Comprehensive processing and utilizing method for heavy oil

A technology for comprehensive processing and heavy oil, applied in the petroleum industry, processing hydrocarbon oil, cracking, etc., can solve the problems of mismatched production, expensive equipment, lack of economy and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

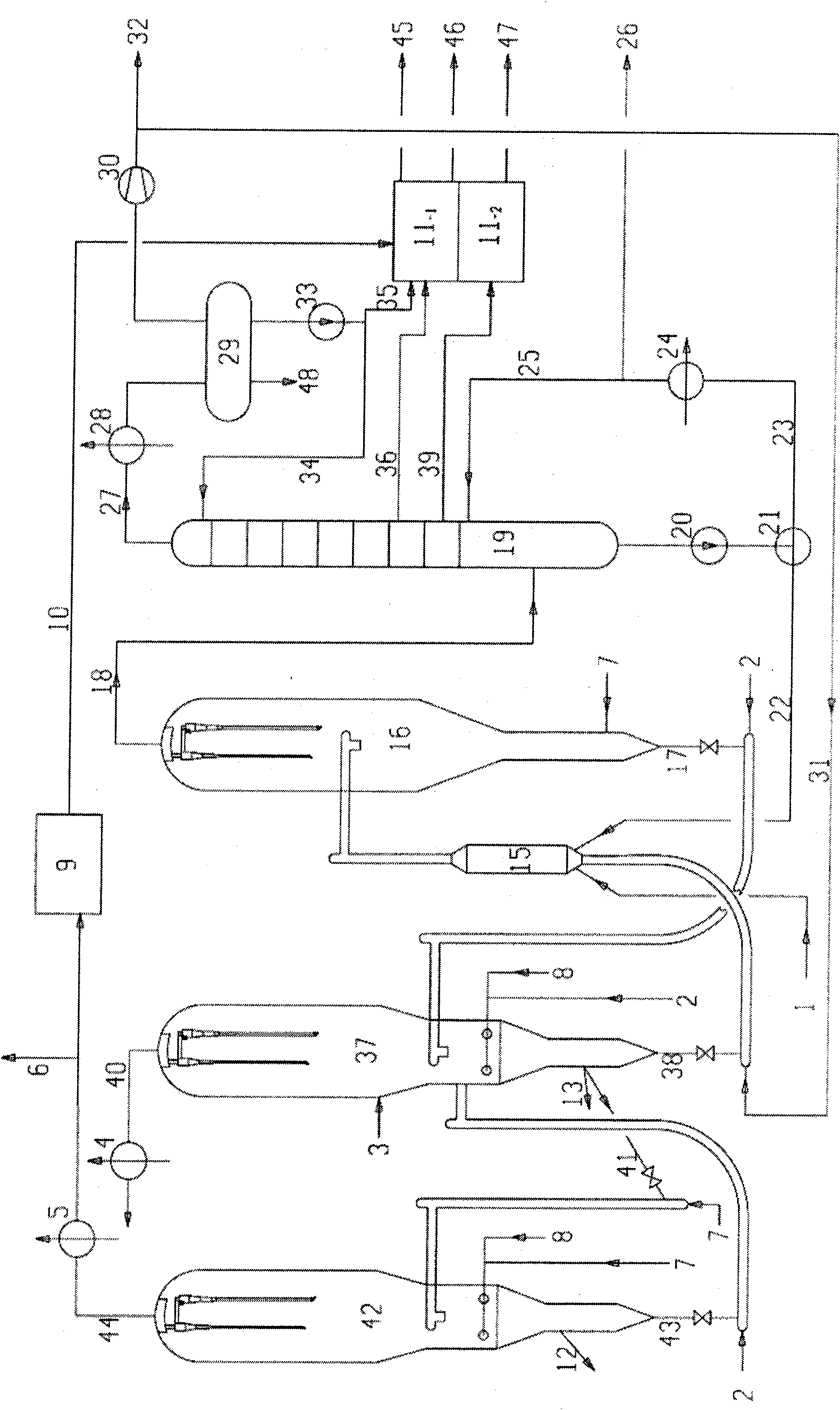

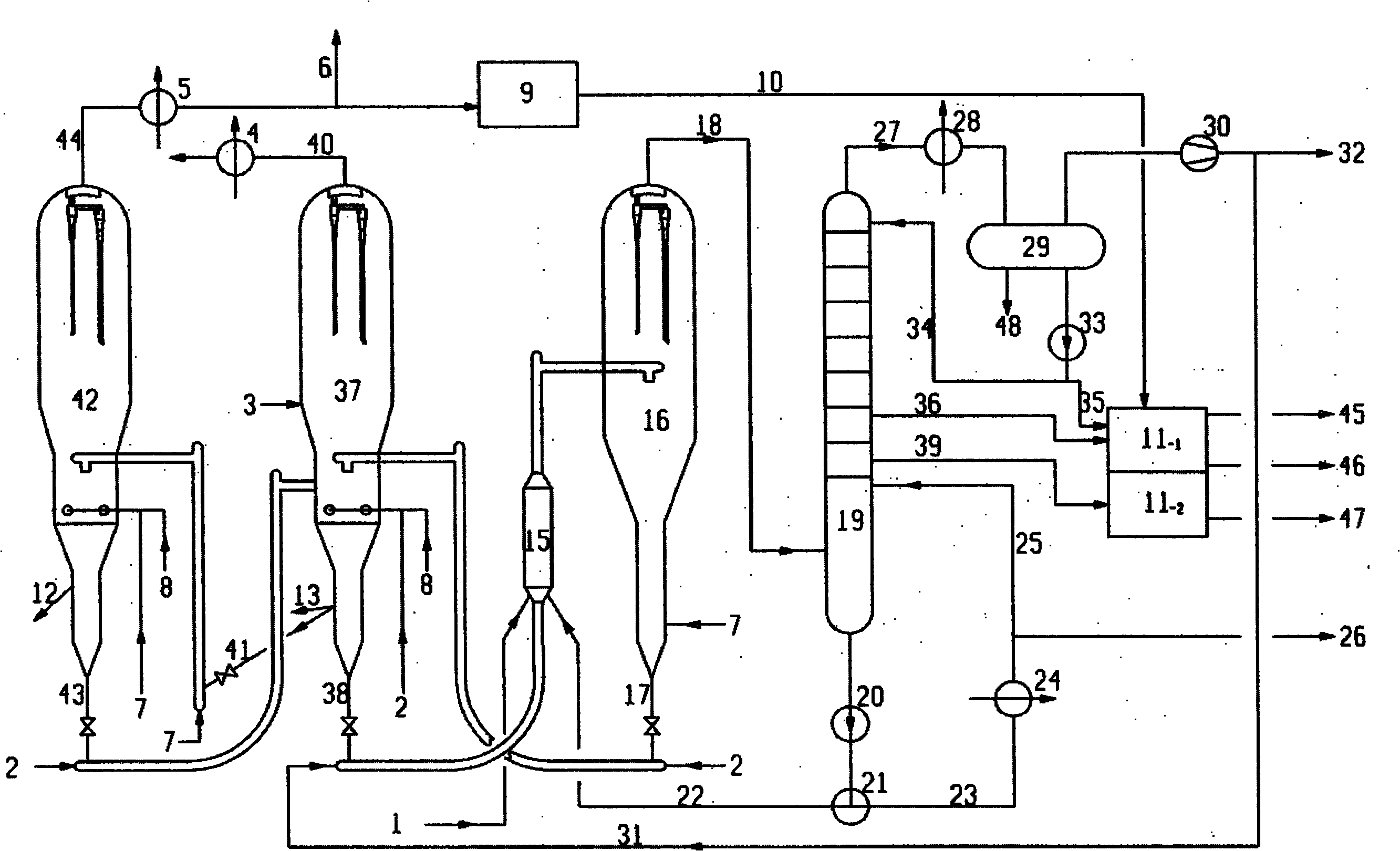

Method used

Image

Examples

