Hydrogenation scale inhibitor and preparation method thereof

A technology of antiscalant and detergent, which is applied in the direction of treatment equipment corrosion/scaling inhibition, petroleum industry, hydrocarbon oil treatment, etc. It can solve the problems of high cost, poor thermal stability, and low antiscalant rate of antiscalant, and achieve the best effect better effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

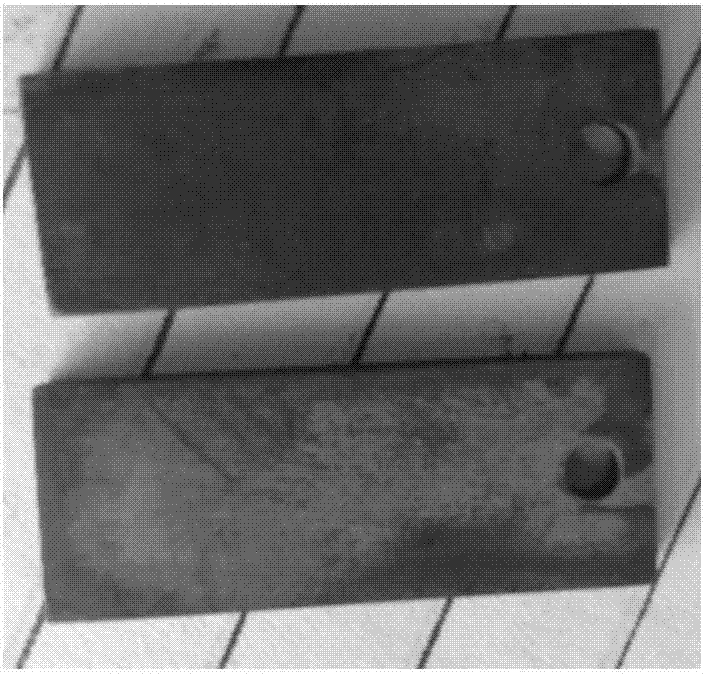

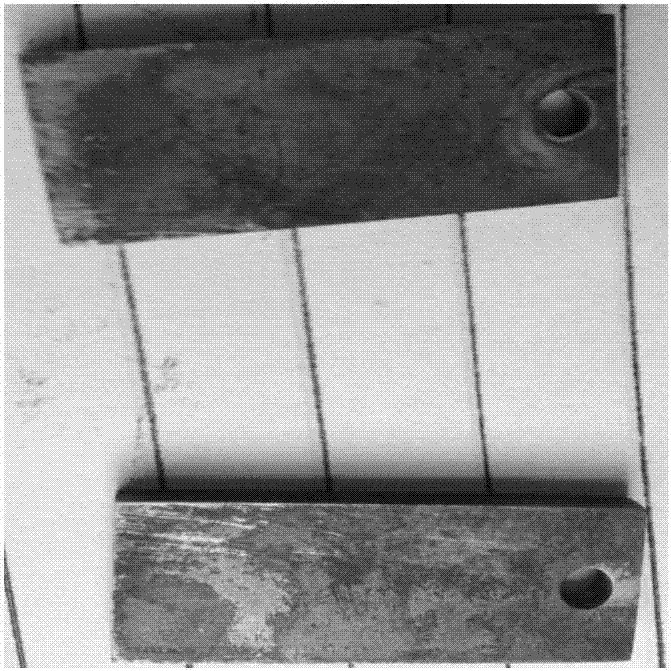

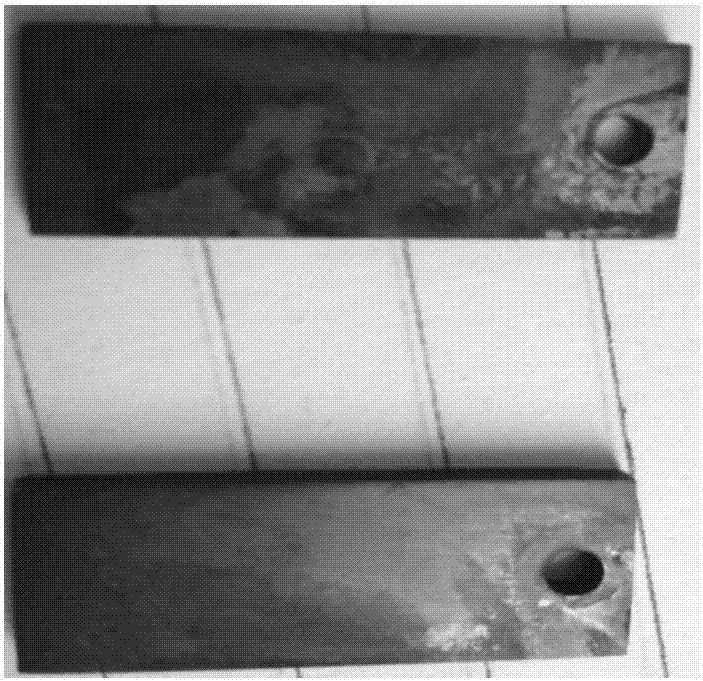

Image

Examples

Embodiment 1

[0029] Take 30% Mannich amine, 10% diisooctyl diphenylamine, 0.5% benzotriazole, 1.5% oleic acid stearylamine, 1% acetamide, 57% gasoline, at room temperature Under normal pressure, stir evenly.

Embodiment 2

[0031] Take 30% Mannich amine, 10% diisooctyl diphenylamine, 0.5% α-mercaptobenzothiazole, 1.5% oleic acid octadecylamine, 1% acetamide, 57% gasoline, Under normal temperature and pressure, just stir evenly.

Embodiment 3

[0033] Get 29% Mannich amine, 8% diisooctyl diphenylamine, 1% benzotriazole, 1% stearic acid cyclohexylamine, 1% acetamide, 60% heavy aromatics, Under normal temperature and pressure, just stir evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com