Heat recovery liquid nitrogen evaporation system suitable for oil and gas fields

An evaporation system and heat recovery technology, which is applied to heat pumps, refrigeration and liquefaction, lighting and heating equipment, etc., can solve the problems of inconvenient access to electricity on the job site, increased equipment manufacturing costs and operating costs, and large operating power consumption. To achieve the effect of safety and environmental protection in the evaporation process, reducing the amount of refrigerant and leakage points, and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

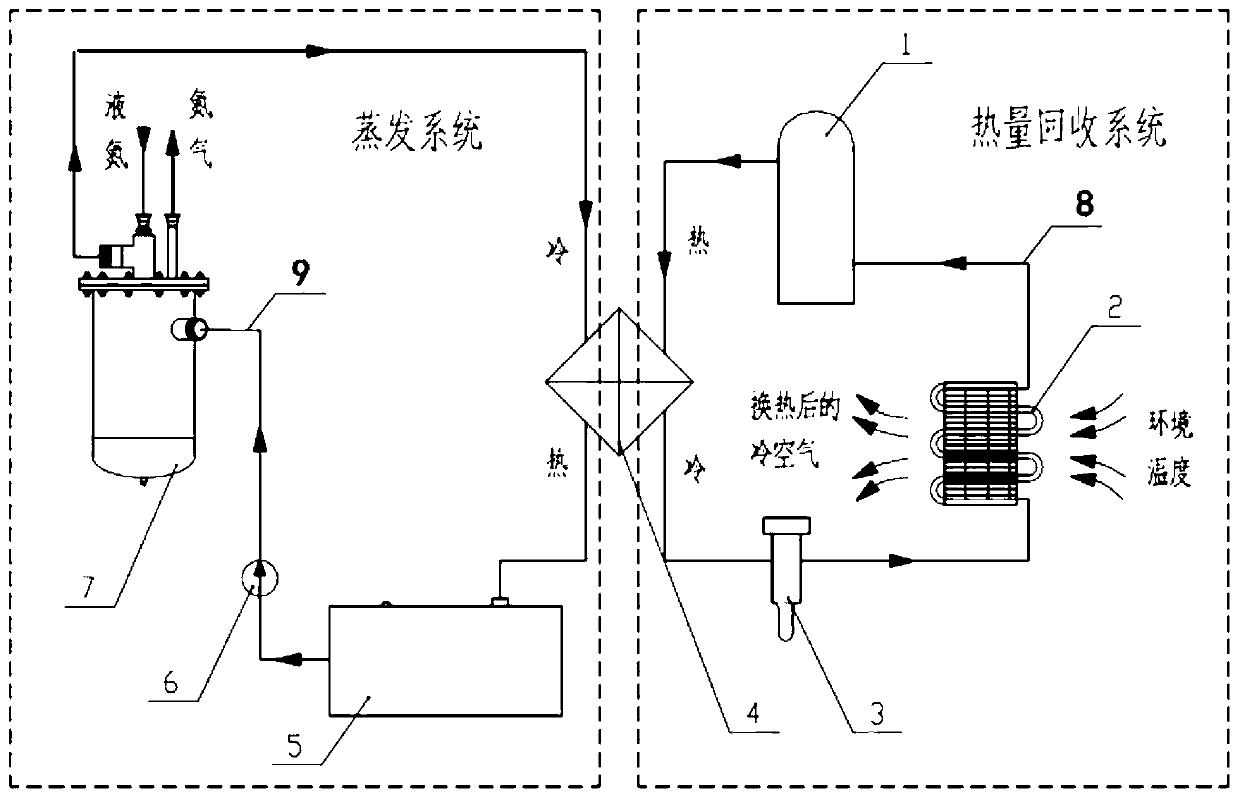

Embodiment 1

[0022] A heat recovery liquid nitrogen evaporation system suitable for oil and gas fields, including a relatively independent evaporation system and a heat recovery system, the evaporation system and the heat recovery system are connected through a heat exchanger 4, and the two systems exchange heat through the heat exchanger; the heat recovery system includes The air heat exchanger 2, the heat pump compressor 1, and the expansion valve 3 are sequentially connected to the first medium transmission pipeline 8. The freon refrigerant absorbs heat from the external environment through the air heat exchanger 2, evaporates the refrigerant, and evaporates the refrigerant After being compressed by the heat pump compressor 1, high-temperature gas is formed. The compressed high-temperature gas releases heat through the heat exchanger and transfers it to the medium in the evaporation system. At the same time, the Freon refrigerant is condensed by the heat exchanger 4 and enters the air hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com