Method for controlling corrosion of acidic produced liquid of oil field

A produced fluid and acid technology, applied in chemical instruments and methods, mining wastewater treatment, water/sludge/sewage treatment, etc., can solve the problems of corrosion of oil and gas gathering and transportation equipment or pipelines, taking care of one and the other, and extending the maintenance-free period of oil wells , reduce the dosage, and solve the effect of corrosion problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] An oil well A in Gudao Oil Production Plant of Shengli Oilfield 12 , the daily liquid production is 134.8t, the daily oil production is 2.8t, and the water cut is 97.9%. The oil well is severely corroded, and the lower part of the working cylinder and the screen pipe are corroded and broken off, resulting in frequent operations. The maintenance-free period before the test is 176 days. Implement the concrete steps of the present invention in this oil well as follows:

[0033] (1) Water quality analysis of produced fluid

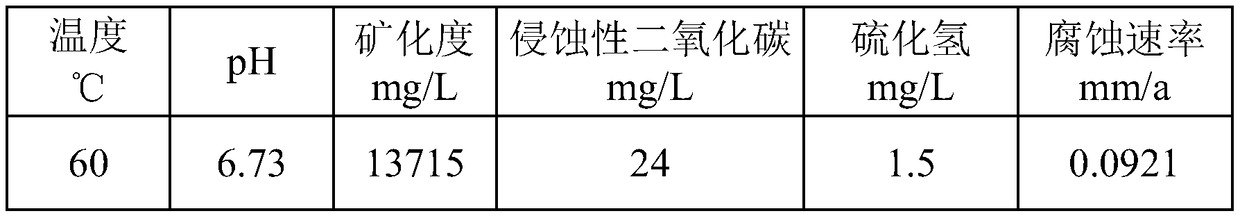

[0034] The indicators of water quality analysis include: temperature, pH, salinity, hydrogen sulfide content and aggressive carbon dioxide content of produced fluid. Well A 12 The analysis results of the produced fluid are shown in Table 1.

[0035] Table 1 Well A 12 Produced water quality analysis results

[0036]

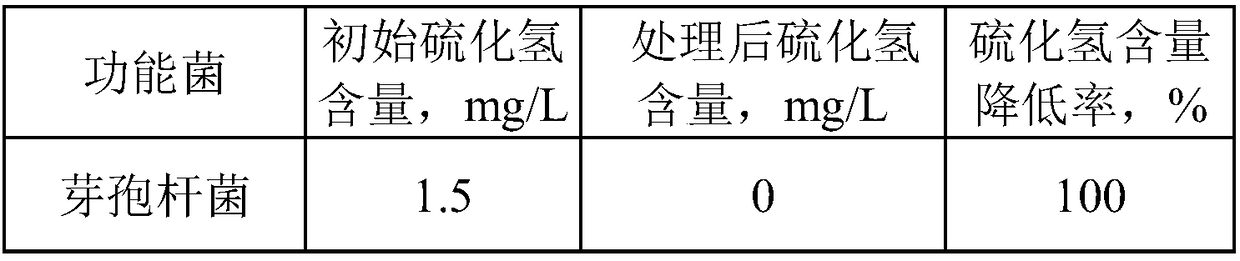

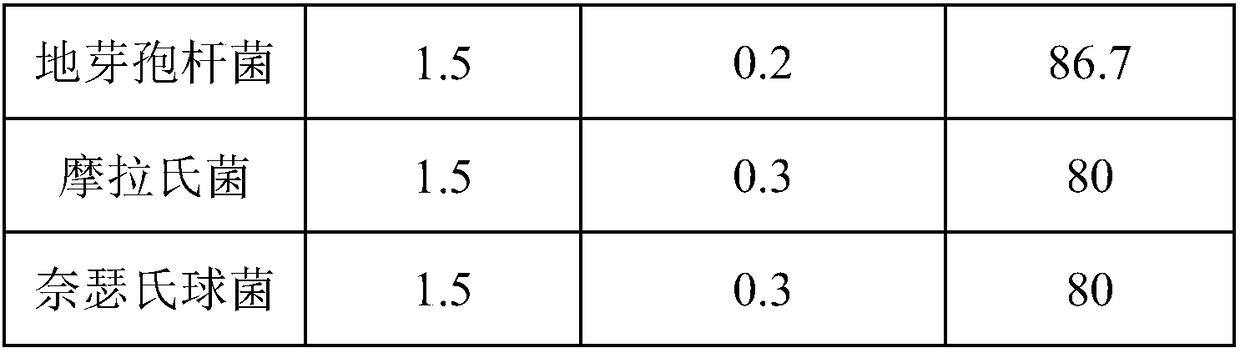

[0037] (2) Screening of produced fluid

[0038] Well A 12 The temperature of the produced fluid is ≤85°C, pH<7.0, salinity ≤200,...

Embodiment 2

[0063] An oil well B in Gudao Oil Production Plant of Shengli Oilfield 2 , the daily liquid production is 139t, the daily oil production is 4t, and the water content is 97.1%. The oil well is severely corroded, and the joints at the lower part of the pump barrel are corroded and fractured, resulting in frequent operations. The maintenance-free period before the test is 133d. Implement the concrete steps of the present invention in this oil well as follows:

[0064] (1) Water quality analysis of produced fluid

[0065] The indicators of water quality analysis include: the temperature, pH, salinity, hydrogen sulfide content and aggressive carbon dioxide content of the produced fluid, oil well B 2 The test results of the produced fluid are shown in Table 5.

[0066] Table 5 Well B 2 Produced water quality test results

[0067]

[0068] (2) Screening of produced fluid

[0069] oil well B 2 The temperature of the produced fluid is ≤85°C, pH<7.0, salinity ≤200,000mg / L, hydr...

Embodiment 3

[0093] An oil well C in Gudong Oil Production Plant of Shengli Oilfield 5 , the daily liquid production is 102t, the daily oil production is 2.3t, and the water content is 97.7%. Many oil pipes are corroded and perforated, resulting in frequent operations. The maintenance-free period before the test is 179d. Implement the concrete steps of the present invention in this oil well as follows:

[0094] (2) Water quality analysis of produced fluid

[0095] The indicators of water quality analysis include: temperature, pH, salinity, hydrogen sulfide content and aggressive carbon dioxide content of produced fluid. oil well C 5 The analysis results of the produced fluid are shown in Table 9.

[0096] Table 9 Well C 5 Produced water quality test results

[0097]

[0098] (2) Screening of produced fluid

[0099] oil well C 5 The outlet temperature is ≤85°C, pH<7.0, salinity ≤200000mg / L, hydrogen sulfide content≤60mg / L, and corrosive carbon dioxide content≤100mg / L. All indexes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com