Hydrogenation catalyst support and preparation method thereof

A hydrogenation catalyst, carrier technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve the effects of adjustable process conditions, flexible product plans, and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of hydrogenation catalyst carrier of the present invention, comprises the steps:

[0029] (1) Hydrogen-type molecular sieves are steamed at a temperature of 300-700°C for 1-6 hours. The optimum condition is that the treatment temperature is 500-600°C and the treatment time is 3-5 hours.

[0030] (2) Molecular sieves are treated with acid or alkali. The acid can be one or more of nitric acid, hydrochloric acid, citric acid, oxalic acid, and acetic acid. The acid concentration is 0.01-1mol / L. 20-60 minutes. The alkali can be one or both of sodium hydroxide and potassium hydroxide, the concentration is 0.01-1mol / L, the treatment temperature is room temperature-100°C, and the treatment time is 20-60 minutes.

[0031] (3) The treated molecular sieve is mixed with amorphous heat-resistant oxide, binder and extrusion aid in a certain proportion, shaped, then dried and calcined to make a catalyst carrier.

[0032] The hydrogenation catalyst carrier in ...

Embodiment 1

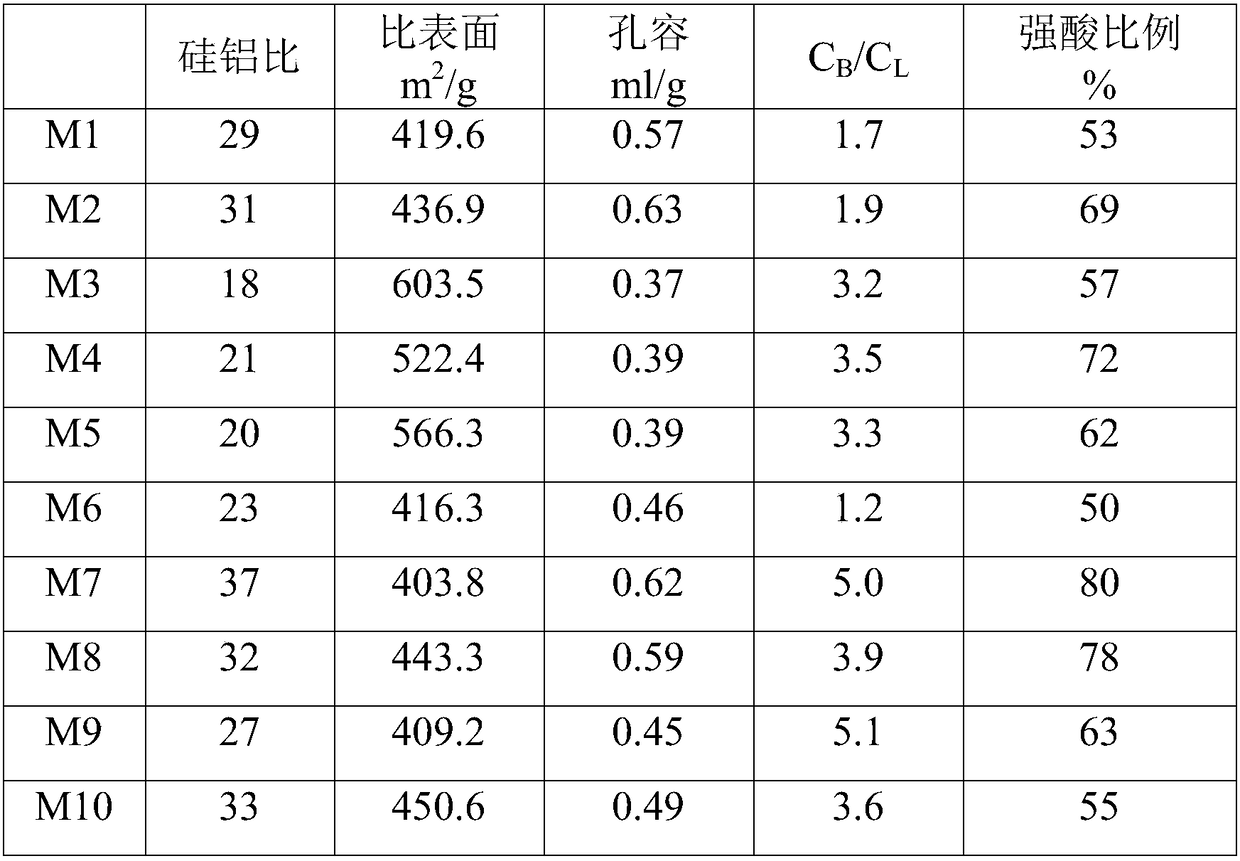

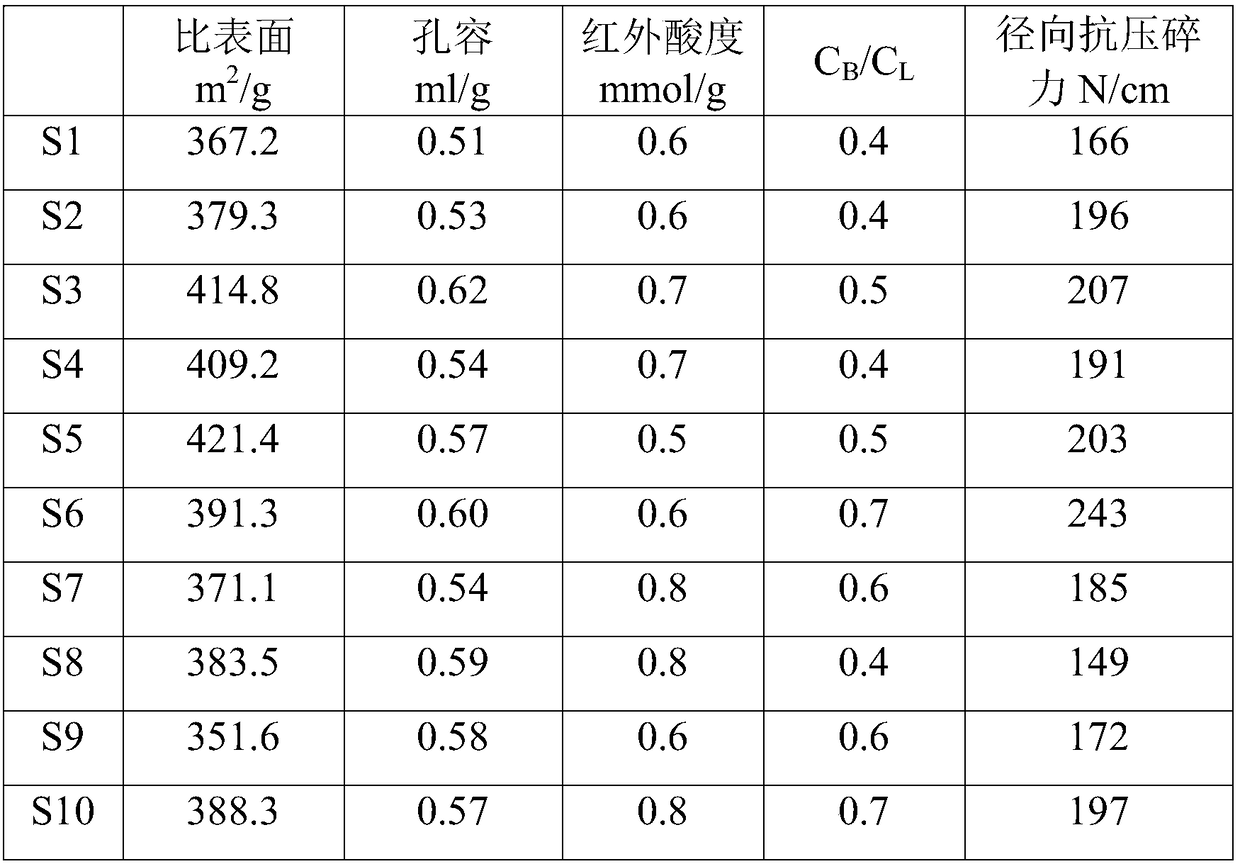

