Static, magnetic filed and chemical dosing united water treatment novel method

A water treatment and new method technology, applied in the field of electrostatic, magnetic field, chemical dosing combined water treatment, can solve the problems of limited scale inhibitor, high cost, low scale inhibition performance, etc., to achieve environmental friendliness, reduce dosage, improve The effect of scale inhibition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

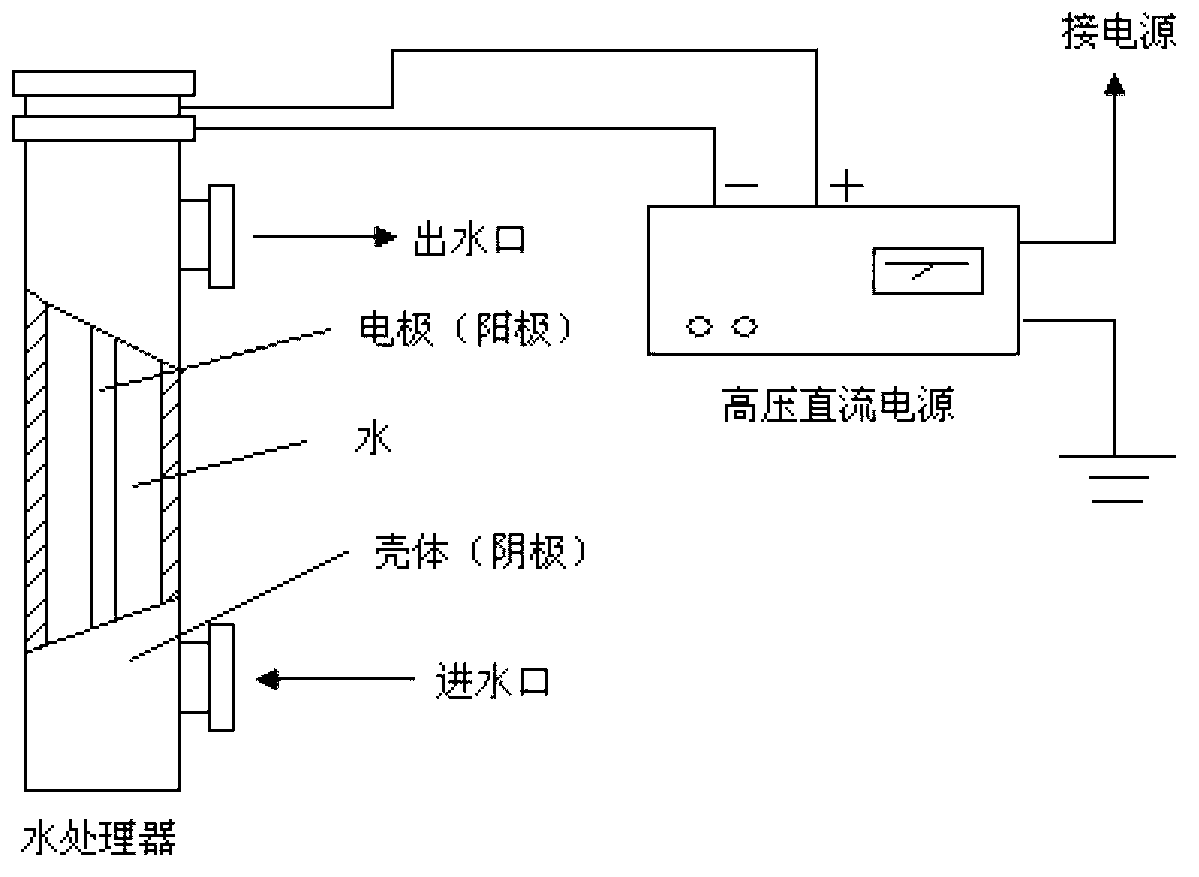

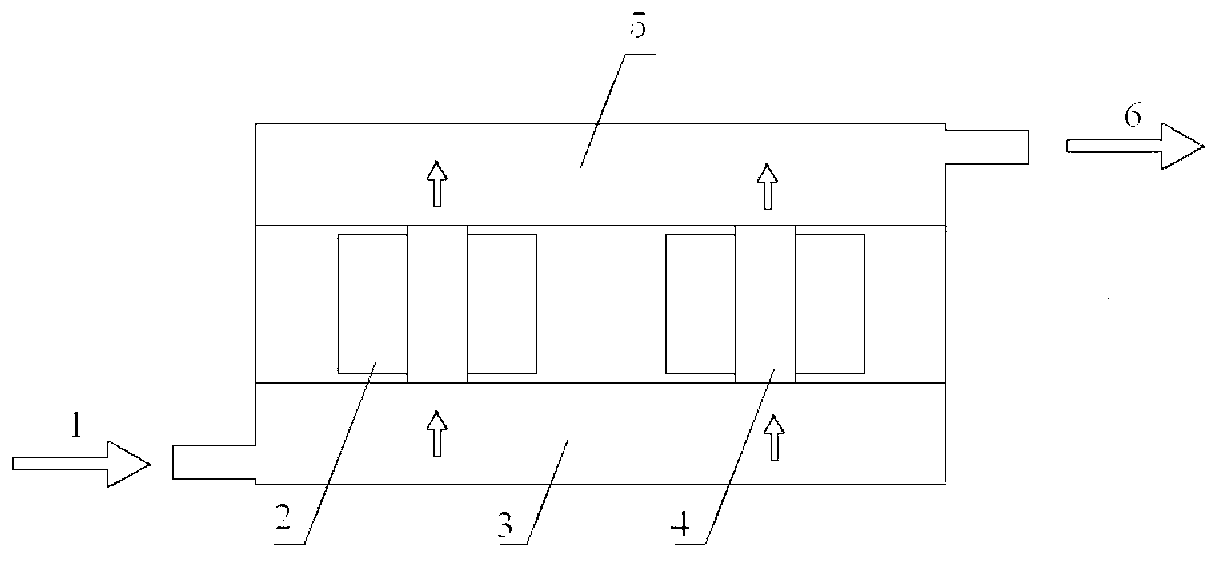

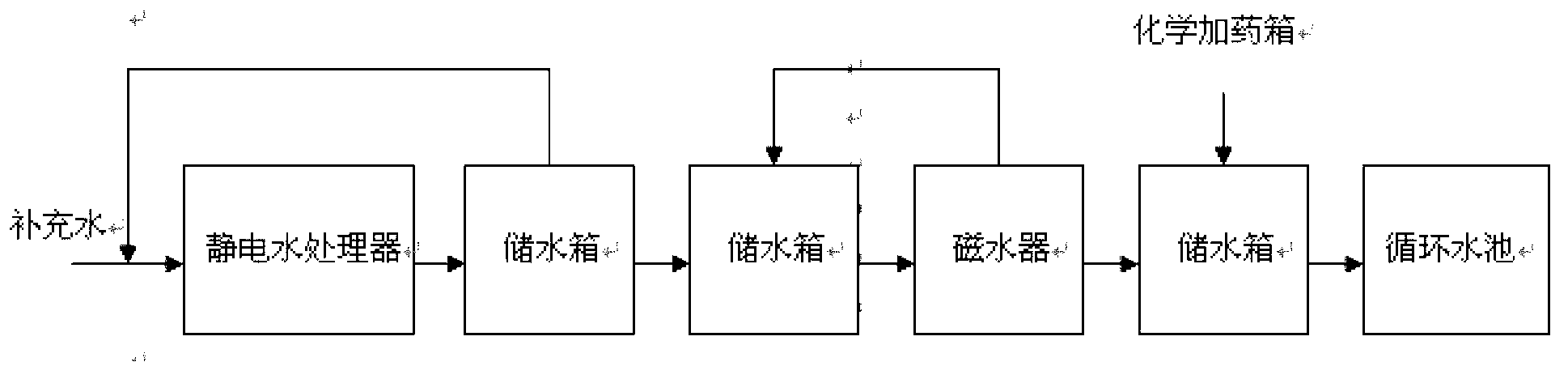

Method used

Image

Examples

Embodiment 1

[0021] When the electrostatic conditions and magnetic field conditions are: the flow rate of water passing through the electrostatic water processor is 200L / h, the electrostatic voltage is 5000V, and the electrostatic time is 1.0h; the flow rate of magnetized water is 180L / h, the magnetic field strength is 0.6T, and the magnetization time is 40min. Table 1.1 Resistance to CaCO under this condition 3 Performance studies, Table 1.2 for barrier Ca 3 (PO 4 ) 2 performance studies.

[0022] Table 1.1 Resistance to CaCO 3 performance research

[0023]

[0024] Table 1.2 Resistance to Ca 3 (PO 4 ) 2 performance research

[0025]

Embodiment 2

