Steam turbine blade processing method based on molded line adjustment

A steam turbine blade and processing method technology, applied in the direction of electrical program control, digital control, etc., can solve the problems of low work efficiency and heavy workload, and achieve the effects of reducing workload, improving processing efficiency, and simple software operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0043] The steam turbine blade processing method based on profile adjustment of the present embodiment, the method is realized through the following steps:

[0044] Step 1. Definition:

[0045] (1) The workpiece coordinate system whose contact point between the workpiece and the tool is the center of the circle and which rotates and translates at all times is used as the five-axis linkage program coordinate system; wherein, the five-axis linkage program coordinate system is a function of the rotation angle A; the tool axis direction of the tool is five The Z-axis direction of the axis linkage program coordinate system;

[0046] (2), using the absolute coordinates of four key points determined on the Y-Z plane under the machine tool coordinate system, a circle can be generated according to the five-axis linkage program; wherein,

[0047] The absolute coordinates of the four key points are:

[0048] First point: X0, Y0, Z100, A90

[0049] Second point: X0, Y-100, Z0, A180

...

specific Embodiment approach 2

[0057] The difference from the specific embodiment 1 is that in the steam turbine blade processing method based on profile adjustment in this embodiment, the process of solving the transformation law of the coordinate system of the five-axis linkage program described in step 2, and obtaining the coordinate transformation matrix of the instantaneous coordinate system is as follows:

[0058]Step 21. Set the movement along the X-axis, Y-axis or Z-axis relative to the previous point as a relative value, which has nothing to do with the coordinate system of parallel movement, and set the machine tool coordinate system fixedly connected to the turning center of the machine tool, and the workpiece coordinates are also Fixed on the rotary center of the machine tool;

