Hydrogenation catalyst and preparation method thereof

A hydrogenation catalyst and catalyst technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as insufficient self-sufficiency of raw materials and restrict development, and achieve flexible product solutions, good product quality, and process conditions. adjustable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

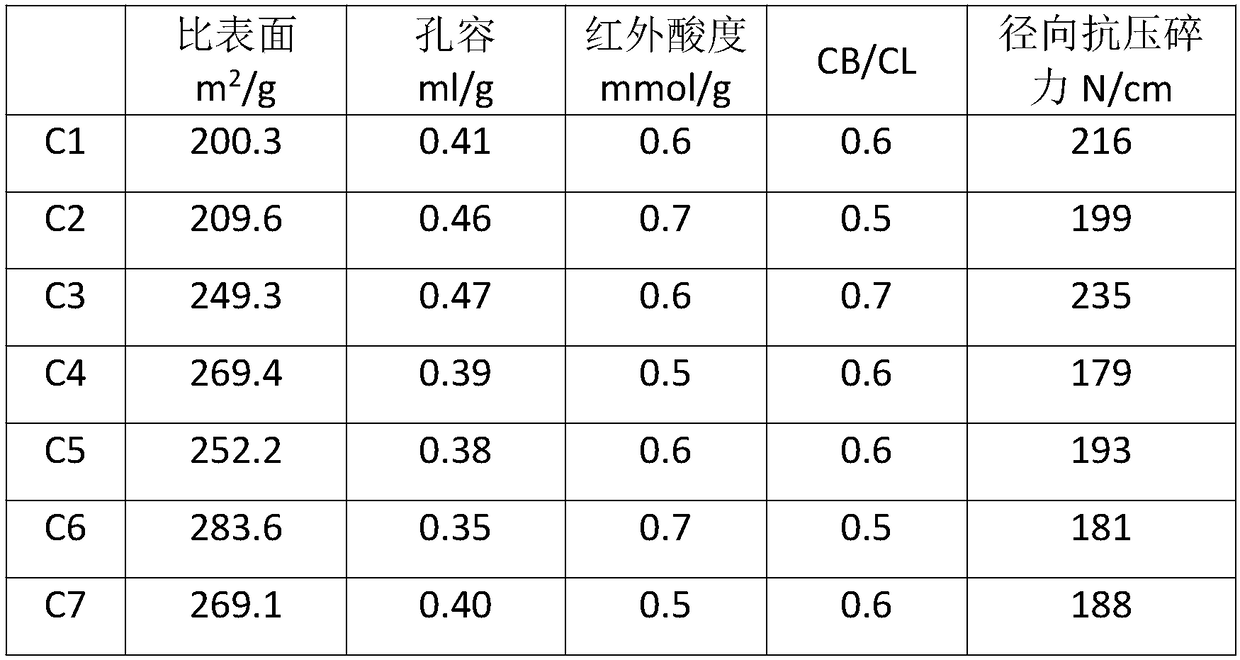

Examples

Embodiment 1

[0031] Weigh 50 g of MCM-22 molecular sieve. In the high-temperature treatment furnace, pass water vapor to treat, keep the treatment furnace at 550°C, and conduct hydrothermal treatment for 4 hours. The molecular sieves were treated with 500 ml of 0.5 mol / L oxalic acid solution at room temperature for 40 min. Dry at 100°C for 4 hours, and calcined at 550°C for 3 hours to obtain the modified molecular sieve M1.

Embodiment 2

[0033] Weigh 50 g of MCM-22 molecular sieve. In the high-temperature treatment furnace, water vapor was introduced to treat, and the treatment furnace was kept at 600° C., and the hydrothermal treatment was carried out for 4 hours. The molecular sieves were treated with 400 ml of 1 mol / L citric acid solution at room temperature for 20 min. Dry at 100°C for 4 hours, and bake at 500°C for 4 hours to obtain the modified molecular sieve M2.

Embodiment 3

[0035] Weigh 50 g of MCM-22 molecular sieve. In the high-temperature treatment furnace, water vapor is passed through to treat, and the treatment furnace is kept at 700° C., and the hydrothermal treatment is performed for 1 hour. The molecular sieves were treated with 500 ml of 0.01 mol / L sodium hydroxide solution at room temperature for 60 min. Dry at 120°C for 3 hours, and bake at 550°C for 4 hours to obtain the modified molecular sieve M3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com