[0027] When the electrostatic conditions and magnetic field conditions are: the flow rate of water passing through the electrostatic water processor is 400L / h, the electrostatic voltage is 3000V, and the electrostatic time is 1.0h; the flow rate of magnetized water is 120L / h, the magnetic field strength is 0.6T, and the magnetization time is 20min. Table 2.1 Resistance to CaCO under this condition 3 Performance studies, Table 2.2 for barrier Ca 3 (PO 4 ) 2 performance studies.

[0028] Table 2.1 Resistance to CaCO 3 performance research

[0029]

[0030] Table 2.2 Resistance to Ca 3 (PO 4 ) 2 performance research

[0031]

Embodiment 3

[0033] When the electrostatic conditions and magnetic field conditions are: the flow rate of water passing through the electrostatic water processor is 400L / h, the electrostatic voltage is 7000V, and the electrostatic time is 2.0h; the flow rate of magnetized water is 120L / h, the magnetic field strength is 0.7T, and the magnetization time is 40min. Table 3.1 Resistance to CaCO under this condition 3 Performance studies, Table 3.2 for barrier Ca 3 (PO 4 ) 2 performance studies.

[0034] Table 3.1 Resistance to CaCO 3 performance research

[0035]

[0036]

[0037] Table 3.2 Resistance to Ca 3 (PO 4 ) 2 performance research

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com