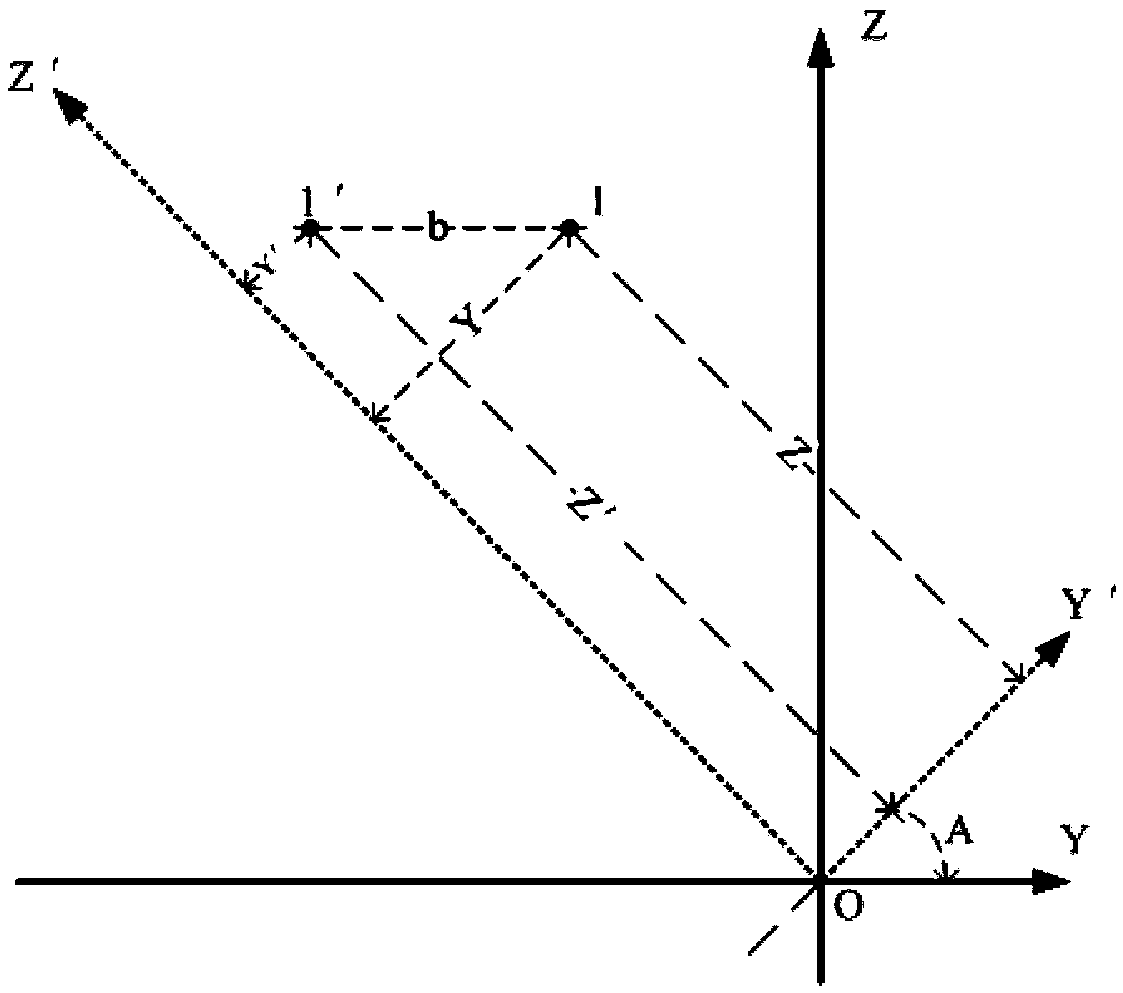

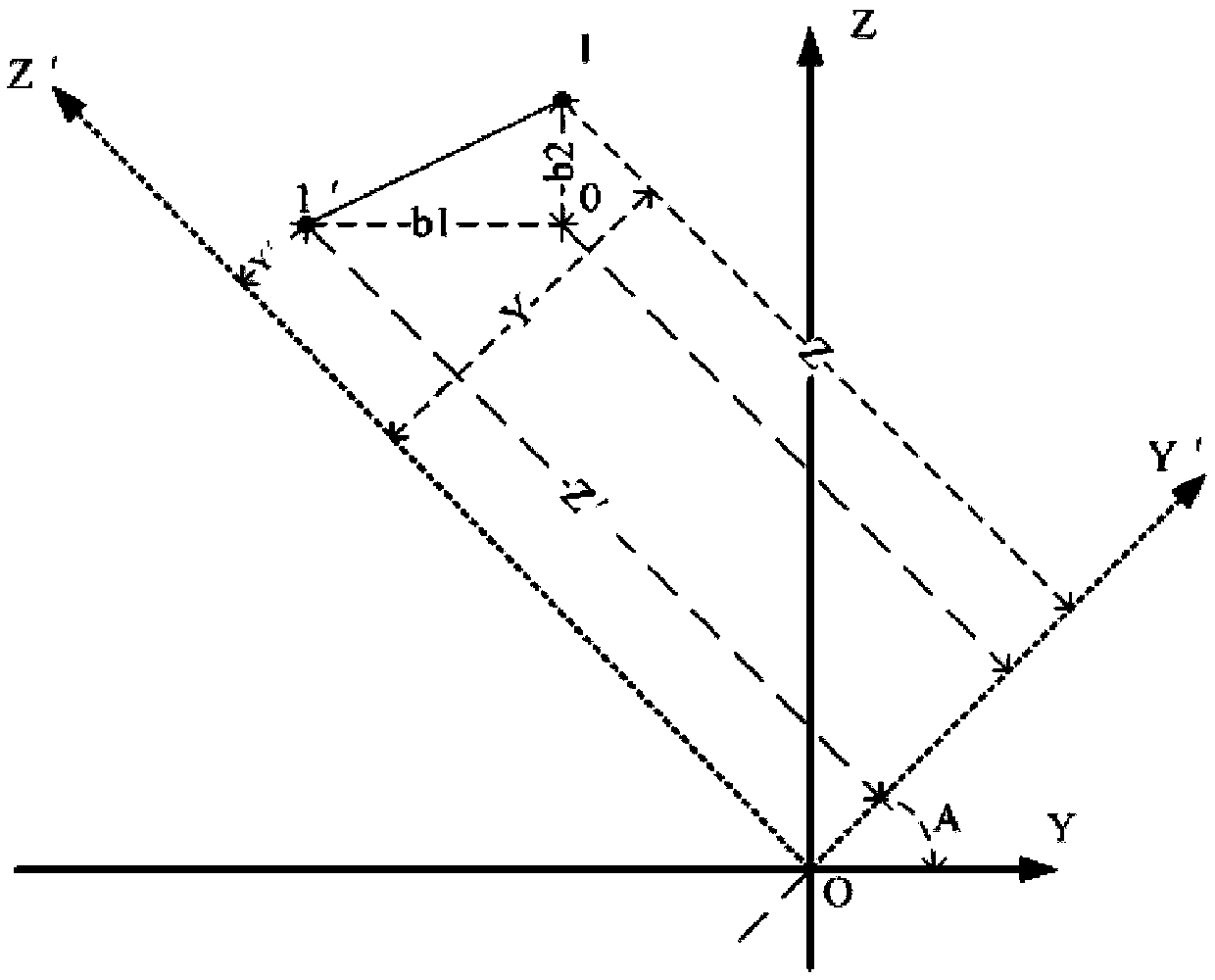

[0059] (1) In the simple case of four-axis linkage, on the Y-Z plane:

