Special antisludging agent for saline-alkali soil bitter desalting plant and preparation method therefor

A technology of desalination of brackish water and antiscalant, which is applied in chemical instruments and methods, descaling and water softening, complex/solubilizing agent treatment, etc. It can solve the problems of short service life, low scale inhibition rate and high corrosion rate , to achieve the effect of reducing corrosion rate, high scale inhibition rate and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

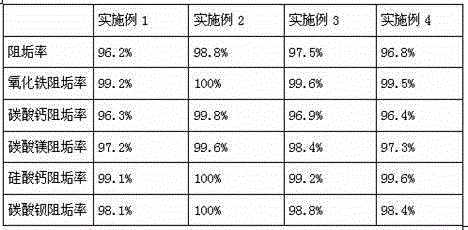

Examples

Embodiment 1

[0025] Example 1 A special antiscalant for saline-alkali land brackish water desalination equipment

[0026] The weight proportion of each component of scale inhibitor is:

[0027] 30 parts of chlorogenic acid, 8 parts of sodium lignosulfonate, 8 parts of citric acid, 7 parts of malic acid, 2 parts of tannic acid, 3 parts of polyepoxysuccinic acid, 1 part of dimethyl sulfoxide, tetradecyl 2 parts of dimethyl benzyl ammonium chloride, 0.5 parts of allyl polyether, 48 parts of deionized water.

Embodiment 2

[0028] Example 2 A special antiscalant for saline-alkali land brackish water desalination equipment

[0029] The weight proportion of each component of scale inhibitor is:

[0030] 32 parts of chlorogenic acid, 8 parts of sodium lignosulfonate, 9 parts of citric acid, 9 parts of malic acid, 3 parts of tannic acid, 4 parts of polyepoxysuccinic acid, 1 part of dimethyl sulfoxide, tetradecyl 3 parts of dimethyl benzyl ammonium chloride, 1 part of allyl polyether, 48 parts of deionized water.

Embodiment 3

[0031] Example 3 A special antiscalant for saline-alkali land brackish water desalination equipment

[0032] The weight proportion of each component of scale inhibitor is:

[0033] 33 parts of chlorogenic acid, 9 parts of sodium lignosulfonate, 9 parts of citric acid, 9 parts of malic acid, 3 parts of tannic acid, 3 parts of polyepoxysuccinic acid, 1 part of dimethyl sulfoxide, tetradecyl 3 parts of dimethyl benzyl ammonium chloride, 1.2 parts of allyl polyether, 49 parts of deionized water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion rate | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com