate and concentrate the nickel nitrate / cobalt solution, and the water vapor generated during the evaporation process is condensed into water for reuse.

[0038] b. The concentrated nickel nitrate / cobalt solution is subjected to spray pyrolysis at a temperature of 300°C to obtain nickel / cobalt oxide powder. The nickel / cobalt oxide powder contains 70% Co, NO 3 - 2.8%, the water vapor generated during the pyrolysis process is condensed into water for reuse, and nitrogen oxides are made into nitric acid for reuse.

[0039] c. Wash the nickel / cobalt oxide powder with water, control the liquid-solid ratio to 2:1, wash at 40°C, perform two-stage countercurrent washing, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com