[0060] Assuming that the point converted from position 1' to position 1 in the coordinate system of the five-axis linkage program has a horizontal m...

specific Embodiment approach 3

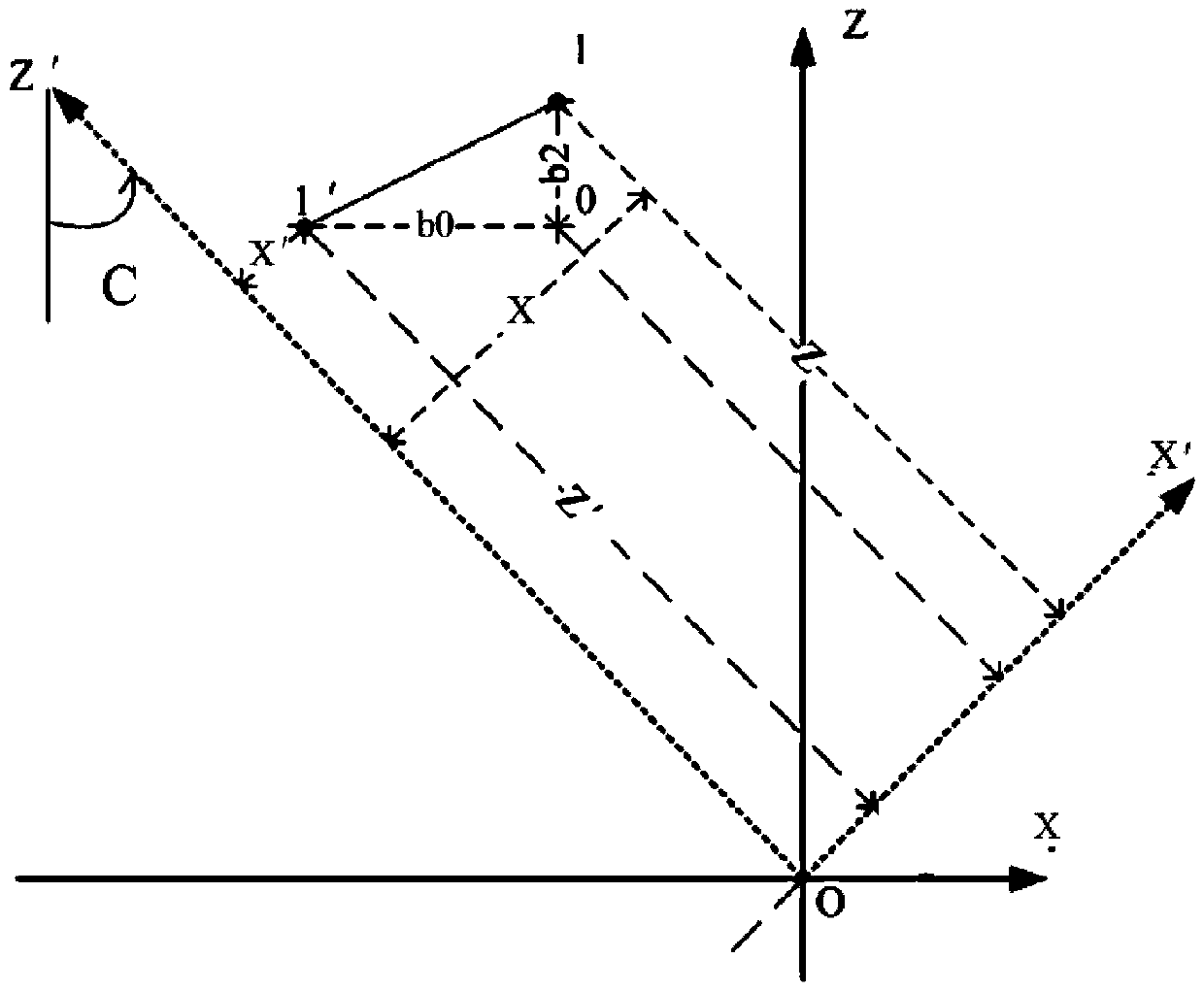

[0101] Different from the second specific embodiment, in the steam turbine blade processing method based on profile adjustment of the present embodiment, the process of realizing the special operating system of the machine tool with the help of QT and C++ described in step 22 is to copy the opened file to the specified file folder, and then open the ISO file with Notepad, and then the cycle starts when it is found, then find X and assign the number after X to variable X, then find Y and assign the number after Y to variable Y, then find Z and assign Assign the number after Z to variable Z, then search for A and assign the number after A to variable A, then search for C and assign the number after A to variable C; then do the substitution shown in the following formula, if you encounter a return Car, this time the search assignment calculation is over, continue to search for the assignment calculation, if you encounter the end of the cycle, exit the program file and save it; amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com