[0034] Weigh 20 g of MCM-22 molecular sieve. In the high-temperature treatment furnace, water vapor was introduced to treat, and the temperature of the treatment furnace was kept at 550° C., and the hydrothermal treatment was carried out for 4 hours. The molecular sieves were treated with 200 ml of 1 mol / L oxalic acid solution at room temperature for 60 min. Dry at 100°C for 4 hours, and calcined at 550°C for 4 hours to obtain the modified molecular sieve M1. Take 10 g of M1 modified molecular sieve, 50 g of amorphous silica-alumina, 20 g of macroporous alumina and 20 g of small-pore alumina, add 4 g of nitric acid with a mass concentration of 65%, and carry out kneading and molding. The formed catalyst carrier was dried at 120°C for 4 hours, and calcined at 550°C for 4 hours to obtain the hydrogenation catalyst carrier S1.

Embodiment 2

[0036]Weigh 50 g of MCM-22 molecular sieve. In the high-temperature treatment furnace, water vapor is introduced to treat, and the treatment furnace is kept at 600° C., and the hydrothermal treatment is performed for 1 hour. The molecular sieves were treated with 400 ml of 1 mol / L citric acid solution at room temperature for 50 min. Dry at 100°C for 4 hours, and bake at 550°C for 4 hours to obtain the modified molecular sieve M2. Take 30g of M2 modified molecular sieve, 50g of macroporous alumina and 20g of small pore alumina, add 4g of nitric acid with a mass concentration of 65%, and carry out kneading and molding. The formed catalyst carrier was dried at 120°C for 4 hours, and calcined at 600°C for 4 hours to obtain the hydrogenation catalyst carrier S2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com