Embodiment

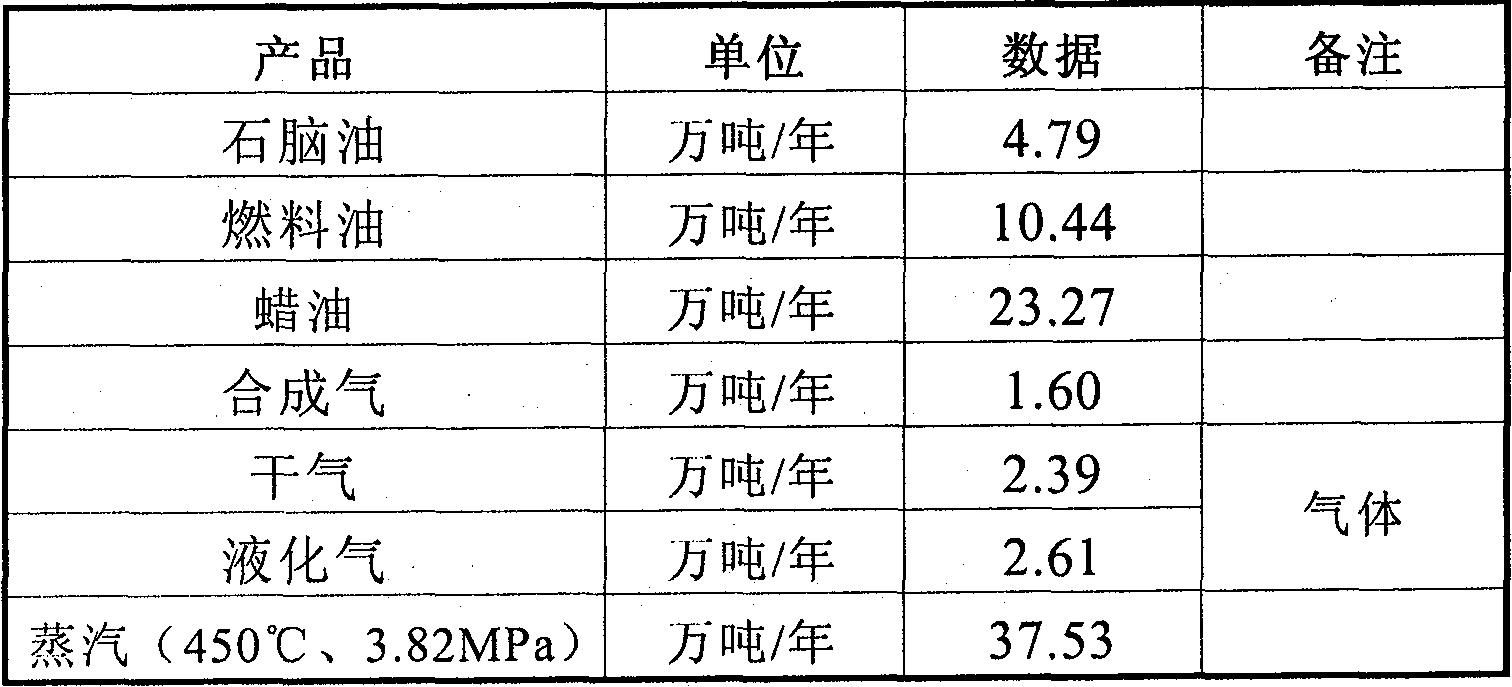

[0055] This embodiment is a 500,000-ton / year heavy oil comprehensive utilization processing device built in a refinery, and the heavy oil to be processed is petroleum atmospheric residue.

[0056] Raw material properties:

[0057] The main properties of petroleum atmospheric residue are shown in Table 1.

[0058] Table 1 Main properties of heavy oil

[0059] project

unit

value

Remark

d 4 20

0.923

carbon residue value

weight%

13.0

Kang's Charcoal

centistokes, 100°C

2580

S content

weight%

1.5

[0060] N content

weight%

0.43

Ni

ppm

36

V

ppm

14

[0061] Main operating conditions:

[0062] The operating conditions of the cracking reactor are: the pressure is 0.12MPa(G), and the temperature is 490-500°C;

[0063] The operating conditions of the settler are: the pressure is 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com